- Y Diweddaraf sydd Ar Gael (Diwygiedig)

- Pwynt Penodol mewn Amser (01/07/2013)

- Gwreiddiol (Fel y’i mabwysiadwyd gan yr UE)

Council Directive of 26 July 1971 on the approximation of the laws of the Member States relating to the braking devices of certain categories of motor vehicles and of their trailers (71/320/EEC) (repealed)

You are here:

- Dangos Graddfa Ddaearyddol(e.e. Lloegr, Cymru, Yr Alban aca Gogledd Iwerddon)

- Dangos Llinell Amser Newidiadau

Rhagor o Adnoddau

PDF o Fersiynau Diwygiedig

- ddiwygiedig 01/11/20140.44 MB

- ddiwygiedig 01/07/20131.78 MB

- ddiwygiedig 01/01/20071.13 MB

- ddiwygiedig 01/05/20041.16 MB

- ddiwygiedig 24/10/20021.16 MB

- ddiwygiedig 07/04/19981.14 MB

- ddiwygiedig 22/08/19910.91 MB

- ddiwygiedig 30/03/19880.84 MB

- ddiwygiedig 03/01/19860.84 MB

- ddiwygiedig 24/04/19790.57 MB

- ddiwygiedig 31/07/19750.50 MB

- ddiwygiedig 20/02/19740.40 MB

- ddiwygiedig 01/01/19730.36 MB

- ddiwygiedig 30/07/19710.36 MB

When the UK left the EU, legislation.gov.uk published EU legislation that had been published by the EU up to IP completion day (31 December 2020 11.00 p.m.). On legislation.gov.uk, these items of legislation are kept up-to-date with any amendments made by the UK since then.

Mae hon yn eitem o ddeddfwriaeth sy’n deillio o’r UE

Mae unrhyw newidiadau sydd wedi cael eu gwneud yn barod gan y tîm yn ymddangos yn y cynnwys a chyfeirir atynt gydag anodiadau.Ar ôl y diwrnod ymadael bydd tair fersiwn o’r ddeddfwriaeth yma i’w gwirio at ddibenion gwahanol. Y fersiwn legislation.gov.uk yw’r fersiwn sy’n weithredol yn y Deyrnas Unedig. Y Fersiwn UE sydd ar EUR-lex ar hyn o bryd yw’r fersiwn sy’n weithredol yn yr UE h.y. efallai y bydd arnoch angen y fersiwn hon os byddwch yn gweithredu busnes yn yr UE. EUR-Lex Y fersiwn yn yr archif ar y we yw’r fersiwn swyddogol o’r ddeddfwriaeth fel yr oedd ar y diwrnod ymadael cyn cael ei chyhoeddi ar legislation.gov.uk ac unrhyw newidiadau ac effeithiau a weithredwyd yn y Deyrnas Unedig wedyn. Mae’r archif ar y we hefyd yn cynnwys cyfraith achos a ffurfiau mewn ieithoedd eraill o EUR-Lex. The EU Exit Web Archive legislation_originated_from_EU_p3

Changes over time for: ANNEX X

Version Superseded: 01/11/2014

Status:

EU Directives are published on this site to aid cross referencing from UK legislation. Since IP completion day (31 December 2020 11.00 p.m.) no amendments have been applied to this version.

[F1ANNEX X U.K. Test requirements for vehicles with anti-lock braking systems

Textual Amendments

1. GENERAL U.K.

1.1. This Annex defines the required braking performance for road vehicles fitted with anti-lock braking systems. In addition, motor vehicles which are authorised to tow a trailer, and trailers equipped with compressed-air braking systems, shall, when the vehicles are laden, meet the requirements for compatibility set out in the Appendix to point 1.1.4.2 of Annex II. U.K.

1.2. The anti-lock braking systems known at present comprise a sensor or sensors, a controller or controllers and a modulator or modulators. Any systems of a different design which may be introduced in the future will be deemed to be anti-lock braking systems within the meaning of this Annex and the Appendix to point 1.1.4.2 of Annex II, if they provide performances equal to those prescribed by this Annex. U.K.

2. DEFINITIONS U.K.

2.1. An ‘ anti-lock braking system ’ is part of a service braking system which automatically controls the degree of slip, in the direction of rotation of the wheel(s), on one or more wheels of the vehicle during braking. U.K.

2.2. ‘ Sensor ’ means a component designed to identify and transmit to the controller the conditions of rotation of the wheel(s) or the dynamic conditions of the vehicle. U.K.

2.3. ‘ Controller ’ means a component designed to evaluate the data transmitted by the sensor(s) and to transmit a signal to the modulator. U.K.

2.4. ‘ Modulator ’ means a component designed to vary the braking force(s) in accordance with the signal received from the controller. U.K.

2.5. ‘Directly controlled wheel’ means a wheel whose braking force is modulated according to data provided at least by its own sensor (1) . U.K.

2.6. ‘Indirectly controlled wheel’ means a wheel whose braking force is modulated according to data provided by the sensor(s) of other wheel(s) (5) . U.K.

3. TYPES OF ANTI-LOCK BRAKING SYSTEMS U.K.

3.1. A motor vehicle shall be deemed to be equipped with an anti-lock braking system within the meaning of point 1 of the Appendix to point 1.1.4.2 of Annex II, if one of the following systems is fitted: U.K.

3.1.1. Category 1 anti-lock braking system: U.K.

A vehicle equipped with a category 1 anti-lock braking system shall meet all the relevant requirements of this Annex.

3.1.2. Category 2 anti-lock braking system: U.K.

A vehicle equipped with a category 2 anti-lock braking system shall meet all the relevant requirements of this Annex, except those of point 5.3.5.

3.1.3. Category 3 anti-lock braking system: U.K.

A vehicle equipped with a category 3 anti-lock braking system shall meet all the relevant requirements of this Annex except those of points 5.3.4 and 5.3.5. On such vehicles, any individual axle (or bogie) which does not include at least one directly controlled wheel shall fulfil the conditions of adhesion utilisation and the wheel-locking sequence of the Appendix to point 1.1.4.2. of Annex II, instead of the adhesion utilisation requirements prescribed in point 5.2 of this Annex. However, if the relative positions of the adhesion utilisation curves do not meet the requirements of point 3.1.1 of the Appendix to point 1.1.4.2 of Annex II, a check shall be made to ensure that the wheels on at least one of the rear axles do not lock before those on the front axle or axles under the conditions prescribed in points 3.1.1 and 3.1.4 of the Appendix to point 1.1.4.2 of Annex II with regard to the braking rate and the load respectively. These requirements may be checked on high- or low-adhesion road surfaces (about 0,8 and 0,3 maximum) by modulating the service braking control force.

3.2. A trailer shall be deemed to be equipped with an anti-lock braking system within the meaning of point 1 of the Appendix to point 1.1.4.2 of Annex II, when at least two wheels on opposite sides of the vehicle are directly controlled and all remaining wheels are either directly or indirectly controlled by the anti-lock braking system. In the case of full trailers, at least two wheels on one front axle and two wheels on one rear axle shall be directly controlled with each of these axles having at least one independent modulator and all remaining wheels are either directly or indirectly controlled. In addition, the anti-lock equipped trailer shall meet one of the following conditions: U.K.

3.2.1. Category A anti-lock braking system: U.K.

A trailer equipped with a category A anti-lock braking system shall meet all the relevant requirements of this Annex.

3.2.2. Category B anti-lock braking system: U.K.

A trailer equipped with a category B anti-lock braking system shall meet all the relevant requirements of this Annex, except point 6.3.2.

4. GENERAL REQUIREMENTS U.K.

4.1. Any electrical failure or sensor anomaly that affects the system with respect to the functional and performance requirements in this Annex, including those in the supply of electricity, the external wiring to the controller(s), the controller(s) (2) and the modulator(s) shall be signalled to the driver by a specific optical warning signal. U.K.

4.1.1. The warning signal shall light up when the anti-lock braking system is energised and, with the vehicle stationary, it shall be verified that none of the above-mentioned defects are present before extinguishing the signal. U.K.

4.1.2. The static sensor check may verify that a sensor was not functioning the last time that the vehicle was at a speed greater than 10 km/h (3) . Also during this verification phase, the electrically controlled pneumatic modulator valve(s) shall cycle at least once. U.K.

4.2. Motor vehicles equipped with an anti-lock braking system and authorised to tow a trailer equipped with such a system, with the exception of vehicles of categories M 1 and N 1 , shall be fitted with a separate optical warning signal for the anti-lock braking system of the trailer, meeting the requirements of point 4.1 of this Annex. U.K.

4.2.1. This warning signal shall not light up when a trailer without an anti-lock braking system is coupled or when no trailer is coupled. This function shall be automatic. U.K.

4.3. The abovementioned optical warning signal(s) shall be visible even in daylight and it shall be easy for the driver to check that they are in working order. U.K.

4.4. Except for vehicles of categories M 1 and N 1 , O 1 and O 2 , the electrical connections used for the anti-lock braking systems of towing vehicles and trailers shall be effected by a special connector conforming to ISO Standard 7638-1985 or ISO/DIS Standard 7638-1996 (4) . U.K.

4.5. In the event of a failure of the anti-lock braking system, the residual braking performance shall be that prescribed for the vehicle in question in the event of a failure of a part of the transmission of the service braking system (see point 2.2.1.4 of Annex I). This requirement shall not be construed as a departure from the requirements concerning secondary braking. In the case of trailers, the residual braking performance in the event of a defect in the anti-lock braking system according to point 4.1 of this Annex shall be at least 80 % of the laden prescribed performance for the service braking system of the relevant trailer. U.K.

4.6. The operation of the system shall not be adversely affected by magnetic or electrical fields (5) . U.K.

4.7. A manual device may not be provided to disconnect or change the control mode (6) of the anti-lock braking system, except on off-road motor vehicles of categories N 2 or N 3 . Where a device is fitted to N 2 or N 3 off-road motor vehicles, the following conditions shall be met: U.K.

4.7.1. the motor vehicle with the anti-lock braking system disconnected or the control mode changed by the device referred to in point 4.7 above shall satisfy all the relevant requirements in the Appendix to point 1.1.4.2 of Annex II; U.K.

4.7.2. an optical warning signal shall inform the driver that the anti-lock braking system has been disconnected or the control mode changed; the anti-lock failure warning signal may be used for this purpose; U.K.

4.7.3. the anti-lock braking system shall automatically be reconnected/returned to on-road mode when the ignition (start) device is again set to the ‘ on ’ (run) position; U.K.

4.7.4. the vehicle user's handbook provided by the manufacturer should warn the driver of the consequences of manual disconnection or mode change of the anti-lock braking system; U.K.

4.7.5. the device referred to in point 4.7 above may, in conjunction with the towing vehicle, disconnect/change the control mode of the anti-lock braking system of the trailer; a separate device for the trailer alone is not permitted. U.K.

5. SPECIAL PROVISIONS CONCERNING MOTOR VEHICLES U.K.

5.1. Energy consumption U.K.

Braking systems equipped with anti-lock braking systems shall maintain their performance when the service braking control device is fully applied for long periods. Compliance with the requirement shall be verified by means of the following tests:

5.1.1. Test procedure U.K.

5.1.1.1. The initial energy level in the energy storage device(s) shall be that specified by the manufacturer. This level shall be at least such as to ensure the efficiency prescribed for service braking when the vehicle is laden. The energy storage device(s) for pneumatic auxiliary equipment shall be isolated. U.K.

5.1.1.2. From an initial speed of not less than 50 km/h, on a surface with a coefficient of adhesion of 0,3 (7) or less, the brakes of the laden vehicle shall be fully applied for a time t, during which time the energy consumed by the indirectly controlled wheels shall be taken into consideration and all directly controlled wheels shall remain under control of the anti-lock braking system throughout that time. U.K.

5.1.1.3. The vehicle's engine shall be then stopped or the supply to the energy storage device(s) cut off. U.K.

5.1.1.4. The service braking control shall be then fully actuated four times in succession with the vehicle stationary. U.K.

5.1.1.5. When the control is applied for the fifth time, it shall be possible to brake the vehicle with at least the performance prescribed for secondary braking of the laden vehicle. U.K.

5.1.1.6. During the tests, in the case of a motor vehicle authorised to tow a trailer equipped with a compressed-air braking system, the supply line shall be blocked of and an energy storage device of 0,5 litre capacity shall be connected to the control line (in accordance with point 1.2.2.3 of Annex IV, section A). When the brakes are applied for the fifth time, as provided in point 5.1.1.5, the energy level supplied to the control line shall not be below half the level obtained at a full application starting with the initial energy level. U.K.

5.1.2. Additional requirements U.K.

5.1.2.1. The coefficient of adhesion of the road surface is measured with the vehicle in question, by the method described in point 1.1 of Appendix 2 to this Annex. U.K.

5.1.2.2. The braking test shall be conducted with the engine disconnected and idling, and with the vehicle laden. U.K.

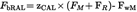

5.1.2.3. The braking time t shall be determined by the formula:  (but not less than 15 seconds) U.K.

(but not less than 15 seconds) U.K.

where t is expressed in seconds and v max represents the maximum design speed of the vehicle expressed in km/h, with an upper limit of 160 km/h.

5.1.2.4. If the time t cannot be completed in a single braking phase, further phases may be used, up to a maximum of four in all. U.K.

5.1.2.5. If the test is conducted in several phases, no fresh energy shall be supplied between the phases of the test. From the second phase, the energy consumption corresponding to the initial brake application may be taken into account, by subtracting one full brake application from the four full applications prescribed in point 5.1.1.4 (and 5.1.1.5, 5.1.1.6 and 5.1.2.6) of this Annex for each of the second, third and fourth phases used in the test prescribed in point 5.1.1 of this Annex as applicable. U.K.

5.1.2.6. The performance prescribed in point 5.1.1.5 shall be deemed to be satisfied if, at the end of the fourth application, with the vehicle stationary, the energy level in the storage device(s) is at or above that required for secondary braking with the laden vehicle. U.K.

5.2. Utilisation of adhesion U.K.

5.2.1. The utilisation of adhesion by the anti-lock braking system takes into account the actual increase in braking distance beyond the theoretical minimum. The anti-lock braking system shall be deemed to be satisfactory when the condition U.K.

is satisfied, where ε represents the adhesion utilised, as defined in point 1.2 of Appendix 2 to this Annex.

5.2.2. The adhesion utilisation (ε) shall be measured on road surfaces with a coefficient of adhesion of 0,3 (8) or less, and of about 0,8 (dry road), with an initial speed of 50 km/h. To eliminate the effects of differential brake temperatures it is recommended that Z AL be determined prior to the determination of k. U.K.

5.2.3. The test procedure to determine the coefficient of adhesion (k) and the formulae for calculation of the adhesion utilisation (ε) shall be those laid down in Appendix 2 to this Annex. U.K.

5.2.4. The utilisation of adhesion by the anti-lock braking system shall be checked on complete vehicles equipped with anti-lock braking systems of categories 1 or 2. In the case of vehicles equipped with category 3 anti-lock braking systems, only the axle(s) with at least one directly controlled wheel shall satisfy this requirement. U.K.

5.2.5. The condition ε ≥ 0,75 shall be checked with the vehicle laden and unladen. The laden test on the high-adhesion surface may be omitted if the prescribed force on the control device does not achieve full cycling of the anti-lock braking system. For the unladen test, the control force may be increased up to 100 daN if no cycling is achieved with its full force value (9) . If 100 daN is insufficient to make the system cycle, then this test may be omitted. For air braking systems, the air pressure may not be increased above the cut-out pressure for the purpose of this test. U.K.

5.3. Additional checks U.K.

The following additional checks shall be carried out with the engine disconnected, with the vehicle laden and unladen:

5.3.1. The wheels directly controlled by an anti-lock braking system shall not lock when the full force (10) is suddenly applied on the control device, on the road surfaces specified in point 5.2.2 of this Annex, at an initial speed of 40 km/h and at a high initial speed as indicated in the table below (11) : U.K.

5.3.2. When an axle passes from a high-adhesion surface (k H ) to a low-adhesion (k L ) where k H ≥ 0,5 and k H /k L ≥ 2 (12) , with the full force (13) applied on the control device, the directly controlled wheels shall not lock. The running speed and the instant of applying the brakes shall be so calculated that, with the anti-lock braking system fully cycling on the high-adhesion surface, the passage from one surface to the other is made at high and at low speed, under the conditions laid down in point 5.3.1 above (14) . U.K.

5.3.3. When a vehicle passes from a low-adhesion surface (k L ) to a high-adhesion (k H ) where k H ≥ 0,5 and k H /k L ≥ 2, with the full force (15) applied on the control device, the deceleration of the vehicle shall rise to the appropriate high value within a reasonable time and the vehicle shall not deviate from its initial course. The running speed and the instant of applying the brakes shall be so calculated that, with the anti-lock braking system fully cycling on the low-adhesion surface, the passage from one surface to the other occurs at approximately 50 km/h. U.K.

5.3.4. In the case of vehicles equipped with anti-lock braking systems of categories 1 and 2, when the right and left wheels of the vehicle are situated on surfaces with differing coefficients of adhesion (k H and k L ) where k H ≥ 0,5 and k H /k L ≥ 2, the directly controlled wheels shall not lock when the full force (16) is suddenly applied on the control device at a speed of 50 km/h. U.K.

5.3.5. Furthermore, laden vehicles equipped with anti-lock braking systems of category 1 shall, under the conditions of point 5.3.4 above, satisfy the prescribed braking rate in Appendix 3 to this Annex. U.K.

5.3.6. However, in the tests provided for in points 5.3.1, 5.3.2, 5.3.3, 5.3.4 and 5.3.5 above, brief periods of wheel-locking are allowed. Furthermore, wheel-locking is permitted when the vehicle speed is less than 15 km/h; likewise, locking of indirectly controlled wheels is permitted at any speed, but stability and steerability shall not be affected. U.K.

5.3.7. During the tests provided for in points 5.3.4 and 5.3.5 above, steering correction is permitted if the angular rotation of the steering control is within 120° during the initial 2 seconds and not more than 240° in all. Furthermore, at the beginning of these tests the longitudinal median plane of the vehicle shall pass over the boundary between the high- and low-adhesion surfaces and during these tests no part of the (outer)tyres shall cross this boundary. U.K.

6. SPECIAL PROVISIONS CONCERNING TRAILERS U.K.

6.1. Energy consumption U.K.

Trailers equipped with anti-lock braking systems shall be so designed that, even after the service braking control device has been fully applied for some time, the vehicle retains sufficient energy to bring it to a halt within a reasonable distance.

6.1.1. Compliance with the above requirement shall be checked by the procedure specified below, with the vehicle unladen, on a straight and level road with a surface having a good coefficient of adhesion (17) , and with the brakes adjusted as closely as possible and with the brake load sensing device (if fitted) held in the ‘laden’ position throughout the test. U.K.

6.1.2. In the case of compressed-air braking systems, the initial energy level in the energy storage device(s) shall be equivalent to a pressure of 8,0 bar at the coupling head of the trailer's supply line. U.K.

6.1.3. With an initial vehicle speed of at least 30 km/h, the brakes shall be fully applied for a time t = 15 s, during which time the energy consumed by the indirectly controlled wheels shall be taken into consideration and all directly controlled wheels shall remain under control of the anti-lock braking system. During this test, the supply to the energy storage device(s) shall be cut off. U.K.

If the time t = 15 s cannot be completed in a single braking phase, further phases may be used. During these phases, no fresh energy shall be supplied to the energy storage device(s) and, as from the second phase, the additional energy consumption for filling the actuators is to be taken into account, e.g. by the following test procedure.

The pressure in the reservoir(s) when starting the first phase is to be that stated in point 6.1.2 above. At the beginning of the following phase(s), the pressure in the reservoir(s) after application of the brakes shall be not less than the pressure in the reservoir(s) at the end of the preceding phase. At the subsequent phase(s), the only time to be taken into account is from the point at which the pressure in the reservoir(s) is equal to that at the end of the preceding phase.

6.1.4. At the end of the braking, with the vehicle stationary, the service braking control device shall be fully actuated four times. During the fifth application, the pressure in the operating circuits shall be sufficient to provide a total braking force at the periphery of the wheels equal to not less than 22,5 % of the maximum stationary wheel load and without causing and automatic application of any braking system not being under the control of the anti-lock braking system. U.K.

6.2. Utilisation of adhesion U.K.

6.2.1. Trailers equipped with an anti-lock braking system shall be deemed acceptable when the condition ε ≥ 0,75 is satisfied, where ε represents the adhesion utilised, as defined in point 2 of Appendix 2 to this Annex. This condition shall be verified with the vehicle unladen, on a straight and level road with a surface having a good coefficient of adhesion (18) (19) . U.K.

6.2.2. To eliminate the effects of differential brake temperatures, it is recommended that Z RAL be determined prior to the determination of k R . U.K.

6.3. Additional checks U.K.

6.3.1. At speeds exceeding 15 km/h, the wheels directly controlled by an anti-lock braking system shall not lock when the full force (20) is suddenly applied on the control device of the towing vehicle. This shall be checked, under the conditions prescribed in point 6.2 of this Annex, at initial speeds of 40 km/h and 80 km/h. U.K.

6.3.2. The provisions of this point shall only apply to trailers equipped with an anti-lock braking system of category A. U.K.

When the right and left wheels are situated on surfaces which produce differing maximum braking rates (Z RALH and Z RALL ), where

the directly controlled wheels shall not lock when the full force (21) is suddenly applied on the control device of the towing vehicle at a speed of 50 km/h. The ratio z RALH /z RALL may be ascertained by the procedure in point 2 of Appendix 2 to this Annex or by calculating the ratio z RALH /z RALL . Under this condition, the unladen vehicle shall satisfy the prescribed braking rate in Appendix 3 of this Annex (22) .

6.3.3. At vehicle speeds ≥ 15 km/h, the directly controlled wheels are permitted to lock for brief periods, but a speeds < 15 km/h, any locking is permissible. Indirectly controlled wheels are permitted to lock at any speed. In all cases, stability must not be affected. U.K.

Appendix 1 Symbols and definitions

| a F Mnd and F MD : in case of two-axled motor vehicles: these symbols may be simplified to corresponding F i symbols. | |

| Symbol | Notes |

|---|---|

| E | wheelbase |

| E R | distance between king-pin and centre of axle of semi-trailer (or distance between drawbar coupling and centre of axle or axles of centre-axle trailer) |

| ε | the adhesion utilised by the vehicle: quotient of the maximum braking rate with the anti-lock braking system operative (z AL ) and the coefficient of adhesion (k) |

| ε i | the ε-value measured on axle i (in the case of a motor vehicle with a category 3 anti-lock system) |

| ε Η | the ε-value on the high-friction surface |

| ε L | the ε-value on the low-friction surface |

| F | force [N] |

| F bR | braking force of the trailer with the anti-lock braking system inoperative |

| F bRmax | maximum value of F bR |

| F bRmax,i | value of F bRmax with only axle i of the trailer braked |

| F bRAL | braking force of the trailer with the anti-lock braking system operative |

| F Cnd | total normal reaction of road surface on the unbraked and non-driven axles of the vehicle combination under static conditions |

| F Cd | total normal reaction of road surface on the unbraked and driven axles of the vehicle combination under static conditions |

| F dyn | normal reaction of road under dynamic conditions with the anti-lock braking system operative |

| F idyn | F dyn on axle i in case of motor vehicles or full trailers |

| F i | normal reaction of road surface on axle i under static conditions |

| F M | total normal static reaction of road surface on all wheels of motor (towing) vehicle |

| F Mnd a | total normal static reaction of road surface on the unbraked and non-driven axles of the motor vehicle |

| F Md a | total normal static reaction of road surface on the unbraked and driven axles of the motor vehicle |

| F R | total normal static reaction of road surface on all wheels of trailer |

| F Rdyn | total normal dynamic reaction of road surface on the axle(s) of semi-trailer or centre-axle trailer |

| F wM a | 0,01 F Mnd + 0,015 F Md |

| g | acceleration due to gravity (9,81 m/s 2 ) |

| h | height of centre of gravity specified by the manufacturer and agreed by the technical service conducting the approval test |

| h D | height of drawbar (hinge point on trailer) |

| h K | height of fifth wheel coupling (king pin) |

| h R | height of centre of gravity of the trailer |

| k | coefficient of adhesion between tyre and road |

| k f | k-factor of one front axle |

| k H | k-value determined on the high-friction surface |

| k i | k-value determined on axle i for a vehicle with a category 3 anti-lock braking system |

| k L | k-value determined on the low-friction surface |

| k lock | value of adhesion for 100 % slip |

| k M | k-factor of the motor vehicle |

| k peak | maximum value of the curve ‘ adhesion versus slip ’ |

| k r | k-factor of one rear axle |

| k R | k-factor of the trailer |

| P | mass of individual vehicle [kg] |

| R | ratio of k peak to k lock |

| t | time interval [s] |

| t m | mean value of t |

| t min | minimum value of t |

| z | braking rate |

| z AL | braking rate z of the vehicle with the anti-lock braking system operative |

| z C | braking rate z of the vehicle combination, with the trailer only braked and the anti-lock braking system inoperative |

| z CAL | braking rate z of the vehicle combination, with the trailer only braked and the anti-lock braking system operative |

| z Cmax | maximum value of z C |

| z Cmax,i | maximum value of z C , with only axle i of the trailer braked |

| z m | mean braking rate |

| z max | maximum value of z |

| z MALS | z AL of the motor vehicle on a ‘split surface’ |

| z R | braking rate z of the trailer with the anti-lock braking system inoperative |

| z RAL | z AL of the trailer obtained by braking all the axles, the towing vehicle unbraked and its engine disconnected |

| z RALH | z RAL on the surface with the high coefficient of adhesion |

| z RALL | z RAL on the surface with the low coefficient of adhesion |

| z RALS | z RAL on the split surface |

| z RH | z R on the surface with the high coefficient of adhesion |

| z RL | z R on the surface with the low coefficient of adhesion |

| z RHmax | maximum value of z RH |

| z RLmax | maximum value of z RL |

| z Rmax | maximum value of z R |

Appendix 2 Utilisation of adhesion

1. METHOD OF MEASUREMENT FOR MOTOR VEHICLES U.K.

1.1. Determination of the coefficient of adhesion (k) U.K.

1.1.1. The coefficient of adhesion (k) shall be determined as the quotient of the maximum braking forces without locking the wheels and the corresponding dynamic load on the axle being braked. U.K.

1.1.2. The brakes shall be applied only on one axle of the vehicle under test, at an initial speed of 50 km/h. The braking forces shall be distributed between the wheels of the axle to reach maximum performance. The anti-lock braking system shall be disconnected, or inoperative, between 40 km/h and 20 km/h. U.K.

1.1.3. A number of tests at increments of line pressure shall be carried out to determine the maximum braking rate of the vehicle (z max ). U.K.

During each test, a constant input force shall be maintained and the braking rate shall be determined by reference to the time taken (t) for the speed to reduce from 40 km/h to 20 km/h using the formula:

z max is the maximum value of z

t is in seconds.

1.1.3.1. Wheel-lock may occur below 20 km/h. U.K.

1.1.3.2. Starting from the minimum measured value of t, called t min , then select three values of t comprised within t min and 1,05 t min and calculate their arithmetical mean value t m , U.K.

then calculate

If it is demonstrated that for practical reasons the three values determined above cannot be obtained, then the minimum time t min may be utilised. However, the requirements of point 1.3 still apply.

1.1.4. The braking forces shall be calculated from the measured braking rate and the rolling resistance of the unbraked axle(s) which is equal to 0,015 and 0,010 of the static axle load for a driven axle and a non-driven axle, respectively. U.K.

1.1.5. The dynamic load on the axle shall be that given by the relations in the Appendix to point 1.1.4.2 of Annex II. U.K.

1.1.6. The value of k shall be rounded to three decimal places. U.K.

1.1.7. Then, the test will be repeated for the other axles(s) as defined in points 1.1.1 to 1.1.6 above (for exemptions, see points 1.4 and 1.5 below). U.K.

1.1.8. For example, in the case of a two-axle rear-wheel drive vehicle, with the front axle (23) being braked, the coefficient of adhesion (k) is given by: U.K.

1.1.9. One coefficient will be determined for the front axle k f and one for the rear axle k r . U.K.

1.2. Determination of the adhesion utilised (ε) U.K.

1.2.1. The adhesion utilised (ε) is defined as the quotient of the maximum braking rate with the anti-lock braking system operative z AL ) and the coefficient of adhesion K M , i. e. U.K.

1.2.2. From an initial vehicle speed of 55 km/h, the maximum value for the braking rate (z AL ) shall be measured with the anti-lock braking system operative. This value for z AL shall be based on the average value of three tests, as previously described in point 1.1.3 of this Appendix, using the time taken for the speed to reduce from 45 km/h to 15 km/h, according to the following formula: U.K.

1.2.3. The coefficient of adhesion k M shall be determined by weighting with the dynamic axle loads: U.K.

where:

1.2.4. The value of ε shall be rounded to two decimal places. U.K.

1.2.5. In the case of a vehicle equipped with an anti-lock braking system of category 1 or 2, the value of z AL is based on the whole vehicle, with the anti-lock braking system in operation, and the adhesion utilised (ε) shall be given by the same formula quoted in point 1.2.1 above. U.K.

1.2.6. In the case of a vehicle equipped with an anti-lock braking system of category 3, the value of z AL shall be measured on each axle which has at least one directly controlled wheel. U.K.

Example: for a two-axle vehicle with an anti-lock braking system acting only on the rear axle (2), the adhesion utilised (ε) is given by:

This calculation shall be made for each axle having at least one directly controlled wheel.

1.3. If ε > 1,00, the measurements of coefficients of adhesion shall be repeated. A tolerance of 10 % is acceptable. U.K.

1.4. For motor vehicles equipped with three axles, only the axle not associated with a close-coupled bogie shall be used to establish a k value for the vehicle (24) . U.K.

1.5. For vehicles of categories N 2 and N 3 with a wheel base less than 3,80 m and with h/E > 0,25, the determination of the coefficient of adhesion for the rear axle shall be omitted. U.K.

1.5.1. In that case, the adhesion utilised (ε) is defined as the quotient of the maximum braking rate with the anti-lock braking system operative (z AL ) and the coefficient of adhesion (k f ), i. e. U.K.

2. METHOD OF MEASUREMENT FOR TRAILERS U.K.

2.1. General U.K.

2.1.1. The coefficient of adhesion (k) shall be determined as the quotient of the maximum braking forces without locking the wheels and the corresponding dynamic load on the axle being braked. U.K.

2.1.2. The brakes shall be applied on only one axle of the trailer under test, at an initial speed of 50 km/h. The braking forces shall be distributed between the wheels of the axle to reach maximum performance. The anti-lock braking system shall be disconnected or inoperative between 40 km/h and 20 km/h. U.K.

2.1.3. A number of tests at increments of line pressure shall be carried out to determine the maximum braking rate of the vehicle combination (z Cmax ) with the trailer only braked. During each test, a constant input force shall be maintained and the braking rate shall be determined by reference to the time taken (t) for the speed to reduce from 40 km/h to 20 km/h using the formula: U.K.

2.1.3.1. Wheel-lock may occur below 20 km/h. U.K.

2.1.3.2. Starting from the minimum measured value of t, called t min , then select three values of t comprised within t min and 1,05 t min and calculate their arithmetical mean value t m . U.K.

then calculate:

If it is demonstrated that for practical reasons the three values determined above cannot be obtained, then the minimum time t min may be utilised.

2.1.4. The adhesion utilised (ε) shall be calculated by means of the formula: U.K.

The k value shall be determined according to point 2.2.3 for full trailers or point 2.3.1 for semi-trailers, respectively.

2.1.5. If ε > 1,00 the measurements of coefficients of adhesion shall be repeated. A tolerance of 10 % is accepted. U.K.

2.1.6. The maximum braking rate (z RAL ) shall be measured with the anti-lock braking system operative and the towing vehicle unbraked, based on the average value of three tests, as in point 2.1.3 of this Appendix. U.K.

2.2. Full trailers U.K.

2.2.1. The measurement of k (with the anti-lock braking system being disconnected, or inoperative, between 40 km/h and 20 km/h) shall be performed for the front and rear axles. U.K.

For one front axle i:

For one rear axle i:

2.2.2. The values of k f and k r shall be rounded to three decimal places. U.K.

2.2.3. The coefficient of adhesion k R shall be determined proportionally according to the dynamic axle loads. U.K.

2.2.4. Measurement of z RAL (with the anti-lock braking system operative) U.K.

z RAL shall be determined on a surface with a high coefficient of adhesion and, for vehicles with a category A anti-lock braking system, also on a surface with a low coefficient of adhesion.

2.3. Semi-trailers and centre-axle trailers U.K.

2.3.1. The measurement of k (with the anti-lock braking system being disconnected, or inoperative, between 40 km/h and 20 km/h) shall be carried out with wheels fitted only on one axle, the wheels of the other axle(s) are removed. U.K.

2.3.2. The measurement of z RAL (with the anti-lock braking system operative) shall be carried out with all wheels fitted. U.K.

z RAL shall be determined on a surface with a high coefficient of adhesion and, for vehicles with a category A anti-lock braking system, also on a surface with a low coefficient of adhesion.

Appendix 3 Performance on differing adhesion surfaces

1. MOTOR VEHICLES U.K.

1.1. The prescribed braking rate referred to in point 5.3.5 of this Annex may be calculated by reference to the measured coefficient of adhesion of the two surfaces on which this test is carried out. U.K.

These two surfaces shall satisfy the conditions prescribed in point 5.3.4 of this Annex.

1.2. The coefficient of adhesion (k H and k L ) of the high- and low-adhesion surfaces, respectively, shall be determined in accordance with the provisions in point 1.1 of Appendix 2 to this Annex. U.K.

1.3. The braking rate (z MALS ) for laden motor vehicles shall be: U.K.

2. TRAILERS U.K.

2.1. The braking rate referred to in point 6.3.2 of this Annex may be calculated by reference to the measured braking rates z RALH and z RALL on the two surfaces on which the tests are carried out with the anti-lock braking system operative. These tow surfaces shall satisfy the conditions prescribed in point 6.3.2 of this Annex. U.K.

2.2. The braking rate zU.K.

RALS

shall be:

and

If ε Η > 0,95 use ε Η = 0,95.

Appendix 4 Method of selection of the low-adhesion surface

1. Details of the coefficient of adhesion of the surface selected, as determined in point 5.1.1.2 of this Annex, shall be given to the technical service. U.K.

1.1. These data shall include a curve of the coefficient of adhesion versus slip (from 0 to 100 % slip) for a speed of approximately 40 km/h (25) . U.K.

1.1.1. The maximum value of the curve will represent k peak and the value at 100 % slip will represent k lock . U.K.

1.1.2. The ratio R shall be determined as the quotient of the k peak and k lock . U.K.

1.1.3. The value of R shall be rounded to one decimal place. U.K.

1.1.4. The surface to be used shall have a ratio R between 1,0 and 2,0 (26) . U.K.

2. Prior to the tests, the technical service shall ensure that the selected surface meets the specified requirements and shall be informed of the following: U.K.

test method to determine R,

type of vehicle (motor vehicle, trailer, etc.),

axle load and tyres (different loads and different tyres have to be tested and the results shown to the technical service which will decide if they are representative for the vehicle to be approved).

2.1. The value of R shall be mentioned in the test report. U.K.

The calibration of the surface has to be carried out at least once a year with a representative vehicle to verify the stability of R.]

[F1Anti-lock braking systems with ‘ select-high ’ control are deemed to include both directly and indirectly controlled wheels; in systems with ‘ select-low ’ control, all sensed wheels are deemed to be directly controlled wheels.

Until uniform test procedures have been agreed, the manufacturer shall provide the technical service with an analysis of potential failures within the controller(s) and their effects. This information shall be subject to discussion and agreement between the technical service and the vehicle manufacturer.

The warning signal may light up again while the vehicle is stationary, provided that it is extinguished before the vehicle speed reaches 10 km/h when no defect is present.

The wiring specification of point 6.2 of ISO 7638-1985 or point 5.4 of ISO/DIS standard 7638-1996 for the trailer may only be reduced if the trailer is equipped with its own independent fuse. The rating of the fuse shall be such that the current rating of the conductors is not exceeded.

With the exception of vehicles of categories N 3 and O 4 , and until a uniform international standard has been agreed, the electrical connection between towing vehicles and trailers equipped with a 12 volt electrical system shall conform with DIN standard 72570, Part 4.

This shall be demonstrated by compliance with the technical requirements laid down in Council Directive 72/245/EEC ( OJ L 152, 6.7.1972, p. 15 ), as last amended by Directive 95/54/EC ( OJ L 266, 3.11.1995, p. 1 ).

It is understood that devices changing the control mode of the anti-lock braking system are not subject to point 4.7 if in the changed control mode condition all requirements for the category of anti-lock braking system, with which the vehicle is equipped, are fulfilled. However, in this case points 4.7.2, 4.7.3 and 4.7.4 shall be met.

Until such test surfaces become generally available, tyres at the limit of wear, and higher values up to 0,4 may be used at the discretion of the technical service. The actual value obtained and the type of tyres and surface shall be recorded.

Until such test surfaces become generally available, tyres at the limit of wear, and higher values up to 0,4 may be used at the discretion of the technical service. The actual value obtained and the type of tyres and surface shall be recorded.

‘ Full force ’ means the maximum force laid down in Annex II for the category of vehicle: a higher force may be used if required to activate the anti-lock braking system.

‘ Full force ’ means the maximum force laid down in Annex II for the category of vehicle: a higher force may be used if required to activate the anti-lock braking system.

The purpose of these tests is to check that the wheels do not lock and that the vehicle remains stable; it is not necessary, therefore, to make complete stops and bring the vehicle to a complete halt on the low-adhesion surface.

k h is the high-adhesion surface coefficient.

k L is the low-adhesion surface coefficient.

k H and k L are measured as laid down in Appendix 2 to this Annex.

‘ Full force ’ means the maximum force laid down in Annex II for the category of vehicle: a higher force may be used if required to activate the anti-lock braking system.

The purpose of these tests is to check that the wheels do not lock and that the vehicle remains stable; it is not necessary, therefore, to make complete stops and bring the vehicle to a complete halt on the low-adhesion surface.

‘ Full force ’ means the maximum force laid down in Annex II for the category of vehicle: a higher force may be used if required to activate the anti-lock braking system.

‘ Full force ’ means the maximum force laid down in Annex II for the category of vehicle: a higher force may be used if required to activate the anti-lock braking system.

If the coefficient of adhesion of the test track is too high, preventing the anti-lock braking system from cycling then the test may be carried out on a surface with a lower coefficient of adhesion.

If the coefficient of adhesion of the test track is too high, preventing the anti-lock braking system from cycling then the test may be carried out on a surface with a lower coefficient of adhesion.

In the case of trailers fitted with a brake load sensing device the pressure setting may be increased to ensure full cycling.

‘ Full force ’ means the maximum force laid down in Annex II for the category of vehicle: a higher force may be used if required to activate the anti-lock braking system.

‘ Full force ’ means the maximum force laid down in Annex II for the category of vehicle: a higher force may be used if required to activate the anti-lock braking system.

In the case of trailers fitted with a brake load sensing device the pressure setting may be increased to ensure full cycling.

Anti-lock braking systems with ‘ select-high ’ control are deemed to include both directly and indirectly controlled wheels; in systems with ‘ select-low ’ control, all sensed wheels are deemed to be directly controlled wheels.

Until a uniform test procedure is agreed, vehicles with more than three axles and special vehicles will be subject to consultation with the technical service.

Until a uniform test procedure is established for the determination of the adhesion curve for vehicles with a maximum mass exceeding 3,5 tonnes, the curve established for passenger cars may be used. In this case, for vehicles with a maximum mass exceeding 3,5 tonnes, the ratio k peak to k lock shall be established using a value of k peak as defined in Appendix 2 of this Annex. With the consent of the technical service, the coefficient of adhesion described in this item may be determined by another method provided that the equivalence of the values of k peak and k lock are demonstrated.

Until such test surfaces become generally available, a ratio R up to 2,5 is acceptable, subject to discussion with the technical service.]

Textual Amendments

Options/Help

Print Options

PrintThe Whole Directive

PrintThis Annex only

You have chosen to open the Whole Directive

The Whole Directive you have selected contains over 200 provisions and might take some time to download. You may also experience some issues with your browser, such as an alert box that a script is taking a long time to run.

Would you like to continue?

You have chosen to open Schedules only

Y Rhestrau you have selected contains over 200 provisions and might take some time to download. You may also experience some issues with your browser, such as an alert box that a script is taking a long time to run.

Would you like to continue?

Mae deddfwriaeth ar gael mewn fersiynau gwahanol:

Y Diweddaraf sydd Ar Gael (diwygiedig):Y fersiwn ddiweddaraf sydd ar gael o’r ddeddfwriaeth yn cynnwys newidiadau a wnaed gan ddeddfwriaeth ddilynol ac wedi eu gweithredu gan ein tîm golygyddol. Gellir gweld y newidiadau nad ydym wedi eu gweithredu i’r testun eto yn yr ardal ‘Newidiadau i Ddeddfwriaeth’.

Gwreiddiol (Fel y’i mabwysiadwyd gan yr UE): Mae'r wreiddiol version of the legislation as it stood when it was first adopted in the EU. No changes have been applied to the text.

Pwynt Penodol mewn Amser: This becomes available after navigating to view revised legislation as it stood at a certain point in time via Advanced Features > Show Timeline of Changes or via a point in time advanced search.

Gweler y wybodaeth ychwanegol ochr yn ochr â’r cynnwys

Rhychwant ddaearyddol: Indicates the geographical area that this provision applies to. For further information see ‘Frequently Asked Questions’.

Dangos Llinell Amser Newidiadau: See how this legislation has or could change over time. Turning this feature on will show extra navigation options to go to these specific points in time. Return to the latest available version by using the controls above in the What Version box.

Rhagor o Adnoddau

Gallwch wneud defnydd o ddogfennau atodol hanfodol a gwybodaeth ar gyfer yr eitem ddeddfwriaeth o’r tab hwn. Yn ddibynnol ar yr eitem ddeddfwriaeth sydd i’w gweld, gallai hyn gynnwys:

- y PDF print gwreiddiol y fel adopted version that was used for the EU Official Journal

- rhestr o newidiadau a wnaed gan a/neu yn effeithio ar yr eitem hon o ddeddfwriaeth

- pob fformat o’r holl ddogfennau cysylltiedig

- slipiau cywiro

- dolenni i ddeddfwriaeth gysylltiedig ac adnoddau gwybodaeth eraill

Llinell Amser Newidiadau

Mae’r llinell amser yma yn dangos y fersiynau gwahanol a gymerwyd o EUR-Lex yn ogystal ag unrhyw fersiynau dilynol a grëwyd ar ôl y diwrnod ymadael o ganlyniad i newidiadau a wnaed gan ddeddfwriaeth y Deyrnas Unedig.

Cymerir dyddiadau fersiynau’r UE o ddyddiadau’r dogfennau ar EUR-Lex ac efallai na fyddant yn cyfateb â’r adeg pan ddaeth y newidiadau i rym ar gyfer y ddogfen.

Ar gyfer unrhyw fersiynau a grëwyd ar ôl y diwrnod ymadael o ganlyniad i newidiadau a wnaed gan ddeddfwriaeth y Deyrnas Unedig, bydd y dyddiad yn cyd-fynd â’r dyddiad cynharaf y daeth y newid (e.e. ychwanegiad, diddymiad neu gyfnewidiad) a weithredwyd i rym. Am ragor o wybodaeth gweler ein canllaw i ddeddfwriaeth ddiwygiedig ar Ddeall Deddfwriaeth.

Rhagor o Adnoddau

Defnyddiwch y ddewislen hon i agor dogfennau hanfodol sy’n cyd-fynd â’r ddeddfwriaeth a gwybodaeth am yr eitem hon o ddeddfwriaeth. Gan ddibynnu ar yr eitem o ddeddfwriaeth sy’n cael ei gweld gall hyn gynnwys:

- y PDF print gwreiddiol y fel adopted fersiwn a ddefnyddiwyd am y copi print

- slipiau cywiro

liciwch ‘Gweld Mwy’ neu ddewis ‘Rhagor o Adnoddau’ am wybodaeth ychwanegol gan gynnwys

- rhestr o newidiadau a wnaed gan a/neu yn effeithio ar yr eitem hon o ddeddfwriaeth

- manylion rhoi grym a newid cyffredinol

- pob fformat o’r holl ddogfennau cysylltiedig

- dolenni i ddeddfwriaeth gysylltiedig ac adnoddau gwybodaeth eraill