- Y Diweddaraf sydd Ar Gael (Diwygiedig)

- Gwreiddiol (Fel y’i mabwysiadwyd gan yr UE)

Commission Regulation (EC) No 273/2008 (repealed)Dangos y teitl llawn

Commission Regulation (EC) No 273/2008 of 5 March 2008 laying down detailed rules for the application of Council Regulation (EC) No 1255/1999 as regards methods for the analysis and quality evaluation of milk and milk products (repealed)

You are here:

- Rheoliadau yn deillio o’r UE

- 2008 No. 273

- ANNEX IX

- REFERENCE METHOD FOR THE...

Rhagor o Adnoddau

PDF o Fersiynau Diwygiedig

- ddiwygiedig 07/02/20180.44 MB

- ddiwygiedig 01/07/20133.59 MB

Pan adawodd y DU yr UE, cyhoeddodd legislation.gov.uk ddeddfwriaeth yr UE a gyhoeddwyd gan yr UE hyd at ddiwrnod cwblhau’r cyfnod gweithredu (31 Rhagfyr 2020 11.00 p.m.). Ar legislation.gov.uk, mae'r eitemau hyn o ddeddfwriaeth yn cael eu diweddaru'n gyson ag unrhyw ddiwygiadau a wnaed gan y DU ers hynny.

Mae'r eitem hon o ddeddfwriaeth yn tarddu o'r UE

Mae legislation.gov.uk yn cyhoeddi fersiwn y DU. Mae EUR-Lex yn cyhoeddi fersiwn yr UE. Mae Archif Gwe Ymadael â’r UE yn rhoi cipolwg ar fersiwn EUR-Lex o ddiwrnod cwblhau’r cyfnod gweithredu (31 Rhagfyr 2020 11.00 p.m.).

Status:

EU_status_warning_original_version

This legislation may since have been updated - see the latest available (revised) version

REFERENCE METHOD FOR THE DETECTION OF COWS’ MILK AND CASEINATE IN CHEESES FROM EWES’ MILK, GOATS’ MILK OR BUFFALOS’ MILK OR MIXTURES OF EWES’, GOATS’ AND BUFFALOS’ MILK

1.SCOPE

Detection of cows’ milk and caseinate in cheeses made from ewes’ milk, goats’ milk, buffalos’ milk or mixtures of ewes’, goats’ and buffalos’ milk by isoelectric focusing of γ-caseins after plasminolysis.

2.FIELD OF APPLICATION

The method is suitable for sensitive and specific detection of native and heat-treated cows’ milk and caseinate in fresh and ripened cheeses made from ewes’ milk, goats’ milk, buffalos’ milk or mixtures of ewes’, goats’ and buffalos’ milk. It is not suitable for the detection of milk and cheese adulteration by heat-treated bovine whey protein concentrates.

3.PRINCIPLE OF THE METHOD

3.1.Isolation of caseins from cheese and the reference standards

3.2.Dissolving of the isolated caseins and submitting to plasmin (EC.3.4.21.7) cleavage

3.3.Isoelectric focusing of plasmin-treated caseins in the presence of urea and staining of proteins

3.4.Evaluation of stained γ3 and γ2-casein patterns (evidence of cows’ milk) by comparison of the pattern obtained from the sample with those obtained in the same gel from the reference standards containing 0 % and 1 % cows’ milk.

4.REAGENTS

Unless otherwise indicated, analytical grade chemicals must be used. Water must be double-distilled or of equivalent purity.

Note: The following details apply to laboratory prepared polyacrylamide gels containing urea, of dimensions 265 × 125 × 0,25 mm. Where other sizes and types of gel are used, the separation conditions may have to be adjusted.

Isoelectric focusing

4.1.Reagents for production of the urea containing polyacrylamide gels

4.1.1.Stock gel solution

Dissolve:

4,85 g acrylamide

0,15 g N, N'-methylene-bis-acrylamide (BIS)

48,05 g urea

15,00 g glycerol (87 % w/w),

in water and make up to 100 ml and store in a brown glass bottle in the refrigerator.

Note: A commercially available preblended acrylamide/BIS solution can be used in preference to the quoted fixed weights of the neurotoxic acrylamides. Where such a solution contains 30 % w/v acrylamide and 0,8 % w/v BIS, a volume of 16,2 ml must be used for the formulation instead of the fixed weights. The shelf life of the stock solution is a maximum of 10 days; if its conductivity is more than 5 μS, de-ionize by stirring with 2 g Amberlite MB-3 for 30 minutes, then filter through a 0,45 μm membrane.

4.1.2.Gel solution

Prepare a gel solution by mixing additives and ampholytes with the stock gel solution (see 4.1.1).

9,0 ml stock solution

24 mg β-alanine

500 μl ampholyte pH 3,5-9,5(1)

250 μl ampholyte pH 5-7(1)

250 μl ampholyte pH 6-8(1).

Mix the gel solution and de-gas for two to three minutes in an ultrasonic bath or in vacuum.

Note: Prepare the gel solution immediately prior to pouring it (see 6.2).

4.1.3.Catalyst solutions

4.1.3.1.N, N, N' N' — tetramethylethylenediamine (Temed)

4.1.3.2.40 % w/v ammonium persulphate (PER):

Dissolve 800 mg PER in water and make up to 2 ml.

Note: Always use freshly prepared PER solution.

4.2.Contact fluid

Kerosene or liquid paraffin

4.3.Anode solution

Dissolve 5,77 g phosphoric acid (85 % w/w) in water and dilute to 100 ml.

4.4.Cathode solution

Dissolve 2,00 g sodium hydroxide in water and dilute to 100 ml with water.

Sample preparation

4.5.Reagents for protein isolation

4.5.1. Dilute acetic acid (25,0 ml of glacial acetic acid made up to 100 ml with water)

4.5.2. Dichloromethane

4.5.3. Acetone

4.6.Protein dissolving buffer

Dissolve

5,75 g glycerol (87 % w/w)

24,03 g urea

250 mg dithiothreitol,

in water and make up to 50 ml

Note: Store in a refrigerator, maximum shelf-life one week.

4.7.Reagents for plasmin cleavage of caseins

4.7.1.Ammonium carbonate buffer

Titrate a 0,2 mol/l ammonium hydrogencarbonate solution (1,58 g/100 ml water) containing 0,05 mol/l ethylenediaminetetraacetic acid (EDTA, 1,46 g/100 ml with a 0,2 mol/l ammonium carbonate solution (1,92 g/100 ml water) containing 0,05 mol/l EDTA to ph 8.

4.7.2. Bovine plasmin (EC. 3.4.21.7), activity at least 5 U/ml

4.7.3.ε-Aminocaproic acid solution for enzyme inhibition

Dissolve 2,624 g ε-aminocaproic acid (6 amino-n-hexanoic acid) in 100 ml of 40 % (v/v) ethanol.

4.8.Standards

4.8.1. Certified reference standards of a mixture of renneted ewes’ and goats’ skimmed milk containing 0 % and 1 % of cows’ milk are available from the Commission’s Institute for Reference Materials and Measurements, B-2440 Geel, Belgium

4.8.2.Preparation of laboratory interim-standards of buffalos’ renneted milk containing 0 % and 1 % of cows’ milk

Skimmed milk is prepared by centrifuging of either buffalo or bovine raw bulk milk at 37 °C at 2 500 g for 20 minutes. After cooling the tube and contents rapidly to 6 to 8 °C, the upper fat layer is removed completely. For the preparation of the 1 % standard add 5,00 ml of bovine skimmed milk to a 495 ml of buffalos’ skimmed milk in a 1 l beaker, adjust the pH to 6,4 by the addition of dilute lactic acid (10 % w/v). Adjust the temperature to 35 °C and add 100 μl of calf rennet (rennet activity 1: 10 000, c. 3 000 U/ml), stir for 1 minute and then leave the beaker covered with an aluminium foil at 35 °C for one hour to allow formation of the curd. After the curd has formed, the whole renneted milk is freeze-dried without prior homogenization or draining of the whey. After freeze-drying it is finely ground to produce a homogeneous powder. For the preparation of the 0 % standard, carry out the same procedure using genuine buffalo skimmed milk. The standards must be stored at -20 °C.

Note: It is advisable to check the purity of the buffalos’ milk by isoelectric focusing of the plasmin-treated caseins before preparation of the standards.

Reagents for protein staining

4.9.Fixative

Dissolve 150 g trichloroacetic acid in water and make up to 1 000 ml.

4.10.Destaining solution

Dilute 500 ml methanol and 200 ml glacial acetic acid to 2 000 ml with distilled water.

Note: Prepare the destaining solution fresh every day; it can be prepared by mixing equal volumes of stock solutions of 50 % (v/v) methanol and 20 % (v/v) glacial acetic acid.

4.11.Staining solutions

4.11.1.Staining solution (stock solution 1)

Dissolve 3,0 g Coomassie Brilliant Blue G-250 (C.I. 42655) in 1 000 ml 90 % (v/v) methanol using a magnetic stirrer (approximately 45 minutes), filter through two medium-speed folded filters.

4.11.2.Staining solution (stock solution 2)

Dissolve 5,0 g copper sulphate pentahydrate in 1 000 ml 20 % (v/v) acetic acid.

4.11.3.Staining solution (working solution)

Mix together 125 ml of each of the stock solutions (4.11.1, 4.11.2) immediately prior to staining.

Note: The staining solution should be prepared on the day that it is used.

5.EQUIPMENT

5.1.Glass plates (265 × 125 × 4 mm); rubber roller (width 15 cm); levelling table

5.2.Gel carrier sheet (265 × 125 mm)

5.3.Covering sheet (280 × 125 mm). Stick on strip of adhesive tape (280 × 6 × 0,25 mm) to each long edge (see Figure 1)

5.4.Electrofocusing chamber with cooling plate (e.g. 265 × 125 mm) and suitable power supply (≥ 2,5 kV) or automatic electrophoresis device

5.5.Circulation cryostat, thermostatically controlled at 12 ± 0,5 °C

5.6.Centrifuge, adjustable to 3 000 g

5.7.Electrode strips (≥ 265 mm long)

5.8.Plastic dropping bottles for the anode and cathode solutions

5.9.Sample applicators (10 × 5 mm, viscose or low protein-adsorption filter paper)

5.10.Stainless steel scissors, scalpels and tweezers

5.11.Stainless steel or glass staining and destaining dishes (e.g. 280 × 150 mm instrument trays)

5.12.Adjustable rod homogenizer (10 mm shaft diameter), rpm range 8 000 to 20 000

5.13.Magnetic stirrer

5.14.Ultrasonic bath

5.15.Film welder

5.16.25 μl micropipettes

5.17.Vacuum concentrator or freeze-dryer

5.18.Thermostatically controlled water bath adjustable to 35 and 40 ± 1 °C with shaker

5.19.Densitometer equipment reading at λ = 634 nm

6.PROCEDURE

6.1.Sample preparation

6.1.1.Isolation of caseins

Weigh the amount equivalent to 5 g dry mass of cheese or the reference standards into a 100 ml centrifuge tube, add 60 ml distilled water and homogenize with a rod homogenizer (8 000 to 10 000 rpm). Adjust to pH 4,6 with dil. acetic acid (4.5.1) and centrifuge (5 minutes, 3 000 g). Decant the fat and whey, homogenize the residue at 20 000 rpm in 40 ml distilled water adjusted to pH 4,5 with dil. acetic acid (4.5.1), add 20 ml dichloromethane (4.5.2), homogenize again and centrifuge (5 minutes, 3 000 g). Remove the casein layer that lies between the aqueous and organic phases (see Figure 2) with a spatula and decant off both phases. Rehomogenize the casein in 40 ml distilled water (see above) and 20 ml dichloromethane (4.5.2) and centrifuge. Repeat this procedure until both extraction phases are colourless (two to three times). Homogenize the protein residue with 50 ml acetone (4.5.3) and filter through a medium-speed folded filter paper. Wash the residue on the filter with two separate 25 ml portions of acetone each time and allow to dry in the air or a stream of nitrogen, then pulverize finely in a mortar.

Note: Dry casein isolates should be kept at -20 °C.

6.1.2.Plasmin cleavage of β-caseins to intensify γ-caseins

Disperse 25 mg of isolated caseins (6.1.1) in 0,5 ml ammonium carbonate buffer (4.7.1) and homogenize for 20 minutes by e.g. using ultrasonic treatment. Heat to 40 °C and add 10 μl plasmin (4.7.2), mix and incubate for one hour at 40 °C with continuous shaking. To inhibit the enzyme add 20 μl ε-aminoproic acid solution (4.7.3), then add 200 mg of solid urea and 2 mg of dithiothreitol.

Note: To obtain more symmetry in the focused casein bands it is advisable to freeze-dry the solution after adding the ε-aminocaproic acid and then dissolving the residues in 0,5 ml protein dissolving buffer (4.6).

6.2.Preparation of the urea containing polyacrylamide gels

With the aid of a few drops of water roll the gel carrier sheet (5.2) onto a glass plate (5.1), removing any extraneous water with paper towel or tissue. Roll the cover sheet (5.3) with spacers (0,25 mm) onto another glass plate in the same way. Lay the plate horizontally on a levelling table.

Add 10 μl Temed (4.1.3.1) to the prepared and de-aerated gel solution (4.1.2), stir and add 10 μl PER-solution (4.1.3.2), mix thoroughly and immediately pour out evenly onto the centre of the cover sheet. Place one edge of the gel carrier plate (sheet side down) on the cover sheet plate and lower it slowly so that a gel film forms between the sheets and spreads out regularly and free of bubbles (Figure 3). Carefully lower the gel carrier plate completely using a thin spatula and place three more glass plates on top of it to act as weights. After polymerization is complete (about 60 minutes) remove the gel polymerized onto the gel carrier sheet along with the cover sheet by tipping the glass plates. Clean the reverse of the carrier sheet carefully to remove gel residues and urea. Weld the gel sandwich into a film tube and store in a refrigerator (maximum six weeks).

Note: The cover sheet with the spacers can be re-used. The polyacrylamide gel can be cut to smaller sizes, recommended when there are few samples or if an automatic electrophoresis device is used (two gels, size 4,5 × 5 cm).

6.3.lsoelectric focusing

Set the cooling thermostat to 12 °C. Wipe off the reverse of the gel carrier sheet with kerosene, then drip a few drops of kerosene (4.2) onto the centre of the cooling block. Then roll the gel sandwich, carrier side down, onto it, taking care to avoid bubbles. Wipe off any excess kerosene and remove the cover sheet. Soak the electrode strips with the electrode solutions (4.3, 4.4), cut to gel length and place in the positions provided (distance of electrodes 9,5 cm).

Conditions for isoelectric focusing:

6.3.1.Gel size 265 × 125 × 0,25 mm

| a Sample application: After pre-focusing (step 1), pipette 18 μl of the sample and standard solutions onto the sample applicators (10 × 5 mm), place them on the gel at 1 mm intervals from each other and 5 mm longitudinally from the anode and press lightly. Carry out focusing using the above conditions, carefully removing the sample applicators after the 60 minutes of sample focusing. | |||||

| Step | Time(min.) | Voltage(V) | Current(mA) | Power(W) | Volt-hours(Vh) |

|---|---|---|---|---|---|

1.Pre-focusing | 30 | maximum 2 500 | maximum 15 | constant 4 | c. 300 |

2.Sample focusinga | 60 | maximum 2 500 | maximum 15 | constant 4 | c. 1 000 |

3.Final focusing | 60 | maximum 2 500 | maximum 5 | maximum 20 | c. 3 000 |

| 40 | maximum 2 500 | maximum 6 | maximum 20 | c. 3 000 | |

| 30 | maximum 2 500 | maximum 7 | maximum 25 | c. 3 000 | |

Note: If thickness or width of the gels are changed, the values for current and power have to be suitably adjusted (e.g. double the values for electric current and power if a 265 × 125 × 0,5 mm gel is used).

6.3.2.Example of a voltage programme for an automatic electrophoresis device (2 gels of 5,0 × 4,5 cm), electrodes without strips applied directly to the gel

Place sample applicator in step 2 at 0 Vh.

Remove sample applicator in step 2 at 30 Vh.

6.4.Protein staining

6.4.1.Protein fixation

Remove the electrode strips immediately after turning off the power and put the gel immediately into a staining/destaining dish filled with 200 ml fixative (4.9); leave for 15 minutes, shaking continuously.

6.4.2.Washing and staining the gel plate

Thoroughly drain off the fixative and wash the gel plate twice for 30 seconds each time with 100 ml destaining solution (4.10). Pour off the destaining solution and fill the dish with 250 ml staining solution (4.11.3); allow to stain for 45 minutes with gentle shaking.

6.4.3.Destaining the gel plate

Pour off the staining solution, wash the gel plate twice using a 100 ml destaining solution (4.10) each time, then shake with 200 ml destaining solution for 15 minutes and repeat the destaining step at least two or three times until the background is clear and uncoloured. Then rinse the gel plate with distilled water (2 × 2 minutes) and dry in the air (2 to 3 hours) or with a hairdryer (10 to 15 minutes).

Note 1: Carry out fixing, washing, staining and destaining at 20 °C. Do not use elevated temperatures.

Note 2: If more sensitive silver staining (e.g. Silver Staining Kit, Protein, Pharmacia Biotech, Code No 17-1150-01) is preferred, plasmin-treated casein samples have to be diluted to 5 mg/ml.

7.EVALUATION

Evaluation is performed by comparing the protein patterns of the unknown sample with reference standards on the same gel. Detection of cows’ milk in cheeses from ewes’ milk, goats’ milk and buffalos’ milk and mixtures of ewes’, goats’ and buffalos’ milk is done via the γ3- and γ2-caseins, whose isoelectric points range between pH 6,5 and pH 7,5 (Figures 4 a, b, Figure 5). The detection limit is less than 0,5 %.

7.1.Visual estimation

For visual evaluation of the amount of bovine milk it is advisable to adjust the concentrations of samples and standards to obtain the same level of intensity of the ovine, caprine and/or buffalo γ2- and γ3-caseins (see ‘γ2 E,G,B’ and ‘γ3 E,G,B’ in Figures 4 a, b and Figure 5). After which the amount of bovine milk (less than, equal to or greater than 1 %) in the unknown sample can be judged directly by comparing the intensity of the bovine γ3- and γ2-caseins (see ‘γ3 C’ and ‘γ2 C’ in Figures 4a, b and Figure 5) to those of the 0 % and 1 % reference standards (ewe, goat) or, laboratory interim-standards (buffalo).

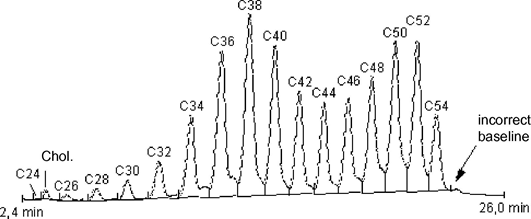

7.2.Densitometric estimation

If available, apply densitometry (5.19) for the determination of the peak area ratio of bovine to ovine, caprine and/or buffalo γ2- and γ3-caseins (see Figure 5). Compare this value to γ2- and γ3-casein peak area ratio of the 1 % reference standard (ewe, goat) or laboratory interim-standard (buffalo) analysed on the same gel.

Note: The method is operating satisfactorily, if there is a clear positive signal for both bovine γ2- and γ3-caseins in the 1 % reference standard but not in the 0 % reference standard. If not, optimize the procedure following the details of the method precisely.

A sample is judged as being positive, if both bovine γ2- and γ3-caseins or the corresponding peak area ratios are equal to or greater than the level of the 1 % reference standard.

8.REFERENCES

Addeo F., Moio L., Chianese L., Stingo C., Resmini P., Berner I, Krause I., Di Luccia A., Bocca A.: Use of plasmin to increase the sensitivity of the detection of bovine milk in ovine and/or caprine cheese by gel isoelectric focusing of γ2-caseins. Milchwissenschaft 45, 708-711 (1990).

Addeo F., Nicolai M.A., Chianese L., Moio L., Spagna Musso S., Bocca A., Del Giovine L.: A control method to detect bovine milk in ewe and water buffalo cheese using immunoblotting. Milchwissenschaft 50, 83-85 (1995).

Krause I., Berner I, Klostermeyer H.: Sensitive detection of cow milk in ewe and goat milk and cheese by carrier ampholyte — and carrier ampholyte/immobilized pH gradient — isoelectric focusing of γ-caseins using plasmin as signal amplifier. in: Electrophoresis-Forum 89 (B. J. Radola, ed.) pp 389-393, Bode-Verlag, München (1989).

Krause Ι., Belitz H.-D., Kaiser K.-P.: Nachweis von Kuhmilch in Schaf and Ziegenmilch bzw. –käse durch isoelektrische Fokussierung in harnstoffhaltigen Polyacrylamidgelen. Z. Lebensm. Unters. Forsch. 174, 195-199 (1982).

Radola B.J.: Ultrathin-layer isoelectric focusing in 50-100 μm polyacrylamide gels on silanised glass plates or polyester films. Electrophoresis 1, 43-56 (1980).

a = spacer tape (0,25 mm); b = covering sheet (5.3); c, e = glass plates (5.1); d = gel solution (4.1.2); f = gel carrier sheet (5.2)

Figure 4a

Isoelectric focusing of plasmin-treated caseins from ewes’ and goats’ milk cheese containing different amounts of cows’ milk.

% CM = percentage of cows’ milk, C = cow, E = ewe, G = goat

Upper half of the IEF gel is shown.

Figure 4b

Isoelectric focusing of plasmin treated caseins from cheese made from mixtures of ewes’, goats’ and buffalos’ milk containing different amounts of cows’ milk.

% CM = percentage of cows’ milk; 1 + = sample containing 1 % of cows’ milk and spiked with pure bovine casein at the middle of the track. C = cow, E = ewe, G = goat, B = buffalo.

Total separation distance of the IEF gel is shown.

Figure 5

Superposition of densitograms of standards (STD) and cheese samples made from a mixture of ewes’ and goats’ milk after isoelectric focusing

a,b = standards containing 0 and 1 % of cows’ milk; c-g = cheese samples containing 0, 1, 2, 3 and 7 % of cows’ milk. C = cow, E = ewe, G = goat.

Upper half of the IEF gel was scanned at λ = 634 nm.

The produce Ampholine® pH 3,5-9,5 (Pharmacia) and Resolyte® pH 5-7 and pH 6-8 (BDH, Merck) have proved particularly suitable for obtaining the required separation of γ-caseins.

Options/Help

Print Options

PrintThe Whole Regulation

PrintThe Whole Annex

PrintThis Division only

You have chosen to open the Whole Regulation

The Whole Regulation you have selected contains over 200 provisions and might take some time to download. You may also experience some issues with your browser, such as an alert box that a script is taking a long time to run.

Would you like to continue?

You have chosen to open Schedules only

Y Rhestrau you have selected contains over 200 provisions and might take some time to download. You may also experience some issues with your browser, such as an alert box that a script is taking a long time to run.

Would you like to continue?

Mae deddfwriaeth ar gael mewn fersiynau gwahanol:

Y Diweddaraf sydd Ar Gael (diwygiedig):Y fersiwn ddiweddaraf sydd ar gael o’r ddeddfwriaeth yn cynnwys newidiadau a wnaed gan ddeddfwriaeth ddilynol ac wedi eu gweithredu gan ein tîm golygyddol. Gellir gweld y newidiadau nad ydym wedi eu gweithredu i’r testun eto yn yr ardal ‘Newidiadau i Ddeddfwriaeth’.

Gwreiddiol (Fel y’i mabwysiadwyd gan yr UE): Mae'r wreiddiol version of the legislation as it stood when it was first adopted in the EU. No changes have been applied to the text.

Rhagor o Adnoddau

Gallwch wneud defnydd o ddogfennau atodol hanfodol a gwybodaeth ar gyfer yr eitem ddeddfwriaeth o’r tab hwn. Yn ddibynnol ar yr eitem ddeddfwriaeth sydd i’w gweld, gallai hyn gynnwys:

- y PDF print gwreiddiol y fel adopted version that was used for the EU Official Journal

- rhestr o newidiadau a wnaed gan a/neu yn effeithio ar yr eitem hon o ddeddfwriaeth

- pob fformat o’r holl ddogfennau cysylltiedig

- slipiau cywiro

- dolenni i ddeddfwriaeth gysylltiedig ac adnoddau gwybodaeth eraill

Rhagor o Adnoddau

Defnyddiwch y ddewislen hon i agor dogfennau hanfodol sy’n cyd-fynd â’r ddeddfwriaeth a gwybodaeth am yr eitem hon o ddeddfwriaeth. Gan ddibynnu ar yr eitem o ddeddfwriaeth sy’n cael ei gweld gall hyn gynnwys:

- y PDF print gwreiddiol y fel adopted fersiwn a ddefnyddiwyd am y copi print

- slipiau cywiro

liciwch ‘Gweld Mwy’ neu ddewis ‘Rhagor o Adnoddau’ am wybodaeth ychwanegol gan gynnwys

- rhestr o newidiadau a wnaed gan a/neu yn effeithio ar yr eitem hon o ddeddfwriaeth

- manylion rhoi grym a newid cyffredinol

- pob fformat o’r holl ddogfennau cysylltiedig

- dolenni i ddeddfwriaeth gysylltiedig ac adnoddau gwybodaeth eraill