ANNEX IU.K. Standard models for the information document and the EC type-approval certificate

PART 1U.K. Information document

MODEL U.K.

Information document No … relating to the EC type-approval of a vehicle with regard to lane departure warning systems.

The following information shall be supplied in triplicate and include a list of contents. Any drawings shall be supplied in appropriate scale and in sufficient detail on size A4 or on a folder of A4 format. Photographs, if any, shall show sufficient detail.

If the systems, components or separate technical units referred to in this Annex have electronic controls, information concerning their performance shall be supplied.

0.GENERALU.K.

0.1.Make (trade name of manufacturer): …U.K.

0.2.Type: …U.K.

0.2.0.1.Chassis: …U.K.

0.2.0.2.Bodywork/complete vehicle: …U.K.

0.2.1.Commercial name(s) (if available): …U.K.

0.3.Means of identification of type, if marked on the vehicle(1): …U.K.

0.3.0.1.Chassis: …U.K.

0.3.0.2.Bodywork/complete vehicle: …U.K.

0.3.1.Location of that marking: …U.K.

0.3.1.1.Chassis: …U.K.

0.3.1.2.Bodywork/complete vehicle: …U.K.

0.4.Category of vehicle(2): …U.K.

0.5.Name and address of manufacturer: …U.K.

0.6.Location and method of attachment of statutory plates and location of vehicle identification number: …U.K.

0.6.1.On the chassis: …U.K.

0.6.2.On the bodywork: …U.K.

0.9.Name and address of the manufacturer’s representative (if any): …U.K.

1.GENERAL CONSTRUCTION CHARACTERISTICS OF THE VEHICLEU.K.

1.1.Photographs and/or drawings of a representative vehicle: …U.K.

1.2.Dimensional drawing of the whole vehicle: …U.K.

1.3.Number of axles and wheels: …U.K.

1.3.1.Number and position of axles with twin wheels: …U.K.

1.3.2.Number and position of steered axles: …U.K.

1.3.3.Powered axles (number, position, interconnection): …U.K.

1.8.Hand of drive: left/right(3).U.K.

2.MASSES AND DIMENSIONS(4) (5) U.K.

(in kg and mm) (Refer to drawing where applicable)

2.1.Wheelbase(s) (fully loaded)(6) U.K.

2.1.1.Two axle vehicles: …U.K.

2.1.1.1.Vehicles with three or more axlesU.K.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3.Axle track(s) and width(s)U.K.

2.3.1.Track of each steered axle(7): …U.K.

2.3.2.Track of all other axles(7): …U.K.

2.3.3.Width of the widest rear axle: …U.K.

2.3.4.Width of the foremost axle (measured at the outermost part of the tyres excluding the bulging of the tyres close to the ground): …U.K.

2.4.Range of vehicle dimensions (overall)U.K.

2.4.1.For chassis without bodyworkU.K.

2.4.1.1.Length(8): …U.K.

2.4.1.1.1.Maximum permissible length: …U.K.

2.4.1.1.2.Minimum permissible length: …U.K.

2.4.1.2.Width(9): …U.K.

2.4.1.2.1.Maximum permissible width: …U.K.

2.4.1.2.2.Minimum permissible width: …U.K.

2.4.2.For chassis with bodyworkU.K.

2.4.2.1.Length(8): …U.K.

2.4.2.1.1.Length of the loading area: …U.K.

2.4.2.2.Width(9): …U.K.

2.4.3.For bodywork approved without chassis (vehicles M2 and M3)U.K.

2.4.3.1.Length(8): …U.K.

2.4.3.2.Width(9): …U.K.

2.6.Mass in running orderU.K.

Mass of the vehicle with bodywork and, in the case of a towing vehicle of category other than M1, with coupling device, if fitted by the manufacturer, in running order, or mass of the chassis or chassis with cab, without bodywork and/or coupling device if the manufacturer does not fit the bodywork and/or coupling device (including liquids, tools, spare wheel, if fitted, and driver and, for buses and coaches, a crew member if there is a crew seat in the vehicle)(10) (maximum and minimum for each variant): …

4.7.Maximum vehicle design speed (in km/h)(11): …U.K.

13.SPECIAL PROVISIONS FOR BUSES AND COACHESU.K.

13.1.Class of vehicle: Class III/Class B(3) U.K.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Explanatory notes U.K.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PART 2U.K.

MODEL U.K.(maximum format: A4 (210 × 297 mm))U.K. EC TYPE-APPROVAL CERTIFICATE U.K.

Stamp of type-approval authority

Communication concerning:

EC type-approval(12)

Extension of EC type-approval(12)

Refusal of EC type-approval(12)

Withdrawal of EC type-approval(12)

of a type of vehicle with regard to lane departure warning systems

with regard to Commission Regulation (EU) No 351/2012 as amended.

EC type-approval Number: _

Reason for extension:

SECTION I U.K.

0.1.Make (trade name of manufacturer):U.K.

0.2.Type:U.K.

0.2.1.Commercial name(s) (if available):U.K.

0.3.Means of identification of type if marked on the vehicle(13):U.K.

0.3.1.Location of that marking:U.K.

0.4.Category of vehicle(14):U.K.

0.5.Name and address of manufacturer:U.K.

0.8.Names and address(es) of assembly plant(s):U.K.

0.9.Representative of the manufacturer:U.K.

SECTION II U.K.

1.Additional information (where applicable): see AddendumU.K.

2.Technical service responsible for carrying out the tests:U.K.

3.Date of test report:U.K.

4.Number of test report:U.K.

5.Remarks (if any): see AddendumU.K.

6.Place:U.K.

7.Date:U.K.

8.Signature:U.K.

:

Information package.

Test report.

Addendumto EC type-approval certificate No …

1.Additional informationU.K.

1.1.Brief description of lane departure warning system fitted to the vehicle:U.K.

4.Annex II test resultsU.K.

4.1.Visible lane markings used for the testingU.K.

4.2.Documentation demonstrating compliance with all other lane markings identified in the Appendix to Annex II to Commission Regulation (EU) No 351/2012U.K.

4.3.Description of the variants of the lane departure warning system with regional specific adjustments that fulfil the requirementsU.K.

4.4.Mass and condition of load of the vehicle when testedU.K.

4.5.Warning threshold setting (only in case where the lane departure warning system is equipped with a user-adjustable warning threshold)U.K.

4.6.Result of optical warning signal verification testU.K.

4.7.Results of the lane departure warning testU.K.

4.8.Results of the failure detection testU.K.

4.9.Results of the deactivation test (only if the vehicle is equipped with means to deactivate the lane departure warning system)U.K.

5.Remarks (if any):U.K.

ANNEX IIU.K. Requirements and tests for the type-approval of motor vehicles with regard to lane departure warnings systems

1. Requirements U.K.

1.1. General requirements U.K.

1.1.1.The effectiveness of the lane departure warning system (LDWS) shall not be adversely affected by magnetic or electrical fields. This shall be demonstrated by compliance with UNECE Regulation No 10(15).U.K.

1.2. Performance requirements U.K.

1.2.1.Whenever the system is active, as specified in point 1.2.3., the LDWS shall warn the driver if the vehicle crosses over a visible lane marking for the lane in which it is running, on a road with a directional form that varies between straight and a curve having an inner lane marking with a minimum radius of 250 m, when there has been no purposeful demand to do so.U.K.

Specifically:

it shall provide the driver with the warning specified in point 1.4.1., when tested in accordance with the provisions of point 2.5. (departure warning test) and with lane markings as specified in point 2.2.3.;

the warning mentioned in point 1.2.1. may be suppressed when there is a driver action which indicates an intention to depart from the lane.

1.2.2.The system shall also provide the driver with the warning specified in point 1.4.2., when tested in accordance with the provisions of point 2.6. (failure detection test). The signal shall be constant.U.K.

1.2.3.The LDWS shall be active at least at vehicle speeds above 60 km/h, unless manually deactivated in accordance with point 1.3.U.K.

1.3.If a vehicle is equipped with a means to deactivate the LDWS function, the following conditions shall apply as appropriate:U.K.

The LDWS function shall be automatically reinstated at the initiation of each new ignition ‘on’ (run) cycle.

A constant optical warning signal shall inform the driver that the LDWS function has been deactivated. The yellow warning signal specified in point 1.4.2. may be used for this purpose.

1.4. Warning indication U.K.

1.4.1.The warning referred to in point 1.2.1. shall be noticeable by the driver and be provided by either of the following:U.K.

at least two warning means, to be chosen between optical, acoustic and haptic;

one warning means, to be chosen between haptic and acoustic, with spatial indication about the direction of unintended drift of the vehicle.

1.4.1.1.Where an optical signal is used for the lane departure warning, it may use the failure warning signal as specified in point 1.2.2. in a flashing mode.U.K.

1.4.2.The failure warning referred to in point 1.2.2. shall be a yellow optical warning signal.U.K.

1.4.3.The LDWS optical warning signals shall be activated either when the ignition (start) switch is turned to the ‘on’ (run) position or when the ignition (start) switch is in a position between the ‘on’ (run) and ‘start’ that is designated by the manufacturer as a check position (initial system (power-on)). This requirement does not apply to warning signals shown in a common space.U.K.

1.4.4.The optical warning signals shall be visible even by daylight; the satisfactory condition of the signals must be easily verifiable by the driver from the driver’s seat.U.K.

1.4.5.When the driver is provided with an optical warning signal to indicate that the LDWS is temporarily not available, for example due to inclement weather conditions, the signal shall be constant. The failure warning signal specified in point 1.4.2. may be used for this purpose.U.K.

1.5. Provisions for the periodic technical inspection U.K.

1.5.1.At a periodic technical inspection it shall be possible to confirm the correct operational status of the LDWS by a visible observation of the failure warning signal status, following a ‘power-ON’ (off – system OK, on – system fault present).U.K.

In the case of the failure warning signal being in a common space, the common space must be observed to be functional prior to the failure warning signal status check.

1.5.2.At the time of type-approval, the means to protect against simple unauthorised modification of the operation of the failure warning signal chosen by the manufacturer shall be confidentially outlined.U.K.

Alternatively, this protection requirement is fulfilled when a secondary means of checking the correct operational status of the LDWS is available.

2. Test procedures U.K.

2.1.The manufacturer shall provide a brief documentation package which gives access to the basic design of the system and, if applicable, the means by which it is linked to other vehicle systems. The function of the system shall be explained and the documentation shall describe how the operational status of the system is checked, whether there is an influence on other vehicle systems, and the method(s) used in establishing the situations which will result in a failure warning signal being displayed.U.K.

2.2. Test conditions U.K.

2.2.1.The test shall be performed on a flat, dry asphalt or concrete surface.U.K.

2.2.2.The ambient temperature shall be between 0 °C and 45 °C.U.K.

2.2.3. Visible lane markings U.K.

2.2.3.1.The visible lane markings used in the lane departure warning tests of point 2.6. shall be one of those identified in the Appendix to this Annex, with the markings being in good condition and of a material conforming to the standard for visible lane markings applied in the Member State concerned. The visible lane marking layout used for the testing shall be recorded.U.K.

2.2.3.2.The vehicle manufacturer shall demonstrate, through the use of documentation, compliance with all the other lane markings identified in the Appendix to this Annex. Any such documentation shall be appended to the test report.U.K.

2.2.3.3.Where the vehicle type can be equipped with different variants of the LDWS with regional specific adjustments, the manufacturer shall demonstrate through documentation that the requirements of this Regulation are fulfilled in all variants.U.K.

2.2.4.The test shall be performed under visibility conditions that allow safe driving at the required test speed.U.K.

2.3. Vehicle conditions U.K.

2.3.1. Test weight U.K.

The vehicle may be tested at any condition of load, the distribution of the mass among the axles being that stated by the vehicle manufacturer without exceeding any of the maximum permissible mass for each axle. No alteration shall be made once the test procedure has begun. The vehicle manufacturer shall demonstrate through the use of documentation that the system works at all conditions of load.

2.3.2.The vehicle shall be tested at the tyre pressures recommended by the vehicle manufacturer.U.K.

2.3.3.Where the LDWS is equipped with a user-adjustable warning threshold, the test as specified in point 2.5. shall be performed with the warning threshold set at its maximum lane departure setting. No alteration shall be made once the test procedure has begun.U.K.

2.4. Optical warning signal verification test U.K.

With the vehicle stationary check that the optical warning signal(s) comply with the requirements of point 1.4.3.

2.5. Lane departure warning test U.K.

2.5.1.Drive the vehicle at a speed of 65 km/h +/- 3 km/h into the centre of the test lane in a smooth manner so that the attitude of the vehicle is stable.U.K.

Maintaining the prescribed speed, gently drift the vehicle, either to the left or the right, at a rate of departure of between 0,1 and 0,8 m/s so that the vehicle crosses the lane marking. Repeat the test at a different rate of departure within the range 0,1 and 0,8 m/s.

Repeat the above tests drifting in the opposite direction.

2.5.2.The LDWS shall provide the lane departure warning indication mentioned in point 1.4.1. at the latest when the outside of the tyre of the vehicle’s front wheel closest to the lane markings crosses a line 0,3 m beyond the outside edge of the visible lane marking to which the vehicle is being drifted.U.K.

2.6. Failure detection test U.K.

2.6.1.Simulate a LDWS failure, for example by disconnecting the power source to any LDWS component or disconnecting any electrical connection between LDWS components. The electrical connections for the failure warning signal of point 1.4.2. and the LDWS disable control of point 1.3. shall not be disconnected when simulating a LDWS failure.U.K.

2.6.2.The failure warning signal mentioned in point 1.4.2. shall be activated and remain activated while the vehicle is being driven and be reactivated after a subsequent ignition ‘off’ ignition ‘on’ cycle as long as the simulated failure exists.U.K.

2.7. Deactivation Test U.K.

2.7.1.If the vehicle is equipped with means to deactivate the LDWS, turn the ignition (start) switch to the ‘on’ (run) position and deactivate the LDWS. The warning signal mentioned in point 1.3.2. shall be activated. Turn the ignition (start) switch to the ‘off’ position. Again, turn the ignition (start) switch to the ‘on’ (run) position and verify that the previously activated warning signal is not reactivated, thereby indicating that the LDWS has been reinstated as specified in point 1.3.1. If the ignition system is activated by means of a ‘key’, the above requirement shall be fulfilled without removing the key.U.K.

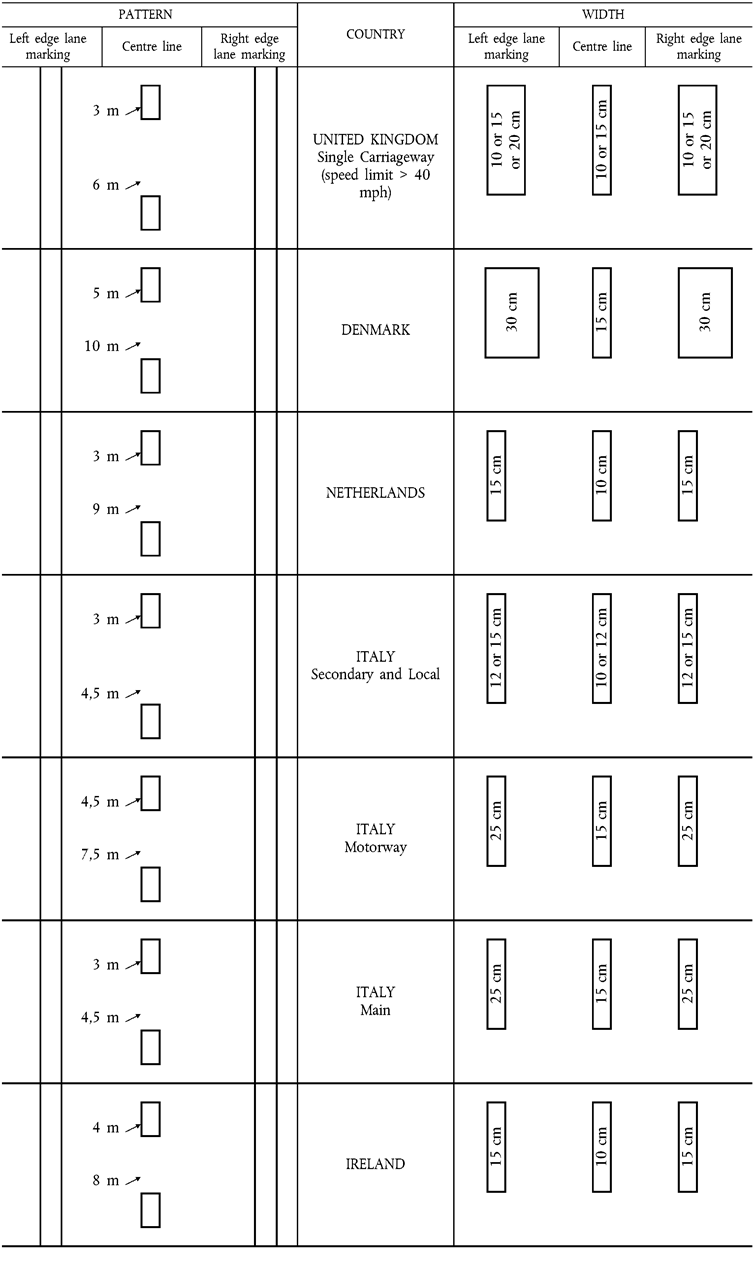

Appendix Visible lane marking identification

1.For the purpose of the test procedures referred to in points 2.2. and 2.5. of Annex II, the test lane width shall be greater than 3,5 m.U.K.

2.The visible lane markings identified in Table 1 are assumed to be white, unless otherwise indicated in this Appendix.U.K.

3.Table 1 shall be used for approval in accordance with points 2.2. and 2.5. of Annex II to this Regulation.U.K.

Table 1 Identified visible lane markings U.K.

If the means of identification of type contains characters not relevant to describe the vehicle, component or separate technical unit types covered by this information document, such characters shall be represented in the documentation by the symbol ‘?’ (e.g. ABC??123??).

Classified according to the definitions set out in Part A of Annex II to Directive 2007/46/EC.

Delete where not applicable (there are cases where nothing needs to be deleted when more than one entry is applicable).

Where there is one version with a normal cab and another with a sleeper cab, both sets of masses and dimensions are to be stated

Standard ISO 612: 1978 – Road vehicles – Dimensions of motor vehicles and towed vehicles – terms and definitions.

(g1)

The vehicle wheelbase shall be determined in accordance with:

item No 6.4.1. of Standard ISO 612:1978 for motor vehicle and drawbar trailer:

item No 6.4.2. of Standard ISO ISO 612:1978 for semi-trailer and centre-axle trailer

Note:U.K.

In the case of a centre-axle trailer, the axis of the coupling shall be considered as the foremost axle.

(g4)

The track of axles shall be determined in accordance with item No 6.5. of Standard ISO 612:1978

(g5)

vehicle length shall be determined in accordance with:

item No 6.1. of Standard ISO 612:1978 for vehicles of category M1:

point 2.4.1. of Annex I to Directive 97/27/EC of the European Parliament and of the Councila for vehicles other than those of category M1

In the case of trailers, the lengths shall be determined in accordance with item No 6.1.2. of Standard ISO 612:1978.

(g7)

The width of vehicles of category M1 shall be determined in accordance with item No 6.2. of Standard ISO 612:1978. For vehicles other than those of category M1 the width shall be determined in accordance with point 2.4.2. of Annex I to Directive 97/27/EC.

The mass of the driver and, if applicable, of the crew member is assessed at 75 kg (subdivided into 68 kg occupant mass and 7 kg luggage mass according to ISO Standard 2416 - 1992), the fuel tank is filled to 90 % and the other liquid containing systems (except those for used water) to 100 % of the capacity specified by the manufacturer.

With respect to trailers, maximum speed permitted by the manufacturer.

Delete where not applicable.

If the means of identification of type contains characters not relevant to describe the vehicle, component or separate technical unit types covered by this information, such characters shall be represented in the documentation by the symbol ‘?’ (e.g. ABC??123??).

As defined in Section A of Annex II to Directive 2007/46/EC.