- Latest available (Revised)

- Point in Time (28/07/2006)

- Original (As adopted by EU)

Commission Decision of 28 July 2006 concerning the technical specification of interoperability relating to the subsystem ‘rolling stock — freight wagons’ of the trans-European conventional rail system (notified under document number C(2006) 3345) (Text with EEA relevance) (2006/861/EC) (repealed)

You are here:

- Show Geographical Extent(e.g. England, Wales, Scotland and Northern Ireland)

- Show Timeline of Changes

More Resources

Revised version PDFs

- Revised 01/01/20140.46 MB

- Revised 24/01/201332.14 MB

- Revised 01/07/20095.26 MB

When the UK left the EU, legislation.gov.uk published EU legislation that had been published by the EU up to IP completion day (31 December 2020 11.00 p.m.). On legislation.gov.uk, these items of legislation are kept up-to-date with any amendments made by the UK since then.

This item of legislation originated from the EU

Legislation.gov.uk publishes the UK version. EUR-Lex publishes the EU version. The EU Exit Web Archive holds a snapshot of EUR-Lex’s version from IP completion day (31 December 2020 11.00 p.m.).

Changes over time for: Division 7.

Version Superseded: 01/07/2009

Status:

Point in time view as at 28/07/2006.

Changes to legislation:

There are currently no known outstanding effects for the Commission Decision of 28 July 2006 concerning the technical specification of interoperability relating to the subsystem ‘rolling stock — freight wagons’ of the trans-European conventional rail system (notified under document number C(2006) 3345) (Text with EEA relevance) (2006/861/EC) (repealed), Division 7..![]()

Changes to Legislation

Revised legislation carried on this site may not be fully up to date. At the current time any known changes or effects made by subsequent legislation have been applied to the text of the legislation you are viewing by the editorial team. Please see ‘Frequently Asked Questions’ for details regarding the timescales for which new effects are identified and recorded on this site.

7.IMPLEMENTATIONU.K.

7.1.GENERALU.K.

The implementation of the TSIs must take into consideration the overall migration of the conventional rail network towards full interoperability.

In order to support this migration, the TSIs allow for staged, gradual application and co-ordinated implementation with other TSIs.

In the case of this TSI it shall be implemented in close co-ordination with the Noise TSI.

7.2.TSI REVISIONU.K.

In conformity with article 6(3) of Directive 2001/16/EC as modified by Directive 2004/50/EC, the Agency shall be responsible for preparing the review and updating of TSIs and making appropriate recommendations to the Committee referred to in Article 21 of this directive in order to take account of developments in technology or social requirements. In addition, the progressive adoption and revision of other TSIs may also impact this TSI. Proposed changes to this TSI shall be subject to rigorous review and updated TSIs will be published on an indicative periodic basis of 3 years.

The Agency shall be notified of any innovative solutions under consideration in order to determine its future inclusion within the TSI.

7.3.APPLICATION OF THIS TSI TO NEW ROLLING STOCKU.K.

Sections 2 to 6 and any specific provisions in paragraph 7.7 below apply in full to new freight wagons being placed into service, with the following exceptions:

the provisions of section 4.2.4.1.2.2 (Braking Performance elements) deceleration profile in braking power, for which a date of implementation will be given in future revisions of the TSI.

This TSI does not apply to wagons being subject to a contract already signed or under final phase of tendering procedure before the date of entry into force of this TSI.

7.4.EXISTING ROLLING STOCKU.K.

7.4.1.APPLICATION OF THIS TSI TO EXISTING ROLLING STOCKU.K.

Existing freight wagons are freight wagons that are already in service before this TSI enters into force.

The TSI does not apply to existing rolling stock as long as it is not renewed or upgraded.

7.4.2.UPGRADING AND RENEWAL OF EXISTING FREIGHT WAGONSU.K.

Upgraded or renewed freight wagons requiring new authorisation for placing into service within the meaning of Directive 2001/16/EC Article 14.3, shall comply with:

sections 4.2, 5.3, 6.1.1 and 6.2 and any specific provisions in paragraph 7.7 below, as soon as this TSI comes into force and

The following exceptions shall apply:

4.2.3.3.2 Hot axle box detection (To be specified at the next revision of this TSI);

4.2.4.1.2.2 Deceleration profile in braking power;

4.2.6 Environmental conditions;

4.2.6.2 Aerodynamic effects (T be specified at the next revision of this TSI);

4.2.6.3 Cross winds (To be specified at the next revision of this TSI);

4.2.8 Maintenance file.

For these exceptions, national rules apply.

With regards to wagons operating under the agreements specified in 7.5 below, the conditions to be applied when renewing or upgrading these wagons are those mentioned in the relevant agreements, if any. In the absence of such conditions, this TSI is applicable.

7.4.3.ADDITIONAL REQUIREMENTS FOR WAGON MARKINGU.K.

In addition to the general case above for upgraded or renewed freight wagons, all existing interoperable freight wagons are required to comply with the requirements of this TSI with respect to the design of wagon markings from the date of the next overall repainting of the wagon without the intervention of a notified body. A Member State is permitted to define an earlier date of compliance.

7.5.WAGONS OPERATING UNDER NATIONAL, BILATERAL, MULTILATERAL OR INTERNATIONAL AGREEMENTSU.K.

7.5.1.EXISTING AGREEMENTSU.K.

Member States shall notify the Commission, within 6 months after the entry into force of this TSI, of the following agreements under which freight wagons related to the scope of this TSI (construction, renewal, upgrading, placing in service, operation and management of wagons as defined in chapter 2 of this TSI) are operated:

National, bilateral or multilateral agreements between Member States and Railway Undertakings or Infrastructure Managers, agreed on either a permanent or temporary basis, and required due to the very specific or local nature of the intended transport service;

bilateral or multilateral agreements between Railway Undertakings, Infrastructure Managers or between Safety Authorities, which deliver significant levels of local or regional interoperability;

international agreements between one or more Member States and at least one third country, or between Railway Undertakings or Infrastructure Managers of Member States and at least one Railway Undertaking or Infrastructure Manager of a third country, which deliver significant levels of local or regional interoperability.

Continued operation/maintenance of wagons covered by these agreements shall be permitted as far as they do comply with Community legislation.

The compatibility of these agreements with EU legislation including their non-discriminatory character and, in particular, this TSI, will be assessed and the Commission will take the necessary measures such as, for example, the revision of this TSI to include possible specific cases or transitional measures.

The RIV Agreement and COTIF instruments shall not be notified.

7.5.2.FUTURE AGREEMENTSU.K.

Any future agreement or modification of existing agreements shall take into account EU legislation and, in particular, this TSI. Member States shall notify the Commission with such agreements/modifications. The same procedure of § 7.5.1 then applies.

7.6.PLACING IN SERVICE OF WAGONSU.K.

In accordance with Article 16(1) of Directive 2001/16/EC, where compliance with the TSIs has been achieved and an EC Declaration of Verification is granted within one Member State for freight wagons, this shall be mutually recognised by all Member States.

When seeking safety certification under article 10 of directive 2004/49 (Part B of the certificate) or authorisation of placing in service under article 14(1) of directive 2001/16, Railway Undertakings may seek certification/authorisation of placing in service for grouped wagons. Wagons may be grouped according to series or type.

Once safety certification or authorisation of placing in service is granted for grouped wagons in one Member State, this shall be mutually recognised by all Member States in order to avoid duplication of safety/interoperability checks by Safety Authorities.

As far as this TSI contains Open Points, authorisation for putting into service will be mutually accepted, except as indicated in Annex JJ.

However, it must be verified that the wagons are operated on compatible infrastructures; this may be done through the use of Infrastructure and Rolling Stock registers.

7.7.SPECIFIC CASESU.K.

7.7.1.INTRODUCTIONU.K.

The following special provisions are permitted in the specific cases below.

These specific cases belong to two categories: the provisions apply either permanently (case “P”), or temporarily (case “T”). In temporary cases, it is recommended that the Member States concerned should conform with the relevant subsystem either by 2010 (case “T1”), an objective set out in Decision No 1692/96/EC of the European Parliament and of the Council of 23 July 1996 on Community guidelines for the development of the trans-European transport network, or by 2020 (case “T2”).

7.7.2.LIST OF SPECIFIC CASESU.K.

General specific case on the network of 1 524 mm

Member State: Finland

Case “P”:

In the territory of Finland and at Swedish cross-border station Haparanda (1 524 mm), the bogies, wheelsets and other track gauge interfaces related interoperability constituents or/and subsystems built for track gauge 1 524 mm network are only accepted, if they comply with the following mentioned Finnish specific cases for track gauge interfaces. Without prejudice to the above-mentioned restriction (1 524 mm gauge) all the interoperability constituents and/or subsystems complying with the TSI requirements for 1 435 mm track gauge are accepted at Finnish cross-border station Tornio (1 435 mm) and at train-ferry harbours on the tracks for 1 435 mm.

7.7.2.1. Structures and mechanical parts: U.K.

7.7.2.1.1.Interface (e. g. Coupling) between vehicles, between set of vehicles and between trainsU.K.

7.7.2.1.1.1.Track gauge 1 524 mmU.K.

Member State: Finland

Case “P”

For vehicles, which are intended for traffic in Finland, the distance between buffer centrelines is permitted to be 1 830 mm. Alternatively, it is permitted that these wagons be equipped with SA-3 couplers, or SA-3 compatible couplers, with or without side buffers.

For vehicles which are intended for traffic in Finland it is required that where the distance between the buffer centrelines is 1 790 mm, the width of the buffer plates shall be increased by 40 mm towards the outside.

7.7.2.1.1.2.Track gauge 1 520 mmU.K.

Member State: Poland, Slovakia, Lithuania, Latvia, Estonia, Hungary

Case “P”

All wagons intended to operate occasionally on 1 520 mm track gauge in Poland and Slovakia on selected 1 520 mm lines, Lithuania, Latvia and Estonia shall meet the following requirements:

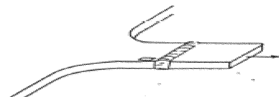

Each wagon compliant with this TSI for track gauge 1 520 mm and 1 435 mm shall be equipped both with automatic coupler and screw coupling according to one of the following solutions:

the kind of coupler can be changed at the border between the 1 435 mm and 1 520 mm networks

or

the wagon can be equipped with buffers and automatic coupler type SA3 and intermediate coupler

or

the wagon can be equipped with hidden buffers and automatic coupler; buffers in advanced position shall allow operating a wagon with screw coupling or intermediate coupler.

Buffers and couplers — version CU.K.

Coupler Version D

Buffer and Coupler Version D

Tank wagons for dangerous goods shall be equipped with couplers shock absorber complying with following parameters:

dynamic absorption minimum 130 kJ

terminal force under quasi-static loading minimum 1 000 kN.

7.7.2.1.1.3.Track gauge 1 520 mm / 1 524 mmU.K.

Member State: Lithuania, Latvia, Estonia, Finland and Poland

Case “P”

With regards to wagons operating, or intended to operate, in bilateral traffic permanently on 1 520 mm / 1 524 mm lines between Member States and third countries, sections 4 and 5 of this TSI are not applicable.

7.7.2.1.1.4.Track gauge 1 520 mmU.K.

Member State: Lithuania, Latvia, and Estonia

Case “T”

For wagons operating permanently on 1 520 mm lines between Member States, sections 4 and 5 of this TSI are not applicable until the next revision of this TSI. The next revision shall take into consideration the specific cases as identified from the process given in 7.5.1 of this TSI.

7.7.2.1.1.5.Track gauge 1 668 mm — Distance between buffers centrelinesU.K.

Member State: Spain and Portugal

Case “P”

For vehicles, which are intended for traffic to Spain or Portugal, it is permissible for the distance between buffer centrelines to be 1 850 mm (± 10 mm). In this case the compatibility with buffers in a standard arrangement shall be demonstrated.

Buffer plates dimensions for two-axle wagons and bogie wagons:

Unified width of buffer plates for wagons which are intended for traffic to Spain or Portugal (distance between centrelines 1 850 mm) shall be 550 mm or 650 mm depending of characteristics of wagons included in applicable national regulations.

7.7.2.1.1.6.Interface between vehiclesU.K.

Member State: Republic of Ireland and Northern Ireland

Case “P”

For Ireland, the buffer centres are 1 905 mm apart, and the buffer and draw gear centre heights above the rail must be between 1 067 mm min. and 1 092 mm max with no load on the wagon. To facilitate coupling and uncoupling during shunting, “instantor” link couplings may be permitted on freight wagons (see Annex HH).

7.7.2.1.1.7.General specific case on the network of 1 000 mm or lessU.K.

Member state: Greece

Case “T1”:

For the existing isolated 1 000 mm gauge, which is not in the scope of this TSI, national rules shall apply.

7.7.2.1.2.Safe access and egress for rolling stockU.K.

7.7.2.1.2.1.Safe access and egress for rolling stock Republic of Ireland and Northern IrelandU.K.

Member State: Republic of Ireland and Northern Ireland

Case “P”

For Ireland, the requirement will be that “steps and handrails where provided will be for access and egress only, and not to permit the shunter to ride on the outside of the vehicle.”

Annex EE is not applicable in the Republic of Ireland and Northern Ireland.

7.7.2.1.3.Strength of main vehicle structure and securing of freightU.K.

7.7.2.1.3.1.1 520 mm gauge linesU.K.

Member State: Poland, Slovakia, Lithuania, Latvia, Estonia, Hungary

Case “P”

All wagons intended to operate permanently or occasionally on 1 520 mm track gauge shall meet the following requirements:

Design loads

Longitudinal design loads

| Category | Minimal values [kN] |

|---|---|

| Compressive force at automatic coupler level | 3 000 |

| Tractive force at automatic coupler level | 2 500 |

| Compressive force at axis at each buffer | 1 000 |

| Compressive force applied eccentric (50 mm) from axis at each buffer | 750 |

| Compressive force applied diagonally via side buffers (if fitted) | 400 |

Vehicles meeting these requirements can be shunted without restriction.

Maximum Vertical Load

Load of a wagon in boundary design condition at 150 % of maximum load shall not cause plastic strain.

Deflection of a wagon frame related to standstill shall be not more than 3 ‰ of king-pin base.

Load combinations

The structure shall conform to load combinations from the most inconvenient case of vertical load combined with compressive force 3 000 kN at automatic coupler and forces applied to axis at each buffer.

Vertical, dynamical surplus resulting from reaction inertial force of load on body of a wagon and its horizontal components reacting transversely to track shall be considered by calculation.

For tank wagons internal pressure, partial vacuum and pressure from hydraulic shock shall be considered in addition.

Load during lifting

Wagon shall be resistant to forces during lifting without plastic strain. Additional points of support under norms to 1 520 mm vehicles should be regarded.

Requirements for dynamic forces applied at automatic coupler

General

A loaded and unloaded freight wagon shall be resistant to the impact of a ram wagon. This shall be demonstrated by a test on a straight track. The weight of the ram wagon shall be equal to at least the weight of the tested wagon. For tests of two-axle wagons a ram wagon of 100 ±3 t is recommended.

A ram wagon shall be equipped with automatic coupler type SA3 and a coupler shock absorber. The difference between the axes of automatic couplers shall not exceed 50 mm.

The test shall apply with the following specifications:

single test wagon not braked;

contra-ram formed by 3 or 4 wagons formed as a group at least 300 t mass.

The applied force in loaded state shall be 3 000 kN ±10 %.

The contra ram group of wagons shall be protected against rolling by hand-brake or braking skids.

Impact in unloaded state

The speed of the ram wagon shall be 12 km/h. The tested wagon shall be unbraked.

Loads shall not cause any plastic deflection. Tensions in selected critical points such as connection bogie/frame, frame/wagon body and superstructure shall be recorded.

Impact in loaded state

The tested wagon shall be loaded with the maximum load.

The maximum speed of the ram wagon shall be 12 km/h. Impact tests shall start gradually from 2 to 3 km/h.

The test shall be performed for the following ranges:

up to 5 km/h,

5 to 10 km/h,

above 10 km/h.

At least 5 impacts shall be carried out for each speed range. Additionally, 3 impact tests shall be carried out with the impact of a compressive force equals 3 000 kN. This impact force shall be supported by calculation.

During the tests the permissible impact compressive force shall not exceed the limit of more than 10 %. If a boundary value of 3 000 kN ±10 % is reached just below 12 km/h the speed shall not be increased.

Additionally in order to simulate long-term sustainability 40 impact test shall be carried out either at 12 km/h or with an impact compressive force of 3 000 kN.

Loads shall not cause any plastic deflection.

Dynamic strength condition during operation of wagons

Wagons shall be resistant to longitudinal compressive and tractive forces of 1 000 kN at 120 km/h.

7.7.2.1.3.2.1 668 mm gauge lines — Lifting and jackingU.K.

Member State: Spain and Portugal

Case “P”

For two-axle wagons:

Provision shall be made to limit the drop of the spring when the wagon is lifted.

An example of solution is shown in Annex X Plate 3.

For lifting by jacks (limited to the “connections” at the maximum), each wagon shall be fitted with four base plates, two under each underframe sole-bar, placed symmetrically in relation to the transverse axis of the wagon.

This arrangement may also be appropriate for new axle changeover pit facility (including for multiple or articulated wagons with no limitation on number of units).

Base plates shall have the following dimensions:

In the longitudinal direction of the wagon: 150 mm at the maximum.

In the transverse direction of the wagon: 100 mm.

Thickness: 15 mm.

They shall be cross-grooved, with the slots parallel and perpendicular to the longitudinal axis of the wagons:

Groove depth: 5 to 7 mm approximately.

Groove width: 4 to 6 mm approximately.

The wagon infrastructure shall provide for clearance of the wheelsets when the base plates, when in the raised position (with normal lifting jack movement of 800 mm), reach a maximum height of 1 550 mm in relation to rail level.

Annex X Plate 6 shows the clearances to be provided on wagons for engaging the lifting-jack heads.

For bogie wagons:

Bogies with interchangeable axles shall be fitted with a device to limit the descent of the springs on lifting the wagons with their bogies.

It is recommended that the device shown in Annex X Plate 10 be adopted.

The maximum wagon length over buffers may not exceed 24,486 m. The underframe structure shall be capable of bearing the weight of the bogie frames during of lifting in the conditions defined in the next paragraph.

The positioning of lifting jacks on work sites shall comply with the diagram shown in Annex X Plate 13.

The arrangements adopted are appropriate for handling all wagons with an overall length not exceeding 24,48 m.

The wagon lifting operations shall be effected by simultaneous raising of the underframe and bogie frames. The wagons shall be provided with cables to secure the bogie frames to the body during these operations. Annex X Plate 14 shows the devices fitted to the bogies at 4 points and to the wagon underframe at 8 points, to enable such securing to be carried out at the time of lifting and the cables to be placed in the idle position when not in use.

Wagon underframes shall be fitted with base plates to the following dimensions:

Length in longitudinal direction of wagon: 250 mm minimum.

Width in transverse direction of wagon: 100 mm.

Thickness: 15 mm.

The contact surface of base plates shall be grooved in accordance with indications given in paragraph relating to 2-axle wagons.

The position of the base-plates on the wagon underframes and the clearances to be provided for engaging the lifting jacks noses are represented in Annex X Plate 15. This position is appropriate for new axle-changeover pit installing (also for multiple or articulated wagons with no limitation on the number of units).

The wagon infrastructure shall provide for clearance of the wheelsets when the base-plates, in the raised position (with normal lifting jack movement of 900 mm), reach a maximum height of 1 650 m in relation to rail level.

7.7.2.2.Vehicle track interaction and gaugingU.K.

7.7.2.2.1.Kinematic gaugeU.K.

7.7.2.2.1.1.Kinematic gauge Great BritainU.K.

Member State: Great Britain

Case “P”

For wagons intended to run on the British network, see Annex T.

7.7.2.2.1.2.1 520 mm and 1 435 mm track gauge wagonsU.K.

Member State: Poland, Slovakia, Lithuania, Latvia and Estonia

Case “P”

For wagons intended to run on 1 520 mm and 1 435 mm track gauge, see Annex U.

7.7.2.2.1.3.Kinematic gauge FinlandU.K.

Member State: Finland

Case “P”

For wagons which are intended only for traffic in Finland and at the Swedish cross-border station Haparanda (1 524 mm), the vehicle gauge shall not exceed the gauge FIN 1 as defined in Annex W.

7.7.2.2.1.4.Kinematic gauge Spain and PortugalU.K.

Member State: Spain and Portugal

Case “P”

Passing over vertical transition curves (including marshalling yard humps) and over braking, shunting or stopping devices.

It shall be possible for bogies to negotiate an angle of elevation for access to ferry-boats, whose maximum link-span angle with the horizontal is 2o 30' on 120 m curves.

Passing over curves.

It shall be possible for the wagons to run through curve of 60 m radius for flat wagons and 75 m for other types on standard-gauge track and through curves of 120 m on broad-gauge track.

7.7.2.2.1.5.Kinematic gauge IrelandU.K.

Member State: Republic of Ireland and Northern Ireland

Case “P”

Dynamic wagon loading gauge:

Freight wagons operating between Ireland and Northern Ireland shall conform to the Iarnród Éireann wagons dynamic loading gauge and the Northern Ireland (GNR) wagons dynamic loading gauge shown on the composite gauge drawing no. 07000/121 Annex HH. Static wagon gauge dimensions indicated on this drawing must also be respected.

Wagon construction:

The maximum construction gauge of the wagons shall be determined in accordance with the national rules.

7.7.2.2.2.Static axle load, dynamic wheel load and linear loadU.K.

7.7.2.2.2.1.Static axle load, dynamic wheel load and linear load FinlandU.K.

Member State: Finland

Case “P”

For vehicles intended for traffic in Finland, the admissible axle load shall be 22,5 tonnes at the maximum speed of 120 km/h and 25 tonnes at the maximum speed of 100 km/h, when the wheel diameter is between 920 to 840 mm.

7.7.2.2.2.2.Static axle load, dynamic wheel load and linear load Great BritainU.K.

Member State: Great Britain

Case “P”

The classification of lines and line sections in Great Britain is carried out according to the Notified National Standard (Railway Group Standard GE/RT8006 “Interface between Rail Vehicle Weights and Underline Bridges”). Vehicles intended to operate in Great Britain shall obtain classification according to this standard.

The classification for the wagon is determined according to the geometrical position and the loads on each axle.

7.7.2.2.2.3.Static axle load, dynamic wheel load and linear load Lithuania, Latvia, EstoniaU.K.

Member State: Lithuania, Latvia, Estonia

Case “P”

For the vehicle gauge national rules shall be applied.

7.7.2.2.2.4.Static axle load, dynamic wheel load and linear load Republic of Ireland and Northern IrelandU.K.

Member State: Republic of Ireland and Northern Ireland

Case “P”

The static axle load limit for wagons is 15,75 tonnes for the Irish network, but the operation of bogie wagons with 18,8 tonne axle loading is permitted on certain routes.

7.7.2.2.3.Rolling stock parameters which influence ground based train monitoring systemsU.K.

7.7.2.2.4.Vehicle dynamic behaviourU.K.

Category “P” — permanent

7.7.2.2.4.1.List of specific cases of wheel diameter related to various track gauges.U.K.

| a Burr value included | ||||

| Sizes above are indicated as a function of the height of the upper rail level and shall be met by empty or full wagons. | ||||

| The wheel sets of freight wagons running permanently on 1 520 mm gauge shall be measured in accordance with the wheel set measurement procedure specified for 1 520 mm freight wagons. | ||||

| Designation | Wheel diameter (mm) | Gauge (mm) | Minimum value (mm) | Maximum value (mm) |

|---|---|---|---|---|

| Distance between outside surfaces of the flange (SR) | ≥ 840 | 1 520 | 1 487 | 1 509 |

| 1 524 | 1 487 | 1 514 | ||

| 1 602 | ||||

| 1 668 | 1 643 | 1 659 | ||

| Distance between inner faces of the flange (AR) | ≥ 840 | 1 520 | 1 437 | 1 443 |

| 1 524 | 1 442 | 1 448 | ||

| 1 602 | ||||

| 1 668 | 1 590 | 1 596 | ||

| Width of the rim (BR) | ≥ 330 | 1 520 | 133 | 140a |

| Thickness of the flange (Sd) | ≥ 840 | 1 520 | 24 | 33 |

| < 840 and ≥ 330 | others | 27,5 | 33 | |

| Height of the flange (Sh) | ≥ 760 | 28 | 36 | |

| < 760 and ≥ 630 | 30 | 36 | ||

| < 630 and ≥ 330 | 32 | 36 | ||

| Face of flange (QR) | ≥ 330 | 6.5 | ||

7.7.2.2.4.2.Material for wheels:U.K.

According to the Nordic climatic conditions, a specific wheel material is generally used in Finland and in Norway. It is similar to ER8 but with a level of manganese and silicon increased to improved properties against shelling. For domestic traffic this material may be used if agreed between the parties.

7.7.2.2.4.3.Specific loads cases:U.K.

Additional forces shall be used if the parameters of the line generate higher forces.

(e.g.: small curves …)

7.7.2.2.4.4.Vehicle dynamic behaviour Spain and PortugalU.K.

Member State: Spain and Portugal

Case “P”

Width of the rim.

In the case of axle designed for 22,5 t loads, use may be made of those whose drawings are given in Annex X Plate 1 and which are derived for the ERRI standard axle design. Additional arrangements shall be made in some cases so as to comply with the gauge of the active surfaces of the wheel flanges of the axle included in the present TSI.

7.7.2.2.4.5.Vehicle dynamic behaviour Republic of Ireland and Northern IrelandU.K.

Member State: Republic of Ireland and Northern Ireland

Case “P”

Rolling stock should be designed to operate safely over a track twist of up to 17o/oo over a 2,7 m base, and up to 4o/oo over a 11,2 m base.

The maximum and minimum values for SR and AR are as follows:

| SR | All wheel diameters | 1 571 mm min. | 1 588 mm max. |

| AR | All wheel diameters | 1 523 mm min | 1 524 mm max. |

| BR | All wheel diameters | 127 mm min. | 135 mm max. |

| Sd | All wheel diameters | 24 mm min | 32 mm max. |

| Sh | All wheel diameters | 30,5 mm min. | 38 mm max. |

| QR | All wheel diameters | 6,5 |

7.7.2.2.5.Longitudinal compressive forcesU.K.

7.7.2.2.5.1.Longitudinal compressive forces Poland and Slovakia in selected 1 520 mm lines, Lithuania, Latvia and EstoniaU.K.

Member State: Poland and Slovakia in selected 1 520 mm lines, Lithuania, Latvia and Estonia

Case “P”

Requirements for 1 520 mm gauge wagons for wagons of gauge 1 435 mm to operate on 1 520 mm network.

Countries: Poland and Slovakia in selected 1 520 mm lines, Lithuania, Latvia, Estonia

Wagons equipped with automatic couplers shall be resistant to longitudinal compressive and tractive forces of 1 000 kN at 120 km/h.

7.7.2.2.6.Bogie and Running GearU.K.

7.7.2.2.6.1.Bogie and Running Gear Poland and Slovakia in selected 1 520 mm lines, Lithuania, Latvia, EstoniaU.K.

Member State: Poland and Slovakia in selected 1 520 mm lines, Lithuania, Latvia, Estonia

Case “P”

In Poland and Slovakia in selected 1 520 mm lines, Lithuania, Latvia, Estonia, the requirements for wagons with variable-gauge running gear of 1 435 mm/1 520 mm gauge required to operate on 1 520 mm network are the following.

General

For two-axle bogies permissible wheelset spacing shall be between 1 800 mm and 2 400 mm.

Running gear intended for use on European rail networks of 1 520 mm gauge shall be able to withstand an operating temperature range of - 40 oC to + 40 oC. For Asian 1 520 mm gauge networks, running gear shall be suitable for a temperature range of - 60 oC to + 45 oC and a relative humidity of 0-100 %.

Running gear frames

The running gear frame may be welded or cast. The steel used shall be weldable without pre-heating and shall have a minimum tensile strength of 370 N/mm2. The minimum values to be obtained for notched bar impact strength (V notch as specified for ISO test) are summarised in the following table:

| Notched bar impact strength [J] | ||

|---|---|---|

| -20 oC | -40 oC | -60 oC |

| 27 | 27 | 21 |

Proof required for running on 1 520 mm gauge system only.

7.7.2.2.6.2.Bogie and Running Gear Spain and PortugalU.K.

Member State: Spain and Portugal

Case “P”

Overall dimensions of bogie.

Bogies with interchangeable axles shall have a minimum wheelbase of 1,8 m and a distance between suspension planes of 2,17 m. The overall dimensions of the bogie are given in Annex X Plate 7. The overall dimensions thus defined apply to a bogie suitable for S braking conditions. The French and Spanish National Authorities shall be consulted over application of the SS braking conditions.

The height of the pivoting centre shall be 925 mm above rail level and the radius of the pivoting bearing shall be 190 mm as for the standard-gauge bogie. The pivot shall comply with the drawing in Annex X Plate 8.

Axle box for wagon bogies.

Axle boxes shall comply with the drawing shown in Annex X Plate 9.

Retractable safety device linking axle to bogie frame.

Axle boxes shall comprise a safety system enabling the axles to be secured to the bogie frame. Such a device, shown in Annex X Plate 11, shall be retractable during axle changeover operations.

Wheels.

For two-axle wagons:

The diameter of the running tread of new wheels shall be 1 000 mm maximum.

For bogie wagons:

The diameter of the running tread of new wheels shall be 920 mm.

Wheelsets.

The wheelsets shall bear a serial number, a type number and the owner's mark.

These indications, together with the date (month and year) of the last overhaul of the wheelsets, the code index of the owning or registering railway, and the index of the location which has carried out the overhaul, shall be shown on a floating collar on the axle shaft.

The code number of the owning or registering railway and the date (month and year) of the last overhaul shall be reproduced in white paint on the front of each axle box.

Axle box and guard plates.

The axle boxes, axle guards and spring buckles shall be designed to enable the indications shown in Plate 2 to be respected (the diameter of the hole in the upper side of the axle box shall allow for the use of a ring or stop for adjustment of the suspension, as shown in Annex X).

As the wheel of the broad-gauge axle are quite close to the wagon underframe, a stirrup with 14 or 10 mm axle-guard shall be used: see Plate 18.

It is recommended that use should be made of axle-guard stays that can be removed and assembled quickly. They shall be fixed by means of 2 M-20 × 55 bolts fitted with growed washers. On construction, the distance between hole centres shall be 483 +1/0 mm.

Overall surface area of wheelsets.

The underframes of vehicles shall have a completely unobstructed space, level with each wheel, as shown in Plate 4.

Axle design

The axles shall be capable of supporting the maximum load laid down for lines suitable for 20t axle-loads (lines in category C) or for 22,5t axle-loads (lines in category D). They shall be fitted with roller bearing axle boxes and be interchangeable with existing axles. The new axles shall be designed in accordance with the provisions laid down in the present TSI. The use of automatic variable-gauge wheelsets, which are able to run on both 1 435 mm and 1 668 mm lines, are allowed only with the agreement of Spanish and French competent Authorities for international transport through this latter Member State..

7.7.2.3.BrakingU.K.

7.7.2.3.1.Braking performanceU.K.

7.7.2.3.1.1.Braking performance Great BritainU.K.

Member State: Great Britain

Case “P”

Freight wagons intended for use on the British network see Annex V section V2

7.7.2.3.1.2.Braking performance Poland and Slovakia in selected 1 520 mm lines, Lithuania, Latvia, EstoniaU.K.

Member State: Poland and Slovakia in selected 1 520 mm lines, Lithuania, Latvia, Estonia

Case “P”

Distributors

Interoperability wagons for 1 435 mm to operate on 1 520 mm network shall be equipped with additional braking systems in accordance with the following:

Option 1: fit two distributors with a changeover device

for the 1 435 mm gauge: distributor according to Annex I

for the 1 520 mm gauge: type 483 distributor

Option 2: fit a standard distributor or an approved KE/483 distributor combination on the wagon that meets the technical braking requirements of both 1 435 mm and 1 520 mm gauge railways, with a changeover device allowing the system to switch to the respective operating regime.

Under option 1, the wagon's brake equipment must include “brake on/off” and “freight/passenger” changeover devices as well as an “empty/loaded” device it there is no automatic load-proportional braking facility According to Annex I and a “brake on/off” and “empty — partly loaded — loaded” device as per the standards for the 1 520 mm gauge and the “Technical Requirements for the Brake Equipment of Wagons built in RF Workshops”.

Each distributor must have its own release valve with a pull chord with handles on both sides of the wagon.

For braking option 2, a distributor should preferably be used in combination with an automatic load-proportional braking system. When the braking position is switched over manually in accordance with the load, there must be at least two graduated positions for the braking force.

Load-proportional braking, brake power and brake performance

The wagon's brakes must ensure that the prescribed values for the braked weight and the theoretical brake farce coefficients are guaranteed for operation on both 1 435 mm and 1 520 mm gauges at the respective maximum speeds.

For operation on the 1 435 mm gauge, wagons shall be fitted with either a hand-operated load-changeover device or an automatic load-proportional braking system meeting the requirements according to Annex I.

For operation on the 1 520 mm gauge, wagons shall be fitted with either an automatic load-proportional braking system or a hand-operated load-changeover device with at least two positions. Use of the automatic system and its configuration for the 1 520 mm track gauge shall give due consideration to the bogie design used and the type of transition from one gauge to the other.

Brake performance shall be calculated on the basis of the “Standard Braking Calculation for Freight and Refrigerator Wagons”. Here, the theoretical coefficient calculated for the wagon brake block force when the brake system is switched on to the 1 520 mm gauge shall satisfy the following values:

for K (composite) brake blocks: at least 0,14 up to a maximum of 0,31 for a fully-laden wagon and at least 0,22 up to a maximum of 0,37 for an empty wagon;

for GG (cast-iron) brake blocks: at least 0,36 up to a maximum of 0,7 for a fully-laden wagon and at least 0,62 up to a maximum of 0,81 for an empty wagon.

The different wagon braking forces specified in the standards for operation on 1 435 mm and 1 520 mm track gauges can be accommodated by an appropriate adjustment to the brake rigging or the brake cylinder.

Changeover device for switching from 1 435 to 1 520 mm track gauges

The changeover from one distributor system to another shall take place during the gauge changeover operation using the 1 435 mm/1 520 mm changeover device. Actuation of this device must require minimum effort and must jack reliably into its final position. The final position selected must correspond to one braking system only and must render the second braking system non-operational. When one braking system fails, the other must remain operational, assuming the wagon has two separate distributors.

The switch from one braking system to another may only be effected in the gauge changeover station either manually (by means of a special device) or automatically.

The braking system selected must be clearly indicated, even when the changeover takes place automatically.

Where the changeover takes place automatically, an automatic load-proportional braking system should preferably be used.

7.7.2.3.1.3.Braking performance FinlandU.K.

Member State: Finland

Case “P”

For vehicles for 1 524 mm gauge only, braking power shall be determined based on the minimum distance of 1 200 m between signals on the Finnish network. Minimum braked weight percentage is 55 % for 100 km/h and 85 % for 120 km/h.

The requirements for energy limits related to the slope with a mean declivity of 21 ‰ and a length of 46 km (slope of St Gothard's line) are not valid for vehicles for 1 524 mm gauge only.

In vehicles for 1 524 mm gauge only, the parking brake shall be designed such that fully loaded wagons shall be held on a gradient of 2,5 % with maximum adhesion of 0,15 with no wind. In wagons built for the transport of road vehicles the parking brake is operated from the ground.

7.7.2.3.1.4.Braking performance Spain and PortugalU.K.

Member State: Spain and Portugal

Case “P”

Brake-shoe arrangement.

For two-axle wagons:

Brake shoes shall be assembled in accordance with the requirements indicated in Plate 5. The assembly in Plate 12 for bogie wagons may also be used.

For bogie wagons:

Brake shoes shall be assembled in accordance with the provisions in Plate 12.

7.7.2.3.1.5.Braking performance Finland, Sweden, Norway, Estonia, Latvia and LithuaniaU.K.

Member State: Finland, Sweden, Norway, Estonia, Latvia and Lithuania

Case “T1”

Requirements of this TSI concerning the use of composite blocks approved based on the existing UIC specifications and test methods are not in general valid for Finland, Norway, Sweden, Estonia and Lithuania.

Composite brake blocks shall be assessed on a national basis and shall take into consideration environmental winter conditions.

This specific case is valid until the specifications and assessment methods have been further developed and proven to be sufficient for Nordic Winter Conditions.

That does not preclude freight wagons from other member states from operating in Nordic and Baltic states.

7.7.2.3.1.6.Braking performance Republic of Ireland and Northern IrelandU.K.

Member State: Republic of Ireland and Northern Ireland

Case “P”

Service Brake: The stopping distance of a new wagon operating on straight and level track on the railway network in Ireland must not exceed:

Stopping distance = (v2/(2*0,55) m

(where v = max operating speed of wagon on IR network in m/s)

The maximum operating speed must be less than or equal to 120 km/h. These conditions must be met for all conditions of loading.

7.7.2.3.2.Parking brakeU.K.

7.7.2.3.2.1.Parking brake Great BritainU.K.

Member State: UK

Case “P”

Freight wagons intended for use on the British network see Annex V section V1

7.7.2.3.2.2.Parking brake Republic of Ireland and Northern IrelandU.K.

Member State: Republic of Ireland and Northern Ireland

Case “P”

For new wagons used solely on the railway network in Ireland every wagon has to be equipped with a parking brake that must hold a fully loaded wagon on a gradient of 2,5 % with a maximum of 10 % adhesion with no wind.

Ireland requests exception from requirements where the parking brake is to be operated ‘from the vehicle’, in favour of a requirement that ‘the parking brake is to operated from the vehicle or from the ground’.

7.7.2.4.Environmental conditionsU.K.

7.7.2.4.1.Environmental conditionsU.K.

7.7.2.4.1.1.Environmental conditions Spain and PortugalU.K.

Member State: Spain and Portugal

Case “P”

In Spain and Portugal the upper external temperature limit is + 50 instead of + 45 given by temperature class Ts in section 4.2.6.1.2.2.

7.7.2.4.2.Fire safetyU.K.

7.7.2.4.2.1.Fire safety Spain and PortugalU.K.

Member State: Spain and Portugal

Case “P”

Spark arrester.

Category “P”- permanent

For two-axle wagons:

Spark arrester shields shall be constructed and arranged in accordance with Plate 16.

The external part of these shields shall be directed downwards, and their upper part shall be curved.

The width of their upper part shall be 415 +5/0 mm; the distance between inside edges shall be 1 120 mm.

The vertical part of these shields shall be 115 mm in height, and the part pointing downwards 32 mm at 30o. The distance of these shields in relation to the floor shall be 20 mm, and the radius of the curved part 1 800 mm. Axle wagons accepted for transit between France and Spain, with dangerous goods in RID classes 1a and 1b shall have their brake isolated while running.

For bogie wagons:

The spark arrester shields shall be constructed and arranged in accordance with Plate 17.

They shall be smooth and 500 mm wide.

The distance between their inside edges shall be 1 100 mm ± 10.

In relation to the floor, the minimum distance of these shields shall be 80 mm.

7.7.2.4.3.Electrical protectionU.K.

7.7.2.4.3.1.Electrical protection Poland and Slovakia in selected 1 520 mm lines, Lithuania, Latvia, EstoniaU.K.

Member State: Poland and Slovakia in selected 1 520 mm lines, Lithuania, Latvia, Estonia

Case “P”

Additional requirements for 1 520 mm wagons and 1 435 mm wagons to operate on 1 520 mm network.

7.7.3.TABLE OF SPECIFIC CASES ARRANGED BY MEMBER STATEU.K.

| Country | Section | Parameter | Specific case | Category |

|---|---|---|---|---|

| All countries | 4.2.3.4 | Vehicle dynamic behaviour | 7.7.2.2.4.1. | P |

| Finland | 4.2.2.1 | Interface (e.g. coupling) between vehicles | 7.7.2.1.1.1 | P |

| Finland | 4.2.3.1 | Kinematic gauge | 7.7.2.2.1.3 | P |

| Finland | 4.2.3.2 | Static axle load, dynamic wheel load and linear load | 7.7.2.2.2.1 | P |

| Finland | 4.2.4.1 | Braking performance | 7.7.2.3.1.3 | P |

| Finland, Sweden, Norway, Estonia, Latvia and Lithuania | 6.2.3.3 (Annex P) | Braking performance | 7.7.2.3.1.5 | T1 |

| Finland, Estonia, Latvia, Lithuania, Poland | Sections 4 and 5 | Subsystem characterisation and interoperability constituents | 7.7.2.1.1.3 | P |

| Finland and Norway | 5.3.2.3 | Wheels | 7.7.2.2.4.2 | P |

| Great Britain | 4.2.3.1 | Kinematic gauge | 7.7.2.2.1.1 | P |

| Great Britain | 4.2.3.2 | Static axle load, dynamic wheel load and linear load | 7.7.2.2.2.2 | P |

| Great Britain | 4.2.4.1.2.2 | Braking performance | 7.7.2.3.1.1 | P |

| Great Britain | 4.2.4.1.2.8 | Parking brake | 7.7.2.3.2 | P |

| Greece | 4.2.3.4 | Vehicle dynamic behaviour | 7.7.2.1.1.6 | T1 |

| Poland, Slovakia, Lithuania, Latvia and Estonia | 4.2.2.1 | Interface (e.g. coupling) between vehicles | 7.7.2.1.1.2 | P |

| Poland, Slovakia, Lithuania, Latvia and Estonia | 4.2.2.3 | Strength of main vehicle structure | 7.7.2.1.3.1 | P |

| Poland, Slovakia, Lithuania, Latvia and Estonia | 4.2.3.1 | Kinematic gauge | 7.7.2.2.1.2 | P |

| Lithuania, Latvia and Estonia | 4.2.3 | Static axle load, dynamic wheel load and linear load | 7.7.2.2.2.3 | P |

| Lithuania, Latvia and Estonia | Sections 4 and 5 | Subsystem characterisation and interoperability constituents | 7.7.2.1.1.4 | T |

| Poland, Slovakia, Lithuania, Latvia and Estonia | 4.2.3.4 | Vehicle dynamic behaviour | 7.7.2.2.4 | P |

| Poland, Slovakia, Lithuania, Latvia and Estonia | 4.2.3.5 | Longitudinal compressive forces | 7.7.2.2.5.1 | P |

| Poland, Slovakia, Lithuania, Latvia and Estonia | 5.3.2.1 | Bogies and running gear | 7.7.2.2.6.1 | P |

| Poland, Slovakia, Lithuania, Latvia and Estonia | 4.2.4.1 | Braking performance | 7.7.2.3.1.2 | P |

| Poland, Slovakia, Lithuania, Latvia and Estonia | 4.2.7.3 | Electrical protection | 7.7.2.4.3.1 | P |

| Republic of Ireland and Northern Ireland | 4.2.1 | Interface (e.g. coupling) between vehicles | 7.7.2.1.1.5 | P |

| Republic of Ireland and Northern Ireland | 4.2.2.2 | Safe access and egress | 7.7.2.1.2.1 | P |

| Republic of Ireland and Northern Ireland | 4.2.3 | Static axle load, dynamic wheel load and linear load | 7.7.2,2.2.4 | P |

| Republic of Ireland and Northern Ireland | 4.2.3.4 | Vehicle dynamic behaviour | 7.7.2.2.4.5 | P |

| Republic of Ireland and Northern Ireland | 4.2.4.1 | Braking performance | 7.7.2.3.1.5 | P |

| Republic of Ireland and Northern Ireland | 4.2.4.1.2.8 | Parking brake | 7.7.2.3.2.2 | P |

| Spain and Portugal | 4.2.2.1 | Interface (e.g. coupling) between vehicles | 7..2.1.1.4 | P |

| Spain and Portugal | 4.2.2.3 | Strength of main vehicle structure | 7.7.2.1.3.2 | P |

| Spain and Portugal | 4.2.3.1 | Kinematic gauge | 7.7.2.2.1.4 | P |

| Spain and Portugal | 4.2.3.4 | Vehicle dynamic behaviour | 7.7.2.2.4.4 | P |

| Spain and Portugal | 5.3.2.1 | Bogies and Running Gear | 7.7.2.2.6.2 | P |

| Spain and Portugal | 4.2.4.1 | Braking performance | 7.7.2.3.1.4 | P |

| Spain and Portugal | 4.2.6.1.2.2 | Environmental conditions | 7.7.2.4.1.1 | P |

| Spain and Portugal | 4.2.7.2 | Fire Safety | 7.7.2.4.2.1 | P |

Options/Help

Print Options

PrintThe Whole Decision

PrintThe Whole Annex

PrintThe Whole Division

PrintThis Division only

You have chosen to open the Whole Decision

The Whole Decision you have selected contains over 200 provisions and might take some time to download. You may also experience some issues with your browser, such as an alert box that a script is taking a long time to run.

Would you like to continue?

You have chosen to open Schedules only

The Schedules you have selected contains over 200 provisions and might take some time to download. You may also experience some issues with your browser, such as an alert box that a script is taking a long time to run.

Would you like to continue?

Legislation is available in different versions:

Latest Available (revised):The latest available updated version of the legislation incorporating changes made by subsequent legislation and applied by our editorial team. Changes we have not yet applied to the text, can be found in the ‘Changes to Legislation’ area.

Original (As adopted by EU): The original version of the legislation as it stood when it was first adopted in the EU. No changes have been applied to the text.

Point in Time: This becomes available after navigating to view revised legislation as it stood at a certain point in time via Advanced Features > Show Timeline of Changes or via a point in time advanced search.

See additional information alongside the content

Geographical Extent: Indicates the geographical area that this provision applies to. For further information see ‘Frequently Asked Questions’.

Show Timeline of Changes: See how this legislation has or could change over time. Turning this feature on will show extra navigation options to go to these specific points in time. Return to the latest available version by using the controls above in the What Version box.

More Resources

Access essential accompanying documents and information for this legislation item from this tab. Dependent on the legislation item being viewed this may include:

- the original print PDF of the as adopted version that was used for the EU Official Journal

- lists of changes made by and/or affecting this legislation item

- all formats of all associated documents

- correction slips

- links to related legislation and further information resources

Timeline of Changes

This timeline shows the different versions taken from EUR-Lex before exit day and during the implementation period as well as any subsequent versions created after the implementation period as a result of changes made by UK legislation.

The dates for the EU versions are taken from the document dates on EUR-Lex and may not always coincide with when the changes came into force for the document.

For any versions created after the implementation period as a result of changes made by UK legislation the date will coincide with the earliest date on which the change (e.g an insertion, a repeal or a substitution) that was applied came into force. For further information see our guide to revised legislation on Understanding Legislation.

More Resources

Use this menu to access essential accompanying documents and information for this legislation item. Dependent on the legislation item being viewed this may include:

- the original print PDF of the as adopted version that was used for the print copy

- correction slips

Click 'View More' or select 'More Resources' tab for additional information including:

- lists of changes made by and/or affecting this legislation item

- confers power and blanket amendment details

- all formats of all associated documents

- links to related legislation and further information resources