- Latest available (Revised)

- Original (As adopted by EU)

Commission Implementing Decision of 24 January 2014 authorising methods for grading pig carcases in Italy (notified under document C(2014) 279) (Only the Italian text is authentic) (2014/38/EU)

You are here:

More Resources

Revised version PDFs

- Revised 01/01/20140.64 MB

When the UK left the EU, legislation.gov.uk published EU legislation that had been published by the EU up to IP completion day (31 December 2020 11.00 p.m.). On legislation.gov.uk, these items of legislation are kept up-to-date with any amendments made by the UK since then.

This item of legislation originated from the EU

Legislation.gov.uk publishes the UK version. EUR-Lex publishes the EU version. The EU Exit Web Archive holds a snapshot of EUR-Lex’s version from IP completion day (31 December 2020 11.00 p.m.).

Status:

This is the original version as it was originally adopted in the EU.

This legislation may since have been updated - see the latest available (revised) version

ANNEX METHODS FOR GRADING PIG CARCASES IN ITALY

PART I Fat-O-Meater I (FOM I)

1.The rules provided for in this Part shall apply when the grading of pig carcases is carried out by means of the apparatus termed ‘Fat-O-Meater I’ (FOM I).

2.The apparatus shall be equipped with a probe of 6 mm diameter containing a photodiode of the Siemens SFH 950 type and a photo detector (type SFH 960), having an operating distance of between 5 and 115 mm. The results of the measurements are converted into estimated lean meat content by means of a computer.

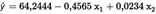

3.The lean meat content of the carcase shall be calculated according to one of the following two formulae:

carcases weighing between 110,1 and 180 kg

where:

=

the estimated percentage of lean meat in the carcase,

=

the thickness of back fat (including rind) in millimetres, measured at 8 cm off the midline of the carcase at the level placed between the third and fourth last ribs

=

the thickness of the Longissimus dorsi muscle, measured at the same time and in the same place as x1.

PART II Hennessy Grading Probe (HGP 7)

1.The rules provided for in this Part shall apply when the grading of pig carcases is carried out by means of the apparatus called ‘Hennessy Grading Probe 7’ (HGP 7).

2.The apparatus shall be equipped with a probe of 5,95 mm diameter (and have abutting 6,3 mm of blade on either side of the probe at its head)containing a photodiode (Siemens LED of the type LYU 260-EO and photodetector of the type 58 MR) and having an operating distance of between 0 and 120 mm. The results of the measurements shall be transformed in terms of estimated lean meat content by means of the HGP 7 itself as well as a computer linked to it.

3.The lean meat content of the carcase shall be calculated according to one of the following two formulae:

carcases weighing between 110,1 and 180 kg

where:

=

the estimated percentage of lean meat in the carcase,

=

the thickness of back fat (including rind) in millimetres, measured at 8 cm off the midline of the carcase at the level placed between the third and fourth last ribs,

=

the thickness of the Longissimus dorsi muscle, measured at the same time and in the same place as x1.

PART III Fat-O-Meat’er II (FOM II)

1.The rules provided for in this Part shall apply when the grading of pig carcases is carried out by means of the apparatus called ‘Fat-O-Meat’er II’ (FOM II).

2.The apparatus is a new version of the Fat-O-Meat’er measurement system. The FOM II consists of an optical probe with a knife, a depth measurement device having an operating distance of between 0 and 125 millimetres and a data acquisition and analysis board – Carometec Touch Panel i15 computer (Ingress Protection IP69K). The results of the measurements are converted into estimated lean meat content by the FOM II apparatus itself.

3.The lean meat content of the carcase shall be calculated according to one of the following two formulae:

carcases weighing between 110,1 and 180 kg

where:

=

the estimated percentage of lean meat in the carcase,

=

the thickness of back fat (including rind) in millimetres, measured at 8 cm off the midline of the carcase at the level placed between the third and fourth last ribs,

=

the thickness of the Longissimus dorsi muscle, measured at the same time and in the same place as x1.

PART IV AutoFom III

1.The rules provided for in this Part shall apply when the grading of pig carcases is carried out by means of the apparatus known as ‘AutoFom III’.

2.The apparatus shall be equipped with sixteen 2 MHz ultrasonic transducers (Carometec A/S), with an operating distance between transducers of 25 mm. The ultrasonic data shall comprise measurements of back fat thickness, muscle thickness and related parameters. The results of the measurements are converted into estimates of the percentage of lean meat by using a computer.

3.The lean meat content of the carcase shall be calculated according to one of the following two formulae:

carcases weighing between 70 and 110 kg

where:

=

the estimated percentage of lean meat in the carcase,

=

(R2P1) average skin thickness in mm

=

(R2P4) the P2 fat measure at the selected position in mm where P2 is the minimum fat depth 7 cm from the midline 2/3 rib without skin

=

(R2P11) minpair filter result. Vector of cross section at minimum fat thickness position of the loin.

=

(R2P16) coarse assessment of size of fat layer depth

=

(R3P1) the meat measure at the selected P2 point in mm

=

(R3P5) the max meat measure

carcases weighing between 110,1 and 180 kg

where:

=

the estimated percentage of lean meat in the carcase

=

(R2P6) weighted average of the two minimum fat measures in mm

=

(R2P11) minpair filter result. Vector of cross section at minimum fat thickness position of the loin

=

(R2P14) The initial assessment of carcase size minus P2 skin, where P2 is the minimum fat depth 7 cm from the midline 2/3 rib

=

(R3P5) maximum muscle depth

PART V CSB Image Meater

1.The rules provided for in this Part shall apply when the grading of pig carcases is carried out by means of the apparatus known as ‘CSB Image-Meater’.

2.The CSB Image-Meater consists in particular of a video camera, a PC equipped with an image-analysis card, a screen, a printer, a command mechanism, a rate mechanism and interfaces. The 3 Image-Meater variables are all measured at the split line in the ham area (around M. gluteus medius):

The results of the measurements shall be converted into estimates of the percentage of lean meat by using a computer.

3.The lean meat content of the carcase shall be calculated according to one of the following two formulae:

carcases weighing between 70 and 110 kg

where:

=

the estimated percentage of lean meat in the carcase,

=

(MF) mean lean mass, measured in correspondence of the muscle gluteus medius (mm)

=

(ML) length of the muscle gluteus medius

=

(MS) medium fat mass, measured in correspondence of the muscle gluteus medius (mm)

=

(WbS) medium fat mass, measured in correspondence of the second vertebra, detected starting from the front (cranial) end of the muscle gluteus medius (Vb)

carcases weighing between 110,1 and 180 kg

where:

=

the estimated percentage of lean meat in the carcase,

=

(MF) mean meat measure — over the length of muscle gluteus medius (mm)

=

(ML) length of the muscle gluteus medius

=

(MS) mean fat measure above (dorsal of) muscle gluteus medius (mm)

=

S (mm) depth of the fat layer, measured at the thinnest point over the muscle gluteus medius

PART VI Manual method (ZP)

1.The rules provided for in this Part shall apply when the grading of pig carcases is carried out by use of the ‘manual method (ZP)’ measuring by ruler

2.This method may be implemented using a ruler, with the grading determined on the basis of the prediction equation. It is based on the manual measurement on the midline of the split carcase of the thickness of the fat and of the thickness of the muscle.

3.The lean meat content of the carcase shall be calculated according to one of the following two formulae:

carcases weighing between 110,1 and 180 kg

where:

=

the estimated percentage of lean meat in the carcase,

=

the minimal fat depth in millimetres (including rind) over the muscle gluteus medius

=

the minimal muscle depth in millimetres between the anterior extremity of the muscle gluteus medius and the dorsal part of the medullary canal

Options/Help

Print Options

PrintThe Whole Decision

PrintThis Annex only

Legislation is available in different versions:

Latest Available (revised):The latest available updated version of the legislation incorporating changes made by subsequent legislation and applied by our editorial team. Changes we have not yet applied to the text, can be found in the ‘Changes to Legislation’ area.

Original (As adopted by EU): The original version of the legislation as it stood when it was first adopted in the EU. No changes have been applied to the text.

More Resources

Access essential accompanying documents and information for this legislation item from this tab. Dependent on the legislation item being viewed this may include:

- the original print PDF of the as adopted version that was used for the EU Official Journal

- lists of changes made by and/or affecting this legislation item

- all formats of all associated documents

- correction slips

- links to related legislation and further information resources

More Resources

Use this menu to access essential accompanying documents and information for this legislation item. Dependent on the legislation item being viewed this may include:

- the original print PDF of the as adopted version that was used for the print copy

- correction slips

Click 'View More' or select 'More Resources' tab for additional information including:

- lists of changes made by and/or affecting this legislation item

- confers power and blanket amendment details

- all formats of all associated documents

- links to related legislation and further information resources