- Latest available (Revised)

- Original (As adopted by EU)

Commission Directive 2013/60/EUShow full title

Commission Directive 2013/60/EU of 27 November 2013 amending for the purposes of adapting to technical progress, Directive 97/24/EC of the European Parliament and of the Council on certain components and characteristics of two or three-wheel motor vehicles, Directive 2002/24/EC of the European Parliament and of the Council relating to the type-approval of two or three-wheel motor vehicles and Directive 2009/67/EC of the European Parliament and of the Council on the installation of lighting and light-signalling devices on two- or three-wheel motor vehicles (Text with EEA relevance)

You are here:

More Resources

When the UK left the EU, legislation.gov.uk published EU legislation that had been published by the EU up to IP completion day (31 December 2020 11.00 p.m.). On legislation.gov.uk, these items of legislation are kept up-to-date with any amendments made by the UK since then.

This item of legislation originated from the EU

Legislation.gov.uk publishes the UK version. EUR-Lex publishes the EU version. The EU Exit Web Archive holds a snapshot of EUR-Lex’s version from IP completion day (31 December 2020 11.00 p.m.).

Status:

This is the original version (as it was originally adopted).

ANNEX I

Annexes I, II and IV to Chapter 5 of Directive 97/24/EC are amended as follows:

Annex I to Chapter 5 of Directive 97/24/EC is amended as follows:

points 2.2 to 2.2.1.2.2 are replaced by the following:

‘2.2. Description of tests

2.2.1.The category L1e, L2e or L6e vehicle in compliance with Euro 3 emissions shall be subjected to Type I and II tests, as specified below:

2.2.1.1.Type I test (average emissions of gaseous pollutants in a congested urban area after cold start)

The test vehicle is placed on a chassis dynamometer equipped with a brake and a flywheel. The following test procedure shall be carried out:

A cold test phase 1 lasting a total of 448 seconds and comprising four elementary cycles is carried out without interruption;

A warm test phase 2 shall follow cold test phase 1 without delay, lasting a total of 448 seconds and comprising four elementary cycles. The warm test phase 2 shall be carried out without interruption;

Each elementary cycle in cold test phase 1 or in warm test phase 2 shall comprise of seven operations (idle, acceleration, steady speed, deceleration, steady state, deceleration, idle). During both cold and warm test phases the exhaust gases shall be diluted with fresh air to ensure that the flow volume of the mixture remains constant.

In the type I test:

A continuous flow of samples of the mixture of exhaust gas and dilution air shall be collected in bag No 1 collected during cold phase 1. A continuous flow of samples of the exhaust gases and dilution air mixture shall be collected in a separate bag No 2 collected during warm phase 2. The concentrations of carbon monoxide, total hydrocarbons, oxides of nitrogen and carbon dioxide in bag No 1 and bag No 2 shall be determined separately one after the other;

The total volume of the mixture in each bag shall be measured and added up to produce the total bag volume;

At the end of each test phase the distance effectively travelled is recorded from the total shown on the cumulative revolution counter driven by the roller.

The test is carried out in accordance with the test procedure described in Appendix 1. The gases are collected and analysed according to the methods laid down.

Subject to the provisions of point 2.2.1.1.4, the test is carried out three times. The total mass of carbon monoxide, hydrocarbons and nitrogen oxides obtained in each test shall be less than the Euro 3 limit values set out in the table below.

Table 1

Euro 3 emission limits for vehicle categories L1e, L2e and L6e

| a The limit for the mass of CO shall be 3,5 g/km in the case of three-wheel mopeds (L2e) and light quadricycles (L6e). | |

| Component type-approval and conformity of production | |

|---|---|

| CO (g/km) | HC + NOx (g/km) |

| L1 | L2 |

| 1a | 1,2 |

However, one of the three results for each of the abovementioned pollutants may exceed the limit value prescribed for the moped concerned by a maximum of 10 %, provided the arithmetical mean of the three results is less than the prescribed limit value. If more than one pollutant exceeds the prescribed limit values, it is immaterial whether this occurs in the same test or in different tests.

The number of tests prescribed in point 2.2.1.1.3 is reduced under the conditions described below, where V1 is the result of the first test and V2 is the result of the second test for each of the pollutants referred to in that point.

Only one test is required if V1 ≤ 0,70 L for all the pollutants concerned.

Only two tests are required if V1 ≤ 0,85 L for all the pollutants concerned and if, for at least one pollutant, V1> 0,70 L. In addition, for each of the pollutants concerned, V2 shall be such that V1 + V2 < 1,70 L and V2 < L.

A category L1e, L2e or L6e vehicle complying with the Euro 3 test type I limits set out in point 2.2.1.1.3.1 and the test type I requirements set out in this Annex shall be approved as Euro 3 compliant.

2.2.1.2.Type II test (carbon monoxide and unburnt hydrocarbons emissions at idling speed).

The mass of carbon monoxide and the mass of unburnt hydrocarbons emitted with the engine at idling speed are measured for one minute.

This test shall be carried out in accordance with the procedure described in Appendix 2.’;

in Appendix 1, points 4.2 to 4.2.3 are replaced by the following:

‘4.2. Gas-collection equipment

The gas-collection equipment shall consist of the following components (see Sub-appendices 2 and 3):

A device to collect all the exhaust gases produced during the test, whilst maintaining atmospheric pressure at the moped exhaust outlet (s);

A tube connecting the exhaust-gas collection equipment and the exhaust-gas sampling system. This connecting tube and the gas collection equipment shall be made of stainless steel, or of another material which will not affect the composition of the gases collected and will resist their temperature;

A device to suck in the diluted gases. This device shall guarantee constant flow of a sufficient volume to ensure that all the exhaust gases are sucked in;’;

in Appendix 1, points 4.2.4 to 4.2.8 are replaced by the following:

‘4.2.4.A sampling probe attached to the outside of the gas-collection device which can collect a constant sample of the dilution air using a pump, a filter and a flow meter for the duration of the test;

4.2.5.A sampling probe directed upstream of the flow of diluted gases to sample the mixture for the duration of the test at a constant rate of flow using, if necessary, a filter, a flow meter and a pump. The minimum rate of flow of the gases in the two sampling systems described above shall be at least 150 l/h;

4.2.6.Three-way valves on the sampling circuits described above to direct the flow of samples either to the atmosphere or to their respective sampling bags for the duration of the test;

4.2.7.Leak-tight sampling bags to collect the mixture of exhaust gas and dilution air. These shall be unaffected by the pollutants concerned and of sufficient capacity not to disrupt the normal flow of sampling. There shall be at least one separate sampling bag (bag No 1) for cold test phase 1 and one separate sampling bag (bag No 2) for warm test phase 2;

These sampling bags shall each have an automatic sealing device which can be closed rapidly and tightly, either on the sampling circuit or on the analysis circuit at the end of the test.

The sealing device on bag No 1 shall close after 448 seconds after the start of the type I test.

The sealing device on bag No 2 shall immediately open subsequent to the sealing of bag No 1 and close again 896 seconds after the start of the type I test;

4.2.8.There shall be a method of measuring the total volume of diluted gases passing through the sampling device during the test. The exhaust dilution system shall comply with the requirements of Appendix 2 to Chapter 6 of Annex I to UNECE Regulation No 83.

4.2.9.

in Appendix 1 the following point 4.3.3 is inserted:

‘4.3.3The analytical equipment shall be capable of measuring independently the mixture sample of exhaust gases and dilution air captured in bags No 1 and 2.’;

in Appendix 1 points 5.4 to 5.4.3 are replaced by the following:

‘5.4. Conditioning of the test vehicle

5.4.1.The tyre pressure of the test vehicle shall be as stated by the manufacturer for normal road use. However, if the diameter of the rollers is less than 500 mm, the pressure in the tyres may be increased by 30-50 %.

5.4.2.The fuel tank(s) shall be drained through the drain(s) provided and charged with the test fuel specified in Annex IV.

5.4.3.The test vehicle shall be moved to the test area and the following operations shall be performed:’;

in Appendix 1, the following points 5.4.3.1 to 5.4.3.5 are inserted:

The test vehicle shall be driven or pushed onto a chassis dynamometer and operated through the test cycle set out in 2.1 The test vehicle need not be cold, and may be used to set dynamometer power.

The load on the driving wheel shall be within ± 3 kg of the load on a vehicle in normal road use, with a driver weighing 75 kg ± 5 kg, sitting in an upright position.

Practice runs over the test cycle set out in 2.1 may be performed at test points, provided an emission sample is not taken, to determine the minimum throttle action required to maintain the proper speed-time relationship.

Before being placed in the soak area the test vehicle shall undergo four consecutive operating cycles as set out in 2.1, each lasting 112 seconds. This preconditioning test cycle shall be performed with the dynamometer settings laid down in 5.1 and 5.2 Measurement of the tailpipe emissions is not required for this preconditioning test cycle.

Within five minutes of the completion of preconditioning, the test vehicle shall be removed from the dynamometer and driven or pushed to the soak area to be parked. The ambient temperature in the soak area shall be controlled at 298 K ± 5 K. The vehicle shall be stored for not less than six hours and not more than 36 hours prior to the cold start type I test or until the engine oil temperature TOil, the coolant temperature TCoolant or the sparkplug seat/gasket temperature TSP (only for air cooled engines) equals the air temperature of the soak area. The test report shall indicate which of the criteria has been selected.’;

in Appendix 1, points 7.1 to 7.1.3 are replaced by the following:

‘7.1. Sampling

7.1.1.Sampling begins as soon as the test commences, as indicated in point 6.2.2.

7.1.2.Bags Nos 1 and 2 shall be hermetically sealed and follow the sealing sequence set out in point 4.2.7.1 They shall not be connected during cold test phase 1 or warm test phase 2.

7.1.3.At the end of the final cycle the device for collecting the diluted exhaust gases and the dilution air shall be closed and the gases produced by the engine diverted into the atmosphere.’;

in Appendix 1, point 7.2.4 is replaced by the following:

‘7.2.4.The concentrations of HC, CO and NOx and CO2 in the samples of diluted exhaust gases and in the bags collecting the dilution air are determined from the values shown or recorded by the measuring equipment by applying the relevant calibration curves.’;

in Appendix 1, points 8 to 8.4.1 are replaced by the following:

‘8.DETERMINATION OF THE QUANTITY OF GASEOUS POLLUTANTS EMITTED

8.1.The masses of CO2 and gaseous pollutants CO, HC, NOx shall be determined separately for bag Nos 1 and 2 in accordance with points 8.2 to 8.6.

8.2.The mass of carbon monoxide gas emitted during the test is determined by means of the formula:

where:

COm is the mass of carbon monoxide emitted during the test, expressed in g/km, separately to be calculated for each phase;

SX is the distance actually travelled expressed in km, obtained by multiplying the total number of revolutions shown on the revolution counter by the circumference of the roller,

where:

=

1 for cold phase 1;

=

2 for warm phase 2.

dCO is the density of carbon monoxide at a temperature of 273,2 K (0 °C) and at a pressure of

COc is the volume concentration of carbon monoxide in the diluted gases, expressed in parts per million (ppm) and corrected to take account of the pollution of the dilution air:

where:

COe is the concentration of carbon monoxide, measured in ppm, in the sample of diluted gases collected in bag Sa.

COd is the concentration of carbon monoxide, measured in ppm, in the sample of dilution air collected in bag Sb.

DF is the coefficient defined in 8.6.

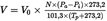

V is the volume, expressed in m3/phase, of diluted gases at reference temperature 273,2 K (0 °C) and reference pressure 101,3 kPa:

where:

V0 is the volume of gas displaced by pump P1 during one rotation expressed in m3/revolution. This volume is a function of the differential pressures between the inlet and outlet sections of the pump itself;

N is the number of rotations made by pump P1 during the four elementary test cycles of each phase;

Pa is the atmospheric pressure expressed in kPa;

Pi is the mean value, expressed in kPa, during performance of the drop in pressure in the inlet section of pump P1;

Tp (°C) is the value of the temperature of the diluted gases measured in the inlet section of pump P1.

8.3.The mass of unburned hydrocarbons emitted through the moped’s exhaust during the test is calculated by means of the formula:

where:

HCm is the mass of hydrocarbons emitted during the test, expressed in g, separately to be calculated for each phase;

SX is the distance defined in 8.2.2;

dHC is the density of hydrocarbons at a temperature of 273,2 K (0 °C) and a pressure of 101,3 kPa (for petrol (E5) (C1H1,89O0,016)) (= 631 g/m3);

HCc is the concentration of the diluted gases expressed in ppm carbon equivalent and corrected to take account of the dilution air:

where:

HCe is the concentration of hydrocarbons, expressed in ppm carbon equivalent, in the sample of diluted gases collected in bag Sa;

HCd is the concentration of hydrocarbons, expressed in ppm carbon equivalent, in the sample of dilution air collected in bag Sb;

DF is the coefficient defined in 8.6.

V is the volume defined in 8.2.5.

8.4.The mass of oxides of nitrogen emitted through the moped’s exhaust during the test is calculated by means of the formula:

where:

NOxm is the mass of oxides of nitrogen emitted during the test, expressed in g, separately to be calculated each phase;’;

in Appendix 1, the following points 8.4.2 to 8.6.3 are inserted:

SX is the distance defined in 8.2.2;

dNO2 is the density of the oxides of nitrogen in the exhaust gases, in NO2 equivalent, at a temperature of 273,2 K (0 °C) and a pressure of 101,3 kPa (= 2,050 103 g/m3);

NOxc is the concentration of oxides of nitrogen in the diluted gases, expressed in ppm and corrected to take account of the dilution air:

where:

NOxe is the concentration of oxides of nitrogen, expressed in ppm, in the sample of diluted gases collected in bag Sa;

NOxd is the concentration of oxides of nitrogen, expressed in ppm, in the sample of dilution air collected in bag Sb;

DF is the coefficient defined in 8.6.

Kh is the correction factor for humidity

where:

V is the volume defined in 8.2.5.

8.5.Carbon dioxide (CO2)

The mass of carbon dioxide emitted by the vehicle’s exhaust during the test shall be calculated by means of the following formula:

where:

CO2m is the mass of carbon dioxide emitted during the test part, in g, separately to be calculated for each phase;

SX is the distance defined in 8.2.2;

V is the volume defined in 8.2.5;

dCO2 is the density of the carbon dioxide at a temperature of 273,2 K (0 °C) and a pressure of 101,3 kPa,

CO2c is the concentration of diluted gases, expressed in per cent carbon dioxide equivalent, corrected to take account of the dilution air by the following equation:

where:

CO2e is the concentration of carbon dioxide expressed in per cent, in the sample of diluted gases collected in bag(s) SA;

CO2d is the concentration of carbon dioxide expressed in per cent, in the sample of dilution air collected in bag(s) SB;

DF is the coefficient defined in 8.6.

8.6.DF is a coefficient expressed by means of the formula:

where:

CCO2 = concentration of CO2 in the diluted exhaust gas contained in the sampling bags, expressed in per cent volume;

CHC = concentration of HC in the diluted exhaust gas contained in the sampling bags, expressed in ppm carbon equivalent;

CCO = concentration of CO in the diluted exhaust gas contained in the sampling bags, expressed in ppm.’;

in Appendix 1, point 9 is replaced by the following:

‘9.Presentation of test results:

The (average) result of the cold phase is named RX1 (in g), the (average) result of the warm phase is named RX2 (in g). Using these emission results the final type I test result RX (in g/km) shall be calculated by means of the following equation:

Where:

X = HC, CO, NOx or CO2

RHC_Cold = HCmass_cold_phase_1 (in g) and RHC_Warm = HCmass_warm_phase_2 (in g), see formula in point 8.3

RCO_Cold = COmass_cold_phase_1 (in g) and RCO_Warm = CO mass_warm_phase_2 (in g), see formula in point 8.2

RNOx_Cold = NOxmass_cold_phase_1 (in g) and RNOx_Warm = NOxmass_warm_phase_2 (in g), see formula in point 8.4

RCO2_Cold = CO2mass_cold_phase_1 (in g) and RCO2_Warm = CO2 mass_warm_phase_2 (in g): see formula in point 8.5

ST:

actually covered by the L1e, L2e or L6e test vehicle in the cold phase 1 and in the warm phase 2 of the entire test cycle.’;

in Appendix 1, the following point 10 is added:

‘10.Fuel consumption

The fuel consumption shall be calculated using the test results from point 9 as follows:

where:

=

the fuel consumption in litre per 100 km;

=

the density of the test fuel in kg/l at 288,2 K (15 °C).’;

the following Appendix 3 is added:

‘Appendix 3 Crankcase gas emissions and interpretation of CO2 emission and fuel consumption test results

1.Zero crankcase gas emissions shall be emitted from the type-approved vehicle of categories L1e, L2e and L6e. Crankcase gas emissions shall not be discharged directly into the ambient atmosphere from any L-category vehicle throughout its useful life.

2.Interpretation of CO2 emission and fuel consumption test type I results of categories L1e, L2e and L6e vehicles

2.1.The CO2 and fuel consumption values adopted as the type-approval value shall be as declared by the manufacturer provided this is not exceeded by more than four per cent by the value measured by the technical service The measured value may be lower without any limitations.

2.2.If the measured value of CO2 and fuel consumption exceeds the manufacturer’s declared CO2 value and fuel consumption by more than four per cent another test is run on the same vehicle.

2.3.If the average of the two test results does not exceed the manufacturer’s declared value by more than four per cent the value declared by the manufacturer is taken as the type-approval value.

2.4.If the average of the two test results still exceeds the declared value by more than four per cent, a final test is run on the same vehicle. The average of the three test results is taken as the type-approval value.’;”

point 2.2.1.1.7 of Annex II to Chapter 5 of Directive 97/24/EC is amended as follows:

‘2.2.1.1.7.The recorded data are completed in the relevant sections of the document referred to in Annex VII of Directive 2002/24/EC. The appropriate Euro level shall be entered in point 46.2 of Annex IV to Directive 2002/24/EC in accordance with the rules set out in the footnote to this point.’;

Annex IV to Chapter 5 of Directive 97/24/EC is replaced by the following:

‘ANNEX IV SPECIFICATIONS FOR THE REFERENCE FUELS

Petrol (E5) and diesel (B5) reference fuels shall be specified in accordance with section A of Annex IX to Commission Regulation (EC) No 692/2008(1);”

Options/Help

Print Options

PrintThe Whole Directive

PrintThis Annex only

Legislation is available in different versions:

Latest Available (revised):The latest available updated version of the legislation incorporating changes made by subsequent legislation and applied by our editorial team. Changes we have not yet applied to the text, can be found in the ‘Changes to Legislation’ area.

Original (As adopted by EU): The original version of the legislation as it stood when it was first adopted in the EU. No changes have been applied to the text.

More Resources

Access essential accompanying documents and information for this legislation item from this tab. Dependent on the legislation item being viewed this may include:

- the original print PDF of the as adopted version that was used for the EU Official Journal

- lists of changes made by and/or affecting this legislation item

- all formats of all associated documents

- correction slips

- links to related legislation and further information resources

More Resources

Use this menu to access essential accompanying documents and information for this legislation item. Dependent on the legislation item being viewed this may include:

- the original print PDF of the as adopted version that was used for the print copy

- correction slips

Click 'View More' or select 'More Resources' tab for additional information including:

- lists of changes made by and/or affecting this legislation item

- confers power and blanket amendment details

- all formats of all associated documents

- links to related legislation and further information resources