ANNEX IIIU.K.(Part-66)

66.1U.K.

For the purpose of this Part, the competent authority shall be the authority designated by the Member State to whom a person applies for the issuance of an aircraft maintenance licence.

[F1SECTION A U.K. TECHNICAL REQUIREMENTS]

SUBPART AAIRCRAFT MAINTENANCE LICENCE AEROPLANES AND HELICOPTERSU.K.

66.A.1ScopeU.K.

This section establishes the requirements for the issue of an aircraft maintenance licence and conditions of its validity and use, for aeroplanes and helicopters of the following categories:

Category A

Category B1

Category B2

Category C

[F166.A.10 Application U.K.

(a) An application for an aircraft maintenance licence or change to such licence shall be made on an EASA Form 19 in a manner established by the competent authority and submitted thereto. U.K.

(b) An application for the change to an aircraft maintenance licence shall be made to the competent authority of the Member State that first issued the aircraft maintenance licence. U.K.

(c) In addition to the documents required in points 66.A.10(a), 66.A.10(b) and 66.B.105, as appropriate, the applicant for additional basic categories or subcategories to an aircraft maintenance licence shall submit his/her current original aircraft maintenance licence to the competent authority together with EASA Form 19. U.K.

(d) Where the applicant for change of the basic categories qualifies for such change via the procedure referred to in point 66.B.100 in a Member State other than the Member State in which he/she first qualified, the application shall be sent to the Member State of first qualification. U.K.

(e) Where the applicant for change of the basic categories qualifies for such change via the procedure referred to in point 66.B.105 in a Member State other than the Member State in which he/she first qualified, the maintenance organisation approved in accordance with Annex II (Part-145) shall send the aircraft maintenance licence together with the EASA Form 19 to the competent authority of the Member State of first qualification for Member State stamp and signature of the change or reissue of the licence.] U.K.

66.A.15EligibilityU.K.

An applicant for an aircraft maintenance licence shall be at least 18 years of age.

66.A.20PrivilegesU.K.

Subject to compliance with paragraph (b), the following privileges shall apply:

A category A aircraft maintenance licence permits the holder to issue certificates of release to service following minor scheduled line maintenance and simple defect rectification within the limits of tasks specifically endorsed on the authorisation. The certification privileges shall be restricted to work that the licence holder has personally performed in a Part-145 organisation.

A category B1 aircraft maintenance licence shall permit the holder to issue certificates of release to service following maintenance, including aircraft structure, powerplant and mechanical and electrical systems. Replacement of avionic line replaceable units, requiring simple tests to prove their serviceability, shall also be included in the privileges. Category B1 shall automatically include the appropriate A subcategory.

A category B2 aircraft maintenance licence shall permit the holder to issue certificates of release to service following maintenance on avionic and electrical systems.

A category C aircraft maintenance licence shall permit the holder to issue certificates of release to service following base maintenance on aircraft. The privileges apply to the aircraft in its entirety in a Part-145 organisation.

The holder of an aircraft maintenance licence may not exercise certification privileges unless:

in compliance with the applicable requirements of Part-M and/or Part-145.

in the preceding two-year period he/she has, either had six months of maintenance experience in accordance with the privileges granted by the aircraft maintenance licence or, met the provision for the issue of the appropriate privileges.

he/she is able to read, write and communicate to an understandable level in the language(s) in which the technical documentation and procedures necessary to support the issue of the certificate of release to service are written.

66.A.25Basic knowledge requirementsU.K.

An applicant for an aircraft maintenance licence or the addition of a category or subcategory to such an aircraft maintenance licence shall demonstrate, by examination, a level of knowledge in the appropriate subject modules in accordance with Appendix I to this Part.

The basic knowledge examinations shall be conducted by a training organisation appropriately approved under Part-147 or by the competent authority.

Full or partial credit against the basic knowledge requirements and associated examination shall be given for any other technical qualification considered by the competent authority to be equivalent to the knowledge standard of this Part. Such credits shall be established in accordance with Section B, Subpart E of this Part.

66.A.30Experience requirementsU.K.

An applicant for an aircraft maintenance licence shall have acquired:

for category A and subcategories B1.2 and B1.4:

three years of practical maintenance experience on operating aircraft, if the applicant has no previous relevant technical training; or

two years of practical maintenance experience on operating aircraft and completion of training considered relevant by the competent authority as a skilled worker, in a technical trade; or

one year of practical maintenance experience on operating aircraft and completion of a Part-147 approved basic training course.

for category B2 and subcategories B1.1 and B1.3:

five years of practical maintenance experience on operating aircraft if the applicant has no previous relevant technical training; or

three years of practical maintenance experience on operating aircraft and completion of training considered relevant by the competent authority as a skilled worker, in a technical trade; or

two years of practical maintenance experience on operating aircraft and completion of a Part -147 approved basic training course.

for category C with respect to large aircraft:

three years of experience exercising category B1.1, B1.3 or B2 privileges on large aircraft or as Part-145 B1.1, B1.3 or B2 support staff, or, a combination of both; or

five years of experience exercising category B1.2 or B1.4 privileges on large aircraft or as Part-145 B1.2 or B1.4 support staff, or a combination of both; or

for category C with respect to non large aircraft:

three years of experience exercising category B1 or B.2 privileges on non large aircraft or as Part-145 B1 or B.2 support staff, or a combination of both; or

for category C obtained through the academic route:

an applicant holding an academic degree in a technical discipline, from a university or other higher educational institution recognised by the competent authority, three years of experience working in a civil aircraft maintenance environment on a representative selection of tasks directly associated with aircraft maintenance including six months of observation of base maintenance tasks.

An applicant for an extension to an aircraft maintenance licence shall have a minimum civil aircraft maintenance experience requirement appropriate to the additional category or subcategory of licence applied for as defined in Appendix IV to this Part.

For category A, B1 and B2 the experience must be practical which means being involved with a representative cross section of maintenance tasks on aircraft.

For all applicants, at least one year of the required experience must be recent maintenance experience on aircraft of the category/subcategory for which the initial aircraft maintenance licence is sought. For subsequent category/subcategory additions to an existing aircraft maintenance licence, the additional recent maintenance experience required may be less than one year, but must be at least three months. The required experience must be dependent upon the difference between the licence category/subcategory held and applied for. Such additional experience must be typical of the new licence category/subcategory sought.

Notwithstanding paragraph (a), aircraft maintenance experience gained outside a civil aircraft maintenance environment shall be accepted when such maintenance is equivalent to that required by this Part as established by the competent authority. Additional experience of civil aircraft maintenance shall, however, be required to ensure understanding of the civil aircraft maintenance environment.

[F166.A.40 Continued validity of the aircraft maintenance licence U.K.

(a) The aircraft maintenance licence becomes invalid five years after its last issue or change, unless the holder submits his/her aircraft maintenance licence to the competent authority that issued it, in order to verify that the information contained in the licence is the same as that contained in the competent authority records, pursuant to point 66.B.120. U.K.

(b) The holder of an aircraft maintenance licence shall complete the relevant parts of EASA Form 19 and submit it with the holder's copy of the licence to the competent authority that issued the original aircraft maintenance licence, unless the holder works in a maintenance organisation approved in accordance with Annex II (Part-145) that has a procedure in its exposition whereby such organisation may submit the necessary documentation on behalf of the aircraft maintenance licence holder. U.K.

(c) Any certification privilege based upon a aircraft maintenance licence becomes invalid as soon as the aircraft maintenance licence is invalid. U.K.

(d) The aircraft maintenance licence is only valid (i) when issued and/or changed by the competent authority and (ii) when the holder has signed the document.] U.K.

66.A.45Type/task training and ratingsU.K.

The holder of a category A aircraft maintenance licence may only exercise certification privileges on a specific aircraft type following the satisfactory completion of the relevant category A aircraft task training carried out by an appropriately approved Part-145 or Part-147 organisation. The training shall include practical hands on training and theoretical training as appropriate for each task authorised. Satisfactory completion of training shall be demonstrated by an examination and/or by workplace assessment carried out by an appropriately approved Part-145 or Part-147 organisation.

Except as otherwise specified in paragraph (g), the holder of a category B1, B2 or C aircraft maintenance licence shall only exercise certification privileges on a specific aircraft type when the aircraft maintenance licence is endorsed with the appropriate aircraft type rating.

Except as otherwise specified in paragraph (h), ratings shall be granted following satisfactory completion of the relevant category B1, B2 or C aircraft type training approved by the competent authority or conducted by an appropriately approved Part-147 maintenance training organisation.

Category B1 and B2 approved type training shall include theoretical and practical elements and consist of the appropriate course in relation to the 66.A.20(a) privileges. Theoretical and practical training shall comply with Appendix III to this Part.

Category C approved type training shall comply with Appendix III to this Part. In the case of a category C person qualified by holding an academic degree as specified in 66.A.30(a), (5), the first relevant aircraft type theoretical training shall be at the category B1 or B2 level. Practical training is not required.

Completion of approved aircraft type training, as required by paragraphs (b) to (e), shall be demonstrated by an examination. The examination shall comply with Appendix III to this Part. The examinations in respect of category B1 or B2 or C aircraft type ratings shall be conducted by training organisations appropriately approved under Part-147, the competent authority, or the training organisation conducting the approved type training course.

Notwithstanding paragraph (b), for aircraft other than large aircraft, the holder of a category B1 or B2 aircraft maintenance licence may also exercise certification privileges, when the aircraft maintenance licence is endorsed with the appropriate group ratings, or manufacturer group ratings, unless the Agency has determined that the complexity of the aircraft in question requires a type rating.

Manufacturer group ratings may be granted after complying with the type rating requirements of two aircraft types representative of the group from the same manufacturer.

Full group ratings may be granted after complying with the type rating requirements of three aircraft types representative of the group from different manufacturers. However, no full group rating may be granted to B1 multiple turbine engine aeroplanes, where only manufacturer group rating applies.

The groups shall consist of the following:

for category B1 or C:

helicopter piston engine

helicopter turbine engine

aeroplane single piston engine — metal structure

aeroplane multiple piston engines — metal structure

aeroplane single piston engine — wooden structure

aeroplane multiple piston engines — wooden structure

aeroplane single piston engine — composite structure

aeroplane multiple piston engines — composite structure

aeroplane turbine — single engine

aeroplane turbine — multiple engine

for category B2 or C:

aeroplane

helicopter

[F1Notwithstanding paragraph (c), ratings on aircraft other than large aircraft may also be granted, subject to satisfactory completion of the relevant category B1, B2 or C aircraft type examination and demonstration of practical experience on the aircraft type, unless the Agency has determined that the aircraft is complex, where paragraph (c) approved type training is required.

In the case of a category C rating on aircraft other than large aircraft, for a person qualified by holding an academic degree as specified in point 66.A.30 (a) 5, the first relevant aircraft type examination shall be at the category B1 or B2 level.

Category B1, B2 and C approved type examinations must consist of a mechanical examination for category B1 and an avionics examination for category B2 and both mechanical and avionics examination for category C.

The examination shall comply with Appendix III to Annex III (Part-66). The examination shall be conducted by training organisations appropriately approved in accordance with Annex IV (Part-147) or by the competent authority.

Aircraft type practical experience shall include a representative cross section of maintenance activities relevant to the category.]

[F266.A.55 Evidence of qualification U.K.

Personnel exercising certification privileges must produce their licence, as evidence of qualification, if requested by an authorised person, within 24 hours.]

Textual Amendments

66.A.70Conversion provisionsU.K.

The holder of a certifying staff qualification valid in a Member State, prior to the date of entry into force of this Part shall be issued an aircraft maintenance licence without further examination subject to the conditions specified in 66.B.300.

A person undergoing a qualification process valid in a Member State, prior to the date of entry into force of this Part may continue to be qualified. The holder of a qualification gained following such qualification process shall be issued an aircraft maintenance licence without further examination subject to the conditions specified in 66.B.300

Where necessary, the aircraft maintenance licence shall contain technical limitations in relation to the scope of the pre-existing qualification.

SUBPART BAIRCRAFT OTHER THAN AEROPLANES AND HELICOPTERSU.K.

66.A.100GeneralU.K.

Until such time as this Part specifies a requirement for certifying staff of aircraft other than aeroplanes and helicopters, the relevant Member State regulation shall apply.

SUBPART CCOMPONENTSU.K.

66.A.200GeneralU.K.

Until such time as this Part specifies a requirement for certifying components, the relevant Member State regulation shall apply.

Textual Amendments

F1 Substituted by Commission Regulation (EU) No 127/2010 of 5 February 2010 amending Regulation (EC) No 2042/2003 on the continuing airworthiness of aircraft and aeronautical products, parts and appliances, and on the approval of organisations and personnel involved in these tasks (Text with EEA relevance).

SECTION BU.K.PROCEDURE FOR COMPETENT AUTHORITIES

SUBPART AGENERALU.K.

66.B.05ScopeU.K.

This section establishes the administrative requirements to be followed by the competent authorities in charge of the application and the enforcement of Section A of this Part.

66.B.10Competent authorityU.K.

[F1(a) General U.K.

The Member State shall designate a competent authority with allocated responsibilities for the issuance, continuation, change, suspension or revocation of aircraft maintenance licences. This competent authority shall establish an organisational structure and documented procedures for ensuring compliance with Annex III (Part-66).]

(b)ResourcesU.K.

The competent authority shall be appropriately staffed to carry out the requirements of this Part.

(c)ProceduresU.K.

The competent authority shall establish procedures detailing how compliance with this Part is accomplished.

The procedures shall be reviewed and amended to ensure continued compliance.

66.B.15Acceptable means of complianceU.K.

The Agency shall develop acceptable means of compliance that the Member States may use to establish compliance with this Part. When the acceptable means of compliance are complied with, the related requirements of this Part shall be considered as met.

66.B.20Record-keepingU.K.

[F1The competent authority shall establish a system of record-keeping that allows adequate traceability of the process to issue, revalidate, change, suspend or revoke each aircraft maintenance licence.]

The records for the oversight of the Part shall include:

the application for an aircraft maintenance licence or change to that licence, including all supporting documentation;

a copy of the aircraft maintenance licence including any changes;

copies of all relevant correspondence;

details of any exemption and enforcement actions;

any report from other competent authorities relating to the aircraft maintenance licence holder;

records of examinations conducted by the competent authority;

aircraft maintenance licence conversion reports;

examination credit reports.

Records referred to in paragraph (b), 1. to 5. shall be kept at least five years after the end of the licence validity.

Records referred to in paragraph (b), 6. shall be kept at least five years.

Records referred to in paragraph (b), 7. and 8. shall be kept for an unlimited period.

66.B.25Mutual exchange of informationU.K.

In order to contribute to the improvement of air safety, the competent authorities shall participate in a mutual exchange of all necessary information in accordance with Article 11 of the basic Regulation.

Without prejudice to the competencies of the Member States, in the case of a potential safety threat involving several Member States, the concerned competent authorities shall assist each other in carrying out the necessary oversight action.

66.B.30ExemptionsU.K.

All exemptions granted in accordance with Article 10, 3. of the basic Regulation shall be recorded and retained by the competent authority.

SUBPART BISSUE OF AN AIRCRAFT MAINTENANCE LICENCEU.K.

This Subpart provides the procedures to be followed by the competent authority to issue or vary or to permit continuity of the aircraft maintenance licence.

66.B.100Procedure for the issue of an aircraft maintenance licence by the competent authorityU.K.

On receipt of EASA Form 19 and any supporting documentation, the competent authority shall verify EASA Form 19 for completeness and ensure that the experience claimed meets the requirement of this Part.

The competent authority shall verify an applicant's examination status and/or confirm the validity of any credits to ensure that all required modules of [F1Appendix I] have been met as required by this Part.

When satisfied that the applicant meets the standards of knowledge and experience required by this Part, the competent authority shall issue the relevant aircraft maintenance licence to the applicant. The same information shall be kept on competent authority file.

66.B.105Procedure for the issue of an aircraft maintenance licence via the Part-145 approved maintenance organisationU.K.

A Part-145 maintenance organisation which has been authorised to carry out this activity by the competent authority may prepare the aircraft maintenance licence on behalf of the competent authority or make recommendations to the competent authority regarding the application from an individual for a aircraft maintenance licence so that the competent authority may prepare and issue such licence.

The Part-145 maintenance organisation shall ensure compliance with 66.B.100 (a) and (b). In all cases, the competent authority shall issue the aircraft maintenance licence to the applicant.

[F166.B.110 Procedure for the change of an aircraft maintenance licence to include an additional basic category or subcategory U.K.

(a) At the completion of the procedures specified in points 66.B.100 or 66.B.105, the competent authority shall endorse the additional basic category or subcategory on the aircraft maintenance licence by stamp and signature or reissue the licence. U.K.

(b) The competent authority record system shall be changed accordingly.] U.K.

[F166.B.115 Procedure for the change of an aircraft maintenance licence to include an aircraft type or group U.K.

On receipt of a satisfactory EASA Form 19 and any supporting documentation demonstrating compliance with the applicable type rating and/or group rating requirements and the accompanying aircraft maintenance licence, the competent authority shall either endorse the applicant's aircraft maintenance licence with the aircraft type or group or reissue the said licence to include the aircraft type or group. The competent authority record system shall be changed accordingly.]

[F166.B.120 Procedure for the renewal of an aircraft maintenance licence validity U.K.

(a) The competent authority shall compare the holder's aircraft maintenance licence with the competent authority records and verify any pending revocation, suspension or change action pursuant to point 66.B.500. If the documents are identical and no action is pending pursuant to point 66.B.500, the holder's copy shall be renewed for five years and the file endorsed accordingly. U.K.

(b) If the competent authority records are different from the aircraft maintenance licence held by the licence holder: U.K.

the competent authority shall investigate the reasons for such differences and may choose not to renew the aircraft maintenance licence;

the competent authority shall inform the licence holder and any known maintenance organisation approved in accordance with Annex I (Part-M) Subpart F or Annex II (Part-145) that may be directly affected of such fact;

the competent authority shall, if necessary, take action in accordance with point 66.B.500 to revoke, suspend or change the licence in question.]

SUBPART CEXAMINATIONSU.K.

This Subpart provides the procedure for examinations conducted by the competent authority.

66.B.200Examination by the competent authorityU.K.

All examination questions shall be kept in a secure manner prior to an examination, to ensure that candidates will not know which particular questions will form the basis of the examination. The competent authority shall nominate those persons who control the questions to be used for each examination.

The competent authority shall appoint examiners who shall be present during all examinations to ensure the integrity of the examination.

Basic examinations shall follow the standard specified in Appendix I and II to this Part.

Type examinations must follow the standard specified in Appendix III to this Part.

New essay questions shall be raised at least every six months and used questions withdrawn or rested from use. A record of the questions used shall be retained in the records for reference.

All examination papers shall be handed out at the start of the examination to the candidate and handed back to the examiner at the end of the allotted examination time period. No examination paper may be removed from the examination room during the allotted examination time period.

Apart from specific documentation needed for type examinations, only the examination paper may be available to the candidate during the examination.

Examination candidates shall be separated from each other so that they cannot read each other's examination papers. They may not speak to any person other than the examiner.

Candidates who are proven to be cheating shall be banned from taking any further examination within 12 months of the date of the examination in which they were found cheating.

SUBPART DCONVERSION OF NATIONAL QUALIFICATIONSU.K.

This Subpart provides the requirements for converting national qualifications to aircraft maintenance licences.

66.B.300GeneralU.K.

The competent authority may only perform the conversion specified in 66.A.70 in accordance with a conversion report prepared pursuant to paragraph 66.B.305 or 66.B.310, as applicable.

The conversion report shall be either developed by the competent authority or approved by the competent authority.

66.B.305Conversion report for national qualificationsU.K.

The report shall describe the scope of each type of qualification and show to which aircraft maintenance licence it will be converted, which limitation will be added and the Part-66 module/subjects on which examination is needed to ensure conversion to the aircraft maintenance licence without limitation, or to include an additional (sub-) category. The report shall include a copy of the existing regulation defining the licence categories and scopes.

66.B.310Conversion report for approved maintenance organisations authorisationsU.K.

For each approved maintenance organisation concerned, the report shall describe the scope of each type of authorisation and show to which aircraft maintenance licence it will be converted, which limitation will be added and the module/subjects on which examination is needed to convert to the licence, or to include an additional (sub-)category. The report shall include a copy of the relevant approved maintenance organisation's procedures for the qualification of certifying staff, on which the conversion process is based.

SUBPART EEXAMINATION CREDITSU.K.

This Subpart provides the requirements for granting examination credits in accordance with 66.A.25(b).

66.B.400GeneralU.K.

The competent authority may only grant examination credit on the basis of an examination credit report prepared in accordance with 66.B.405.

The examination credit report must be either developed by the competent authority or approved by the competent authority.

66.B.405Examination credit reportU.K.

For each technical qualification concerned the report shall identify the subject matter and knowledge levels contained in Appendix I to this Part relevant to the particular category being compared.

The report shall include a statement of compliance against each subject stating where, in the technical qualification, the equivalent standard can be found. If there is no equivalent standard for the particular subject, the report shall state such facts.

Based upon paragraph (b) comparison, the report shall indicate for each technical qualification concerned the Appendix I subject matters subject to examination credits.

Where the national qualification standard is changed, the report shall be amended as necessary.

SUBPART FREVOCATION, SUSPENSION OR LIMITATION OF THE AIRCRAFT MAINTENANCE LICENCEU.K.

66.B.500Revocation, suspension or limitation of the aircraft maintenance licenceU.K.

The competent authority shall suspend, limit or revoke the aircraft maintenance licence where it has identified a safety issue or if it has clear evidence that the person has carried out or been involved in one or more of the following activities:

obtaining the aircraft maintenance licence and/or the certification privileges by falsification of submitted documentary evidence.

failing to carry out requested maintenance combined with failure to report such fact to the organisation or person who requested the maintenance.

failing to carry out required maintenance resulting from own inspection combined with failure to report such fact to the organisation or person for whom the maintenance was intended to be carried out.

negligent maintenance.

falsification of the maintenance record.

issuing a certificate of release to service knowing that the maintenance specified on the certificate of release to service has not been carried out or without verifying that such maintenance has been carried out.

carrying out maintenance or issuing a certificate of release to service when adversely affected by alcohol or drugs.

issuing certificate of release to service while not in compliance with this Part

Appendix IBasic knowledge requirements

1.KNOWLEDGE LEVELS — CATEGORY A, B1, B2 AND C AIRCRAFT MAINTENANCE LICENCEU.K.

Basic knowledge for categories A, B1 and B2 are indicated by the allocation of knowledge levels indicators (1, 2 or 3) against each applicable subject. Category C applicants must meet either the category B1 or the category B2 basic knowledge levels.

The knowledge level indicators are defined as follows:

LEVEL 1U.K.

A familiarisation with the principal elements of the subject.

Objectives: The applicant should be familiar with the basic elements of the subject.

The applicant should be able to give a simple description of the whole subject, using common words and examples.

The applicant should be able to use typical terms.

LEVEL 2U.K.

A general knowledge of the theoretical and practical aspects of the subject.

An ability to apply that knowledge.U.K.

Objectives: The applicant should be able to understand the theoretical fundamentals of the subject.

The applicant should be able to give a general description of the subject using, as appropriate, typical examples.

The applicant should be able to use mathematical formulae in conjunction with physical laws describing the subject.

The applicant should be able to read and understand sketches, drawings and schematics describing the subject.

The applicant should be able to apply his knowledge in a practical manner using detailed procedures.

LEVEL 3U.K.

A detailed knowledge of the theoretical and practical aspects of the subject.

A capacity to combine and apply the separate elements of knowledge in a logical and comprehensive manner.U.K.

Objectives: The applicant should know the theory of the subject and interrelationships with other subjects.

The applicant should be able to give a detailed description of the subject using theoretical fundamentals and specific examples.

The applicant should understand and be able to use mathematical formulae related to the subject.

The applicant should be able to read, understand and prepare sketches, simple drawings and schematics describing the subject.

The applicant should be able to apply his knowledge in a practical manner using manufacturer's instructions.

The applicant should be able to interpret results from various sources and measurements and apply corrective action where appropriate.

2.MODULARISATIONU.K.

Qualification on basic subjects for each Part-66 aircraft maintenance licence category or subcategory should be in accordance with the following matrix. Applicable subjects are indicated by an ‘X’:

| Subject modules | A or B1 aeroplane with: | A or B1 helicopter with: | B2 | ||

|---|---|---|---|---|---|

| Turbine engine(s) | Piston engine(s) | Turbine engine(s) | Piston engine(s) | Avionics | |

| 1 | X | X | X | X | X |

| 2 | X | X | X | X | X |

| 3 | X | X | X | X | X |

| 4 | X | X | X | X | X |

| 5 | X | X | X | X | X |

| 6 | X | X | X | X | X |

| 7 | X | X | X | X | X |

| 8 | X | X | X | X | X |

| 9 | X | X | X | X | X |

| 10 | X | X | X | X | X |

| 11 | X | X | |||

| 12 | X | X | |||

| 13 | X | ||||

| 14 | X | ||||

| 15 | X | X | |||

| 16 | X | X | |||

| 17 | X | X | |||

MODULE 1. MATHEMATICS

MODULE 2. PHYSICS

MODULE 3. ELECTRICAL FUNDAMENTALS

MODULE 4. ELECTRONIC FUNDAMENTALS

MODULE 5. DIGITAL TECHNIQUES ELECTRONIC INSTRUMENT SYSTEMS

MODULE 6. MATERIALS AND HARDWARE

MODULE 7. MAINTENANCE PRACTICES

| Level | |||

|---|---|---|---|

| A | B1 | B2 | |

7.1 Safety Precautions-Aircraft and Workshop | 3 | 3 | 3 |

| Aspects of safe working practices including precautions to take when working with electricity, gases especially oxygen, oils and chemicals. | |||

| Also, instruction in the remedial action to be taken in the event of a fire or another accident with one or more of these hazards including knowledge on extinguishing agents. | |||

7.2 Workshop Practices | 3 | 3 | 3 |

| Care of tools, control of tools, use of workshop materials; | |||

| Dimensions, allowances and tolerances, standards of workmanship; | |||

| Calibration of tools and equipment, calibration standards. | |||

7.3 Tools | 3 | 3 | 3 |

| Common hand tool types; | |||

| Common power tool types; | |||

| Operation and use of precision measuring tools; | |||

| Lubrication equipment and methods. | |||

| Operation, function and use of electrical general test equipment; | |||

7.4 Avionic General Test Equipment | — | 2 | 3 |

| Operation, function and use of avionic general test equipment. | |||

7.5 Engineering Drawings, Diagrams and Standards | 1 | 2 | 2 |

| Drawing types and diagrams, their symbols, dimensions, tolerances and projections; | |||

| Identifying title block information; | |||

| Microfilm, microfiche and computerised presentations; | |||

| Specification 100 of the Air Transport Association (ATA) of America; | |||

| Aeronautical and other applicable standards including ISO, AN, MS, NAS and MIL; | |||

| Wiring diagrams and schematic diagrams. | |||

7.6 Fits and Clearances | 1 | 2 | 1 |

| Drill sizes for bolt holes, classes of fits; | |||

| Common system of fits and clearances; | |||

| Schedule of fits and clearances for aircraft and engines; | |||

| Limits for bow, twist and wear; | |||

| Standard methods for checking shafts, bearings and other parts. | |||

[F17.7 Electrical Wiring Interconnection System (EWIS)Continuity, insulation and bonding techniques and testing; Use of crimp tools: hand and hydraulic operated; Testing of crimp joints; Connector pin removal and insertion; Co-axial cables: testing and installation precautions; Identification of wire types, their inspection criteria and damage tolerance. Wiring protection techniques: Cable looming and loom support, cable clamps, protective sleeving techniques including heat shrink wrapping, shielding. EWIS installations, inspection, repair, maintenance and cleanliness standards. | 1 | 3 | 3] |

7.8 Riveting | 1 | 2 | — |

| Riveted joints, rivet spacing and pitch; | |||

| Tools used for riveting and dimpling; | |||

| Inspection of riveted joints. | |||

7.9 Pipes and Hoses | 1 | 2 | — |

| Bending and belling/flaring aircraft pipes; | |||

| Inspection and testing of aircraft pipes and hoses; | |||

| Installation and clamping of pipes. | |||

7.10 Springs | 1 | 2 | — |

| Inspection and testing of springs. | |||

7.11 Bearings | 1 | 2 | — |

| Testing, cleaning and inspection of bearings; | |||

| Lubrication requirements of bearings; | |||

| Defects in bearings and their causes. | |||

7.12 Transmissions | 1 | 2 | — |

| Inspection of gears, backlash; | |||

| Inspection of belts and pulleys, chains and sprockets; | |||

| Inspection of screw jacks, lever devices, push-pull rod systems. | |||

7.13 Control Cables | 1 | 2 | — |

| Swaging of end fittings; | |||

| Inspection and testing of control cables; | |||

| Bowden cables; aircraft flexible control systems. | |||

| 7.14 Material handling | |||

7.14.1 Sheet Metal | — | 2 | — |

| Marking out and calculation of bend allowance; | |||

| Sheet metal working, including bending and forming; | |||

| Inspection of sheet metal work. | |||

7.14.2 Composite and non-metallic | — | 2 | — |

| Bonding practices; | |||

| Environmental conditions | |||

| Inspection methods | |||

| 7.15 Welding, Brazing, Soldering and Bonding | |||

| (a) | — | 2 | 2 |

| Soldering methods; inspection of soldered joints. | |||

| (b) | — | 2 | — |

| Welding and brazing methods; | |||

| Inspection of welded and brazed joints; | |||

| Bonding methods and inspection of bonded joints. | |||

| 7.16 Aircraft Weight and Balance | |||

| (a) | — | 2 | 2 |

| Centre of Gravity/Balance limits calculation: use of relevant documents; | |||

| (b) | — | 2 | — |

| Preparation of aircraft for weighing; | |||

| Aircraft weighing; | |||

7.17 Aircraft Handling and Storage | 2 | 2 | 2 |

| Aircraft taxiing/towing and associated safety precautions; | |||

| Aircraft jacking, chocking, securing and associated safety precautions; | |||

| Aircraft storage methods; | |||

| Refuelling/defuelling procedures; | |||

| De-icing/anti-icing procedures; | |||

| Electrical, hydraulic and pneumatic ground supplies. | |||

| Effects of environmental conditions on aircraft handling and operation. | |||

| 7.18 Disassembly, Inspection, Repair and Assembly Techniques | |||

| (a) | 2 | 3 | 2 |

| Types of defects and visual inspection techniques. | |||

| Corrosion removal, assessment and reprotection. | |||

| (b) | — | 2 | — |

| General repair methods, Structural Repair Manual; | |||

| Ageing, fatigue and corrosion control programmes; | |||

| (c) | — | 2 | 1 |

| Non destructive inspection techniques including, penetrant, radiographic, eddy current, ultrasonic and boroscope methods. | |||

| (d) | 2 | 2 | 2 |

| Disassembly and re-assembly techniques. | |||

| (e) | — | 2 | 2 |

| Trouble shooting techniques | |||

| 7.19 Abnormal Events | |||

| (a) | 2 | 2 | 2 |

| Inspections following lightning strikes and HIRF penetration. | |||

| (b) | 2 | 2 | — |

| Inspections following abnormal events such as heavy landings and flight through turbulence. | |||

7.20 Maintenance Procedures | 1 | 2 | 2 |

| Maintenance planning; | |||

| Modification procedures; | |||

| Stores procedures; | |||

| Certification/release procedures; | |||

| Interface with aircraft operation; | |||

| Maintenance Inspection/Quality Control/Quality Assurance; | |||

| Additional maintenance procedures. | |||

| Control of life limited components | |||

MODULE 8. BASIC AERODYNAMICS

MODULE 9. HUMAN FACTORS

MODULE 10. AVIATION LEGISLATION

| Level | |||

|---|---|---|---|

| A | B1 | B2 | |

[F110.1 Regulatory FrameworkRole of International Civil Aviation Organisation; Role of the Member States and National Aviation Authorities; Role of EASA; Role of the European Commission; Relationship between Part-21, Part-M, Part-145, Part-66, Part-147 and EU-OPS | 1 | 1 | 1] |

10.2 Part-66 — Certifying Staff — Maintenance | 2 | 2 | 2 |

| Detailed understanding of Part-66. | |||

10.3 Part-145 — Approved Maintenance Organisations | 2 | 2 | 2 |

| Detailed understanding of Part-145. | |||

[F110.4 EU-OPSCommercial Air Transport/Commercial Operations Air Operators Certificates; Operators Responsibilities, in particular regarding continuing airworthiness and maintenance; Documents to be carried on board; Aircraft Placarding (Markings); | 1 | 1 | 1] |

| 10.5 Aircraft Certification | |||

(a) General | — | 1 | 1 |

| Certification rules: such as EACS 23/25/27/29; | |||

| Type Certification; | |||

| Supplemental Type Certification; | |||

| Part-21 Design/Production Organisation Approvals. | |||

(b) Documents | — | 2 | 2 |

| Certificate of Airworthiness; | |||

| Certificate of Registration; | |||

| Noise Certificate; | |||

| Weight Schedule; | |||

| Radio Station Licence and Approval. | |||

10.6 Part-M | 2 | 2 | 2 |

| Detailed understanding of Part-M. | |||

| 10.7 Applicable National and International Requirements for (if not superseded by EU requirements) | |||

| (a) | 1 | 2 | 2 |

| Maintenance Programmes, Maintenance checks and inspections; | |||

| Master Minimum Equipment Lists, Minimum Equipment List, Dispatch Deviation Lists; | |||

| Airworthiness Directives; | |||

| Service Bulletins, manufacturers service information; | |||

| Modifications and repairs; | |||

| Maintenance documentation: maintenance manuals, structural repair manual, illustrated parts catalogue, etc.; | |||

| (b) | — | 1 | 1 |

| Continuing airworthiness; | |||

| Test flights; | |||

| ETOPS, maintenance and dispatch requirements; | |||

| All Weather Operations, Category 2/3 operations and minimum equipment requirements. | |||

MODULE 11A. TURBINE AEROPLANE AERODYNAMICS, STRUCTURES AND SYSTEMS

MODULE 11B. PISTON AEROPLANE AERODYNAMICS, STRUCTURES AND SYSTEMS

MODULE 12. HELICOPTER AERODYNAMICS, STRUCTURES AND SYSTEMS

| Level | |||

|---|---|---|---|

| A3A4 | B1.3B1.4 | B2 | |

12.1 Theory of Flight — Rotary Wing Aerodynamics | 1 | 2 | — |

| Terminology; | |||

| Effects of gyroscopic precession; | |||

| Torque reaction and directional control; | |||

| Dissymmetry of lift, Blade tip stall; | |||

| Translating tendency and its correction; | |||

| Coriolis effect and compensation; | |||

| Vortex ring state, power settling, overpitching; | |||

| Auto-rotation; | |||

| Ground effect. | |||

12.2 Flight Control Systems | 2 | 3 | — |

| Cyclic control; | |||

| Collective control; | |||

| Swashplate; | |||

| Yaw control: Anti-Torque Control, Tail rotor, bleed air; | |||

| Main Rotor Head: Design and Operation features; | |||

| Blade Dampers: Function and construction; | |||

| Rotor Blades: Main and tail rotor blade construction and attachment; | |||

| Trim control, fixed and adjustable stabilisers; | |||

| System operation: manual, hydraulic, electrical and fly-by-wire; | |||

| Artificial feel; | |||

| Balancing and Rigging. | |||

12.3 Blade Tracking and Vibration Analysis | 1 | 3 | — |

| Rotor alignment; | |||

| Main and tail rotor tracking; | |||

| Static and dynamic balancing; | |||

| Vibration types, vibration reduction methods; | |||

| Ground resonance. | |||

[F112.4 TransmissionsGear boxes, main and tail rotors; Clutches, free wheel units and rotor brake. Tail rotor drive shafts, flexible couplings, bearings, vibration dampers and bearing hangers | 1 | 3 | —] |

| 12.5 Airframe Structures | |||

| (a) | 2 | 2 | — |

| Airworthiness requirements for structural strength; | |||

| Structural classification, primary, secondary and tertiary; | |||

| Fail safe, safe life, damage tolerance concepts; | |||

| Zonal and station identification systems; | |||

| Stress, strain, bending, compression, shear, torsion, tension, hoop stress, fatigue; | |||

| Drains and ventilation provisions; | |||

| System installation provisions; | |||

| Lightning strike protection provision. | |||

| (b) | 1 | 2 | — |

| Construction methods of: stressed skin fuselage, formers, stringers, longerons, bulkheads, frames, doublers, struts, ties, beams, floor structures, reinforcement, methods of skinning and anti-corrosive protection. | |||

| Pylon, stabiliser and undercarriage attachments; | |||

| Seat installation; | |||

| Doors: construction, mechanisms, operation and safety devices; | |||

| Windows and windscreen construction; | |||

| Fuel storage; | |||

| Firewalls; | |||

| Engine mounts; | |||

| Structure assembly techniques: riveting, bolting, bonding; | |||

| Methods of surface protection, such as chromating, anodising, painting; | |||

| Surface cleaning. | |||

| Airframe symmetry: methods of alignment and symmetry checks. | |||

| 12.6 Air Conditioning (ATA 21) | |||

12.6.1 Air supply | 1 | 2 | — |

| Sources of air supply including engine bleed and ground cart; | |||

12.6.2 Air Conditioning | 1 | 3 | — |

| Air conditioning systems; | |||

| Distribution systems; | |||

| Flow and temperature control systems; | |||

| Protection and warning devices. | |||

| 12.7 Instruments/Avionic Systems | |||

12.7.1 Instrument Systems (ATA 31) | 1 | 2 | — |

| Pitot static:altimeter, air speed indicator, vertical speed indicator; | |||

| Gyroscopic:artificial horizon, attitude director, direction indicator, horizontal situation indicator, turn and slip indicator, turn coordinator; | |||

| Compasses: direct reading, remote reading; | |||

| Vibration indicating systems — HUMS; | |||

| Other aircraft system indication. | |||

12.7.2 Avionic Systems | 1 | 1 | — |

| Fundamentals of system layouts and operation of: | |||

| Auto Flight (ATA 22); | |||

| Communications (ATA 23); | |||

| Navigation Systems (ATA 34). | |||

12.8 Electrical Power (ATA 24) | 1 | 3 | — |

| Batteries Installation and Operation; | |||

| DC power generation, AC power generation; | |||

| Emergency power generation; | |||

| Voltage regulation, Circuit protection. | |||

| Power distribution; | |||

| Inverters, transformers, rectifiers; | |||

| External/Ground power. | |||

| 12.9 Equipment and Furnishings (ATA 25) | |||

| (a) | 2 | 2 | — |

| Emergency equipment requirements; | |||

| Seats, harnesses and belts; | |||

| Lifting systems. | |||

| (b) | 1 | 1 | — |

| Emergency flotation systems; | |||

| Cabin lay-out, cargo retention; | |||

| Equipment lay-out; | |||

| Cabin Furnishing Installation. | |||

12.10 Fire Protection (ATA 26) | 1 | 3 | — |

| Fire and smoke detection and warning systems; | |||

| Fire extinguishing systems; | |||

| System tests. | |||

12.11 Fuel Systems (ATA 28) | 1 | 3 | — |

| System lay-out; | |||

| Fuel tanks; | |||

| Supply systems; | |||

| Dumping, venting and draining; | |||

| Cross-feed and transfer; | |||

| Indications and warnings; | |||

| Refuelling and defuelling. | |||

12.12 Hydraulic Power (ATA 29) | 1 | 3 | — |

| System lay-out; | |||

| Hydraulic fluids; | |||

| Hydraulic reservoirs and accumulators; | |||

| Pressure generation: electric, mechanical, pneumatic; | |||

| Emergency pressure generation; | |||

| Pressure Control; | |||

| Power distribution; | |||

| Indication and warning systems; | |||

| Interface with other systems. | |||

[F112.13 Ice and Rain Protection (ATA 30)Ice formation, classification and detection; Anti-icing and de-icing systems: electrical, hot air and chemical; Rain repellant and removal; Probe and drain heating. Wiper system | 1 | 3 | —] |

12.14 Landing Gear (ATA 32) | 2 | 3 | — |

| Construction, shock absorbing; | |||

| Extension and retraction systems: normal and emergency; | |||

| Indications and warning; | |||

| Wheels, tyres, brakes; | |||

| Steering; | |||

| Skids, floats. | |||

12.15 Lights (ATA 33) | 2 | 3 | — |

| External: navigation, landing, taxiing, ice; | |||

| Internal: cabin, cockpit, cargo; | |||

| Emergency. | |||

12.16 Pneumatic/Vacuum (ATA 36) | 1 | 3 | — |

| System lay-out; | |||

| Sources: engine, compressors, reservoirs, ground supply.; | |||

| Pressure control; | |||

| Distribution; | |||

| Indications and warnings; | |||

| Interfaces with other systems. | |||

MODULE 13. AIRCRAFT AERODYNAMICS, STRUCTURES AND SYSTEMS

MODULE 14 PROPULSION

MODULE 15. GAS TURBINE ENGINE

MODULE 16. PISTON ENGINE

MODULE 17. PROPELLER

Appendix IIBasic Examination Standard

1.Standardisation Basis For ExaminationsU.K.

1.1.All basic examinations must be carried out using the multi-choice question format and essay questions as specified below.U.K.

1.2.Each multi-choice question must have three alternative answers of which only one must be the correct answer and the candidate must be allowed a time per module which is based upon a nominal average of 75 seconds per question.U.K.

1.3.Each essay question requires the preparation of a written answer and the candidate must be allowed 20 minutes to answer each such question.U.K.

1.4.Suitable essay questions must be drafted and evaluated using the knowledge syllabus in Part-66 Appendix I Modules 7, 9 and 10.U.K.

1.5.Each question will have a model answer drafted for it, which will also include any known alternative answers that may be relevant for other subdivisions.U.K.

1.6.The model answer will also be broken down into a list of the important points known as Key Points.U.K.

1.7.The pass mark for each Part-66 module and sub-module multi-choice part of the examination is 75 %.U.K.

1.8.The pass mark for each essay question is 75 % in that the candidates answer must contain 75 % of the required key points addressed by the question and no significant error related to any required key point.U.K.

1.9.If either the multi-choice part only or the essay part only is failed, then it is only necessary to retake the multi-choice or essay part, as appropriate.U.K.

1.10.Penalty marking systems must not be used to determine whether a candidate has passed.U.K.

1.11.All Part-66 modules that make up a complete Part-66 aircraft maintenance licence category or subcategory must be passed within a 5 year time period of passing the first module except in the case specified in paragraph 1.12. A failed module may not be retaken for at least 90 days following the date of the failed module examination, except in the case of a Part-147 approved maintenance training organisation which conducts a course of retraining tailored to the failed subjects in the particular module when the failed module may be retaken after 30 days.U.K.

1.12.The 5 year time period specified in paragraph 1.11 does not apply to those modules which are common to more than one Part-66 aircraft maintenance licence category or subcategory and which were previously passed as part of another such category or subcategory examination.U.K.

2.Question Numbers for the Part-66 Appendix I ModulesU.K.

2.1.Subject Module 1 Mathematics:U.K.

Category A-16 multi-choice and 0 essay questions. Time allowed 20 minutes.

Category B1-30 multi-choice and 0 essay questions. Time allowed 40 minutes.

Category B2-30 multi-choice and 0 essay questions. Time allowed 40 minutes.

2.2.Subject Module 2 Physics:U.K.

Category A-30 multi-choice and 0 essay questions. Time allowed 40 minutes.

Category B1-50 multi-choice and 0 essay questions. Time allowed 65 minutes.

Category B2-50 multi-choice and 0 essay questions. Time allowed 65 minutes.

[F12.3. Subject Module 3 Electrical Fundamentals: U.K.

Category A-20 multi-choice and 0 essay questions. Time allowed 25 minutes.

Category B1-50 multi-choice and 0 essay questions. Time allowed 65 minutes.

Category B2-50 multi-choice and 0 essay questions. Time allowed 65 minutes.]

2.4.Subject Module 4 Electronic Fundamentals:U.K.

Category A-None.

Category B1-20 multi-choice and 0 essay questions. Time allowed 25 minutes.

Category B2-40 multi-choice and 0 essay questions. Time allowed 50 minutes.

2.5.Subject Module 5 Digital Techniques/Electronic Instrument Systems:U.K.

Category A-16 multi-choice and 0 essay questions. Time allowed 20 minutes.

Category B1.1 & B1.3-40 multi-choice and 0 essay questions. Time allowed 50 minutes.

Category B1.2 & B1.4-20 multi-choice and 0 essay questions. Time allowed 25 minutes.

Category B2-70 multi-choice and 0 essay questions. Time allowed 90 minutes.

2.6.Subject Module 6 Materials and Hardware:U.K.

Category A-50 multi-choice and 0 essay questions. Time allowed 65 minutes.

Category B1-70 multi-choice and 0 essay questions. Time allowed 90 minutes.

Category B2-60 multi-choice and 0 essay questions. Time allowed 75 minutes.

2.7.Subject Module 7 Maintenance Practices:U.K.

Category A-70 multi-choice and 2 essay questions. Time allowed 90 minutes plus 40 minutes.

Category B1-80 multi-choice and 2 essay questions. Time allowed 100 minutes plus 40 minutes.

Category B2-60 multi-choice and 2 essay questions. Time allowed 75 minutes plus 40 minutes.

2.8.Subject Module 8 Basic Aerodynamics:U.K.

Category A-20 multi-choice and 0 essay questions. Time allowed 25 minutes.

Category B1-20 multi-choice and 0 essay questions. Time allowed 25 minutes.

Category B2-20 multi-choice and 0 essay questions. Time allowed 25 minutes.

2.9.Subject Module 9 Human factors:U.K.

Category A-20 multi-choice and 1 essay question. Time allowed 25 minutes plus 20 minutes.

Category B1-20 multi-choice and 1 essay question. Time allowed 25 minutes plus 20 minutes.

Category B2-20 multi-choice and 1 essay question. Time allowed 25 minutes plus 20 minutes.

2.10.Subject Module 10 Aviation Legislation:U.K.

Category A-30 multi-choice and 1 essay question. Time allowed 40 minutes plus 20 minutes.

Category B1-40 multi-choice and 1 essay question. Time allowed 50 minutes plus 20 minutes.

Category B2-40 multi-choice and 1 essay question. Time allowed 50 minutes plus 20 minutes.

2.11.Subject Module 11a Turbine Aeroplane Aerodynamics, Structures and Systems:U.K.

Category A-100 multi-choice and 0 essay questions. Time allowed 125 minutes.

Category B1-130 multi-choice and 0 essay questions. Time allowed 165 minutes.

Category B2-None.

2.12.Subject Module 11b Piston Aeroplane Aerodynamics, Structures and Systems:U.K.

Category A-70 multi-choice and 0 essay questions. Time allowed 90 minutes.

Category B1-100 multi-choice and 0 essay questions. Time allowed 125 minutes.

Category B2-None.

2.13.Subject Module 12 Helicopter Aerodynamics, Structures and Systems:U.K.

Category A-90 multi-choice and 0 essay questions. Time allowed 115 minutes.

Category B1-115 multi-choice and 0 essay questions. Time allowed 145 minutes.

Category B2-None.

2.14.Subject Module 13 Aircraft Aerodynamics, Structures and Systems:U.K.

Category A-None.

Category B1-None.

Category B2-130 multi-choice and 0 essay questions. Time allowed 165 minutes.

2.15.Subject Module 14 Propulsion:U.K.

Category A-None.

Category B1-None.

Category B2-25 multi-choice and 0 essay questions. Time allowed 30 minutes.

2.16.Subject Module 15 Gas Turbine Engine:U.K.

Category A-60 multi-choice and 0 essay questions. Time allowed 75 minutes.

Category B1-90 multi-choice and 0 essay questions. Time allowed 115 minutes.

Category B2-None.

[F12.17. Subject Module 16 Piston Engine: U.K.

Category A-50 multi-choice and 0 essay questions. Time allowed 65 minutes.

Category B1-70 multi-choice and 0 essay questions. Time allowed 90 minutes.

Category B2-None.

2.18. Subject Module 17 Propeller: U.K.

Category A-20 multi-choice and 0 essay questions. Time allowed 25 minutes.

Category B1-30 multi-choice and 0 essay questions. Time allowed 40 minutes.

Category B2-None.]

Appendix IIIType training and Examination Standard

1.Type training levelsU.K.

The three levels listed below define the objectives that a particular level of training is intended to achieve.

Level 1General familiarisationU.K.

A brief overview of the airframe, systems and powerplants as outlined in the Systems Description Section of the Aircraft Maintenance Manual.

Course objectives: Upon completion of the course, the student will be able to identify safety precautions related to the airframe, its systems and powerplant

Identify maintenance practices important to the airframe, its systems and powerplant

Define the general layout of the aircraft's major systems

Define the general layout and characteristics of the powerplant

Identify special tooling and test equipment used with the aircraft

Level 2Ramp and transitU.K.

Basic system overview of controls, indicators, principal components including their location and purpose, servicing and minor troubleshooting.

Course objectives: In addition to the information contained in the Level 1 General Familiarisation course, at the completion of this Level 2 Ramp and Transit training, the student will be able to:

Recall the safety precautions to be observed when working on or near the aircraft, powerplant and systems.

Demonstrate knowledge of the main ramp and transit (through-flight) activities of the following:

Doors, windows and hatches.

Electrical power supplies.

Fuel.

Auxiliary power unit.

Powerplant.

Fire protection.

Environmental Control Systems.

Hydraulic power.

Landing gear.

Flight controls.

Water/waste.

Oxygen.

Flight and service interphone.

Avionics.

Cabin equipment/furnishings.

Describe systems and aircraft handling particularly access, power availability and sources.

Identify the locations of the principal components.

Explain the normal functioning of each major system, including terminology and nomenclature.

Perform the procedures for ramp and transit servicing associated with the aircraft for the following systems: Fuel, Power Plants, Hydraulics, Landing Gear, Water/Waste, Oxygen.

Demonstrate proficiency in use of crew reports and on-board reporting systems (minor troubleshooting) and determine aircraft airworthiness per the MEL/CDL.

Identify and use appropriate documentation.

Locate those procedures for replacement of components for ramp and transit activities identified in objective 2.

Level 3Line and base maintenance trainingU.K.

Detailed description, operation, component location, removal/installation and bite and troubleshooting procedures to maintenance manual level.

Course objectives: In addition to the information contained in Level 1 and Level 2 training, at the completion of Level III Line and Base Maintenance training, the student will be able to:

Perform system, engine, component and functional checks as specified in the maintenance manual.

Correlate information for the purpose of making decisions in respect of fault diagnosis and rectification to maintenance manual level.

Describe procedures for replacement of components unique to aircraft type.

2.Type training standardU.K.

Type training must include a theoretical and practical element.

2.1.Theoretical elementU.K.

As a minimum the elements in the Syllabus below that are specific to the aircraft type must be covered. Additional elements introduced due to technological changes shall also be included.

Training levels are those levels defined in paragraph 1 above.

After the first type course for category C certifying staff all subsequent courses need only be to level 1.

| Introduction Module Title | |

|---|---|

| General Aircraft(dimensions/weights MTOW etc) Time limits/maintenance checks Levelling and weighing Towing and taxiing Parking/mooring Servicing Standard practices-only type particular B2 module-safety items/mechanical interface B1 module-safety items/avionics interface |

| Aeroplanes turbine | Aeroplanes piston | Helicopters turbine | Helicopters piston | Avionics | |||||

|---|---|---|---|---|---|---|---|---|---|

| B1 | C | B1 | C | B1 | C | B1 | C | B2 | |

| Blade tracking and vibration analysis | — | — | — | — | 3 | 1 | 3 | 1 | — |

| Transmissions | — | — | — | — | 3 | 1 | 3 | 1 | — |

| Airframe structure | — | — | — | — | 3 | 1 | 3 | 1 | 1 |

| Main rotor | — | — | — | — | 3 | 1 | 3 | 1 | — |

| Tail rotor/rotor drive | — | — | — | — | 3 | 1 | 3 | 1 | — |

| Rotor flight control | — | — | — | — | 3 | 1 | 3 | 1 | — |

| Airframe Structure | 3 | 1 | 3 | 1 | — | — | — | — | 1 |

| Fuselage Doors | 3 | 1 | 3 | 1 | — | — | — | — | — |

| Fuselage | 3 | 1 | 3 | 1 | — | — | — | — | — |

| Fuselage Windows | 3 | 1 | 3 | 1 | — | — | — | — | — |

| Wings | 3 | 1 | 3 | 1 | — | — | — | — | — |

| Stabilisers | 3 | 1 | 3 | 1 | — | — | — | — | — |

| Flight Control Surfaces | 3 | 1 | 3 | 1 | — | — | — | — | — |

| Nacelles/Pylons | 3 | 1 | 3 | 1 | — | — | — | — | — |

| Zonal & Station Identification Systems | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Air Supply | 3 | 1 | 3 | 1 | 3 | 1 | 3 | 1 | 1 |

| Air Conditioning | 3 | 1 | 3 | 1 | 3 | 1 | 3 | 1 | 1 |

| Pressurisation | 3 | 1 | — | — | — | — | — | — | 1 |

| Safety & Warning Devices | 3 | 1 | — | — | — | — | — | — | 1 |

| Instrument Systems | 3 | 1 | 3 | 1 | 3 | 1 | 3 | 1 | 3 |

| Avionics Systems | 2 | 1 | 2 | 1 | 2 | 1 | 2 | 1 | 3 |

| Electrical Power | 3 | 1 | 3 | 1 | 3 | 1 | 3 | 1 | 3 |

| Equipment & Furnishings | 3 | 1 | 3 | 1 | 3 | 1 | 3 | 1 | — |

| Electronic Emergency Equip. Requir. & Cabin Entertainment Equipment | — | 1 | — | — | — | — | — | — | 3 |

| Fire Protection | 3 | 1 | 3 | 1 | 3 | 1 | 3 | 1 | 1 |

| Flight Controls | 3 | 1 | 3 | 1 | 3 | 1 | 3 | 1 | 2 |

| Sys. Operation: Electrical/Fly-by-Wire | 3 | 1 | — | — | — | — | — | — | 3 |

| Fuel Systems | 3 | 1 | 3 | 1 | 3 | 1 | 3 | 1 | 1 |

| Hydraulic Power | 3 | 1 | 3 | 1 | 3 | 1 | 3 | 1 | 1 |

| Ice & Rain Protection | 3 | 1 | 3 | 1 | 3 | 1 | 3 | 1 | 1 |

| Landing Gear | 3 | 1 | 3 | 1 | 3 | 1 | 3 | 1 | 1 |

| Lights | 3 | 1 | 3 | 1 | 3 | 1 | 3 | 1 | 3 |

| Oxygen | 3 | 1 | 3 | 1 | — | — | — | — | 1 |

| Pneumatic/Vacuum | 3 | 1 | 3 | 1 | 3 | 1 | 3 | 1 | 1 |

| Water/Waste | 3 | 1 | 3 | 1 | — | — | — | — | 1 |

| On-board Maintenance Systems | 3 | 1 | 3 | 1 | — | — | — | — | 3 |

| Turbine Engines: | |||||||||

| Constructional arrangement and operation | — | — | — | — | — | — | — | — | 1 |

| Engine Performance | 3 | 1 | — | — | 3 | 1 | — | — | 1 |

| Inlet | 3 | 1 | — | — | 3 | 1 | — | — | — |

| Compressors | 3 | 1 | — | — | 3 | 1 | — | — | — |

| Combustion Section | 3 | 1 | — | — | 3 | 1 | — | — | — |

| Turbine Section | 3 | 1 | — | — | 3 | 1 | — | — | — |

| Exhaust | 3 | 1 | — | — | 3 | 1 | — | — | — |

| Bearings and Seals | 3 | 1 | — | — | 3 | 1 | — | — | — |

| Lubricants and Fuels | 3 | 1 | — | — | 3 | 1 | — | — | — |

| Lubrication Systems | 3 | 1 | — | — | 3 | 1 | — | — | — |

| Fuel Systems | 3 | 1 | — | — | 3 | 1 | — | — | 1 |

| Engine controls | 3 | 1 | — | — | 3 | 1 | — | — | 1 |

| FADEC | 2 | 1 | — | — | 2 | 1 | — | — | 3 |

| Air Systems | 3 | 1 | — | — | 3 | 1 | — | — | — |

| Starting & Ignition Systems | 3 | 1 | — | — | 3 | 1 | — | — | — |

| Engine Indicating Systems | 3 | 1 | — | — | 3 | 1 | — | — | 3 |

| Power Augmentation Systems | 3 | 1 | — | — | — | — | — | — | — |

| Turbo-prop Engines | 3 | 1 | — | — | — | — | — | — | — |

| Turbo-shaft Engines | — | — | — | — | 3 | 1 | — | — | — |

| Auxiliary Power Units (APUs) | 3 | 1 | — | — | — | — | — | — | 1 |

| Powerplant Installation | 3 | 1 | — | — | 3 | 1 | — | — | — |

| Fire Protection Systems | 3 | 1 | — | — | 3 | 1 | — | — | 1 |

| Engine Monitoring and Ground Operation | 3 | 1 | — | — | 3 | 1 | — | — | — |

| Engine Storage and Preservation | 3 | 1 | — | — | 3 | 1 | — | — | — |

| Piston Engines: | |||||||||

| Engine Performance | — | — | 3 | 1 | — | — | 3 | 1 | 1 |

| Engine Construction | — | — | 3 | 1 | — | — | 3 | 1 | 1 |

| Engine Fuel Systems | — | — | 3 | 1 | — | — | 3 | 1 | 1 |

| Carburettors | — | — | 3 | 1 | — | — | 3 | 1 | — |

| Fuel injection systems | — | — | 3 | 1 | — | — | 3 | 1 | — |

| Engine controls | 3 | 1 | — | — | 3 | 1 | — | — | 1 |

| FADEC | — | — | 2 | 1 | — | — | 2 | 1 | 3 |

| Starting and Ignition Systems | — | — | 3 | 1 | — | — | 3 | 1 | — |

| Induction, Exhaust and Cooling Systems | — | — | 3 | 1 | — | — | 3 | 1 | — |

| Supercharging/Turbocharging | — | — | 3 | 1 | — | — | 3 | 1 | — |

| Lubricants and Fuels | — | — | 3 | 1 | — | — | 3 | 1 | — |

| Lubrication Systems | — | — | 3 | 1 | — | — | 3 | 1 | — |

| Engine Indication Systems | — | — | 3 | 1 | — | — | 3 | 1 | 3 |

| Powerplant Installation | — | — | 3 | 1 | — | — | 3 | 1 | — |

| Engine Monitoring and Ground Operation | — | — | 3 | 1 | — | — | 3 | 1 | — |

| Engine Storage and Preservation | — | — | 3 | 1 | — | — | 3 | 1 | — |

| Propellers: | |||||||||

| Propeller — General | 3 | 1 | 3 | 1 | — | — | — | — | 1 |

| Propeller Construction | 3 | 1 | 3 | 1 | — | — | — | — | — |

| Propeller Pitch Control | 3 | 1 | 3 | 1 | — | — | — | — | — |

| Propeller Synchronising | 3 | 1 | 3 | 1 | — | — | — | — | — |

| Propeller Electronic control | 2 | 1 | 2 | 1 | — | — | — | — | 3 |

| Propeller Ice Protection | 3 | 1 | 3 | 1 | — | — | — | — | — |

| Propeller Maintenance | 3 | 1 | 3 | 1 | — | — | — | — | — |

2.2.Practical elementU.K.

The practical training element must consist of the performance of representative maintenance tasks and their assessment, in order to meet the following objectives:

Ensure safe performance of maintenance, inspections and routine work according to the maintenance manual and other relevant instructions and tasks as appropriate for the type of aircraft, for example troubleshooting, repairs, adjustments, replacements, rigging and functional checks such as engine run, etc, if required.

Correctly use all technical literature and documentation for the aircraft.

Correctly use specialist/special tooling and test equipment, perform removal and replacement of components and modules unique to type, including any on-wing maintenance activity.

3.Type training examination standardU.K.

Where aircraft type training is required, the examination must be written and comply with the following:

Format of the examination is of the multiple-choice type. Each multiple-choice question must have three alternative answers of which only one must be the correct answer. The time for answering is based upon a nominal average of 120 seconds per level 3 question and 75 seconds per level 1 or 2 question.

The examination must be of the closed book type. No reference material is permitted. An exception will be made for the case of examining a B1 or B2 candidate's ability to interpret technical documents.

The number of questions must be at least one question per hour of instruction subject to a minimum of two questions per Syllabus subject. The competent authority of the Member State will assess number and level of questions on a sampling basis when approving the course.

The examination pass mark is 75 %.

Penalty marking is not to be used to determine whether a candidate has passed.

End of module phase examinations cannot be used as part of the final examination unless they contain the correct number and level of questions required.

4.Type examination standardU.K.

Where type training is not required, the examination must be oral, written or practical assessment based, or a combination thereof.

Oral examination questions must be open.

Written examination questions must be essay type or multiple-choice questions.

Practical assessment must determine a person's competence to perform a task.

Examination subjects must be on a sample of subjects drawn from paragraph 2 type training/examination syllabus, at the indicated level.

The examination must ensure that the following objectives are met:

Properly discuss with confidence the aircraft and its systems.

Ensure safe performance of maintenance, inspections and routine work according to the maintenance manual and other relevant instructions and tasks as appropriate for the type of aircraft, for example troubleshooting, repairs, adjustments, replacements, rigging and functional checks such as engine run, etc, if required.

Correctly use all technical literature and documentation for the aircraft.

Correctly use specialist/special tooling and test equipment, perform removal and replacement of components and modules unique to type, including any on-wing maintenance activity.

A written report must be made by the examiner to explain why the candidate has passed or failed.

Appendix IVExperience requirements for extending a Part-66 Aircraft Maintenance Licence

The table below shows the experience requirements for adding a new category or subcategory to an existing Part-66 licence.

The experience must be practical maintenance experience on operating aircraft in the subcategory relevant to the application.

The experience requirement will be reduced by 50 % if the applicant has completed an approved Part-147 course relevant to the subcategory.

| To:From: | A1 | A2 | A3 | A4 | B1.1 | B1.2 | B1.3 | B1.4 | B2 |

|---|---|---|---|---|---|---|---|---|---|

| A1 | 6 months | 6 months | 6 months | 2 years | 6 months | 2 years | 1 year | 2 years | |

| A2 | 6 months | 6 months | 6 months | 2 years | 6 months | 2 years | 1 year | 2 years | |

| A3 | 6 months | 6 months | 6 months | 2 years | 1 year | 2 years | 6 months | 2 years | |

| A4 | 6 months | 6 months | 6 months | 2 years | 1 year | 2 years | 6 months | 2 years | |

| B1.1 | None | 6 months | 6 months | 6 months | 6 months | 6 months | 6 months | 1 year | |

| B1.2 | 6 months | None | 6 months | 6 months | 2 years | 2 years | 6 months | 2 years | |

| B1.3 | 6 months | 6 months | None | 6 months | 6 months | 6 months | 6 months | 1 year | |

| B1.4 | 6 months | 6 months | 6 months | None | 2 years | 6 months | 2 years | 2 years | |

| B2 | 6 months | 6 months | 6 months | 6 months | 1 year | 1 year | 1 year | 1 year |

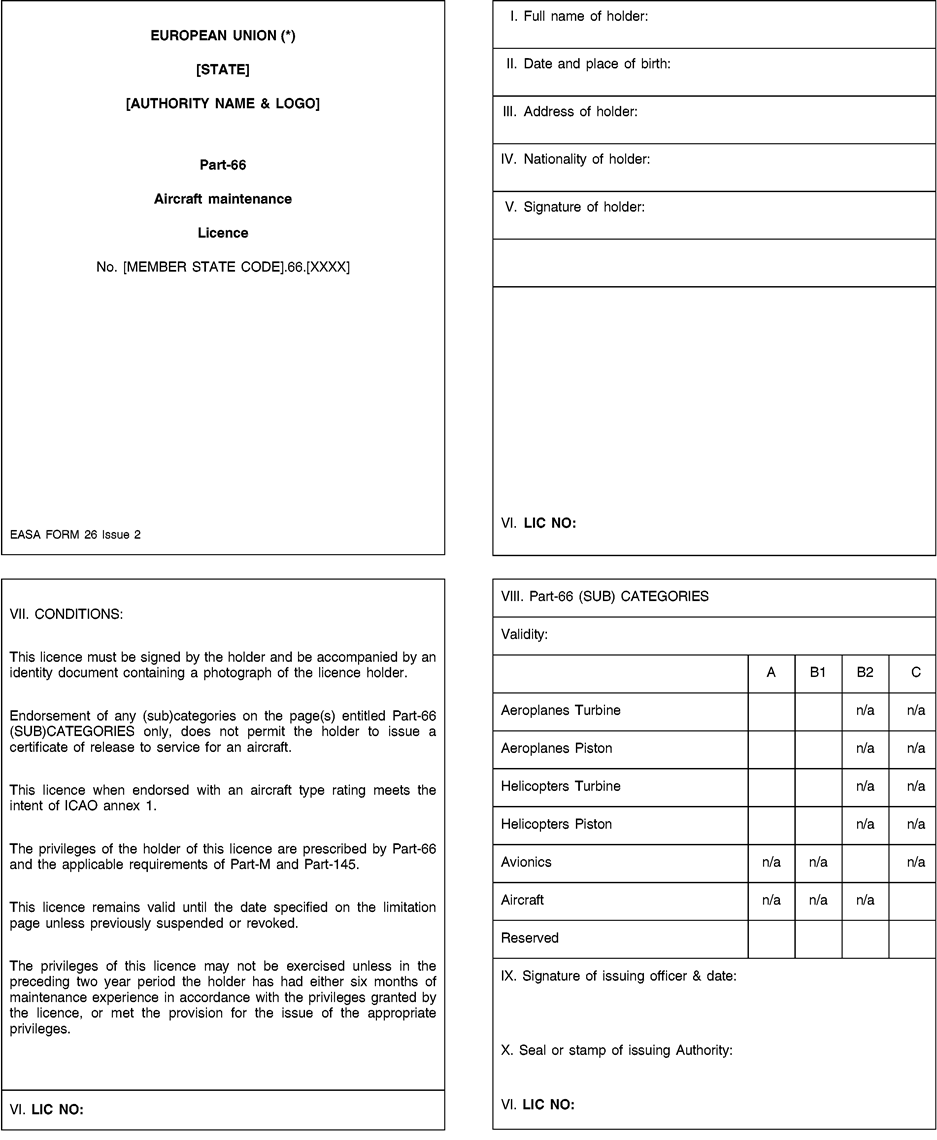

[F1Appendix V

Application Form — EASA Form 19 U.K.

1. This appendix contains an example of the form used for application for the aircraft maintenance licence referred to in Annex III (Part-66). U.K.

2. The competent authority of the Member State may modify the EASA Form 19 only to include additional information necessary to support the case where the National requirements permit or require the aircraft maintenance licence issued in accordance with Annex III (Part-66) to be used outside the requirement of Annex II (Part-145) for non-commercial air transport purposes.] U.K.

[F3Appendix VI

Textual Amendments

F3 Inserted by Commission Regulation (EU) No 127/2010 of 5 February 2010 amending Regulation (EC) No 2042/2003 on the continuing airworthiness of aircraft and aeronautical products, parts and appliances, and on the approval of organisations and personnel involved in these tasks (Text with EEA relevance).