- Latest available (Revised)

- Original (As adopted by EU)

Regulation (EC) No 1222/2009 of the European Parliament and of the CouncilShow full title

Regulation (EC) No 1222/2009 of the European Parliament and of the Council of 25 November 2009 on the labelling of tyres with respect to fuel efficiency and other essential parameters (Text with EEA relevance)

You are here:

- Regulations originating from the EU

- 2009 No. 1222

- Annexes only

- Show Geographical Extent(e.g. England, Wales, Scotland and Northern Ireland)

- Show Timeline of Changes

More Resources

Revised version PDFs

- Revised 26/07/20190.67 MB

- Revised 30/05/20121.46 MB

- Revised 29/03/20110.60 MB

When the UK left the EU, legislation.gov.uk published EU legislation that had been published by the EU up to IP completion day (31 December 2020 11.00 p.m.). On legislation.gov.uk, these items of legislation are kept up-to-date with any amendments made by the UK since then.

This item of legislation originated from the EU

Legislation.gov.uk publishes the UK version. EUR-Lex publishes the EU version. The EU Exit Web Archive holds a snapshot of EUR-Lex’s version from IP completion day (31 December 2020 11.00 p.m.).

Changes to legislation:

There are currently no known outstanding effects by UK legislation for Regulation (EC) No 1222/2009 of the European Parliament and of the Council.![]()

Changes to Legislation

Revised legislation carried on this site may not be fully up to date. At the current time any known changes or effects made by subsequent legislation have been applied to the text of the legislation you are viewing by the editorial team. Please see ‘Frequently Asked Questions’ for details regarding the timescales for which new effects are identified and recorded on this site.

ANNEX IU.K.GRADING OF TYRE PARAMETERS

Part A: Fuel efficiency classesU.K.

[F1The fuel efficiency class must be determined on the basis of the rolling resistance coefficient ( RRC ) according to the ‘A’ to ‘G’ scale specified below and measured in accordance with Annex 6 of UNECE Regulation No 117 and its subsequent amendments and aligned according to the procedure laid down in Annex IVa.]

Textual Amendments

F1Substituted by Commission Regulation (EU) No 1235/2011 of 29 November 2011 amending Regulation (EC) No 1222/2009 of the European Parliament and of the Council with regard to the wet grip grading of tyres, the measurement of rolling resistance and the verification procedure (Text with EEA relevance).

If a tyre type is approved for more than one tyre class (e.g. C1 and C2), the grading scale used to determine the fuel efficiency class of this tyre type should be that which is applicable to the highest tyre class (e.g. C2, not C1).

| C1 tyres | C2 tyres | C3 tyres | |||

|---|---|---|---|---|---|

| RRC in kg/t | Energy efficiency class | RRC in kg/t | Energy efficiency class | RRC in kg/t | Energy efficiency class |

| RRC ≤ 6,5 | A | RRC ≤ 5,5 | A | RRC ≤ 4,0 | A |

| 6,6 ≤ RRC ≤ 7,7 | B | 5,6 ≤ RRC ≤ 6,7 | B | 4,1 ≤ RRC ≤ 5,0 | B |

| 7,8 ≤ RRC ≤ 9,0 | C | 6,8 ≤ RRC ≤ 8,0 | C | 5,1 ≤ RRC ≤ 6,0 | C |

| Empty | D | Empty | D | 6,1 ≤ RRC ≤ 7,0 | D |

| 9,1 ≤ RRC ≤ 10,5 | E | 8,1 ≤ RRC ≤ 9,2 | E | 7,1 ≤ RRC ≤ 8,0 | E |

| 10,6 ≤ RRC ≤ 12,0 | F | 9,3 ≤ RRC ≤ 10,5 | F | RRC ≥ 8,1 | F |

| RRC ≥ 12,1 | G | RRC ≥ 10,6 | G | Empty | G |

Part B: Wet grip classesU.K.

[F11. The wet grip class of C1 tyres must be determined on the basis of the wet grip index ( G ) according to the ‘A’ to ‘G’ scale specified in the table below, calculated in accordance with point 3 and measured in accordance with Annex V. U.K.

2. The wet grip class of C2 and C3 tyres must be determined on the basis of the wet grip index ( G ) according to the ‘A’ to ‘G’ scale specified in the table below, calculated in accordance with point (3) and measured in accordance with ISO 15222:2011 whereby the following Standard Reference Test Tyres (SRTT) must be used: U.K.

for C2 tyres, the SRTT 225/75 R 16 C, ASTM F 2872-11;

for C3 tyres having Nominal Section Width lower than 285 mm, the SRTT 245/70R19.5, ASTM F 2871-11;

for C3 tyres having Nominal Section Width greater than or equal to 285 mm, the SRTT 315/70R22.5, ASTM F 2870-11.

3. Calculation of wet grip index (G) U.K.

G = G(T) – 0,03

where: G(T) = wet grip index of the candidate tyre as measured in one test cycle

| C1 tyres | C2 tyres | C3 tyres | |||

|---|---|---|---|---|---|

| G | Wet grip class | G | Wet grip class | G | Wet grip class |

| 1,55 ≤ G | A | 1,40 ≤ G | A | 1,25 ≤ G | A |

| 1,40 ≤ G ≤ 1,54 | B | 1,25 ≤ G ≤ 1,39 | B | 1,10 ≤ G ≤ 1,24 | B |

| 1,25 ≤ G ≤ 1,39 | C | 1,10 ≤ G ≤ 1,24 | C | 0,95 ≤ G ≤ 1,09 | C |

| Empty | D | Empty | D | 0,80 ≤ G ≤ 0,94 | D |

| 1,10 ≤ G ≤ 1,24 | E | 0,95 ≤ G ≤ 1,09 | E | 0,65 ≤ G ≤ 0,79 | E |

| G ≤ 1,09 | F | G ≤ 0,94 | F | G ≤ 0,64 | F |

| Empty | G | Empty | G | Empty | G] |

Part C: External rolling noise classes and measured valueU.K.

The external rolling noise measured value (N) must be declared in decibels and calculated in accordance with UNECE Regulation No 117 and its subsequent amendments.

The external rolling noise class must be determined on the basis of the limit values (LV) set out in Part C of Annex II of Regulation (EC) No 661/2009 as follows.

ANNEX IIU.K.FORMAT OF THE LABEL

1.Label designU.K.

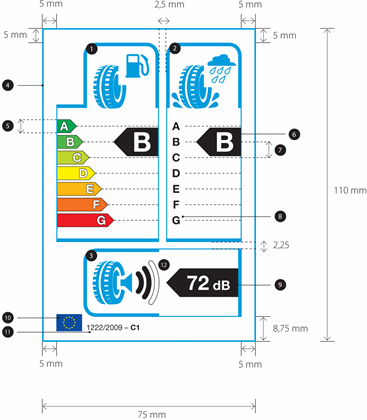

1.1.The label referred to in Articles 4(1) and 5(1) must be in accordance with the illustration below:U.K.

1.2.The following provides specifications for the label:U.K.

1.3.The label must be at least 75 mm wide and 110 mm high. Where the label is printed in a larger format, its content must nevertheless remain proportionate to the specifications above.U.K.

1.4.

The label must conform to the following requirements:U.K.

Colours are CMYK – cyan, magenta, yellow and black – and are given following this example: 00-70-X-00: 0 % cyan, 70 % magenta, 100 % yellow, 0 % black;

The numbers listed below refer to the legends indicated in point 1.2:

Fuel efficiency

Pictogram as supplied: width: 19,5 mm, height: 18,5 mm – Frame for pictogram: stroke: 3,5 pt, width: 26 mm, height: 23 mm – Frame for grading: stroke: 1 pt – Frame end: stroke: 3,5 pt, width: 36 mm – Colour: X-10-00-05;

Wet grip

Pictogram as supplied: width: 19 mm, height: 19 mm – Frame for pictogram: stroke: 3,5 pt, width: 26 mm, height: 23 mm – Frame for grading: stroke: 1 pt – Frame end: stroke: 3,5 pt, width: 26 mm – Colour: X-10-00-05;

External rolling noise

Pictogram as supplied: width: 14 mm, height: 15 mm – Frame for pictogram: stroke: 3,5 pt, width: 26 mm, height: 24 mm – Frame for value: stroke: 1 pt – Frame end: stroke: 3,5 pt, height: 24 mm – Colour: X-10-00-05;

Label border: stroke: 1,5 pt – Colour: X-10-00-05;

‘A’ to ‘G’ scale

Arrows: height: 4,75 mm, gap: 0,75 mm, black stroke: 0,5 pt – colours:

A: X-00-X-00;

B: 70-00-X-00;

C: 30-00-X-00

D: 00-00-X-00;

E: 00-30-X-00

F: 00-70-X-00;

G: 00-X-X-00.

Text: Helvetica Bold 12 pt, 100 % white, black outline: 0,5 pt;

Grading

Arrow: width: 16 mm, height: 10 mm, 100 % black;

Text: Helvetica Bold 27 pt, 100 % white;

Lines in scale: stroke: 0,5 pt, dashed line interval: 5,5 mm, 100 % black;

Scale text: Helvetica Bold 11 pt, 100 % black;

External rolling noise measured value

Arrow: width: 25,25 mm, height: 10 mm, 100 % black;

Text: Helvetica Bold 20 pt, 100 % white;

Unit text: Helvetica Bold 13 pt, 100 % white;

EU logo: width: 9 mm, height: 6 mm;

Regulation reference: Helvetica Regular 7,5 pt, 100 % black;

Tyre class reference: Helvetica Bold 7,5 pt, 100 % black;

External rolling noise class as supplied in part C of Annex I: width: 8,25 mm, height: 15,5 mm – 100 % black

The background must be white.

1.5.The tyre class (C1 or C2) must be indicated on the label in the format prescribed in the illustration in point 1.2.U.K.

2.StickerU.K.

2.1.The sticker referred to in Articles 4(1) and 5(1) consists of two parts: (i) a label printed in the format described in point 1 of this Annex and (ii) a brand space printed in accordance with the specifications described in point 2.2 of this Annex.U.K.

2.2.Brand space: Suppliers must add their trade name or trade mark, the tyre line, tyre dimension, load index, speed rating and other technical specifications on the sticker along with the label, in any colour, format and design, provided that this does not detract from or disrupt the message on the label defined in point 1 of this Annex. The total surface of the sticker shall not exceed 250 cm2 and the total height of the sticker shall not exceed 220 mm.U.K.

ANNEX IIIU.K.Information provided in technical promotional material

1.Information on tyres must be provided in the order specified as follows:U.K.

the fuel efficiency class (letter ‘A’ to ‘G’);

the wet grip class (letter ‘A’ to ‘G’);

the external rolling noise class and measured value (dB).

2.The information provided in point 1 must meet the following requirements:U.K.

be easy to read;

be easy to understand;

if different grading is available for a given tyre type depending on dimension or other parameters, the range between the least and best performing tyre is stated.

3.Suppliers must also make the following available on their websites:U.K.

a link to the relevant [F2United Kingdom Government] webpage dedicated to this Regulation;

an explanation of the pictograms printed on the label;

a statement highlighting the fact that actual fuel savings and road safety depend heavily on the behaviour of drivers, and in particular the following:

eco-driving can significantly reduce fuel consumption,

tyre pressure should be regularly checked to optimise wet grip and fuel efficiency performance,

stopping distances should always be strictly respected,

Textual Amendments

F2Words in Annex 3 para. 3(i) substituted (31.12.2020) by The Motor Vehicle Tyres (Labelling) (Enforcement) (Amendment) (EU Exit) Regulations 2020 (S.I. 2020/1509), regs. 1(3), 18(9)

[F1ANNEX IVU.K. Verification procedure

The conformity of the declared fuel efficiency and wet grip classes, as well as the declared external rolling noise class and declared value, must be assessed for each tyre type or each grouping of tyres as determined by the supplier, according to one of the following procedures:

a single tyre or tyre set is tested first. If the measured values meet the declared classes or external rolling noise declared value to within the tolerance defined in Table 1, the test is successfully passed; and

if the measured values do not meet the declared classes or external rolling noise declared value within the range defined in Table 1, three more tyres or tyre sets are tested. The average measurement value stemming from the three tyres or tyre sets tested is used to assess conformity with the declared information within the range defined in Table 1; or

where the labelled classes or values are derived from type approval test results obtained in accordance with Directive 2001/43/EC, Regulation (EC) No 661/2009, or UNECE Regulation No 117 and its subsequent amendments, [F3the Secretary of State] may make use of measurement data obtained from conformity of production tests on tyres.

Textual Amendments

F3Words in Annex 4 substituted (31.12.2020) by The Motor Vehicle Tyres (Labelling) (Enforcement) (Amendment) (EU Exit) Regulations 2020 (S.I. 2020/1509), regs. 1(3), 18(10)

Assessment of the measurement data obtained from the conformity of production tests must take into account the allowances defined in Table 1.

Table 1

| Measured parameter | Verification tolerances |

|---|---|

| Rolling resistance coefficient (fuel efficiency) | The aligned measured value shall not be greater than the upper limit (the highest RRC ) of the declared class by more than 0,3 kg/ 1 000 kg. |

| External rolling noise | The measured value shall not be greater than the declared value of N by more than 1 dB(A). |

| Wet grip | The measured value shall not be lower than the lower limit (the lowest value of G ) of the declared class.] |

[F4ANNEX IVa U.K. Laboratory alignment procedure for the measurement of rolling resistance

Textual Amendments

F4 Inserted by Commission Regulation (EU) No 1235/2011 of 29 November 2011 amending Regulation (EC) No 1222/2009 of the European Parliament and of the Council with regard to the wet grip grading of tyres, the measurement of rolling resistance and the verification procedure (Text with EEA relevance).

1. DEFINITIONS U.K.

For the purpose of the laboratory alignment procedure, the following definitions apply:

‘Reference laboratory’ means a laboratory that is part of the network of laboratories the references of which have been published for the purpose of the alignment procedure in the Official Journal of the European Union , and is able to achieve the accuracy of test results determined in section 3;

‘ Candidate laboratory ’ means a laboratory participating in the alignment procedure that is not a reference laboratory;

‘ Alignment tyre ’ means a tyre that is tested for the purpose of performing the alignment procedure;

‘ Alignment tyres set ’ means a set of five or more alignment tyres;

‘ Assigned value ’ means a theoretical value of one alignment tyre as measured by a theoretical laboratory which is representative of the network of reference laboratories that is used for the alignment procedure.

2. GENERAL PROVISIONS U.K.

2.1. Principle U.K.

The measured Rolling Resistance Coefficient ( RRC m ) in a reference laboratory ( l ) shall be aligned to the assigned values of the network of reference laboratories.

The RRC m in a candidate laboratory ( c ) shall be aligned through one reference laboratory of the network of its choice.

2.2. Tyre selection requirements U.K.

A set of five or more alignment tyres shall be selected for the alignment procedure in compliance with the criteria below. One set shall be selected for C1 and C2 tyres together, and one set for C3 tyres.

The set of alignment tyres shall be selected so as to cover the range of different RRCs of C1 and C2 tyres together, or of C3 tyres. In any event, the difference between the highest RRC m of the tyre set, and the lowest RRC m of the tyre set shall be at least equal to:

3 kg/t for C1 and C2 tyres; and

2 kg/t for C3 tyres.

The RRC m in the candidate or reference laboratories ( c or l) based on declared RRC values of each alignment tyre of the set shall be spaced out as follows and distributed uniformly:

1,0 +/– 0,5 kg/t for C1 and C2 tyres; and

1,0 +/– 0,5 kg/t for C3 tyres.

The selected tyre section width of each alignment tyre shall be:

≤ 245 mm for machines measuring C1 and C2 tyres; and

≤ 385 mm for machines measuring C3 tyres.

The selected tyre outer diameter of each alignment tyre shall be:

between 510 to 800 mm for machines measuring C1 and C2 tyres; and

between 771 to 1 143 mm for machines measuring C3 tyres.

Load index values shall adequately cover the range of the tyres to be tested, ensuring that the rolling resistance force (RRF) values also cover the range of the tyres to be tested.

Each alignment tyre shall be checked prior to use and replaced when:

it shows a condition which makes it unusable for further tests; and/or

there are deviations of RRC m greater than 1,5 per cent relative to earlier measurements after correction for any machine drift.

2.3. Measurement method U.K.

The reference laboratory shall measure each alignment tyre four times and retain the three last results for further analysis, in accordance with paragraph 4 of Annex 6 of UNECE Regulation No 117 and its subsequent amendments and applying the conditions set out in paragraph 3 of Annex 6 of UNECE Regulation No 117 and its subsequent amendments.

The candidate laboratory shall measure each alignment tyre (n + 1) times with n being specified in section 5 and retain the n last results for further analysis, in accordance with paragraph 4 of Annex 6 of UNECE Regulation No 117 and its subsequent amendments and applying the conditions set out in paragraph 3 of Annex 6 of UNECE Regulation No 117 and its subsequent amendments.

Each time an alignment tyre is measured, the tyre/wheel assembly shall be removed from the machine and the entire test procedure specified in paragraph 4 of Annex 6 of UNECE Regulation No 117 and its subsequent amendments shall be followed again from the start.

The candidate or reference laboratory shall calculate:

the measured value of each alignment tyre for each measurement as specified in Annex 6, paragraphs 6.2 and 6.3, of UNECE Regulation No 117 and its subsequent amendments (i.e. corrected for a temperature of 25 °C and a drum diameter of 2 m);

the mean value of the three (in the case of reference laboratories) or n (in the case of candidate laboratories) last measured values of each alignment tyre; and

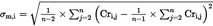

the standard deviation (σ m ) as follows:

where:

is the counter from 1 to p for the number of alignment tyres

is the counter from 2 to n for the number of repetitions of each measurement for a given alignment tyre

is the number of repetitions of tyre measurements (n ≥4)

is the number of alignment tyres (p ≥ 5)

2.4. Data formats to be used for the computations and results U.K.

The measured RRC values corrected from drum diameter and temperature shall be rounded to 2 decimal places.

Then the computations shall be made with all digits: there shall be no further rounding except on the final alignment equations.

All standard deviation values shall be displayed to 3 decimal places.

All RRC values will be displayed to 2 decimal places.

All alignment coefficients (A1 l , B1 l , A2 c and B2 c ) shall be rounded and displayed to 4 decimal places.

3. REQUIREMENTS APPLICABLE TO THE REFERENCE LABORATORIES AND DETERMINATION OF THE ASSIGNED VALUES U.K.

The assigned values of each alignment tyre shall be determined by a network of reference laboratories. After two years the network shall assess the stability and validity of the assigned values.

Each reference laboratory participating in the network shall comply with the specifications of Annex 6 of UNECE Regulation No 117 and its subsequent amendments and have a standard deviation (σ m ) as follows:

not greater than 0,05 kg/t for class C1 and C2 tyres; and

not greater than 0,05 kg/t for class C3 tyres.

The sets of alignment tyres, conforming to the specification of section 2.2 shall be measured in accordance with section 2.3 by each reference laboratory of the network.

The assigned value of each alignment tyre is the average of the measured values given by the reference laboratories of the network for this alignment tyre.

4. PROCEDURE FOR THE ALIGNMENT OF A REFERENCE LABORATORY TO THE ASSIGNED VALUES U.K.

Each reference laboratory ( l ) shall align itself to the assigned values of the alignment tyre set using a linear regression technique, A1 l and B1 l , calculated as follows:

RRC = A1 l * RRC m,l + B1 l

where:

is the assigned value of the rolling resistance coefficient;

is the measured value of the rolling resistance coefficient by the reference laboratory ‘ l ’ (including temperature and drum diameter corrections)

5. REQUIREMENTS APPLICABLE TO CANDIDATE LABORATORIES U.K.

Candidate laboratories shall repeat the alignment procedure at least once every two years and always after any significant machine change or any drift in machine control tyre monitoring data.

A common set of five different tyres, conforming to the specification of section 2.2 shall be measured in accordance with section 2.3 by the candidate laboratory and by one reference laboratory. More than five alignment tyres may be tested at the request of the candidate laboratory.

The alignment tyre set shall be provided by the candidate laboratory to the selected reference laboratory.

The candidate laboratory ( c ) shall comply with the specifications of Annex 6 of UNECE Regulation No 117 and its subsequent amendments and preferably have standard deviations ( σ m ) as follows:

not greater than 0,075 kg/t for C1 and C2 tyres; and

not greater than 0,06 kg/t for C3 tyres.

If the standard deviations (σ m ) of the candidate laboratory are higher than the above values with three measurements, then the number of measurement repetitions shall be increased as follows:

n = ( σ m / γ ) 2 , rounded up to the nearest higher integer value

where:

=

0,043 kg/t for Class C1 and C2 tyres

=

0,035 kg/t for Class C3 tyres

6. PROCEDURE FOR THE ALIGNMENT OF A CANDIDATE LABORATORY U.K.

One reference laboratory ( l ) of the network shall calculate the linear regression function of the candidate laboratory ( c ), A2 c and B2 c , as follows:

RRC m,l = A2 c × RRC m,c + B2 c

where:

is the measured value of the rolling resistance coefficient by the reference laboratory ( l ) (including temperature and drum diameter corrections)

is the measured value of the rolling resistance coefficient by the candidate laboratory ( c ) (including temperature and drum diameter corrections)

The aligned RRC of tyres tested by the candidate laboratory is calculated as follows:

RRC = (A1 l × A2 c ) × RRC m,c + (A1 l × B2 c + B1 l )]

[F5ANNEX V U.K. Testing method for measuring the wet grip index (G) of C1 tyres

Textual Amendments

1. MANDATORY STANDARDS U.K.

The following documents listed apply.

ASTM E 303-93 (Reapproved 2008), Standard Test Method for Measuring Surface Frictional Properties Using the British Pendulum Tester;

ASTM E 501-08, Standard Specification for Standard Rib Tire for Pavement Skid-Resistance Tests;

ASTM E 965-96 (Reapproved 2006), Standard Test Method for Measuring Pavement Macrotexture Depth Using a Volumetric Technique;

ASTM E 1136-93 (Reapproved 2003), Standard Specification for a Radial Standard Reference Test Tire (SRTT14″);

ASTM F 2493-08, Standard Specification for a Radial Standard Reference Test Tire (SRTT16″).

2. DEFINITIONS U.K.

For the purposes of testing wet grip of C1 tyres, the following definitions apply:

‘ test run ’ means a single pass of a loaded tyre over a given test track surface;

‘ test tyre(s) ’ means a candidate tyre, a reference tyre or a control tyre or tyre set that is used in a test run;

‘candidate tyre(s) (T) ’ means a tyre or a tyre set that is tested for the purpose of calculating its wet grip index;

‘reference tyre(s) (R) ’ means a tyre or a tyre set that has the characteristics indicated in ASTM F 2493-08 and referred to as Standard Reference Test Tyre 16 inches (SRTT16″);

‘control tyre(s) (C) ’ means an intermediate tyre or a set of intermediate tyres which is used when the candidate tyre and the reference tyre cannot be directly compared on the same vehicle;

‘ braking force of a tyre ’ means the longitudinal force, expressed in newton, resulting from braking torque application;

‘braking force coefficient of a tyre (BFC) ’ means the ratio of the braking force to the vertical load;

‘ peak braking force coefficient of a tyre ’ means the maximum value of a tyre braking force coefficient that occurs prior to wheel lockup as the braking torque is progressively increased;

‘ lockup of a wheel ’ means the condition of a wheel in which its rotational velocity about the wheel spin axis is zero and it is prevented from rotating in the presence of applied wheel torque;

‘ vertical load ’ means the load in newton imposed on the tyre perpendicular to the road surface;

‘ tyre test vehicle ’ means a dedicated special purpose vehicle which has instruments to measure the vertical and the longitudinal forces on one test tyre during braking.

3. GENERAL TEST CONDITIONS U.K.

3.1 Track characteristics U.K.

The test track shall have the following characteristics:

The surface shall have a dense asphalt surface with a uniform gradient of not more than 2 % and shall not deviate more than 6 mm when tested with a 3 m straight edge.

The surface shall have a pavement of uniform age, composition, and wear. The test surface shall be free of loose material and foreign deposits.

The maximum chipping size shall be 10 mm (tolerances permitted from 8 mm to 13 mm).

The texture depth as measured by a sand patch shall be 0,7 ± 0,3 mm. It shall be measured in accordance with ASTM E 965-96 (Reapproved 2006).

The wetted frictional properties of the surface shall be measured with either method (a) or (b) in section 3.2.

3.2 Methods to measure the wetted frictional properties of the surface U.K.

(a) British Pendulum Number (BPN) method U.K.

The British Pendulum Number method shall be as defined in ASTM E 303-93 (Reapproved in 2008).

Pad rubber component formulation and physical properties shall be as specified in ASTM E 501-08.

The averaged British Pendulum Number (BPN) shall be between 42 and 60 BPN after temperature correction as follows.

BPN shall be corrected by the wetted road surface temperature. Unless temperature correction recommendations are indicated by the British pendulum manufacturer, the following formula is used:

BPN = BPN (measured value) + temperature correction

temperature correction = – 0,0018 t 2 + 0,34 t – 6,1

where t is the wetted road surface temperature in degrees Celsius.

Effects of slider pad wear: The pad shall be removed for maximum wear when the wear on the striking edge of the slider reaches 3,2 mm in the plane of the slider or 1,6 mm vertical to it in accordance with section 5.2.2 and Figure 3 of ASTM E 303-93 (Reapproved 2008).

For the purpose of checking track surface BPN consistency for the measurement of wet grip on an instrumented passenger car: the BPN values of the test track should not vary over the entire stopping distance so as to decrease the dispersion of test results. The wetted frictional properties of the surface shall be measured five times at each point of the BPN measurement every 10 meters and the coefficient of variation of the averaged BPN shall not exceed 10 %.

(b) ASTM E 1136 Standard Reference Test Tyre (SRTT14″) method U.K.

By derogation with point (4) of section 2, this method uses the reference tyre that has the characteristics indicated in ASTM E 1136-93 (Reapproved 2003) and referred to as SRTT14″ (1) .

The average peak braking force coefficient ( μ peak,ave ) of the SRTT14″ shall be 0,7 ± 0,1 at 65 km/h.

The average peak braking force coefficient ( μ peak,ave ) of the SRTT14″ shall be corrected by the wetted road surface temperature as follows:

peak braking force coefficient ( μ peak,ave ) = peak braking force coefficient (measured) + temperature correction

temperature correction = 0,0035 × ( t – 20)

where t is the wetted road surface temperature in degrees Celsius.

3.3 Atmospheric conditions U.K.

The wind conditions shall not interfere with wetting of the surface (wind-shields are allowed).

Both the wetted surface temperature and the ambient temperature shall be between 2 °C and 20 °C for snow tyres and 5 °C and 35 °C for normal tyres.

The wetted surface temperature shall not vary during the test by more than 10 °C.

The ambient temperature must remain close to the wetted surface temperature; the difference between the ambient and the wetted surface temperatures must be less than 10 °C.

4. TESTING METHODS FOR MEASURING WET GRIP U.K.

For the calculation of the wet grip index (G) of a candidate tyre, the wet grip braking performance of the candidate tyre is compared to the wet grip braking performance of the reference tyre on a vehicle travelling straight ahead on a wet, paved surface. It is measured with one of the following methods:

vehicle method consisting of testing a set of tyres mounted on an instrumented passenger car,

testing method using a trailer towed by a vehicle or a tyre test vehicle, equipped with the test tyre(s).

4.1 Testing method using an instrumented passenger car U.K.

4.1.1 Principle U.K.

The testing method covers a procedure for measuring the deceleration performance of C1 tyres during braking, using an instrumented passenger car equipped with an Antilock Braking System (ABS), where ‘ instrumented passenger car ’ means a passenger car that is fitted with the measuring equipment listed in section 4.1.2.2 for the purpose of this testing method. Starting with a defined initial speed, the brakes are applied hard enough on four wheels at the same time to activate the ABS. The average deceleration is calculated between two pre-defined speeds.

4.1.2 Equipment U.K.

4.1.2.1 Vehicle U.K.

Permitted modifications on the passenger car are as follows:

those allowing the number of tyre sizes that can be mounted on the vehicle to be increased,

those permitting automatic activation of the braking device to be installed.

Any other modification of the braking system is prohibited.

4.1.2.2 Measuring equipment U.K.

The vehicle shall be fitted with a sensor suitable for measuring speed on a wet surface and distance covered between two speeds.

To measure vehicle speed, a fifth wheel or non-contact speed-measuring system shall be used.

4.1.3 Conditioning of the test track and wetting condition U.K.

The test track surface shall be watered at least half an hour prior to testing in order to equalise the surface temperature and water temperature. External watering should be supplied continuously throughout testing. For the whole testing area, the water depth shall be 1,0 ± 0,5 mm, measured from the peak of the pavement.

The test track should then be conditioned by conducting at least 10 test runs with tyres not involved in the test programme at 90 km/h.

4.1.4 Tyres and rims U.K.

4.1.4.1 Tyre preparation and break-in U.K.

The test tyres shall be trimmed to remove all protuberances on the tread surface caused by mould air vents or flashes at mould junctions.

The test tyres shall be mounted on the test rim declared by the tyre manufacturer.

A proper bead seat should be achieved by the use of a suitable lubricant. Excessive use of lubricant should be avoided to prevent slipping of the tyre on the wheel rim.

The test tyres/rim assemblies shall be stored in a location for a minimum of two hours such that they all have the same ambient temperature prior to testing. They should be shielded from the sun to avoid excessive heating by solar radiation.

For tyre break-in, two braking runs shall be performed.

4.1.4.2 Tyre load U.K.

The static load on each axle tyre shall lie between 60 % and 90 % of the tested tyre load capacity. Tyre loads on the same axle should not differ by more than 10 %.

4.1.4.3 Tyre inflation pressure U.K.

On the front and rear axles, the inflation pressures shall be 220 kPa (for standard- and extra-load tyres). The tyre pressure should be checked just prior to testing at ambient temperature and adjusted if required.

4.1.5 Procedure U.K.

4.1.5.1 Test run U.K.

The following test procedure applies for each test run:

The passenger car is driven in a straight line up to 85 ± 2 km/h.

Once the passenger car has reached 85 ± 2 km/h, the brakes are always activated at the same place on the test track referred to as ‘ braking starting point ’ , with a longitudinal tolerance of 5 m and a transverse tolerance of 0,5 m.

The brakes are activated either automatically or manually.

The automatic activation of the brakes is performed by means of a detection system made of two parts, one indexed to the test track and one on board the passenger car.

The manual activation of the brakes depends on the type of transmission as follows. In both cases, a minimum of 600 N pedal efforts is required.

For manual transmission, the driver should release the clutch and depress the brake pedal sharply, holding it down as long as necessary to perform the measurement.

For automatic transmission, the driver should select neutral gear and then depress the brake pedal sharply, holding it down as long as necessary to perform the measurement.

The average deceleration is calculated between 80 km/h and 20 km/h.

If any of the specifications listed above (including speed tolerance, longitudinal and transverse tolerance for the braking starting point, and braking time) are not met when a test run is made, the measurement is discarded and a new test run is made.

4.1.5.2 Test cycle U.K.

A number of test runs are made in order to measure the wet grip index of a set of candidate tyres (T) according to the following procedure, whereby each test run shall be made in the same direction and up to three different sets of candidate tyres may be measured within the same test cycle:

First, the set of reference tyres are mounted on the instrumented passenger car.

After at least three valid measurements have been made in accordance with section 4.1.5.1, the set of reference tyres is replaced by a set of candidate tyres.

After six valid measurements of the candidate tyres are performed, two more sets of candidate tyres may be measured.

The test cycle is closed by three more valid measurements of the same set of reference tyres as at the beginning of the test cycle.

EXAMPLES: U.K.

The run order for a test cycle of three sets of candidate tyres (T1 to T3) plus a set of reference tyres (R) would be the following:

R-T1-T2-T3-R

The run order for a test cycle of five sets of candidate tyres (T1 to T5) plus a set of reference tyres (R) would be the following:

R-T1-T2-T3-R-T4-T5-R

4.1.6 Processing of measurement results U.K.

4.1.6.1 Calculation of the average deceleration ( AD ) U.K.

The average deceleration ( AD ) is calculated for each valid test run in m·s – 2 as follows:

where:

S f is the final speed in m·s – 1 ; S f = 20 km/h = 5,556 m·s – 1

S i is the initial speed in m·s – 1 ; S i = 80 km/h = 22,222 m·s – 1

d is the distance covered in m between S i and S f .

4.1.6.2 Validation of results U.K.

The AD coefficient of variation is calculated as follows:

(Standard Deviation / Average) × 100

:

If the AD coefficient of variation of any two consecutive groups of three test runs of the reference tyre set is higher than 3 %, all data should be discarded and the test repeated for all test tyres (the candidate tyres and the reference tyres).

:

The AD coefficients of variation are calculated for each candidate tyre set. If one coefficient of variation is higher than 3 %, the data should be discarded and the test repeated for that candidate tyre set.

4.1.6.3 Calculation of adjusted average deceleration ( Ra ) U.K.

The average deceleration ( AD ) of the reference tyre set used for the calculation of its braking force coefficient is adjusted according to the positioning of each candidate tyre set in a given test cycle.

This adjusted AD of the reference tyre ( Ra ) is calculated in m·s –2 in accordance with table 1 where R 1 is the average of the AD values in the first test of the reference tyre set (R) and R 2 is the average of the AD values in the second test of the same reference tyre set (R).

Table 1

| Number of sets of candidate tyres within one test cycle | Set of candidate tyres | Ra |

|---|---|---|

| 1 ( R 1 -T1- R 2 ) | T1 | Ra = 1/2 ( R 1 + R 2 ) |

| 2 ( R 1 -T1-T2- R 2 ) | T1 | Ra = 2/3 R 1 + 1/3 R 2 |

| T2 | Ra = 1/3 R 1 + 2/3 R 2 | |

| 3 ( R 1 -T1-T2-T3- R 2 ) | T1 | Ra = 3/4 R 1 + 1/4 R 2 |

| T2 | Ra = 1/2 ( R 1 + R 2 ) | |

| T3 | Ra = 1/4 R 1 + 3/4 R 2 |

4.1.6.4 Calculation of the braking force coefficient (BFC) U.K.

The braking force coefficient ( BFC ) is calculated for a braking on the two axles according to Table 2 where Ta ( a = 1, 2 or 3) is the average of the AD values for each candidate tyre ( T ) set that is part of a test cycle.

Table 2

| g is the acceleration due to gravity, g = 9,81 m·s -2 | |

| Test Tyre | Braking force coefficient |

|---|---|

| Reference tyre | BFC(R) = | Ra/g | |

| Candidate tyre | BFC(T) = | Ta/g | |

4.1.6.5 Calculation of the wet grip index of the candidate tyre U.K.

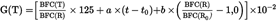

The wet grip index of the candidate tyre ( G(T) ) is calculated as follows:

where:

t is the measured wet surface temperature in degree Celsius when the candidate tyre ( T ) is tested

t 0 is the wet surface reference temperature condition, t 0 = 20 °C for normal tyres and t 0 = 10 °C for snow tyres

BFC(R 0 ) is the braking force coefficient for the reference tyre in the reference conditions, BFC(R 0 ) = 0,68

a = – 0,4232 and b = – 8,297 for normal tyres, a = 0,7721 and b = 31,18 for snow tyres

4.1.7 Wet grip performance comparison between a candidate tyre and a reference tyre using a control tyre U.K.

4.1.7.1 General U.K.

Where the candidate tyre size is significantly different from that of the reference tyre, a direct comparison on the same instrumented passenger car may not be possible. This testing method uses an intermediate tyre, hereinafter called the control tyre as defined in point 5 of section 2.

4.1.7.2 Principle of the approach U.K.

The principle is the use of a control tyre set and two different instrumented passenger cars for the test cycle of a candidate tyre set in comparison with a reference tyre set.

One instrumented passenger car is fitted with the reference tyre set followed by the control tyre set, the other with the control tyre set followed by the candidate tyre set.

The specifications listed in sections 4.1.2 to 4.1.4 apply.

The first test cycle is a comparison between the control tyre set and the reference tyre set.

The second test cycle is a comparison between the candidate tyre set and the control tyre set. It is done on the same test track and during the same day as the first test cycle. The wetted surface temperature shall be within ± 5 °C of the temperature of the first test cycle. The same control tyre set shall be used for the first and the second test cycles.

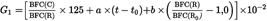

The wet grip index of the candidate tyre ( G(T)) is calculated as follows:

G(T) = G 1 × G 2

where:

G 1 is the relative wet grip index of the control tyre (C) compared to the reference tyre (R) calculated as follows:

G 2 is the relative wet grip index of the candidate tyre (T) compared to the control tyre (C) calculated as follows:

4.1.7.3 Storage and preservation U.K.

It is necessary that all the tyres of a control tyre set have been stored in the same conditions. As soon as the control tyre set has been tested in comparison with the reference tyre, the specific storage conditions defined in ASTM E 1136-93 (Reapproved 2003) shall be applied.

4.1.7.4 Replacement of reference tyres and control tyres U.K.

When irregular wear or damage results from tests, or when wear influences the test results, the use of the tyre shall be discontinued.

4.2 Testing method using a trailer towed by a vehicle or a tyre test vehicle U.K.

4.2.1 Principle U.K.

The measurements are conducted on test tyres mounted on a trailer towed by a vehicle (hereafter referred to as tow vehicle) or on a tyre test vehicle. The brake in the test position is applied firmly until sufficient braking torque is generated to produce the maximum braking force that will occur prior to wheel lockup at a test speed of 65 km/h.

4.2.2 Equipment U.K.

4.2.2.1 Tow vehicle and trailer or tyre test vehicle U.K.

The tow vehicle or the tyre test vehicle shall have the capability of maintaining the specified speed of 65 ± 2 km/h even under the maximum braking forces.

The trailer or the tyre test vehicle shall be equipped with one place where the tyre can be fitted for measurement purposes hereafter called ‘ test position ’ and the following accessories:

(i)equipment to activate brakes in the test position;

(ii)a water tank to store sufficient water to supply the road surface wetting system, unless external watering is used;

(iii)recording equipment to record signals from transducers installed at the test position and to monitor water application rate if the self-watering option is used.

The maximum variation of toe-settings and camber angle for the test position shall be within ± 0,5 ° with maximum vertical load. Suspension arms and bushings shall have sufficient rigidity necessary to minimise free play and ensure compliance under application of maximum braking forces. The suspension system shall provide adequate load-carrying capacity and be of such a design as to isolate suspension resonance.

The test position shall be equipped with a typical or special automotive brake system which can apply sufficient braking torque to produce the maximum value of braking test wheel longitudinal force at the conditions specified.

The brake application system shall be able to control the time interval between initial brake application and peak longitudinal force as specified in section 4.2.7.1.

The trailer or the tyre test vehicle shall be designed to accommodate the range of candidate tyre sizes to be tested.

The trailer or the tyre test vehicle shall have provisions for adjustment of vertical load as specified in section 4.2.5.2.

4.2.2.2 Measuring equipment U.K.

The test wheel position on the trailer or the tyre test vehicle shall be equipped with a rotational wheel velocity measuring system and with transducers to measure the braking force and vertical load at the test wheel.

General requirements for measurement system: The instrumentation system shall conform to the following overall requirements at ambient temperatures between 0 °C and 45 °C:

(i)overall system accuracy, force: ± 1,5 % of the full scale of the vertical load or braking force;

(ii)overall system accuracy, speed: ± 1,5 % of speed or ± 1,0 km/h, whichever is greater.

Vehicle speed: To measure vehicle speed, a fifth wheel or non-contact precision speed-measuring system should be used.

Braking forces: The braking force-measuring transducers shall measure longitudinal force generated at the tyre–road interface as a result of brake application within a range from 0 % to at least 125 % of the applied vertical load. The transducer design and location shall minimise inertial effects and vibration-induced mechanical resonance.

Vertical load: The vertical load-measuring transducer shall measure the vertical load at the test position during brake application. The transducer shall have the same specifications as described previously.

Signal conditioning and recording system: All signal conditioning and recording equipment shall provide linear output with necessary gain and data reading resolution to meet the specified previous requirements. In addition, the following requirements apply:

(i)The minimum frequency response shall be flat from 0 Hz to 50 Hz (100 Hz) within ± 1 % full scale.

(ii)The signal-to-noise ratio shall be at least 20/1.

(iii)The gain shall be sufficient to permit full-scale display for full-scale input signal level.

(iv)The input impedance shall be at least 10 times larger than the output impedance of the signal source.

(v)The equipment shall be insensitive to vibrations, acceleration, and changes in ambient temperature.

4.2.3 Conditioning of the test track U.K.

The test track should be conditioned by conducting at least ten test runs with tyres not involved in the test program at 65 ± 2 km/h.

4.2.4 Wetting conditions U.K.

The tow vehicle and trailer or the tyre test vehicle may be optionally equipped with a pavement-wetting system, less the storage tank, which, in the case of the trailer, is mounted on the tow vehicle. The water being applied to the pavement ahead of the test tyres shall be supplied by a nozzle suitably designed to ensure that the water layer encountered by the test tyre has a uniform cross section at the test speed with a minimum splash and overspray.

The nozzle configuration and position shall ensure that the water jets are directed towards the test tyre and pointed towards the pavement at an angle of 20° to 30°.

The water shall strike the pavement 0,25 m to 0,45 m ahead of the centre of tyre contact. The nozzle shall be located 25 mm above the pavement or at the minimum height required to clear obstacles which the tester is expected to encounter, but in no case more than 100 mm above the pavement.

The water layer shall be at least 25 mm wider than the test tyre tread and applied so the tyre is centrally located between the edges. Water delivery rate shall ensure a water depth of 1,0 ± 0,5 mm and shall be consistent throughout the test to within ± 10 per cent. The volume of water per unit of wetted width shall be directly proportional to the test speed. The quantity of water applied at 65 km/h shall be 18 l·s -1 per meter of width of wetted surface in case of a water depth of 1,0 mm.

4.2.5 Tyres and rims U.K.

4.2.5.1 Tyre preparation and break-in U.K.

The test tyres shall be trimmed to remove all protuberances on the tread surface caused by mould air vents or flashes at mould junctions.

The test tyre shall be mounted on the test rim declared by the tyre manufacturer.

A proper bead seat should be achieved by the use of a suitable lubricant. Excessive use of lubricant should be avoided to prevent slipping of the tyre on the wheel rim.

The test tyres/rim assemblies shall be stored in a location for a minimum of two hours such that they all have the same ambient temperature prior to testing. They should be shielded from the sun to avoid excessive heating by solar radiation.

For tyre break-in, two braking runs shall be performed under the load, pressure and speed as specified in 4.2.5.2, 4.2.5.3 and 4.2.7.1 respectively.

4.2.5.2 Tyre load U.K.

The test load on the test tyre is 75 ± 5 % of the test tyre load capacity.

4.2.5.3 Tyre inflation pressure U.K.

The test tyre cold inflation pressure shall be 180 kPa for standard-load tyres. For extra-load tyres, the cold inflation pressure shall be 220 kPa.

The tyre pressure should be checked just prior to testing at ambient temperature and adjusted if required.

4.2.6 Preparation of the tow vehicle and trailer or the tyre test vehicle U.K.

4.2.6.1 Trailer U.K.

For one axle trailers, the hitch height and transverse position shall be adjusted once the test tyre has been loaded to the specified test load in order to avoid any disturbance of the measuring results. The longitudinal distance from the centre line of the articulation point of the coupling to the transverse centre line of the axle of the trailer shall be at least 10 times the ‘ hitch height ’ or the ‘ coupling (hitch) height ’ .

4.2.6.2 Instrumentation and equipment U.K.

Install the fifth wheel, when used, in accordance with the manufacturer’s specifications and locate it as near as possible to the mid-track position of the tow trailer or the tyre test vehicle.

4.2.7 Procedure U.K.

4.2.7.1 Test run U.K.

The following procedure applies for each test run:

The tow vehicle or the tyre test vehicle is driven onto the test track in a straight line at the specified test speed 65 ± 2 km/h.

The recording system is launched.

Water is delivered to the pavement ahead of the test tyre approximately 0,5 s prior to brake application (for internal watering system).

The trailer brakes are activated within 2 metres of a measurement point of the wetted frictional properties of the surface and sand depth in accordance with points 4 and 5 of section 3.1. The rate of braking application shall be such that the time interval between initial application of force and peak longitudinal force is in the range 0,2 s to 0,5 s.

The recording system is stopped.

4.2.7.2 Test cycle U.K.

A number of test runs are made in order to measure the wet grip index of the candidate tyre (T) according to the following procedure, whereby each test run shall be made at the same spot on the test track and in the same direction. Up to three candidate tyres may be measured within the same test cycle, provided that the tests are completed within one day.

First, the reference tyre is tested.

After at least six valid measurements are performed in accordance with section 4.2.7.1, the reference tyre is replaced by the candidate tyre.

After six valid measurements of the candidate tyre are performed, two more candidate tyres may be measured.

The test cycle is closed by six more valid measurements of the same reference tyre as at the beginning of the test cycle.

EXAMPLES: U.K.

The run order for a test cycle of three candidate tyres (T1 to T3) plus the reference tyre (R) would be the following:

R-T1-T2-T3-R

The run order for a test cycle of five candidate tyres (T1 to T5) plus the reference tyre R would be the following:

R-T1-T2-T3-R-T4-T5-R

4.2.8 Processing of measurement results U.K.

4.2.8.1 Calculation of the peak braking force coefficient U.K.

The tyre peak braking force coefficient ( μ peak ) is the highest value of μ(t) before lockup occurs calculated as follows for each test run. Analogue signals should be filtered to remove noise. Digitally recorded signals must be filtered using a moving average technique.

where:

μ(t) is the dynamic tyre braking force coefficient in real time;

fh(t) is the dynamic braking force in real time, in N;

fv(t) is the dynamic vertical load in real time, in N.

4.2.8.2 Validation of results U.K.

The μ peak coefficient of variation is calculated as follows:

(Standard Deviation / Average) x 100

:

If the coefficient of variation of the peak braking force coefficient ( μ peak ) of the reference tyre is higher than 5 %, all data should be discarded and the test repeated for all test tyres (the candidate tyre(s) and the reference tyre).

:

The coefficient of variation of the peak braking force coefficient ( μ peak ) is calculated for each candidate tyre. If one coefficient of variation is higher than 5 %, the data should be discarded and the test repeated for this candidate tyre.

4.2.8.3 Calculation of the adjusted average peak braking force coefficient U.K.

The average peak braking force coefficient of the reference tyre used for the calculation of its braking force coefficient is adjusted according to the positioning of each candidate tyre in a given test cycle.

This adjusted average peak braking force coefficient of the reference tyre ( Ra ) is calculated in accordance with table 3 where R 1 is the average peak tyre braking coefficient in the first test of the reference tyre (R) and R 2 is the average peak tyre braking coefficient in the second test of the same reference tyre (R).

Table 3

| Number of candidate tyre(s) within one test cycle | Candidate tyre | Ra |

|---|---|---|

| 1 ( R 1 -T1- R 2 ) | T1 | Ra = 1/2 ( R 1 + R 2 ) |

| 2 ( R 1 -T1-T2- R 2 ) | T1 | Ra = 2/3 R 1 + 1/3 R 2 |

| T2 | Ra = 1/3 R 1 + 2/3 R 2 | |

| 3 ( R 1 -T1-T2-T3- R 2 ) | T1 | Ra = 3/4 R 1 + 1/4 R 2 |

| T2 | Ra = 1/2 ( R 1 + R 2 ) | |

| T3 | Ra = 1/4 R 1 + 3/4 R 2 |

4.2.8.4 Calculation of the average peak braking force coefficient ( μ peak,ave ) U.K.

The average value of the peak braking force coefficients ( μ peak,ave ) is calculated according to table 4 whereby Ta ( a = 1, 2 or 3) is the average of the peak braking force coefficients measured for one candidate tyre within one test cycle.

Table 4

| Test tyre | μ peak,ave |

| Reference tyre | μ peak,ave (R) = Ra as per Table 3 |

| Candidate tyre | μ peak,ave (T) = Ta |

4.2.8.5 Calculation of the wet grip index of the candidate tyre U.K.

The wet grip index of the candidate tyre ( G(T) ) is calculated as follows:

where:

t is the measured wet surface temperature in degree Celsius when the candidate tyre ( T ) is tested

t 0 is the wet surface reference temperature condition

t 0 = 20 °C for normal tyres t 0 = 10 °C for snow tyres

μ peak,ave (R 0 ) = 0,85 is the peak braking force coefficient for the reference tyre in the reference conditions

a = – 0,4232 and b = - 8,297 for normal tyres, a = 0,7721 and b = 31,18 for snow tyres.

Appendix A

Test reports examples of wet grip index U.K.

EXAMPLE 1: Test report of wet grip index using trailer method U.K.

| Test report number: | Test date: | |

| Type of road surface: | Texture depth (mm): | |

| μ peak (SRTT14″ E 1136): | BPN: | |

| Speed (km/h): | Water depth (mm): |

| No | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Size | |||||||||||

| Service description | |||||||||||

| Tyre identification | |||||||||||

| Rim | |||||||||||

| Pattern | |||||||||||

| Load (N) | |||||||||||

| Pressure (kPa) | |||||||||||

| μ peak | 1 | ||||||||||

| 2 | |||||||||||

| 3 | |||||||||||

| 4 | |||||||||||

| 5 | |||||||||||

| 6 | |||||||||||

| 7 | |||||||||||

| 8 | |||||||||||

| Average | |||||||||||

| Standard deviation σ | |||||||||||

| (σ/average) ≤ 5 % | |||||||||||

| Ra, Adjusted | |||||||||||

| Wet grip index | |||||||||||

| Surface temp. (°C) | |||||||||||

| Ambient temp. (°C) | |||||||||||

| Remarks | |||||||||||

EXAMPLE 2: Test report of wet grip index using passenger car method U.K.

| Driver: | Test date: | ||||

| Track: | Passenger Car: | Initial speed (km/h): | |||

| Texture depth (mm): | Brand: | Final speed (km/h): | |||

| BPN: | Model: | ||||

| Water depth (mm): | Type | ||||

| No | 1 | 2 | 3 | 4 | 5 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Brand | Uniroyal | TYRE B | TYRE C | TYRE D | Uniroyal | ||||||

| Pattern | ASTM F 2493 SRTT16″ | PATTERN B | PATTERN C | PATTERN D | ASTM F 2493 SRTT16″ | ||||||

| Size | P225/60R16 | SIZE B | SIZE C | SIZE D | P225/60R16 | ||||||

| Service description | 97S | LI/SS | LI/SS | LI/SS | 97S | ||||||

| Tyre identification | XXXXXXXXX | YYYYYYYYY | ZZZZZZZZZ | NNNNNNNNN | XXXXXXXXX | ||||||

| Rim | |||||||||||

| Front axle pressure (kPa) | |||||||||||

| Rear axle pressure (kPa) | |||||||||||

| Front axle load (N) | |||||||||||

| Wet surface temp (°C) | |||||||||||

| Ambient temp (°C) | |||||||||||

| Braking distance (m) | Average deceleration (m/s 2 ) | Braking distance (m) | Average deceleration (m/s 2 ) | Braking distance (m) | Average deceleration (m/s 2 ) | Braking distance (m) | Average deceleration (m/s 2 ) | Braking distance (m) | Average deceleration (m/s 2 ) | ||

| Measurement | 1 | ||||||||||

| 2 | |||||||||||

| 3 | |||||||||||

| 4 | |||||||||||

| 5 | |||||||||||

| 6 | |||||||||||

| 7 | |||||||||||

| 8 | |||||||||||

| 9 | |||||||||||

| 10 | |||||||||||

| Average AD (m/s 2 ) | |||||||||||

| Standard deviation (m/s 2 ) | |||||||||||

| Validation of results Coeff. of variation (%) < 3 % | |||||||||||

| Adjusted average AD of ref. tyre: R a (m/s 2 ) | |||||||||||

| BFC (R) reference tyre (SRTT16″) | |||||||||||

| BFC (T) candidate tyre | |||||||||||

| Wet grip index (%) | ] | ||||||||||

[F5The size of the ASTM E 1136 SRTT is P195/75R14.]

Options/Help

Print Options

PrintThe Whole Regulation

PrintThe Annexes only

Legislation is available in different versions:

Latest Available (revised):The latest available updated version of the legislation incorporating changes made by subsequent legislation and applied by our editorial team. Changes we have not yet applied to the text, can be found in the ‘Changes to Legislation’ area.

Original (As adopted by EU): The original version of the legislation as it stood when it was first adopted in the EU. No changes have been applied to the text.

See additional information alongside the content

Geographical Extent: Indicates the geographical area that this provision applies to. For further information see ‘Frequently Asked Questions’.

Show Timeline of Changes: See how this legislation has or could change over time. Turning this feature on will show extra navigation options to go to these specific points in time. Return to the latest available version by using the controls above in the What Version box.

More Resources

Access essential accompanying documents and information for this legislation item from this tab. Dependent on the legislation item being viewed this may include:

- the original print PDF of the as adopted version that was used for the EU Official Journal

- lists of changes made by and/or affecting this legislation item

- all formats of all associated documents

- correction slips

- links to related legislation and further information resources

Timeline of Changes

This timeline shows the different versions taken from EUR-Lex before exit day and during the implementation period as well as any subsequent versions created after the implementation period as a result of changes made by UK legislation.

The dates for the EU versions are taken from the document dates on EUR-Lex and may not always coincide with when the changes came into force for the document.

For any versions created after the implementation period as a result of changes made by UK legislation the date will coincide with the earliest date on which the change (e.g an insertion, a repeal or a substitution) that was applied came into force. For further information see our guide to revised legislation on Understanding Legislation.

More Resources

Use this menu to access essential accompanying documents and information for this legislation item. Dependent on the legislation item being viewed this may include:

- the original print PDF of the as adopted version that was used for the print copy

- correction slips

Click 'View More' or select 'More Resources' tab for additional information including:

- lists of changes made by and/or affecting this legislation item

- confers power and blanket amendment details

- all formats of all associated documents

- links to related legislation and further information resources