ANNEX XIU.K.[F1GB] TYPE-APPROVAL OF REPLACEMENT POLLUTION CONTROL DEVICES AS SEPARATE TECHNICAL UNIT

Textual Amendments

F1Word in Annex 11 heading substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 66(13)(a)

1.INTRODUCTIONU.K.

1.1.This Annex contains additional requirements for the type-approval of replacement pollution control devices as separate technical units.U.K.

2.GENERAL REQUIREMENTSU.K.

2.1.MarkingU.K.

2.1.1.Each replacement pollution control device shall bear at least the following identifications:U.K.

the manufacturer’s name or trade mark;

the make and identifying part number of the replacement pollution control device as recorded in the information document issued in accordance with the model set out in Appendix 1.

2.1.2.Each original replacement pollution control device shall bear at least the following identifications:U.K.

the vehicle or engine manufacturer’s name or trade mark;

the make and identifying part number of the original replacement pollution control device as recorded in the information referred to in point 2.3.

2.2.DocumentationU.K.

2.2.1.Each replacement pollution control device shall be accompanied by the following information:U.K.

the manufacturer’s name or trade mark;

the make and identifying part number of the replacement pollution control device as recorded in the information document issued in accordance with the model set out in Appendix 1;

the vehicles or engines including year of manufacture for which the replacement pollution control device is approved, including, where applicable, a marking to identify if the replacement pollution control device is suitable for fitting to a vehicle that is equipped with an on-board diagnostic (OBD) system;

installation instructions.

The information referred to in this point shall be available in the product catalogue distributed to points of sale by the manufacturer of replacement pollution control devices.

2.2.2.Each original replacement pollution control device shall be accompanied by the following information:U.K.

the vehicle or engine manufacturer’s name or trade mark;

the make and identifying part number of the original replacement pollution control device as recorded in the information mentioned in Section 2.3;

the vehicles or engines for which the original replacement pollution control device is of a type covered by point 3.2.12.2.1 of Appendix 4 to Annex I, including, where applicable, a marking to identify if the original replacement pollution control device is suitable for fitting to a vehicle that is equipped with an on-board diagnostic (OBD) system;

installation instructions.

This information referred to in this point shall be available in the product catalogue distributed to points of sale by the vehicle or engine manufacturer.

2.3.For an original replacement pollution control device, the vehicle or engine manufacturer shall provide to the approval authority the necessary information in electronic format which makes the link between the relevant part numbers and the type-approval documentation.U.K.

This information shall contain the following:

make(s) and type(s) of vehicle or engine;

make(s) and type(s) of original replacement pollution control device;

part number(s) of original replacement pollution control device;

type-approval number of the relevant engine or vehicle type(s).

3.EC SEPARATE TECHNICAL UNIT TYPE-APPROVAL MARKU.K.

3.1.Every replacement pollution control device conforming to the type approved under this Regulation as a separate technical unit shall bear [F2a GB type-approval] mark.U.K.Textual Amendments

F2Words in Annex 11 substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 66(13)(b)(i)

Textual Amendments

F2Words in Annex 11 substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 66(13)(b)(i)

3.2.[F3A rectangle surrounding the lower-case letter ‘g’ followed by the number 11.]U.K.Textual Amendments

F3Words in Annex 11 point 3.2 substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 66(13)(d)(i)

Textual Amendments

F3Words in Annex 11 point 3.2 substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 66(13)(d)(i)

[F4The GB type-approval] mark shall also include in the vicinity of the rectangle the ‘base approval number’ contained in Section 4 of the type-approval number referred to in [F5Annex IV to Commission Implementing Regulation (EU) 2020/683], preceded by the two figures indicating the sequence number assigned to the latest major technical amendment to Regulation (EC) No 595/2009 or this Regulation on the [F6date GB] type-approval for a separate technical unit was granted. For this Regulation, the sequence number is 00.

Textual Amendments

F4Words in Annex 11 substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 66(13)(b)(ii)

F5Words in Annex 11 point 3.2 substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 66(13)(d)(ii)

F6Words in Annex 11 point 3 substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 66(13)(c)

3.3.[F4The GB type-approval] mark shall be affixed to the replacement pollution control device in such a way as to be clearly legible and indelible. It shall, wherever possible, be visible when the replacement pollution control device is installed on the vehicle.U.K.

3.4.An example of [F4the GB type-approval] mark for a separate technical unit is given in Appendix 8 to Annex I.U.K.

4.TECHNICAL REQUIREMENTSU.K.

4.1.General requirementsU.K.

4.1.1.The replacement pollution control device shall be designed, constructed and capable of being mounted so as to enable the engine and vehicle to comply with the rules with which it was originally in compliance and that pollutant emissions are effectively limited throughout the normal life of the vehicle under normal conditions of use.U.K.

4.1.2.The installation of the replacement pollution control device shall be at the exact position of the original equipment pollution control device, and the position on the exhaust line of the exhaust gas, temperature and pressure sensors shall not be modified.U.K.

4.1.3.If the original equipment pollution control device includes thermal protections, the replacement pollution control device shall include equivalent protections.U.K.

4.1.4.Upon request of the applicant for the type-approval of the replacement component, the approval authority F7... shall make available on a non-discriminatory basis, the information referred to in points 3.2.12.2.6.8.1 and 3.2.12.2.6.8.2 in Part 1 of the information document contained in Appendix 4 to Annex I for each engine to be tested.U.K.Textual Amendments

F7Words in Annex 11 point 4.1.4 omitted (31.12.2022 at 11.00 p.m.) by virtue of The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 66(13)(e)

Textual Amendments

F7Words in Annex 11 point 4.1.4 omitted (31.12.2022 at 11.00 p.m.) by virtue of The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 66(13)(e)

4.2.General durability requirementsU.K.

The replacement pollution control device shall be durable, that is designed, constructed and capable of being mounted so that reasonable resistance to the corrosion and oxidation phenomena to which it is exposed is obtained, having regard to the conditions of use of the vehicle.

The design of the replacement pollution control device shall be such that the elements active in controlling emissions are adequately protected from mechanical shock so as to ensure that pollutant emissions are effectively limited throughout the normal life of the vehicle under normal conditions of use.

The applicant for type-approval shall provide to the approval authority details of the test used to establish robustness to mechanical shock and the results of that test.

4.3.Requirements regarding emissionsU.K.

[F84.3.1. Outline of procedure for evaluation of emissions U.K.

The engines indicated in point (a) of Article 16(4) equipped with a complete emissions control system, including the replacement pollution control device of the type for which approval is requested, shall be subjected to tests appropriate for the intended application as described in Annex 4 to UNECE Regulation No 49, in order to compare its performance with the original emissions control system in accordance with the procedure described in points 4.3.1.1 and 4.3.1.2.]

4.3.1.1.Where the replacement pollution control device does not comprise the complete emissions control system, only new original equipment or new original replacement pollution control components shall be used to provide a complete system.U.K.

4.3.1.2.The emissions control system shall be aged according to the procedure described in point 4.3.2.4 and retested to establish the durability of its emissions performance.U.K.

The durability of a replacement pollution control device is determined from a comparison of the two successive sets of exhaust gas emissions tests:

the first set is that made with the replacement pollution control device which has been run in with 12 WHSC Cycles;

the second set is that made with the replacement pollution control device which has been aged by the procedures detailed below.

Where approval is applied for different types of engines from the same engine manufacturer, and provided that these different types of engines are fitted with an identical original equipment pollution control system, the testing may be limited to at least two engines selected after agreement with the approval authority.

Textual Amendments

F8Substituted by Commission Regulation (EU) No 133/2014 of 31 January 2014 amending, for the purposes of adapting to technical progress as regards emission limits, Directive 2007/46/EC of the European Parliament and of the Council, Regulation (EC) No 595/2009 of the European Parliament and of the Council and Commission Regulation (EU) No 582/2011 (Text with EEA relevance).

4.3.2.Procedure for evaluation of emissions performance of a replacement pollution control deviceU.K.

4.3.2.1.The engine or engines shall be fitted with a new original equipment pollution control device according to Article 16(4).U.K.

[F8The exhaust after-treatment system shall be preconditioned with 12 WHSC cycles. After this preconditioning, the engines shall be tested in accordance with the WHDC test procedures described in Annex 4 to UNECE Regulation No 49. Three exhaust gas tests of each appropriate type shall be performed.]

The test engines with the original exhaust after-treatment system or original replacement exhaust after-treatment system shall comply with the limit values according to the type-approval of the engine or vehicle.

4.3.2.2.Exhaust gas test with replacement pollution control deviceU.K.

The replacement pollution control device to be evaluated shall be fitted to the exhaust after-treatment system tested according to the requirements of point 4.3.2.1, replacing the relevant original equipment exhaust after-treatment device.

[F8The exhaust after-treatment system incorporating the replacement pollution control device shall then be preconditioned with 12 WHSC cycles. After this preconditioning, the engines shall be tested in accordance with the WHDC procedures described in Annex 4 to UNECE Regulation No 49. Three exhaust gas tests of each appropriate type shall be performed.]

4.3.2.3.Initial evaluation of the emission of pollutants of engines equipped with replacement pollution control devicesU.K.

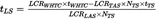

The requirements regarding emissions of the engines equipped with the replacement pollution control device shall be deemed to be fulfilled if the results for each regulated pollutant (CO, HC, NMHC, methane, NOx, NH3, particulate mass and particle number as appropriate for the type-approval of the engine) meet the following conditions:

M ≤ 0,85S + 0,4G;

M ≤ G

where:

:

mean value of the emissions of one pollutant obtained from the three tests with the replacement pollution control device.

:

mean value of the emissions of one pollutant obtained from the three tests with the original or original replacement pollution control device.

:

limit value of the emissions of one pollutant according to the type-approval of the vehicle.

[F94.3.2.4. Durability of emissions performance U.K.

The exhaust after-treatment system tested in accordance with point 4.3.2.2 and incorporating the replacement pollution control device shall be subjected to the durability procedures described in Appendix 3.]

Textual Amendments

F9Substituted by Commission Regulation (EU) 2016/1718 of 20 September 2016 amending Regulation (EU) No 582/2011 with respect to emissions from heavy-duty vehicles as regards the provisions on testing by means of portable emission measurement systems (PEMS) and the procedure for the testing of the durability of replacement pollution control devices (Text with EEA relevance).

4.3.2.5.Exhaust gas test with aged replacement pollution control deviceU.K.

The aged exhaust after-treatment system incorporating the aged replacement control device shall then be fitted to the test engine used in points 4.3.2.1 and 4.3.2.2

[F8The aged exhaust after-treatment systems shall be preconditioned with 12 WHSC cycles and subsequently tested using the WHDC procedures described in Annex 4 to UNECE Regulation No 49. Three exhaust gas tests of each appropriate type shall be performed.]

[F84.3.2.6. Determination of ageing factor for the replacement pollution control device U.K.

The ageing factor for each pollutant shall be the ratio of the applied emission value at the useful life end point and that at the start of the service accumulation (e.g., if the emissions of pollutant A at the start of the service accumulation are 1.50 g/kWh and those at the useful life end point are 1.82 g/kWh, the ageing factor is 1,82/1,50 = 1,21).]

4.3.2.7.Evaluation of the emission of pollutants of engines equipped with replacement pollution control devicesU.K.

The requirements regarding emissions of the engines equipped with the aged replacement pollution control device (as described in point 4.3.2.5) shall be deemed to be fulfilled if the results for each regulated pollutant (CO, HC, NMHC, methane, NOx, NH3, particulate mass and particle number as appropriate for the type-approval of the engine) meet the following condition:

M × AF ≤ G

where:

:

mean value of the emissions of one pollutant obtained from the three tests with the preconditioned replacement pollution control device before ageing (i.e. results from Section 4.3.2)

:

the aging factor for one pollutant

:

limit value of the emissions of one pollutant according to the type-approval of the vehicle(s).

4.3.3.Replacement pollution control device technology familyU.K.

The manufacturer may identify a replacement pollution control device technology family, to be identified by basic characteristics which shall be common to devices within the family.

To belong to the same replacement pollution control device technology family the replacement pollution control devices shall have the following:

the same emissions control mechanism (oxidation catalyst, three-way catalyst, particulate filter, selective catalytic reduction for NOx, etc.);

the same substrate material (same type of ceramic, or same type of metal);

the same substrate type and cell density;

the same catalytically active materials and, where more than one, the same ratio of catalytically active materials;

the same total charge of catalytically active materials;

the same type of washcoat applied by the same process.

4.3.4.Assessment of the durability of emissions performance of a replacement pollution control device by use of a technology family aging factorU.K.

Where the manufacturer has identified a replacement pollution control technology family, the procedures described in point 4.3.2 may be used to determine the Aging Factors (AFs) for each pollutant for the parent of that family. The engine on which these tests are conducted shall have a minimum engine displacement of [0,75 dm3] per cylinder.

4.3.4.1.Determination of durability performance of family membersU.K.

A replacement pollution control device A within a family and intended to be mounted on an engine of displacement CA may be considered to have the same aging factors as the parent replacement pollution control device P, determined on an engine of displacement CP, if the following conditions are fulfilled:

VA/CA ≥ VP/CP

where:

:

Substrate volume (in dm3) of replacement pollution control device A

:

Substrate volume (in dm3) of the parent replacement pollution control device P of the same family; and

both engines use the same method for regeneration of any emissions control devices incorporated in the original exhaust after-treatment system. This requirement shall apply only where devices requiring regeneration are incorporated in the original exhaust after-treatment system.

If these conditions are fulfilled, the emissions durability performance of other members of the family may be determined from the emissions results (S) of that family member determined according to the requirements set out in points 4.3.2.1, 4.3.2.2 and 4.3.2.3 and using the Aging Factors determined for the parent of that family.

[F104.3.5. Fuels U.K.

In the case described in point 1.1.2 of Annex I, the test procedure laid down in points 4.3.1 to 4.3.2.7 of this Annex shall be conducted with the fuels declared by the manufacturer of the original engine system. However, in agreement with the type-approval authority, the durability procedure set out in Appendix 3 and referred to in point 4.3.2.4 may be performed only with the fuel which represents the worst case in terms of ageing.]

Textual Amendments

F10Inserted by Commission Regulation (EU) 2016/1718 of 20 September 2016 amending Regulation (EU) No 582/2011 with respect to emissions from heavy-duty vehicles as regards the provisions on testing by means of portable emission measurement systems (PEMS) and the procedure for the testing of the durability of replacement pollution control devices (Text with EEA relevance).

4.4.Requirements regarding exhaust back-pressureU.K.

The back pressure shall not cause the complete exhaust system to exceed the value specified according to point 4.1.2 of Annex I.

4.5.Requirements regarding OBD compatibility (applicable only to replacement pollution control devices intended to be fitted to vehicles equipped with an OBD system)U.K.

4.5.1.OBD compatibility demonstration is required only when the original pollution control device was monitored in the original configuration.U.K.

4.5.2.The compatibility of the replacement pollution control device with the OBD system shall be demonstrated by using the procedures described in Annex X to this Regulation and Annex 9B to UN/ECE Regulation No 49 for replacement pollution control devices intended to be fitted to engines or vehicles type-approved in accordance with Regulation (EC) No 595/2009 and this Regulation.U.K.

4.5.3.The provisions in UN/ECE Regulation No 49 applicable to components other than pollution control devices shall not apply.U.K.

4.5.4.The replacement pollution control device manufacturer may use the same preconditioning and test procedure as used during the original type-approval. In this case, the approval authority F11... shall provide, on request and on a non-discriminatory basis, F12... the number and type of preconditioning cycles and the type of test cycle used by the original equipment manufacturer for OBD testing of the pollution control device.U.K.Textual Amendments

F11Words in Annex 11 point 4.5.4 omitted (31.12.2022 at 11.00 p.m.) by virtue of The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 66(13)(f)(i)

F12Words in Annex 11 point 4.5.4 omitted (31.12.2022 at 11.00 p.m.) by virtue of The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 66(13)(f)(ii)

Textual Amendments

F11Words in Annex 11 point 4.5.4 omitted (31.12.2022 at 11.00 p.m.) by virtue of The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 66(13)(f)(i)

F12Words in Annex 11 point 4.5.4 omitted (31.12.2022 at 11.00 p.m.) by virtue of The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 66(13)(f)(ii)

4.5.5.In order to verify the correct installation and functioning of all other components monitored by the OBD system, the OBD system shall indicate no malfunction and have no stored fault codes prior to the installation of any of the replacement pollution control device. An evaluation of the status of the OBD system at the end of the tests described in points 4.3.2 to 4.3.2.7 may be used for this purpose.U.K.

4.5.6.The malfunction indicator shall not activate during vehicle operation required by points 4.3.2 to 4.3.2.7.U.K.

[F104.6. Requirements regarding compatibility with the NO x control measures (applicable only to replacement pollution control devices to be fitted to vehicles equipped with sensors directly measuring NO x concentration in the exhaust) U.K.

4.6.1.NO x control measures compatibility demonstration is required only when the original pollution control device was monitored in the original configuration.U.K.

4.6.2.The compatibility of the replacement pollution control device with the NO x control measures shall be demonstrated by using the procedures described in Annex XIII to this Regulation, for replacement pollution control devices intended to be fitted to engines or vehicles type-approved in accordance with Regulation (EC) No 595/2009 and this Regulation.U.K.

4.6.3.The provisions in UN/ECE Regulation No 49 applicable to components other than pollution control devices shall not apply.U.K.

4.6.4.The replacement pollution control device manufacturer may use the same preconditioning and test procedure as used during the original type-approval. In that case, the approval authority F13... shall provide, on request and on a non-discriminatory basis, an information document presented as an appendix to the Information Document provided for in Appendix 4 to Annex I, which contains the number and type of preconditioning cycles and the type of test cycle used by the original equipment manufacturer for NO x control measures testing of the pollution control device.U.K.Textual Amendments

F13Words in Annex 11 point 4.6.4 omitted (31.12.2022 at 11.00 p.m.) by virtue of The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 66(13)(g)

Textual Amendments

F13Words in Annex 11 point 4.6.4 omitted (31.12.2022 at 11.00 p.m.) by virtue of The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 66(13)(g)

4.6.5.Point 4.5.5 shall apply to NO x control measures monitored by the OBD system.]U.K.

5.CONFORMITY OF PRODUCTIONU.K.

5.1.Measures to ensure the conformity of production shall be taken in accordance with [F14Article 31 of Regulation (EU) 2018/858].U.K.Textual Amendments

F14Words in Annex 11 point 5.1 substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 66(13)(h)

Textual Amendments

F14Words in Annex 11 point 5.1 substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 66(13)(h)

5.2.Special provisionsU.K.

5.2.1.The checks referred to in [F15Section 3.2 of Annex IV to Regulation (EU) 2018/858] shall include compliance with the characteristics as defined under ‘type of pollution control device’ in Article 2(8) of Regulation (EC) No 692/2008.U.K.Textual Amendments

F15Words in Annex 11 point 5.2.1 substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 66(13)(i)

Textual Amendments

F15Words in Annex 11 point 5.2.1 substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 66(13)(i)

5.2.2.For the application of [F16Article 31(3) of Regulation (EU) 2018/858], the tests described in Section 4.3 of this Annex (requirements regarding emissions) may be carried out. In this case, the holder of the approval may request, as an alternative, to use as a basis for comparison not the original equipment pollution control device, but the replacement pollution control device which was used during the type-approval tests (or another sample that has been proven to conform to the approved type). Emissions values measured with the sample under verification shall then on average not exceed by more than 15 % the mean values measured with the sample used for reference.U.K.Textual Amendments

F16Words in Annex 11 point 5.2.2 substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 66(13)(j)

Textual Amendments

F16Words in Annex 11 point 5.2.2 substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 66(13)(j)

Appendix 1

MODELInformation document No …U.K.

relating to [F4the GB type-approval] of replacement pollution control devices

The following information shall be supplied in triplicate and include a list of contents. Any drawings shall be supplied in appropriate scale and sufficient detail on size A4 or on a folder of A4 format. Photographs, if any, shall show sufficient detail.

If the systems, components or separate technical units have electronic controls, information concerning their performance shall be supplied.

0.GENERALU.K.

0.1.Make (trade name of manufacturer): …U.K.

0.2.Type …U.K.

Commercial name(s) (if available): …

0.3.Means of identification of type: …U.K.

0.5.Name and address of manufacturer: …U.K.

0.7.In the case of components and separate technical units, location and method of affixing of the [F17GB approval] mark: …U.K.Textual Amendments

F17Words in Annex 11 Appendix 1 point 0.7 substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 66(13)(k)(i)

Textual Amendments

F17Words in Annex 11 Appendix 1 point 0.7 substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 66(13)(k)(i)

0.8.Name(s) and address(es) of assembly plant(s): …U.K.

0.9Name and address of the manufacturer’s authorised representative (if any): …U.K.

1.DESCRIPTION OF THE DEVICEU.K.

1.1.Type of the replacement pollution control device: (oxidation catalyst, three-way catalyst, SCR catalyst, particulate filter, etc.) …U.K.

1.2.Drawings of the replacement pollution control device, identifying in particular all the characteristics referred to under ‘type of pollution control device’ of Article 2 of Regulation (EU) No 582/2011: …U.K.

1.3.Description of the engine and vehicle type or types for which the replacement pollution control device is intended: …U.K.

Number(s) and/or symbol(s) characterising the engine and vehicle type(s): …

Number(s) and/or symbol(s) characterising the original pollution control device(s) which the replacement pollution control device is intended to replace: …

Is the replacement pollution control device intended to be compatible with OBD requirements (Yes/No)(1)

Is the replacement pollution control device compatible with existing vehicle/engine control systems (yes/no)(1)

1.4.Description and drawings showing the position of the replacement pollution control device relative to the engine exhaust manifold(s): …U.K.

F182. . . . . . . . . . . . . . . . . . . . . . . . . U.K.

Textual Amendments

F18Annex 11 Appendix 1 points 2-2.3 omitted (31.12.2022 at 11.00 p.m.) by virtue of The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 66(13)(k)(ii)

F182.1 . . . . . . . . . . . . . . . . . . . . . . . . U.K.

F182.2 . . . . . . . . . . . . . . . . . . . . . . . . U.K.

F182.41 . . . . . . . . . . . . . . . . . . . . . . . . U.K.

Appendix 2MODEL [F19GB TYPE-APPROVAL] CERTIFICATE

Textual Amendments

F19Words in Annex 11 Appendix 2 substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 66(13)(l)(i)

(Maximum format: A4 (210 mm × 297 mm))U.K.

[F19GB TYPE-APPROVAL] CERTIFICATEU.K.

Stamp of administrationU.K.

Communication concerning the:

[F19GB type-approval] (1) …,

extension of [F19GB type-approval] (1) …,

refusal of [F19GB type-approval] (1) …,

withdrawal of [F19GB type-approval] (1) …

of a type of component/separate technical unit(2)

with regard to Regulation (EC) No 595/2009, as implemented by Regulation (EU) No 582/2011.

Regulation (EC) No 595/2009 or Regulation (EU) No 582/2011, as last amended by [F20S.I. …./….] …

Textual Amendments

F20Words in Annex 11 Appendix 2 inserted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 66(13)(l)(ii)

[F19GB type-approval] number: …

Reason for extension: …

SECTION IU.K.

0.1.Make (trade name of manufacturer): …U.K.

0.2.Type: …U.K.

0.3.Means of identification of type marked on the component/separate technical unit(3) (Identifying Part Number): …U.K.

0.3.1.Location of that marking: …U.K.

0.5.Name and address of manufacturer: …U.K.

0.7.In the case of components and separate technical units, location and method of affixing of the [F21GB approval] mark: …U.K.Textual Amendments

F21Words in Annex 11 Appendix 2 Section 1 point 0.7 substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 66(13)(l)(iii)

Textual Amendments

F21Words in Annex 11 Appendix 2 Section 1 point 0.7 substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 66(13)(l)(iii)

0.8.Name and address(es) of assembly plant(s): …U.K.

0.9.Name and address of manufacturer’s representative: …U.K.

SECTION IIU.K.

1.Additional informationU.K.

1.1.Make and type of the replacement pollution control device: (oxidation catalyst, three-way catalyst, SCR catalyst, particulate filter, etc.) …U.K.

1.2.Engine and vehicle type(s) for which the pollution control device type qualifies as replacement part: …U.K.

1.3.Type(s) of engine on which the replacement pollution control device has been tested: …U.K.

1.3.1.Has the replacement pollution control device demonstrated compatibility with OBD requirements (yes/no)(2): …U.K.

2.Technical service responsible for carrying out the tests: …U.K.

3.Date of test report: …U.K.

4.Number of test report: …U.K.

5.Remarks: …U.K.

6.Place: …U.K.

7.Date: …U.K.

8.Signature: …U.K.

:

Information package.

Test report.

[F9Appendix 3

Durability procedure for evaluation of emissions performance of a replacement pollution control device U.K.

1.This Appendix sets out the durability procedure referred to in point 4.3.2.4 of Annex XI, for the purpose of evaluating the emissions performance of a replacement pollution control device.U.K.

2. DESCRIPTION OF THE DURABILITY PROCEDURE U.K.

2.1.The durability procedure shall consist of a data collection phase and a service accumulation schedule.U.K.

2.2. Data collection phase U.K.

2.2.1.The selected engine, equipped with the complete exhaust after-treatment system incorporating the replacement pollution control device, shall be cooled down to ambient temperature and run one cold start WHTC test-cycle in accordance with paragraphs 7.6.1 and 7.6.2 of Annex 4 to UN/ECE Regulation No 49.U.K.

2.2.2.Immediately after the cold start WHTC test-cycle, the engine shall be run for nine consecutive hot start WHTC test-cycles in accordance with paragraph 7.6.4 of Annex 4 to UN/ECE Regulation No 49.U.K.

2.2.3.The test sequence set out in points 2.2.1 and 2.2.2 shall be carried out in accordance with the instructions laid down in paragraph 7.6.5 of Annex 4 to UN/ECE Regulation No 49.U.K.

2.2.4.Alternatively, the relevant data can be collected by driving a fully loaded vehicle equipped with the selected exhaust after-treatment system incorporating the replacement pollution control device. The test can be carried out either on the road following the trip requirements of points 4.5 to 4.5.5 of Annex II to this Regulation with comprehensive recording of the driving data, or on a suitable chassis dynamometer. If an on-road test is chosen, the vehicle shall be driven over a cold test-cycle, as set out in Appendix 5 to this Annex, followed by nine hot test-cycles, identical to the cold one, in a way that the work developed by the engine is the same as the one achieved under points 2.2.1 and 2.2.2. If a chassis dynamometer is chosen, the simulated road gradient of the test-cycle in Appendix 5 shall be adapted to match the work developed by the engine over the WHTC.U.K.

2.2.5.The type-approval authority shall refuse the temperature data obtained under point 2.2.4 if it deems those data to be unrealistic and shall request either the repetition of the test, or the carrying out of a test pursuant to points 2.2.1, 2.2.2 and 2.2.3.U.K.

2.2.6.Temperatures in the replacement pollution control device shall be recorded during the whole test sequence, at the location with the highest temperature.U.K.

2.2.7.In cases where the location with the highest temperature varies over time, or where that location is difficult to define, multiple bed temperatures should be recorded at suitable locations.U.K.

2.2.8.The number and locations of the temperature measurements shall be selected by the manufacturer, in agreement with the type-approval authority, based on best engineering judgement.U.K.

2.2.9.With the agreement of the type-approval authority, a single catalyst bed temperature or the catalyst inlet temperature may be used if measuring multiple bed temperatures is proven to be unfeasible or too difficult.U.K.

2.2.10.The temperatures shall be measured and recorded at a minimum rate of once every second (1 Hz) during the test sequence.U.K.

2.2.11.The measured temperatures shall be tabulated into a histogram with temperature bins no larger than 10 °C. In the case mentioned in point 2.2.7, the highest temperature each second shall be the one recorded in the histogram. Each bar of the histogram shall represent the cumulated frequency in seconds of the measured temperatures falling in the specific bin.U.K.

2.2.12.The time in hours corresponding to each temperature bin must be determined and then extrapolated to the useful life of the replacement pollution control device, in accordance with the values specified in Table 1. The extrapolation shall be based on the assumption that one WHTC cycle corresponds to 20 km driving.U.K.

Table 1

Useful life of the replacement pollution control device for each vehicle category, and equivalent WHTC test-cycles and hours of operation

| Vehicle category | Mileage (km) | Equivalent number of WHTC test-cycles | Equivalent number of hours |

|---|---|---|---|

| Engine systems fitted to vehicles of category M 1 , N 1 and N 2 | 114 286 | 5 714 | 2 857 |

| Engine systems fitted to vehicles of category N 2 , N 3 with a maximum technically permissible mass not exceeding 16 tonnes and M 3 Class I, Class II and Class A, and Class B with a maximum technically permissible mass exceeding 7,5 tonnes | 214 286 | 10 714 | 5 357 |

| Engine systems fitted to vehicles of category N 3 with a maximum technically permissible mass exceeding 16 tonnes, and M 3 , Class III and Class B with a maximum technically permissible mass exceeding 7,5 tonnes | 500 000 | 25 000 | 12 500 |

2.2.13.It is allowed to perform the data collection phase for different devices at the same time.U.K.

2.2.14.In the case of systems operating in the presence of active regeneration, the number, length and temperatures of the regenerations occurring during the test sequence defined in points 2.2.1 and 2.2.2 shall be recorded. If no active regeneration has occurred, the hot sequence defined in point 2.2.2 shall be extended in order to include at least two active regenerations.U.K.

2.2.15.The total lubricant consumed during the data collection period, in g/h, shall be recorded, using any suitable method, as for example the drain and weigh procedure described in Appendix 6. For this purpose, the engine shall be run during 24 hours, performing consecutive WHTC test-cycles. In cases where an accurate measurement of oil consumption cannot be obtained, the manufacturer, in agreement with the type-approval authority, may use the following options for the determination of the lubricant consumption:U.K.

a default value of 30 g/h;

a value requested by the manufacturer, based on sound data and information, and agreed with the type-approval authority.

2.3. Calculation of the equivalent ageing time corresponding to a reference temperature U.K.

2.3.1.The temperatures recorded pursuant to points 2.2 to 2.2.15 shall be reduced to a reference temperature T r , requested by the manufacturer in agreement with the type-approval authority, within the range of the temperatures recorded during the data collection phase.U.K.

2.3.2.In the case specified in point 2.2.13, the value of T r for each one of the devices may vary.U.K.

2.3.3.The equivalent ageing time corresponding to the reference temperature shall be calculated, for each bin referred to in 2.2.11, in accordance with the following equation:U.K.

Equation 1:

Where:

=

thermal reactivity of the replacement pollution control device.

The following values shall be used:

Diesel oxidation catalyst (DOC): 18 050

Catalysed DPF: 18 050

SCR or ammonia oxidation catalyst (AMOX) based on iron-zeolite (Fe-Z): 5 175

SCR copper-zeolite (Cu-Z): 11 550

SCR Vanadium (V): 5 175

LNT (lean-NO x trap): 18 050

=

reference temperature, in K .

=

mid-point temperature, in K , of the temperature bin i to which the replacement pollution control device is exposed during the data collection phase, registered in the temperature histogram.

=

the time, in hours, corresponding to the temperature

=

the equivalent ageing time, in hours, needed to achieve, by exposing the replacement pollution control device at the temperature T r , the same amount of ageing as the one that would result from exposure of the replacement pollution control device at the temperature

=

bin number, where 1 is number for the bin with the lowest temperature and n the value for the bin with the highest temperature.

2.3.4.The total equivalent ageing time shall be calculated in accordance with the following equation:U.K.

Equation 2:

Where:

=

total equivalent ageing time, in hours, needed to achieve, by exposing the replacement pollution control device at the temperature T r , the same amount of ageing as the one that would result from exposure of the replacement pollution control device, over its useful life, to the temperature

=

the equivalent ageing time, in hours, needed to achieve, by exposing the replacement pollution control device at the temperature T r , the same amount of ageing as the one that would result from exposure of the replacement pollution control device at the temperature

=

bin number, where 1 is number for the bin with the lowest temperature and n the value for the bin with the highest temperature.

=

Total number of temperature bins.

2.3.5.In the case referred to in point 2.2.13, AT shall be calculated for each device.U.K.

2.4. Service accumulation schedule U.K.

2.4.1. General requirements U.K.

2.4.1.1.The service accumulation schedule shall allow acceleration of the ageing of the replacement pollution control device, using the information gathered during the data collection phase set out in point 2.2.U.K.

2.4.1.2.The service accumulation schedule shall consist of a thermal accumulation schedule and a lubricant consumption accumulation schedule in accordance with point 2.4.4.6. The manufacturer, in agreement with the type-approval authority, may not have to carry out a lubricant consumption accumulation schedule in case the replacement pollution control devices are placed downstream of an after-treatment filter component (e.g. diesel particulate filter). Both the thermal accumulation schedule and the lubricant consumption accumulation schedule shall consist of a repetition of, respectively, a series of thermal and lubricant consumption sequences.U.K.

2.4.1.3.In the case of replacement pollution control devices operating in the presence of active regeneration, the thermal sequence shall be complemented with an active regeneration mode.U.K.

2.4.1.4.For service accumulation schedules consisting of both thermal and lubricant consumption accumulation schedules, their respective sequences shall be alternated, so that for each thermal sequence that has to be performed, the following sequence corresponds to lubricant consumption.U.K.

2.4.1.5.It is allowed to perform the service accumulation schedule at the same time for different devices. In that case, a single service accumulation schedule shall be set for all the devices.U.K.

2.4.2. Thermal accumulation schedule U.K.

2.4.2.1.The thermal accumulation schedule shall simulate the effect of thermal ageing on the performance of a replacement pollution control device until the end of its lifetime.U.K.

2.4.2.2.The engine used for the performance of the service accumulation schedule, fitted with the exhaust after-treatment system incorporating the replacement pollution control device, is operated for a minimum of three consecutive thermal sequences, as set out in Appendix 4.U.K.

2.4.2.3.The temperatures shall be recorded over a minimum of two thermal sequences. The first sequence, conducted for warming up, shall not be taken into account for the purpose of temperature gathering.U.K.

2.4.2.4.The temperatures shall be recorded at suitable locations, chosen in accordance with points 2.2.6 to 2.2.9, at a minimum rate of once every second (1 Hz).U.K.

2.4.2.5.The effective ageing time corresponding to the thermal sequences referred to in point 2.4.2.3, shall be calculated in accordance with the following equations:U.K.

Where:

=

the effective ageing time, in hours, needed to achieve, by exposing the replacement pollution control device at the temperature T r , the same amount of ageing as the one that would result from exposure of the replacement pollution control device at the temperature T i during the second i .

=

the temperature, in K , measured in the second i , in each one of the thermal sequences.

=

thermal reactivity of the replacement pollution control device. The manufacturer shall agree with the type-approval authority on the R value to be used. It will also be possible, as alternative, to use the following default values:

Diesel oxidation catalyst (DOC): 18 050.

Catalysed DPF: 18 050

SCR or ammonia oxidation catalyst (AMOX) based on iron-zeolite (Fe-Z): 5 175

SCR copper-zeolite (Cu-Z): 11 550

SCR Vanadium (V): 5 175

LNT (lean-NO x trap): 18 050

=

reference temperature, in K , being the same value as in equation 1.

=

Effective ageing time, in hours, needed to achieve, by exposing the replacement pollution control device at the temperature T r , the same amount of ageing as the one that would result from exposure of the replacement pollution control device during the duration of the thermal sequence.

=

total equivalent ageing time, in hours, needed to achieve, by exposing the replacement pollution control device at the temperature T r , the same amount of ageing as the one that would result from exposure of the replacement pollution control device, over its useful life, to the temperature

=

number of temperature measurement.

=

total number of temperature measurements.

=

thermal sequence number, of those conducted for the purpose of temperature gathering, in accordance with point 2.4.2.3.

=

total number of thermal sequences conducted for the purpose of temperature gathering.

2.4.2.6.The total number of thermal sequences to be included in the service accumulation schedule shall be determined by applying the following equation:U.K.

Equation 5:

N TS = AT/AE

Where:

=

total number of thermal sequences to be carried out during the service accumulation schedule

=

total equivalent ageing time, in hours, needed to achieve, by exposing the replacement pollution control device at the temperature T r , the same amount of ageing as the one that would result from exposure of the replacement pollution control device, over its useful life, to the temperature

=

Effective ageing time, in hours, needed to achieve, by exposing the replacement pollution control device at the temperature T r , the same amount of ageing as the one that would result from exposure of the replacement pollution control device during the duration of the thermal sequence.

2.4.2.7.It is allowed to reduce N TS and, consequently the service accumulation schedule, by increasing the temperatures at which each device is exposed at each mode of the ageing cycle through the application of one or several of the following measures:U.K.

insulating the exhaust pipe;

moving the replacement pollution control device closer to the exhaust manifold;

artificially heating up the temperature of the exhaust;

optimising the engine settings without substantially changing the emission behaviour of the engine.

2.4.2.8.When applying the measures referred to in points 2.4.4.6 and 2.4.4.7, the total ageing time calculated from N TS shall not be less than 10 % of the useful life listed in Table 1, e.g. the vehicle category N 1 shall not have an N TS of less than 286 thermal sequences, assuming that each sequence is 1 hour long.U.K.

2.4.2.9.It is allowed to increase N TS and, consequently, the duration of the service accumulation schedule, by lowering the temperatures at each mode of the ageing cycle through the application of one or several of the following measures:U.K.

moving the replacement pollution control device further away from the exhaust manifold;

artificially cooling down the temperature of the exhaust;

optimising the engine settings.

2.4.2.10.In the case referred to in point 2.4.1.5, the following shall apply:U.K.

N TS shall be the same for each device, so that a single service accumulation schedule can be set up.

In order to achieve the same N TS for each device, a first N TS value shall be calculated for each device, with its own AT and AE values.

If the calculated N TS values are different, one or more of the measures set out in points 2.4.2.7 to 2.4.2.10 may be applied on the device or devices for which N TS needs to be modified, over the thermal sequences referred to in point 2.4.2.3, in order to influence the measured T i and therefore conveniently speed up or slow down the artificial ageing of the targeted device or devices.

The new N TS values corresponding to the new temperatures T i obtained in point 2.4.2.10.3 shall be calculated.

The steps set out in points 2.4.2.10.3 and 2.4.2.10.4 shall be repeated until the N TS values obtained for each device in the system match.

The T r values used for obtaining the different N TS in points 2.4.2.10.4 and 2.4.2.10.5 shall be the same ones as those used in points 2.3.2 and 2.3.5 for calculating AT for each device.

2.4.2.11.In the case of an assembly of replacement pollution control devices constituting a system within the meaning of [F22Article 2(20) of Regulation (EU) 2018/858], one of the following two options may be considered for the thermal ageing of the devices:U.K.Textual Amendments

F22Words in Annex 11 Appendix 3 point 2.4.2.11 substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 66(13)(m)(i)

Textual Amendments

F22Words in Annex 11 Appendix 3 point 2.4.2.11 substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 66(13)(m)(i)

The devices within the assembly may be either separately or jointly aged, in accordance with point 2.4.2.10.

If the assembly is built in such a way that it is not possible to decouple the devices (e.g. DOC + SCR in a can), the thermal ageing of the assembly shall be carried out with the highest N TS .

2.4.3. Modified thermal accumulation schedule for devices operating in the presence of active regeneration U.K.

2.4.3.1.The modified thermal accumulation schedule for devices operating in the presence of active regeneration shall simulate the effect of ageing due to both thermal load and active regeneration on a replacement pollution control device at the end of its lifetime.U.K.

2.4.3.2.The engine used for the service accumulation schedule, fitted with the exhaust after-treatment system incorporating the replacement pollution control device, is operated for a minimum of three modified thermal sequences, consisting each sequence of a thermal sequence as set out in Appendix 4, followed by a complete active regeneration, during which the peak temperature reached in the after-treatment system should be not lower than the peak temperature recorded in the data collection phase.U.K.

2.4.3.3.The temperatures shall be recorded over a minimum of two modified thermal sequences. The first sequence, conducted for warming up, shall not be taken into account for the purpose of temperature gathering.U.K.

2.4.3.4.In order to minimise the time elapsed between the thermal sequence as set out in Appendix 4 and the subsequent active regeneration, the manufacturer may artificially trigger the active regeneration by running, after each thermal sequence as set out in Appendix 4, the engine at a steady mode that enables a high production of soot by the engine. In that case, the steady mode shall also be considered as part of the modified thermal sequence set out in point 2.4.3.2.U.K.

2.4.3.5.The effective ageing time corresponding to each modified thermal sequence shall be calculated using equations 3 and 4.U.K.

2.4.3.6.The total number of modified thermal sequences to be conducted during the service accumulation schedule shall be calculated using equation 5.U.K.

2.4.3.7.It is allowed to reduce N TS , and consequently the duration of the service accumulation schedule, by increasing the temperatures at each mode of the modified thermal sequence, applying one or several of the measures set out in point 2.4.2.7.U.K.

2.4.3.8.In addition to the measures referred to in point 2.4.3.7, N TS can also be reduced by increasing the peak temperature of the active regeneration within the modified thermal sequence, without exceeding a bed temperature of 800 °C under any circumstances.U.K.

2.4.3.9. N TS shall never be less than 50 % of the number of active regenerations to which the replacement pollution control device is subjected during its useful life, calculated in accordance with the following equation:U.K.

Equation 5:

Where:

=

number of active regeneration sequences over the useful life of the replacement pollution control device.

=

equivalent number of hours corresponding to the vehicle category for which the replacement pollution control device is intended, obtained from Table 1.

=

duration, in hours, of an active regeneration.

=

time, in hours, between two consecutive active regenerations.

2.4.3.10.If, as consequence of the application of the minimum number of modified thermal sequences as set out in point 2.4.3.9, AE × N TS calculated using equation 4 exceeds the AT calculated using equation 2, the time of each mode of the thermal sequence set out in Appendix 4, and embedded in the modified thermal sequence as set out in point 2.4.3.2, may be reduced in the same proportion, in order to make AE × N TS = AT .U.K.

2.4.3.11.It is allowed to increase N TS and consequently the duration of the service accumulation schedule, by lowering the temperatures at each mode of the thermal-active regeneration sequence by applying one or several of the measures set out in point 2.4.2.9.U.K.

2.4.3.12.In the case referred to in point 2.4.1.5, points 2.4.2.10 and 2.4.2.11 shall applyU.K.

2.4.4. Lubricant consumption accumulation schedule U.K.

2.4.4.1.The lubricant consumption accumulation schedule shall simulate the effect of ageing due to chemical poisoning or deposit formation as a result of lubricant consumption, on the performance of a replacement pollution control device at the end of its lifetime.U.K.

2.4.4.2.The lubricant consumed, in g/h, shall be determined over a minimum of 24 thermal sequences or a corresponding number of modified thermal sequences, using any suitable method, as for example the drain and weigh procedure described in Appendix 6. Fresh lubricant shall be used.U.K.

2.4.4.3.The engine shall be equipped with a constant volume oil sump in order to avoid the need of ‘top-offs’, since oil level influences the oil consumption rate. Any suitable method, as for example the one described in the ASTM standard D7156-09, may be used.U.K.

2.4.4.4.The theoretical time, in hours, that the thermal accumulation schedule or modified thermal accumulation schedule, as it corresponds, would have to be conducted, in order to obtain the same lubricant consumption as the one corresponding to the useful life of the replacement control device, shall be calculated by applying the following equation:U.K.

Equation 6:

Where:

=

theoretical duration, in hours, of the service accumulation schedule required to obtain the same lubricant consumption as the one corresponding to the useful life of the replacement pollution control device, provided that the service accumulation schedule is only made up of a series of consecutive thermal sequences or consecutive modified thermal sequences.

=

lubricant consumption rate, in g/h determined as set out in point 2.2.15.

=

equivalent number of hours corresponding to the vehicle category for which the replacement pollution control device is intended, obtained from Table 1.

=

lubricant consumption rate, in g/h, determined as set out in point 2.4.4.2.

2.4.4.5.The number of thermal sequences or modified thermal sequences corresponding to t TAS shall be calculated by applying the following ratio:U.K.

Equation 7:

Where:

=

number of thermal sequences or modified thermal sequences corresponding to t TAS .

=

theoretical duration, in hours, of the service accumulation schedule required to obtain the same lubricant consumption as the one corresponding to the useful life of the replacement pollution control device, provided that the service accumulation schedule was only made up of a series of consecutive thermal sequences or consecutive modified thermal sequences.

=

duration, in hours, of a single thermal sequence or modified thermal sequence.

2.4.4.6.The value of N shall be compared to the value of N TS calculated in accordance with point 2.4.2.6 or, for devices operating in the presence of active regeneration, in accordance with point 2.4.3.5. If N ≤ N TS , it is not necessary to add a lubricant consumption accumulation schedule to the thermal accumulation schedule. If N > N TS , a lubricant consumption accumulation schedule shall be added to the thermal accumulation schedule.U.K.

2.4.4.7.A lubricant consumption accumulation schedule may not have to be added if, by increasing the lubricant consumption as described in point 2.4.4.8.4, the needed lubricant consumption is already achieved with the conduction of the corresponding thermal accumulation schedule consisting of the performance of N TS thermal sequences or modified thermal sequences.U.K.

2.4.4.8. Development of the lubricant consumption accumulation schedule U.K.

2.4.4.8.1.The lubricant consumption accumulation schedule shall consist of a number of lubricant consumption sequences repeated several times, each lubricant consumption sequence being alternated with each thermal sequence or each modified thermal sequence.U.K.

2.4.4.8.2.Each lubricant consumption sequence shall consist of a steady mode at constant load and speed, the load and the speed being selected in such a way that the lubricant consumption is maximised and effective thermal aging is minimised. The mode shall be determined by the manufacturer in agreement with the type-approval authority, based on best engineering judgement.U.K.

2.4.4.8.3.The duration of each lubricant consumption sequence shall be determined as follows:U.K.

The engine shall be run for an appropriate period of time at the load and speed determined by the manufacturer in accordance with point 2.4.4.8.2 and the lubricant consumed, in g/h, shall be determined using any suitable method, as for example the drain and weigh procedure described in Appendix 6. Lubricant changes are to be completed at the recommended intervals.

The duration of each lubricant consumption sequence shall be calculated by applying the following equation:

Equation 8:

Where:

=

the duration, in hours, of a single lubricant consumption sequence

=

lubricant consumption rate, in g/h determined as set out in point 2.2.15.

=

equivalent number of hours corresponding to the vehicle category for which the replacement pollution control device is intended, obtained from Table 1.

=

lubricant consumption rate, in g/h, determined as set out in point 2.4.4.2.

=

lubricant consumption rate, in g/h, determined as set out in point 2.4.4.8.3.1.

=

duration, in hours, of a single thermal sequence, as set out in Appendix 4, or modified thermal sequence, as set out in point 2.4.3.2.

=

total number of thermal sequences or modified thermal sequences to be carried out during the service accumulation schedule.

2.4.4.8.4.The lubricant consumption rate shall always remain below 0,5 % of the engine fuel consumption rate in order to avoid excessive ash accumulation on the front face of the replacement pollution control device.U.K.

2.4.4.8.5.It is allowed to add the thermal ageing due to the conduction of the lubricant consumption sequence to the AE calculated in equation 4.U.K.

2.4.5. Development of the complete service accumulation schedule U.K.

2.4.5.1.The service accumulation schedule shall be built up alternating a thermal or a modified thermal sequence, as appropriate, with a lubricant consumption sequence. The aforementioned pattern shall be repeated N TS times, being the N TS value the one calculated either in accordance with Section 2.4.2 or with Section 2.4.3, as appropriate. An example of a complete service accumulation schedule is given in Appendix 7. A flowchart describing the development of a complete service accumulation schedule is given in Appendix 8.U.K.

2.4.6. Operation of the service accumulation schedule U.K.

2.4.6.1.The engine, fitted with the exhaust after-treatment system incorporating the replacement pollution control device, shall run the service accumulation schedule set out in point 2.4.5.1.U.K.

2.4.6.2.The engine used for the performance of the service accumulation schedule may be different to the engine used in the data collection phase, being the latter always the one for which the replacement pollution control device to be type-approved has been designed, and the one to be tested for emissions under point 2.4.3.2.U.K.

2.4.6.3.If the engine used for the performance of the service accumulation schedule features a larger displacement by 20 % or more than the engine used in the data collection phase, the exhaust system of the former should be equipped with a by-pass in order to replicate as closely as possible the exhaust flow rate of the latter at the ageing conditions selected.U.K.

2.4.6.4.In the case referred to in point 2.4.6.2, the engine used for the performance of the service accumulation schedule shall be type-approved under Regulation (EC) No 595/2009. In addition, if the device or devices under test are intended for being fitted in an engine system with exhaust gas recirculation (EGR), the engine system used for the service accumulation schedule shall also be fitted with an EGR. If the device or devices under test are intended for not being fitted in an engine system with EGR, the engine system used for the service accumulation schedule shall also not be fitted with an EGR.U.K.

2.4.6.5.The lubricant and the fuel used in the service accumulation schedule shall be as similar as possible to those used during the data collection phase set out in point 2.2. The lubricant must be in line with the recommendation of the engine manufacturer for which the pollution control device is designed. The fuels used should be market fuels fulfilling the corresponding requirements of [F23the Motor Fuel (Composition and Content) Regulations 1999]. On the request of the manufacturer also reference fuels in accordance with this Regulation can be used.U.K.Textual Amendments

F23Words in Annex 11 Appendix 3 point 2.4.6.5 substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 66(13)(m)(ii)

Textual Amendments

F23Words in Annex 11 Appendix 3 point 2.4.6.5 substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 66(13)(m)(ii)

2.4.6.6.The lubricant shall be changed for maintenance, at the intervals scheduled by the manufacturer of the engine used in the data collection phase.U.K.

2.4.6.7.In the case of an SCR, the urea injection shall be performed in accordance with the strategy defined by the manufacturer of the replacement pollution control device.]U.K.

[F10Appendix 4

Sequence for thermal ageing U.K.

| Mode | Speed (% of high idle) | Load (% for a given speed) | Time (s) |

|---|---|---|---|

| 1 | 2,92 | 0,58 | 626 |

| 2 | 45,72 | 1,58 | 418 |

| 3 | 38,87 | 3,37 | 300 |

| 4 | 20,23 | 11,36 | 102 |

| 5 | 11,37 | 14,90 | 62 |

| 6 | 32,78 | 18,52 | 370 |

| 7 | 53,12 | 20,19 | 410 |

| 8 | 59,53 | 34,73 | 780 |

| 9 | 78,24 | 54,38 | 132 |

| 10 | 39,07 | 62,85 | 212 |

| 11 | 47,82 | 62,94 | 188 |

| Regeneration mode (if applicable) | To be defined (see point 2.4.3.4) | To be defined (see point 2.4.3.4) | To be defined (see point 2.4.3.4) |

| Lubricant consumption mode (if applicable) | To be defined according to point 2.4.4.8.2 | To be defined according to point 2.4.4.8.2 | To be defined according to point 2.4.4.8.3 |

Note: The sequence of the modes 1 to 11 has been arranged by ascending load in order to maximise the temperature of the exhaust gas in the high load modes. With the agreement of the type-approval authority, this order can be modified in order to optimise the temperature of the exhaust gas if this can help in reducing the actual aging time.U.K.

Appendix 5

Test-cycle for chassis dynamometer or on-road data gathering U.K.

| Time | Speed | Time | Speed | Time | Speed | Time | Speed | Time | Speed | Time | Speed | Time | Speed |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| s | km/h | s | km/h | s | km/h | s | km/h | s | km/h | s | km/h | s | km/h |

| 1 | 0 | 261 | 22,38 | 521 | 35,46 | 781 | 18,33 | 1 041 | 39,88 | 1 301 | 66,39 | 1 561 | 86,88 |

| 2 | 0 | 262 | 24,75 | 522 | 36,81 | 782 | 18,31 | 1 042 | 41,25 | 1 302 | 66,74 | 1 562 | 86,7 |

| 3 | 0 | 263 | 25,55 | 523 | 37,98 | 783 | 18,05 | 1 043 | 42,07 | 1 303 | 67,43 | 1 563 | 86,81 |

| 4 | 0 | 264 | 25,18 | 524 | 38,84 | 784 | 17,39 | 1 044 | 43,03 | 1 304 | 68,44 | 1 564 | 86,81 |

| 5 | 0 | 265 | 23,94 | 525 | 39,43 | 785 | 16,35 | 1 045 | 44,4 | 1 305 | 69,52 | 1 565 | 86,81 |

| 6 | 0 | 266 | 22,35 | 526 | 39,73 | 786 | 14,71 | 1 046 | 45,14 | 1 306 | 70,53 | 1 566 | 86,81 |

| 7 | 2,35 | 267 | 21,28 | 527 | 39,8 | 787 | 11,71 | 1 047 | 45,44 | 1 307 | 71,47 | 1 567 | 86,99 |

| 8 | 5,57 | 268 | 20,86 | 528 | 39,69 | 788 | 7,81 | 1 048 | 46,13 | 1 308 | 72,32 | 1 568 | 87,03 |

| 9 | 8,18 | 269 | 20,65 | 529 | 39,29 | 789 | 5,25 | 1 049 | 46,79 | 1 309 | 72,89 | 1 569 | 86,92 |

| 10 | 9,37 | 270 | 20,18 | 530 | 38,59 | 790 | 4,62 | 1 050 | 47,45 | 1 310 | 73,07 | 1 570 | 87,1 |

| 11 | 9,86 | 271 | 19,33 | 531 | 37,63 | 791 | 5,62 | 1 051 | 48,68 | 1 311 | 73,03 | 1 571 | 86,85 |

| 12 | 10,18 | 272 | 18,23 | 532 | 36,22 | 792 | 8,24 | 1 052 | 50,13 | 1 312 | 72,94 | 1 572 | 87,14 |

| 13 | 10,38 | 273 | 16,99 | 533 | 34,11 | 793 | 10,98 | 1 053 | 51,16 | 1 313 | 73,01 | 1 573 | 86,96 |

| 14 | 10,57 | 274 | 15,56 | 534 | 31,16 | 794 | 13,15 | 1 054 | 51,37 | 1 314 | 73,44 | 1 574 | 86,85 |

| 15 | 10,95 | 275 | 13,76 | 535 | 27,49 | 795 | 15,47 | 1 055 | 51,3 | 1 315 | 74,19 | 1 575 | 86,77 |

| 16 | 11,56 | 276 | 11,5 | 536 | 23,63 | 796 | 18,19 | 1 056 | 51,15 | 1 316 | 74,81 | 1 576 | 86,81 |

| 17 | 12,22 | 277 | 8,68 | 537 | 20,16 | 797 | 20,79 | 1 057 | 50,88 | 1 317 | 75,01 | 1 577 | 86,85 |

| 18 | 12,97 | 278 | 5,2 | 538 | 17,27 | 798 | 22,5 | 1 058 | 50,63 | 1 318 | 74,99 | 1 578 | 86,74 |

| 19 | 14,33 | 279 | 1,99 | 539 | 14,81 | 799 | 23,19 | 1 059 | 50,2 | 1 319 | 74,79 | 1 579 | 86,81 |

| 20 | 16,38 | 280 | 0 | 540 | 12,59 | 800 | 23,54 | 1 060 | 49,12 | 1 320 | 74,41 | 1 580 | 86,7 |

| 21 | 18,4 | 281 | 0 | 541 | 10,47 | 801 | 24,2 | 1 061 | 48,02 | 1 321 | 74,07 | 1 581 | 86,52 |

| 22 | 19,86 | 282 | 0 | 542 | 8,85 | 802 | 25,17 | 1 062 | 47,7 | 1 322 | 73,77 | 1 582 | 86,7 |

| 23 | 20,85 | 283 | 0,5 | 543 | 8,16 | 803 | 26,28 | 1 063 | 47,93 | 1 323 | 73,38 | 1 583 | 86,74 |

| 24 | 21,52 | 284 | 0,57 | 544 | 8,95 | 804 | 27,69 | 1 064 | 48,57 | 1 324 | 72,79 | 1 584 | 86,81 |

| 25 | 21,89 | 285 | 0,6 | 545 | 11,3 | 805 | 29,72 | 1 065 | 48,88 | 1 325 | 71,95 | 1 585 | 86,85 |

| 26 | 21,98 | 286 | 0,58 | 546 | 14,11 | 806 | 32,17 | 1 066 | 49,03 | 1 326 | 71,06 | 1 586 | 86,92 |

| 27 | 21,91 | 287 | 0 | 547 | 15,91 | 807 | 34,22 | 1 067 | 48,94 | 1 327 | 70,45 | 1 587 | 86,88 |

| 28 | 21,68 | 288 | 0 | 548 | 16,57 | 808 | 35,31 | 1 068 | 48,32 | 1 328 | 70,23 | 1 588 | 86,85 |

| 29 | 21,21 | 289 | 0 | 549 | 16,73 | 809 | 35,74 | 1 069 | 47,97 | 1 329 | 70,24 | 1 589 | 87,1 |

| 30 | 20,44 | 290 | 0 | 550 | 17,24 | 810 | 36,23 | 1 070 | 47,92 | 1 330 | 70,32 | 1 590 | 86,81 |

| 31 | 19,24 | 291 | 0 | 551 | 18,45 | 811 | 37,34 | 1 071 | 47,54 | 1 331 | 70,3 | 1 591 | 86,99 |

| 32 | 17,57 | 292 | 0 | 552 | 20,09 | 812 | 39,05 | 1 072 | 46,79 | 1 332 | 70,05 | 1 592 | 86,81 |

| 33 | 15,53 | 293 | 0 | 553 | 21,63 | 813 | 40,76 | 1 073 | 46,13 | 1 333 | 69,66 | 1 593 | 87,14 |

| 34 | 13,77 | 294 | 0 | 554 | 22,78 | 814 | 41,82 | 1 074 | 45,73 | 1 334 | 69,26 | 1 594 | 86,81 |

| 35 | 12,95 | 295 | 0 | 555 | 23,59 | 815 | 42,12 | 1 075 | 45,17 | 1 335 | 68,73 | 1 595 | 86,85 |

| 36 | 12,95 | 296 | 0 | 556 | 24,23 | 816 | 42,08 | 1 076 | 44,43 | 1 336 | 67,88 | 1 596 | 87,03 |

| 37 | 13,35 | 297 | 0 | 557 | 24,9 | 817 | 42,27 | 1 077 | 43,59 | 1 337 | 66,68 | 1 597 | 86,92 |

| 38 | 13,75 | 298 | 0 | 558 | 25,72 | 818 | 43,03 | 1 078 | 42,68 | 1 338 | 65,29 | 1 598 | 87,14 |

| 39 | 13,82 | 299 | 0 | 559 | 26,77 | 819 | 44,14 | 1 079 | 41,89 | 1 339 | 63,95 | 1 599 | 86,92 |

| 40 | 13,41 | 300 | 0 | 560 | 28,01 | 820 | 45,13 | 1 080 | 41,09 | 1 340 | 62,84 | 1 600 | 87,03 |

| 41 | 12,26 | 301 | 0 | 561 | 29,23 | 821 | 45,84 | 1 081 | 40,38 | 1 341 | 62,21 | 1 601 | 86,99 |

| 42 | 9,82 | 302 | 0 | 562 | 30,06 | 822 | 46,4 | 1 082 | 39,99 | 1 342 | 62,04 | 1 602 | 86,96 |

| 43 | 5,96 | 303 | 0 | 563 | 30,31 | 823 | 46,89 | 1 083 | 39,84 | 1 343 | 62,26 | 1 603 | 87,03 |

| 44 | 2,2 | 304 | 0 | 564 | 30,29 | 824 | 47,34 | 1 084 | 39,46 | 1 344 | 62,87 | 1 604 | 86,85 |

| 45 | 0 | 305 | 0 | 565 | 30,05 | 825 | 47,66 | 1 085 | 39,15 | 1 345 | 63,55 | 1 605 | 87,1 |

| 46 | 0 | 306 | 0 | 566 | 29,44 | 826 | 47,77 | 1 086 | 38,9 | 1 346 | 64,12 | 1 606 | 86,81 |

| 47 | 0 | 307 | 0 | 567 | 28,6 | 827 | 47,78 | 1 087 | 38,67 | 1 347 | 64,73 | 1 607 | 87,03 |

| 48 | 0 | 308 | 0 | 568 | 27,63 | 828 | 47,64 | 1 088 | 39,03 | 1 348 | 65,45 | 1 608 | 86,77 |

| 49 | 0 | 309 | 0 | 569 | 26,66 | 829 | 47,23 | 1 089 | 40,37 | 1 349 | 66,18 | 1 609 | 86,99 |

| 50 | 1,87 | 310 | 0 | 570 | 26,03 | 830 | 46,66 | 1 090 | 41,03 | 1 350 | 66,97 | 1 610 | 86,96 |

| 51 | 4,97 | 311 | 0 | 571 | 25,85 | 831 | 46,08 | 1 091 | 40,76 | 1 351 | 67,85 | 1 611 | 86,96 |

| 52 | 8,4 | 312 | 0 | 572 | 26,14 | 832 | 45,45 | 1 092 | 40,02 | 1 352 | 68,74 | 1 612 | 87,07 |

| 53 | 9,9 | 313 | 0 | 573 | 27,08 | 833 | 44,69 | 1 093 | 39,6 | 1 353 | 69,45 | 1 613 | 86,96 |

| 54 | 11,42 | 314 | 0 | 574 | 28,42 | 834 | 43,73 | 1 094 | 39,37 | 1 354 | 69,92 | 1 614 | 86,92 |

| 55 | 15,11 | 315 | 0 | 575 | 29,61 | 835 | 42,55 | 1 095 | 38,84 | 1 355 | 70,24 | 1 615 | 87,07 |

| 56 | 18,46 | 316 | 0 | 576 | 30,46 | 836 | 41,14 | 1 096 | 37,93 | 1 356 | 70,49 | 1 616 | 86,92 |

| 57 | 20,21 | 317 | 0 | 577 | 30,99 | 837 | 39,56 | 1 097 | 37,19 | 1 357 | 70,63 | 1 617 | 87,14 |

| 58 | 22,13 | 318 | 0 | 578 | 31,33 | 838 | 37,93 | 1 098 | 36,21 | 1 358 | 70,68 | 1 618 | 86,96 |

| 59 | 24,17 | 319 | 0 | 579 | 31,65 | 839 | 36,69 | 1 099 | 35,32 | 1 359 | 70,65 | 1 619 | 87,03 |

| 60 | 25,56 | 320 | 0 | 580 | 32,02 | 840 | 36,27 | 1 100 | 35,56 | 1 360 | 70,49 | 1 620 | 86,85 |

| 61 | 26,97 | 321 | 0 | 581 | 32,39 | 841 | 36,42 | 1 101 | 36,96 | 1 361 | 70,09 | 1 621 | 86,77 |

| 62 | 28,83 | 322 | 0 | 582 | 32,68 | 842 | 37,14 | 1 102 | 38,12 | 1 362 | 69,35 | 1 622 | 87,1 |

| 63 | 31,05 | 323 | 0 | 583 | 32,84 | 843 | 38,13 | 1 103 | 38,71 | 1 363 | 68,27 | 1 623 | 86,92 |

| 64 | 33,72 | 324 | 3,01 | 584 | 32,93 | 844 | 38,55 | 1 104 | 39,26 | 1 364 | 67,09 | 1 624 | 87,07 |

| 65 | 36 | 325 | 8,14 | 585 | 33,22 | 845 | 38,42 | 1 105 | 40,64 | 1 365 | 65,96 | 1 625 | 86,85 |

| 66 | 37,91 | 326 | 13,88 | 586 | 33,89 | 846 | 37,89 | 1 106 | 43,09 | 1 366 | 64,87 | 1 626 | 86,81 |

| 67 | 39,65 | 327 | 18,08 | 587 | 34,96 | 847 | 36,89 | 1 107 | 44,83 | 1 367 | 63,79 | 1 627 | 87,14 |

| 68 | 41,23 | 328 | 20,01 | 588 | 36,28 | 848 | 35,53 | 1 108 | 45,33 | 1 368 | 62,82 | 1 628 | 86,77 |

| 69 | 42,85 | 329 | 20,3 | 589 | 37,58 | 849 | 34,01 | 1 109 | 45,24 | 1 369 | 63,03 | 1 629 | 87,03 |

| 70 | 44,1 | 330 | 19,53 | 590 | 38,58 | 850 | 32,88 | 1 110 | 45,14 | 1 370 | 63,62 | 1 630 | 86,96 |

| 71 | 44,37 | 331 | 17,92 | 591 | 39,1 | 851 | 32,52 | 1 111 | 45,06 | 1 371 | 64,8 | 1 631 | 87,1 |

| 72 | 44,3 | 332 | 16,17 | 592 | 39,22 | 852 | 32,7 | 1 112 | 44,82 | 1 372 | 65,5 | 1 632 | 86,99 |

| 73 | 44,17 | 333 | 14,55 | 593 | 39,11 | 853 | 33,48 | 1 113 | 44,53 | 1 373 | 65,33 | 1 633 | 86,92 |

| 74 | 44,13 | 334 | 12,92 | 594 | 38,8 | 854 | 34,97 | 1 114 | 44,77 | 1 374 | 63,83 | 1 634 | 87,1 |

| 75 | 44,17 | 335 | 11,07 | 595 | 38,31 | 855 | 36,78 | 1 115 | 45,6 | 1 375 | 62,44 | 1 635 | 86,85 |

| 76 | 44,51 | 336 | 8,54 | 596 | 37,73 | 856 | 38,64 | 1 116 | 46,28 | 1 376 | 61,2 | 1 636 | 86,92 |

| 77 | 45,16 | 337 | 5,15 | 597 | 37,24 | 857 | 40,48 | 1 117 | 47,18 | 1 377 | 59,58 | 1 637 | 86,77 |

| 78 | 45,64 | 338 | 1,96 | 598 | 37,06 | 858 | 42,34 | 1 118 | 48,49 | 1 378 | 57,68 | 1 638 | 86,88 |

| 79 | 46,16 | 339 | 0 | 599 | 37,1 | 859 | 44,16 | 1 119 | 49,42 | 1 379 | 56,4 | 1 639 | 86,63 |

| 80 | 46,99 | 340 | 0 | 600 | 37,42 | 860 | 45,9 | 1 120 | 49,56 | 1 380 | 54,82 | 1 640 | 86,85 |

| 81 | 48,19 | 341 | 0 | 601 | 38,17 | 861 | 47,55 | 1 121 | 49,47 | 1 381 | 52,77 | 1 641 | 86,63 |

| 82 | 49,32 | 342 | 0 | 602 | 39,19 | 862 | 49,09 | 1 122 | 49,28 | 1 382 | 52,22 | 1 642 | 86,77 |

| 83 | 49,7 | 343 | 0 | 603 | 40,31 | 863 | 50,42 | 1 123 | 48,58 | 1 383 | 52,48 | 1 643 | 86,77 |

| 84 | 49,5 | 344 | 0 | 604 | 41,46 | 864 | 51,49 | 1 124 | 48,03 | 1 384 | 52,74 | 1 644 | 86,55 |

| 85 | 48,98 | 345 | 0 | 605 | 42,44 | 865 | 52,23 | 1 125 | 48,2 | 1 385 | 53,14 | 1 645 | 86,59 |

| 86 | 48,65 | 346 | 0 | 606 | 42,95 | 866 | 52,58 | 1 126 | 48,72 | 1 386 | 53,03 | 1 646 | 86,55 |

| 87 | 48,65 | 347 | 0 | 607 | 42,9 | 867 | 52,63 | 1 127 | 48,91 | 1 387 | 52,55 | 1 647 | 86,7 |

| 88 | 48,87 | 348 | 0 | 608 | 42,43 | 868 | 52,49 | 1 128 | 48,93 | 1 388 | 52,19 | 1 648 | 86,44 |

| 89 | 48,97 | 349 | 0 | 609 | 41,74 | 869 | 52,19 | 1 129 | 49,05 | 1 389 | 51,09 | 1 649 | 86,7 |

| 90 | 48,96 | 350 | 0 | 610 | 41,04 | 870 | 51,82 | 1 130 | 49,23 | 1 390 | 49,88 | 1 650 | 86,55 |

| 91 | 49,15 | 351 | 0 | 611 | 40,49 | 871 | 51,43 | 1 131 | 49,28 | 1 391 | 49,37 | 1 651 | 86,33 |

| 92 | 49,51 | 352 | 0 | 612 | 40,8 | 872 | 51,02 | 1 132 | 48,84 | 1 392 | 49,26 | 1 652 | 86,48 |

| 93 | 49,74 | 353 | 0 | 613 | 41,66 | 873 | 50,61 | 1 133 | 48,12 | 1 393 | 49,37 | 1 653 | 86,19 |

| 94 | 50,31 | 354 | 0,9 | 614 | 42,48 | 874 | 50,26 | 1 134 | 47,8 | 1 394 | 49,88 | 1 654 | 86,37 |

| 95 | 50,78 | 355 | 2 | 615 | 42,78 | 875 | 50,06 | 1 135 | 47,42 | 1 395 | 50,25 | 1 655 | 86,59 |

| 96 | 50,75 | 356 | 4,08 | 616 | 42,39 | 876 | 49,97 | 1 136 | 45,98 | 1 396 | 50,17 | 1 656 | 86,55 |

| 97 | 50,78 | 357 | 7,07 | 617 | 40,78 | 877 | 49,67 | 1 137 | 42,96 | 1 397 | 50,5 | 1 657 | 86,7 |

| 98 | 51,21 | 358 | 10,25 | 618 | 37,72 | 878 | 48,86 | 1 138 | 39,38 | 1 398 | 50,83 | 1 658 | 86,63 |

| 99 | 51,6 | 359 | 12,77 | 619 | 33,29 | 879 | 47,53 | 1 139 | 35,82 | 1 399 | 51,23 | 1 659 | 86,55 |

| 100 | 51,89 | 360 | 14,44 | 620 | 27,66 | 880 | 45,82 | 1 140 | 31,85 | 1 400 | 51,67 | 1 660 | 86,59 |

| 101 | 52,04 | 361 | 15,73 | 621 | 21,43 | 881 | 43,66 | 1 141 | 26,87 | 1 401 | 51,53 | 1 661 | 86,55 |

| 102 | 51,99 | 362 | 17,23 | 622 | 15,62 | 882 | 40,91 | 1 142 | 21,41 | 1 402 | 50,17 | 1 662 | 86,7 |

| 103 | 51,99 | 363 | 19,04 | 623 | 11,51 | 883 | 37,78 | 1 143 | 16,41 | 1 403 | 49,99 | 1 663 | 86,55 |

| 104 | 52,36 | 364 | 20,96 | 624 | 9,69 | 884 | 34,89 | 1 144 | 12,56 | 1 404 | 50,32 | 1 664 | 86,7 |

| 105 | 52,58 | 365 | 22,94 | 625 | 9,46 | 885 | 32,69 | 1 145 | 10,41 | 1 405 | 51,05 | 1 665 | 86,52 |

| 106 | 52,47 | 366 | 25,05 | 626 | 10,21 | 886 | 30,99 | 1 146 | 9,07 | 1 406 | 51,45 | 1 666 | 86,85 |

| 107 | 52,03 | 367 | 27,31 | 627 | 11,78 | 887 | 29,31 | 1 147 | 7,69 | 1 407 | 52 | 1 667 | 86,55 |