Appendix 1 Distribution of braking among the axles of vehicles and requirements for compatibility between tractor and towed vehicle

1. General requirements

1.1.Vehicles of categories T, C, R and S

1.1.1.Vehicles of categories Ta, Ca, R2a, R3a, R4a and S2a with a maximum design speed exceeding 30 km/h shall fulfil the following requirements of this Appendix:

1.1.1.1.

the compatibility requirements associated with diagrams 2 and 3, as appropriate, if a special device is used, this shall operate automatically. In the case of trailers with electronically controlled brake force distribution, the requirements of this appendix shall only apply when the trailer is electrically connected to the tractor by the ISO 7638:2003 connector.

1.1.1.2.

in the event of a failure of the control of the special device the braking performance specified in point 5 shall be fulfilled for the relevant vehicle.

1.1.1.3.

the marking requirements laid down in point 6.

1.1.2.Vehicles of categories Tb, R2b, R3b, R4b and S2b shall meet the relevant requirements of this Appendix. If a special device is used, this shall operate automatically.

1.1.3.However, vehicles of the categories mentioned in point 1.1.1 and those in point 1.1.2 equipped with an anti-lock braking system of category 1 or 2 (tractors) and category A or B (towed vehicles) fulfilling the relevant requirements of Annex XI shall also fulfil all the relevant requirements of this Appendix with the following exceptions:

1.1.3.1.

compliance with the adhesion utilisation requirements associated with diagram 1 is not required;

1.1.3.2.

in the case of tractors and towed vehicles, compliance with the unladen compatibility requirements associated with diagrams 2 and 3 as appropriate, is not required. However, for all load conditions, a braking rate shall be developed between a pressure of 20 kPa and 100 kPa (pneumatic braking systems) and 350 to 1 800 kPa (hydraulic braking systems) or the equivalent digital demand value at the coupling head of the control line(s);

1.1.3.3.

vehicles equipped with a special device which automatically controls the distribution of braking among the axles or automatically regulates the braking force according to the load on the axle(s) the requirements of points 5 and 6 shall apply.

1.1.4Where the vehicle is installed with an endurance braking system, the retarding force shall not be taken into consideration when determining the vehicle performance with respect to the provisions of this Appendix.

1.2.The requirements relating to the diagrams specified in points 3.1.6.1, 4.1 and 4.2, are valid for vehicles with a pneumatic and electrical control line according to point 2.1.4 of Annex I or a hydraulic control line according to point 2.1.5 of Annex I. In all cases, the reference value (abscissa of the diagrams) will be the value of the transmitted pressure or electrical signal respectively in the control line:

1.2.1.

For vehicles equipped according to point 2.1.4.1.1 of Annex I, this value will be the actual pneumatic pressure in the control line (pm);

1.2.2.

For vehicles equipped according to point 2.1.4.1.2 or 2.1.4.1.3 of Annex I, this value will be the pressure corresponding to the transmitted digital demand value in the electric control line, according to ISO 11992:2003 including ISO 11992-2:2003 and its Amd.1:2007.

Vehicles equipped according to point 2.1.4.1.2 of Annex I (with both pneumatic and electric control lines) shall satisfy the requirements of the diagrams related to both control lines. However, identical braking characteristic curves related to both control lines are not required.

1.2.3.

For vehicles equipped according to point 2.1.5.1 of Annex I, this value shall be the actual hydraulic pressure in the control line (pm).

1.3.Validation of the development of braking force.

1.3.1.At the time of type-approval it shall be checked that the development of braking on an axle of each independent axle group shall be within the following pressure ranges:

1.3.1.1.

Laden vehicles:

At least one axle shall commence to develop a braking force when the pressure at the coupling head is within the pressure range 20 to 100 kPa (pneumatic braking systems) and 350 to 1 800 kPa (hydraulic braking systems) respectively or equivalent digital demand value.

At least one axle of every other axle group shall commence to develop a braking force when the coupling head is at a pressure ≤ 120 kPa (pneumatic braking systems) and 2 100 kPa (hydraulic braking systems) respectively or equivalent digital demand value.

1.3.1.2.

Unladen vehicles:

At least one axle shall commence to develop a braking force when the pressure at the coupling head is within the pressure range 20 to 100 kPa (pneumatic braking systems) and 350 to 1 800 kPa (hydraulic braking systems) respectively or equivalent digital demand value.

1.3.1.3.

With the wheel(s) of the axle(s) raised off and free to rotate, apply an increasing brake demand and measure the coupling head pressure corresponding to when the wheel(s) can no longer be rotated by hand. In the case of tractors of category C an alternative procedure may be used for the validation of the development of braking force (e.g. by removing the tracks). This condition determines the development of the braking force.

2. Symbols

i

=

axle index (i = 1, front axle; i = 2, second axle; etc.)

ER

=

distance between coupling point and centre of axle of rigid drawbar towed vehicle and of centre-axle towed vehicle

fi

=

Ti/Ni, adhesion utilised by axle i

Fi

=

normal reaction of road surface on axle i under static conditions

FM

=

total normal static reaction of road surface on wheels of tractor

g

=

acceleration due to gravity: g = 9,81 m/s2

h

=

height above ground of centre of gravity specified by the manufacturer and agreed by the Technical Services conducting the approval test;

J

=

deceleration of vehicle

k

=

theoretical coefficient of adhesion between tyre and road

Ni

=

normal reaction of road surface on axle i under braking

pm

=

pressure at coupling head of control line

FR

=

total normal static reaction of road surface on all wheels of towed vehicle

FRmax

=

value of FR at maximum mass of towed vehicle

Ti

=

force exerted by the brakes on axle i under normal braking conditions on the road

TM

=

sum of braking forces at the periphery of all wheels of tractors

TR

=

sum of braking forces Ti at periphery of all wheels of towed vehicle

z

=

braking rate of vehicle = J/g

3. Requirements for tractors of category T

3.1.Two-axle tractors

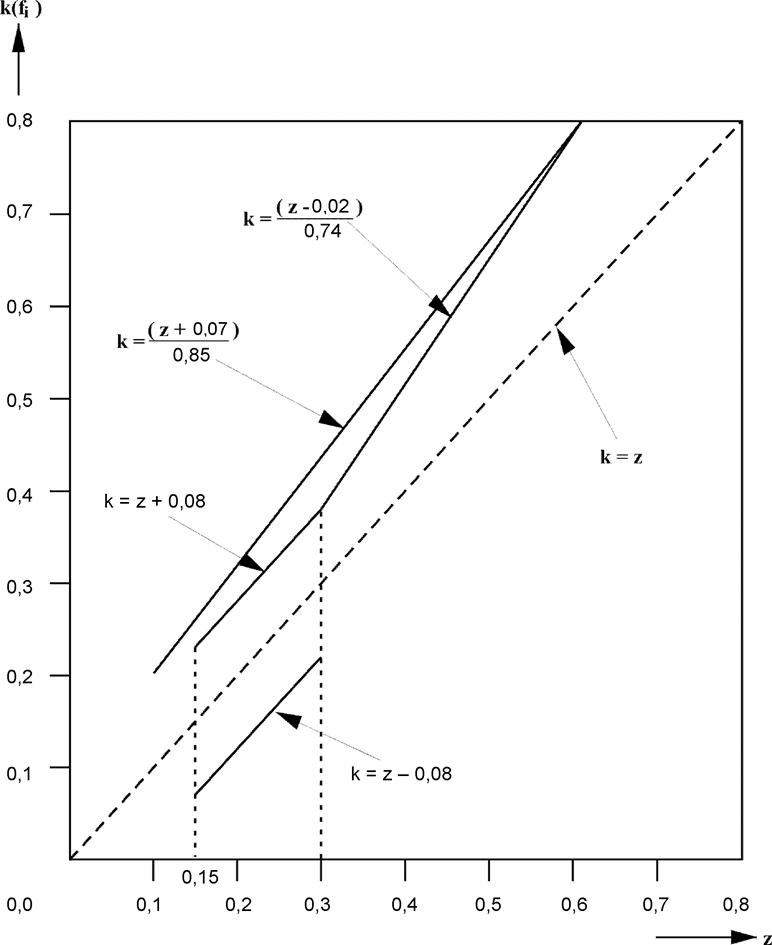

3.1.1.For all categories of tractors for k values between 0,2 and 0,8:

z ≥ 0,10 + 0,85 (k – 0,20)

The provisions laid down in points 3.1.1 and 4.1.1 do not affect the requirements of Annex II relating to the braking performance. However, if, in tests made under the provisions of points 3.1.1. and 4.1.1., braking performances are obtained which are higher than those prescribed in Annex II, the provisions relating to the adhesion utilisation curves shall be applied within the areas of diagram 1 defined by the straight lines k = 0,8 and z = 0,8.

3.1.2.For all states of load of the vehicle, the adhesion utilisation curve of the rear axle shall not be situated above that for the front axle:

3.1.2.1.

for all braking rates between 0,15 and 0,30

This condition is also considered satisfied if, for braking rates between 0,15 and 0,30, the adhesion utilisation curves for each axle are situated between two lines parallel to the line of ideal adhesion utilisation given by the equation k = z + 0,08 as shown in diagram 1 of this Appendix and the adhesion utilisation curve for the rear axle for braking rates z > 0,3 complies with the relation:

z ≥ 0,3 + 0,74 (k – 0,38).

3.1.3.For tractors authorised to tow vehicles of category R3b, R4b and S2b fitted with compressed-air braking systems:

3.1.3.1.

When tested with the energy source stopped, the supply line blocked off, a reservoir of 0,5 litre capacity connected to the pneumatic control line and the system at cut-in and cut-out pressures, the pressure at full application of the braking control device shall be between 650 and 850 kPa at the coupling heads of the supply line and the pneumatic control line, irrespective of the load condition of the vehicle.

3.1.3.2.

For vehicles equipped with an electric control line, a full application of the control device of the service braking system shall provide a digital demand value corresponding to a pressure between 650 and 850 kPa (cf ISO 11992:2003 including ISO 11992-2:2003 and its Amd.1:2007).

3.1.3.3.

These values shall be demonstrably present in the tractor when the latter is uncoupled from the towed vehicle. The compatibility bands in the diagrams specified in points 3.1.6., 4.1. and 4.2., should not be extended beyond 750 kPa and/or the corresponding digital demand value (see ISO 11992:2003 including ISO 11992-2:2003 and its Amd.1:2007).

3.1.3.4.

It shall be ensured that at the coupling head of the supply line, a pressure of at least 700 kPa is available when the system is at cut-in pressure. This pressure shall be demonstrated without applying the service brakes.

3.1.4.For tractors authorised to tow vehicles of category R3b, R4b and S2b fitted with hydraulic braking systems:

3.1.4.1.

When tested with the energy source at idling speed and of 2/3 of maximum engine speed, a control line of the towed vehicle simulator (point 3.6 of Annex III) connected to the hydraulic control line. At full application of the braking control device the pressures shall be between 11 500 and 15 000 kPa at the hydraulic control and shall be between 1 500 and 3 500 kPa at the supplementary line, irrespective of the load condition of the vehicle.

3.1.4.2.

These values shall be demonstrably present in the tractor when uncoupled from the towed vehicle. The compatibility bands in the diagrams specified in points 3.1.6, 4.1 and 4.2, should not be extended beyond 13 300 kPa.

3.1.5.Verification of the requirements of points 3.1.1. and 3.1.2.

3.1.5.1.In order to verify the requirements of points 3.1.1 and 3.1.2, the manufacturer shall provide the adhesion utilisation curves for the front and rear axles calculated by the formulae:

The curves shall be plotted for both the following load conditions:

3.1.5.1.1.

Unladen, not exceeding the minimum mass declared by the manufacturer in the information document;

3.1.5.1.2.

Laden; where provision is made for several possibilities of load distribution, the one whereby the front axle is the most heavily laden shall be the one considered.

3.1.5.2.If it is not possible, for vehicles with permanent all-wheel drive or in the condition when the all-wheel drive is connected during braking, to carry out the mathematical verification pursuant to point 3.1.5.1, the manufacturer may instead verify by means of a wheel lock sequence test that, for all braking rates between 0,15 and 0,8, lockup of the front wheels occurs either simultaneously with or before the lockup of the rear wheels. This alternative option does not exempt the manufacturer to show compliance with point 3.1.5.1 for the condition when the all-wheel drive is not connected during braking.

3.1.5.2.1.However, for tractors which automatically apply the all-wheel drive when the braking is initiated above a vehicle speed of 20 km/h but not automatically connect the all-wheel drive when the service braking system is applied at speeds ≤ 20 km/h, then it is not required to show compliance with point 3.1.5.1 for the condition when the all-wheel drive is not connected during braking.

3.1.5.3.Procedure to verify the requirements of point 3.1.5.2.

3.1.5.3.1.The wheel lock sequence test shall be conducted on road surfaces with a coefficient of adhesion of not more than 0,3 and of about 0,8 (dry road) from the initial test speeds specified in point 3.1.5.3.2.

3.1.5.3.2.Test speeds:

0,8 vmax km/h, but not exceeding 60 km/h for decelerations on low coefficient of friction road surfaces;

0,9 vmax for decelerations on high coefficient of friction road surfaces.

3.1.5.3.3.The pedal force applied may exceed the permissible actuation forces pursuant to point 3.2.1.

3.1.5.3.4.Pedal force is applied and increased such that the second wheel on the vehicle shall reach lockup between 0,5 and 1 s after initiating the brake application, until lockup of both wheels on one axle occurs (additional wheels may also lock during the test, e.g. in the case of simultaneous lockup).

3.1.5.4.The tests prescribed in point 3.1.5.2 shall be carried out twice on each road surface. If the result of one test fails, a third, hence decisive test shall be carried out.

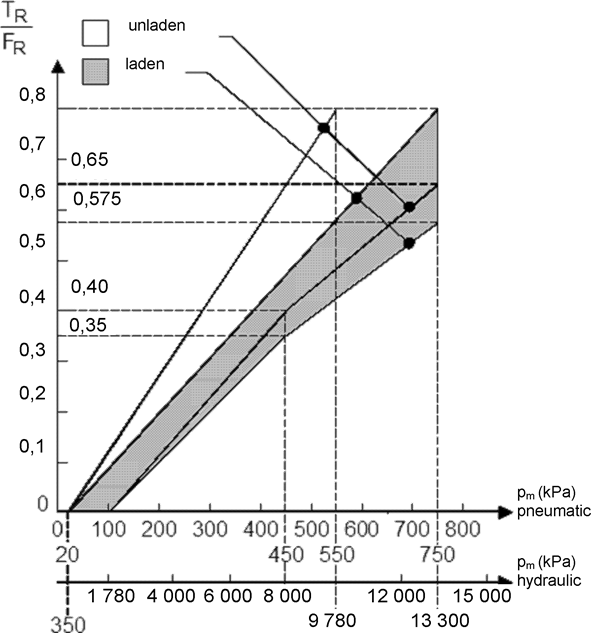

3.1.6.Tractors authorised to draw towed vehicles other than rigid drawbar towed vehicles and centre-axle towed vehicles

3.1.6.1.The permissible relationship between the braking rate TM/FM and the pressure pm shall lie within the areas shown on diagram 2 for all pressures between 20 and 750 kPa (in the case of compressed air braking system) and 350 and 13 300 kPa (in the case of hydraulic braking system)

3.2.Tractors with more than two axles

The requirements of point 3.1 shall apply to vehicles with more than two axles. The requirements of point 3.1.2 with respect to wheel lock sequence shall be considered to be met if, in the case of braking rates between 0,15 and 0,30, the adhesion utilised by at least one of the front axles is greater than that utilised by at least one of the rear axles.

4. Requirements for towed vehicles

4.1.For drawbar towed vehicles fitted with compressed-air and hydraulic braking systems:

4.1.1.

For drawbar towed vehicles with two axles the following requirements apply:

4.1.1.1.

For k values between 0,2 and 0,8:

z ≥ 0,1 + 0,85 (k – 0,2)

The provisions of point 3.1.1. do not affect the requirements of Annex II relating to the braking performance. However, if, in tests made under the provisions of point 3.1.1, braking performances are obtained which are higher than those prescribed in Annex II, the provisions relating to the adhesion utilisation curves shall be applied within the areas of diagrams 1 of this Annex defined by the straight lines k = 0,8 and z = 0,8.

4.1.1.2.

For all states of load of the vehicle, the adhesion utilisation curve of the rear axle shall not be situated above that for the front axle for all braking rates between 0,15 and 0,30. This condition is also considered satisfied if, for braking rates between 0,15 and 0,30, the following two conditions are satisfied:

4.1.1.2.1.

the adhesion utilisation curves for each axle are situated between two lines parallel to the line of ideal adhesion utilisation given by the equations k = z + 0,08 and k = z – 0,08 as shown in diagram 1

and

4.1.1.2.2.

the adhesion utilisation curve for the rear axle for braking rates z ≥ 0,3 complies with the relation z ≥ 0,3 + 0,74 (k – 0,38).

4.1.1.3.

For the verification of the requirements of points 4.1.1.1 and 4.1.1.2 the procedure should be as that in the provisions of point 3.1.5.

4.1.2.

For drawbar towed vehicles with more than two axles the requirements of point 4.1.1 shall apply. The requirements of point 4.1.1 with respect to wheel lock sequence shall be considered to be met if, in the case of braking rates between 0,15 and 0,30, the adhesion utilised by at least one of the front axles is greater than that utilised by at least one of the rear axles.

4.1.3.

The permissible relationship between the braking rate TR/FR and the pressure pm shall lie within the designated areas in diagram 3 for all pressures between 20 and 750 kPa (pneumatic) and 350 and 13 300 kPa (hydraulic) respectively, in both the laden and unladen states of load.

4.2.For rigid drawbar towed vehicles and centre-axle towed vehicles fitted with compressed-air and hydraulic braking systems:

4.2.1.

The permissible relationship between the braking rate TR/FR and the pressure pm shall lie within two areas derived from diagram 3, by multiplying the vertical scale by 0,95. This requirement shall be met at all pressures between 20 and 750 kPa (pneumatic) and 350 and 13 300 kPa (hydraulic) respectively, in both the laden and unladen states of load.

4.3.For drawbar towed vehicles with inertia braking system

4.3.1.The requirements according to point 4.1.1 apply also for drawbar towed vehicles with inertia braking system.

4.3.2.For drawbar towed vehicles with inertia braking system and with more than two axles the requirements according to point 4.1.2 of this Appendix apply.

4.3.3.For the calculation to verify the compliance with the provisions of point 4.1.1.3 the influence of the permissible drawbar force D* (point 10.3.1. of Annex VIII) can be ignored.

5. Requirements to be met in case of failure of the braking distribution system

When the requirements of this Appendix are fulfilled by means of a special device (e.g. controlled mechanically by the suspension of the vehicle), it shall be possible, in the event of the failure of its control, to stop the vehicle under the conditions specified for secondary braking in the case of tractors; tractors authorised to tow a vehicle fitted with compressed-air or hydraulic braking systems, it shall be possible to achieve a pressure at the coupling head of the control line within the range specified in points 3.1.3 and 3.1.4 In the event of failure of the control of the device on towed vehicles, a service braking performance of at least 30 % of that prescribed for the vehicle in question shall be attained.

6. Markings

6.1Vehicles which meet the requirements of this Appendix by means of a device mechanically controlled by the suspension of the vehicle shall be marked in accordance with the requirements laid down on the basis of Article 17(2)(k) and (5) of Regulation (EU) No 167/2013 and with the appropriate data to show the useful travel of the device between the positions corresponding to vehicle unladen and laden states, respectively, and any further information to enable the setting of the device to be checked.

6.1.1.When a brake load sensing device is controlled via the suspension of the vehicle by any other means, the vehicle shall be marked with information to enable the setting of the device to be checked.

6.2.When the requirements of this Appendix are met by means of a device which modulates the air or hydraulic pressure in the brake transmission, the vehicle shall be marked to show the axle loads at the ground, the nominal outlet pressures of the device and an inlet pressure of not less than 80 per cent of the maximum design inlet pressure, as declared by the vehicle manufacturer, for the following states of load:

6.2.1.

Technically permissible maximum axle load for the axle(s) which control(s) the device;

6.2.2.

Axle load(s) corresponding to the unladen mass of the vehicle in running order as stated in the test report for the braking requirements approval;

6.2.3.

The axle load(s) designated by the manufacturer to enable the setting of the device to be checked in service if this is (these are) different from the loads specified in points 6.2.1 to 6.2.2.

6.3.The markings referred to in points 6.1 and 6.2 shall be affixed in a visible position in indelible form. An example of the markings for a mechanically controlled device in a vehicle fitted with compressed-air or hydraulic braking system is provided in accordance with the requirements laid down on the basis of Article 34(3) of Regulation (EU) No 167/2013.

6.4.Electronically controlled brake force distribution systems that cannot fulfil the requirements of points 6.1, 6.2 and 6.3 shall have a self-checking procedure of the functions which influence brake force distribution. In addition, when the vehicle is stationary, it shall be possible to carry out the checks laid down in point 1.3.1, by generating the nominal demand pressure associated with the commencement of braking for both the laden and unladen conditions.

7. Vehicle testing

At the time of type-approval, the technical service shall verify conformity with the requirements contained within this Appendix and carry out any further tests considered necessary to this end. The report of any further tests shall be appended to the type-approval report.

Diagram 1 Tractors of category Tb and drawbar towed vehicles of categories R3b, R4b and S2b (see points 3.1.2.1 and 4.1.1.2)

Note: The lower limit k = z – 0,08 is not applicable for the adhesion utilisation of the rear axle.

Diagram 2 Permissible relationship between braking rate TM/PM and the coupling head pressure pm for tractors of categories T and C with compressed air or hydraulic braking systems

Diagram 3 Permissible relationship between braking rate TR/FR and the coupling head pressure pm for towed vehicles of categories S2, R3 and R4 with compressed air or hydraulic braking systems