- Y Diweddaraf sydd Ar Gael (Diwygiedig)

- Gwreiddiol (Fel y’i mabwysiadwyd gan yr UE)

Commission Regulation (EC) No 543/2008Dangos y teitl llawn

Commission Regulation (EC) No 543/2008 of 16 June 2008 laying down detailed rules for the application of Council Regulation (EC) No 1234/2007 as regards the marketing standards for poultrymeat

You are here:

- Rheoliadau yn deillio o’r UE

- 2008 No. 543

- Annexes only

- Dangos Graddfa Ddaearyddol(e.e. Lloegr, Cymru, Yr Alban aca Gogledd Iwerddon)

- Dangos Llinell Amser Newidiadau

Rhagor o Adnoddau

PDF o Fersiynau Diwygiedig

- ddiwygiedig 01/07/20130.75 MB

- ddiwygiedig 27/12/20120.68 MB

- ddiwygiedig 20/07/20120.67 MB

- ddiwygiedig 24/06/20110.67 MB

- ddiwygiedig 01/07/20100.66 MB

- ddiwygiedig 19/06/20090.28 MB

- ddiwygiedig 01/07/20080.27 MB

When the UK left the EU, legislation.gov.uk published EU legislation that had been published by the EU up to IP completion day (31 December 2020 11.00 p.m.). On legislation.gov.uk, these items of legislation are kept up-to-date with any amendments made by the UK since then.

Mae hon yn eitem o ddeddfwriaeth sy’n deillio o’r UE

Mae unrhyw newidiadau sydd wedi cael eu gwneud yn barod gan y tîm yn ymddangos yn y cynnwys a chyfeirir atynt gydag anodiadau.Ar ôl y diwrnod ymadael bydd tair fersiwn o’r ddeddfwriaeth yma i’w gwirio at ddibenion gwahanol. Y fersiwn legislation.gov.uk yw’r fersiwn sy’n weithredol yn y Deyrnas Unedig. Y Fersiwn UE sydd ar EUR-lex ar hyn o bryd yw’r fersiwn sy’n weithredol yn yr UE h.y. efallai y bydd arnoch angen y fersiwn hon os byddwch yn gweithredu busnes yn yr UE. EUR-Lex Y fersiwn yn yr archif ar y we yw’r fersiwn swyddogol o’r ddeddfwriaeth fel yr oedd ar y diwrnod ymadael cyn cael ei chyhoeddi ar legislation.gov.uk ac unrhyw newidiadau ac effeithiau a weithredwyd yn y Deyrnas Unedig wedyn. Mae’r archif ar y we hefyd yn cynnwys cyfraith achos a ffurfiau mewn ieithoedd eraill o EUR-Lex. The EU Exit Web Archive legislation_originated_from_EU_p3

Changes over time for: Commission Regulation (EC) No 543/2008 (Annexes only)

Alternative versions:

Changes to legislation:

Commission Regulation (EC) No 543/2008 is up to date with all changes known to be in force on or before 04 November 2024. There are changes that may be brought into force at a future date. Changes that have been made appear in the content and are referenced with annotations.![]()

Changes to Legislation

Revised legislation carried on this site may not be fully up to date. Changes and effects are recorded by our editorial team in lists which can be found in the ‘Changes to Legislation’ area. Where those effects have yet to be applied to the text of the legislation by the editorial team they are also listed alongside the legislation in the affected provisions. Use the ‘more’ link to open the changes and effects relevant to the provision you are viewing.

Changes and effects yet to be applied to :

- Recital 3 replacement by EUR 2012/652 Regulation

- Recital 4 replacement by EUR 2012/652 Regulation

- Recital 5 replacement by EUR 2012/652 Regulation

- Art. 5(1) words substituted by S.I. 2019/1422 reg. 8(6)(a) (This amendment not applied to legislation.gov.uk. Reg. 8(6)(a) substituted immediately before IP completion day by S.I. 2020/1453, regs. 1(2)(b), 14(18)(b))

- Recital 6 replacement by EUR 2012/652 Regulation

- Recital 7 replacement by EUR 2012/652 Regulation

- Recital 8 replacement by EUR 2012/652 Regulation

- Recital 11 replacement by EUR 2012/652 Regulation

- Recital 12 replacement by EUR 2012/652 Regulation

- Recital 13 replacement by EUR 2012/652 Regulation

- Recital 15 replacement by EUR 2012/652 Regulation

- Art. 15(1) words substituted by S.I. 2019/1422 reg. 8(14)(a)(ii) (This amendment not applied to legislation.gov.uk. Reg. 8(14)(a)(ii) substituted immediately before IP completion day by S.I. 2020/1453, regs. 1(2)(b), 14(18)(e))

- Recital 16 replacement by EUR 2012/652 Regulation

- Recital 17 replacement by EUR 2012/652 Regulation

- Recital 18 replacement by EUR 2012/652 Regulation

- Art. 20(1) words substituted by S.I. 2019/1422 reg. 8(18)(a) (This amendment not applied to legislation.gov.uk. Reg. 8(18)(a) substituted immediately before IP completion day by S.I. 2020/1453, regs. 1(2)(b), 14(18)(g))

- Recital 24 replacement by EUR 2012/652 Regulation

F1ANNEX IU.K.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Textual Amendments

ANNEX IIU.K.

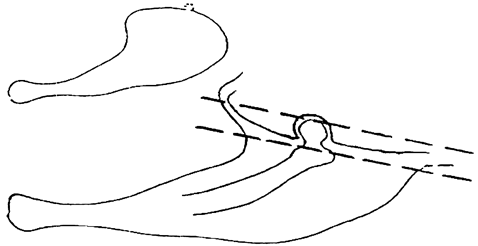

Cut separating thigh/leg and backU.K.

Cut separating thigh and drumstickU.K.

F2ANNEX IIIU.K.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Textual Amendments

F3ANNEX IVU.K.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Textual Amendments

ANNEX VU.K.

The conditions referred to in Article 11 are as follows:

Fed with …% of …

Reference to the following particular feed ingredients may only be made where:

in the case of cereals, they account for at least 65 % by weight of the feed formula given during the greater part of the fattening period, which may not include more than 15 % of cereal by-products; however, where reference is made to one specific cereal, it shall account for at least 35 % of the feed formula used, and for at least 50 % in the case of maize,

in the case of pulses or green vegetables they account for at least 5 % by weight of the feed formula given during most of the fattening period,

in the case of dairy products, they account for at least 5 % by weight of the feed formula given during the finishing stage.

The term ‘Oats-fed goose’ may however be used where the geese are fed during the finishing stage of three weeks not less than 500 g of oats per day.

Extensive indoor (barn-reared)

This term may only be used where:

the stocking rate per m2 floor space does not exceed, in the case of:

chickens, young cocks, capons: 15 birds but not more than 25 kg liveweight,

ducks, guinea fowl, turkeys: 25 kg liveweight,

geese: 15 kg liveweight,

the birds are slaughtered, in the case of:

chickens at 56 days or later,

turkeys at 70 days or later,

geese at 112 days or later,

Peking ducks: 49 days or later,

Muscovy ducks: 70 days or later for females, 84 days or later for males,

female Mulard ducks: 65 days or later,

guinea fowl: 82 days or later,

young geese (goslings): 60 days or later,

young cocks: 90 days or later,

capons: 140 days or later.

Free range

This term may only be used where:

the stocking rate in the house and the age of slaughter are in accordance with the limits fixed under (b), except for chickens, for which the stocking rate may be increased to 13, but not more than 27,5 kg liveweight per m2 and for capons, for which the stocking rate shall not exceed 7,5 m2, and not more than 27,5 kg liveweight per m2,

the birds have had during at least half their lifetime continuous daytime access to open-air runs comprising an area mainly covered by vegetation of not less than:

1 m2 per chicken or guinea fowl,

2 m2 per duck or per capon,

4 m2 per turkey or goose.

In the case of guinea fowls, open-air runs may be replaced by a perchery having a floor surface of at least that of the house and a height of at least 2 m. Perches of at least 10 cm length are available per bird in total (house and perchery),

the feed formula used in the fattening stage contains at least 70 % of cereals,

the poultryhouse is provided with popholes of a combined length at least equal to 4 m per 100 m2 surface of the house.

Traditional free range

This term may only be used where:

the indoor stocking rate per m2 does not exceed in the case of:

chickens: 12 but not more than 25 kg liveweight; however, in the case of mobile houses not exceeding 150 m2 floor space and which remain open at night, the stocking rate may be increased to 20, but not more than 40 kg liveweight per m2,

capons: 6,25 (up to 91 days of age: 12) but not more than 35 kg liveweight,

Muscovy and Peking ducks: 8 males but not more than 35 kg liveweight, 10 females but not more than 25 kg liveweight,

Mulard ducks: 8 but not more than 35 kg liveweight,

guinea fowl: 13 but not more than 25 kg liveweight,

turkeys: 6,25 (up to seven weeks of age: 10) but not more than 35 kg liveweight,

geese: 5 (up to six weeks of age: 10), 3 during last three weeks of fattening if kept in claustration, but not more than 30 kg liveweight,

the total usable area of poultryhouses at any single production site does not exceed 1 600 m2,

each poultryhouse does not contain more than:

4 800 chickens,

5 200 guinea fowl,

4 000 female Muscovy or Peking ducks or 3 200 male Muscovy or Peking ducks or 3 200 Mulard ducks,

2 500 capons, geese and turkeys,

the poultryhouse is provided with popholes of a combined length at least equal to 4 m per 100 m2 surface of the house,

there is continuous daytime access to open-air runs at least as from the age of:

six weeks in the case of chickens, and capons,

eight weeks in the case of ducks, geese, guinea fowl and turkeys,

open-air runs comprise an area mainly covered by vegetation amounting to at least:

2 m2 per chicken or Muscovy or Peking duck or guinea fowl,

3 m2 per Mulard duck,

4 m2 per capon, as from 92 days (2 m2 up to 91st day),

6 m2 per turkey,

10 m2 per goose.

In the case of guinea fowls, open-air runs may be replaced by a perchery having a floor surface of at least double that of the house and a height of at least 2 m. Perches of at least 10 cm length are available per bird in total (house and perchery),

the birds fattened are of a strain recognised as being slow growing,

the feed formula used in the fattening stage contains at least 70 % of cereals,

the minimum age at slaughter is:

81 days for chickens,

150 days for capons,

49 days for Peking ducks,

70 days for female Muscovy ducks,

84 days for male Muscovy ducks,

92 days for Mulard ducks,

94 days for guinea fowl,

140 days for turkeys and geese marketed whole for roasting,

98 days for female turkeys intended for cutting up,

126 days for male turkeys intended for cutting up,

95 days for geese intended for the production of foie gras and magret,

60 days for young geese (goslings),

finition in claustration does not exceed:

for chickens after 90 days of age: 15 days,

for capons: four weeks,

for geese and Mulard ducks intended for the production of foie gras and magret, after 70 days of age: 4 weeks.

Free range — total freedom

The use of this term shall require conformity with the criteria set out under (d), except that the birds shall have continuous daytime access to open-air runs of unlimited area.

In the event of restrictions, including veterinary restrictions adopted under [F4retained direct EU legislation] to protect public and animal health, having the effect of restricting the access of poultry to open-air runs, poultry reared in accordance with the production methods described in points (c), (d) and (e) of the first subparagraph, with the exception of guinea fowls reared in percheries, may continue to be marketed with a special reference to the method of rearing for the duration of the restriction but under no circumstances for more than 12 weeks.

Textual Amendments

ANNEX VIU.K.DETERMINATION OF THAW LOSS(Drip test)

1.Object and scopeU.K.

This method shall be used to determine the amount of water lost from frozen or quick-frozen chickens during thawing. If this drip loss, expressed as a percentage by weight of the carcase (including all the edible offal contained in the pack) exceeds the limit value laid down in point 7, it is considered that excess water has been absorbed during processing.

2.DefinitionU.K.

Drip loss determined by this method shall be expressed as a percentage of the total weight of the frozen or quick-frozen carcase, including edible offal.

3.PrincipleU.K.

The frozen or quick-frozen carcase, including edible offal present, is allowed to thaw under controlled conditions which allow the weight of water lost to be calculated.

4.ApparatusU.K.

4.1.Scales capable of weighing up to 5 kg and accurate to at least 1 g.U.K.

4.2.Plastic bags large enough to hold the carcase and having a secure means of fixing the bag.U.K.

4.3.Thermostatically controlled water-bath with equipment capable of holding the carcases as described in points 5.5 and 5.6. The water-bath shall contain a volume of water not less than eight times that of the poultry to be checked and shall be capable of maintaining the water at a temperature of 42 ± 2 °C.U.K.

4.4.Filter paper or other absorbent paper towels.U.K.

5.MethodU.K.

5.1.Twenty carcases are removed at random from the quantity of poultry to be checked. Until each can be tested as described in points 5.2 to 5.11, they are kept at a temperature no higher than – 18 °C.U.K.

5.2.The outside of the pack is wiped to remove superficial ice and water. The pack and its content are weighed to the nearest gram: this weight is M0.U.K.

5.3.The carcase, together with any edible offal sold with it, is removed from the outer wrap, which is dried and weighed to the nearest gram: this weight is M1.U.K.

5.4.The weight of frozen carcase plus offal is calculated by subtracting M1 from M0.U.K.

5.5.The carcase, including the edible offal, is placed in a strong, waterproof plastic bag with the abdominal cavity facing towards the bottom, closed end of the bag. The bag must be of sufficient length so as to ensure that it can be fixed securely when in the water-bath but not so wide as to allow the carcase to move from the vertical position.U.K.

5.6.The part of the bag containing the carcase end edible offal is completely immersed in a water-bath and remains open, enabling as much air as possible to escape. It is held vertically, if necessary by guide bars or by extra weights put in the bag, so that water from the bath cannot enter it. The individual bags must not touch each other.U.K.

5.7.The bag is left in the water-bath, maintained at 42 ± 2 °C throughout, with continuous movement of the bag or continuous agitation of the water, until the thermal centre of the carcase (the deepest part of the breast muscle close to the breast bone, in chickens without giblets, or the middle of the giblets in chickens with giblets) reaches at least 4 °C, measured in two randomly chosen carcases. The carcases should not remain in the water bath for longer than is necessary to reach 4 °C. The required period of immersion, for carcases stored at – 18 °C is of the order of:U.K.

| Weight class (g) | Weight of carcase + offal (g) | Indicative immersion time in minutes | |

|---|---|---|---|

| Chickens without offal | Chickens with offal | ||

| < 800 | < 825 | 77 | 92 |

| 850 | 825 — 874 | 82 | 97 |

| 900 | 875 — 924 | 85 | 100 |

| 950 | 925 — 974 | 88 | 103 |

| 1 000 | 975 — 1 024 | 92 | 107 |

| 1 050 | 1 025 — 1 074 | 95 | 110 |

| 1 100 | 1 075 — 1 149 | 98 | 113 |

| 1 200 | 1 150 — 1 249 | 105 | 120 |

| 1 300 | 1 250 — 1 349 | 111 | 126 |

| 1 400 | 1 350 — 1 449 | 118 | 133 |

For carcases over 1 400 g, an increase of seven minutes for each additional 100 g is required. If the suggested period of immersion is passed without reaching + 4 °C, in the two carcases which are checked, the thawing process is continued until they do reach + 4 °C in the thermal centre.

5.8.The bag and its content are removed from the water-bath; the bottom of the bag is pierced to allow any water produced on thawing to drain. The bag and its content are allowed to drip for one hour at an ambient temperature of between + 18 °C and + 25 °C.U.K.

5.9.The thawed carcase is removed from the bag and the pack containing offal (if present) is removed from the abdominal cavity. The carcase is dried inside and out with filter paper or paper towels. The bag containing the offal is pierced and, once any water has drained away, the bag and thawed offal are dried as carefully as possible.U.K.

5.10.The total weight of thawed carcase, offal and pack is determined to the nearest gram and expressed as M2.U.K.

5.11.The weight of the pack which contained the offal is determined to the nearest gram and expressed as M3.U.K.

6.Calculation of resultU.K.

The amount of water lost through thawing as a percentage by weight of the frozen or quick-frozen carcase (including offal) is given by:

((M0 – M1 – M2)/(M0 – M1 – M3)) × 100

[F57. Evaluation of result U.K.

If the average water loss on thawing for the 20 carcases in the sample exceeds the percentages given below, it is considered that the amount of water absorbed during processing exceeds the permissible limit.

The percentages are, in the case of:

air chilling: 1,5 %,

air spray chilling: 3,3 %,

immersion chilling: 5,1 %.

other chilling method or a combination of two or more of the methods defined in Article 10: 1,5 %.]

Textual Amendments

ANNEX VIIU.K.DETERMINATION OF THE TOTAL WATER CONTENT OF CHICKENS(Chemical test)

1.Object and scopeU.K.

This method is used to determine the total water content of frozen and quick-frozen chickens. The method involves determination of the water and protein contents of samples from homogenised poultry carcases. The total water content as determined is compared with the limit value given by the formulae indicated in point 6.4, to determine whether or not excess water has been taken up during processing. If the analyst suspects the presence of any substance which may interfere with the assessment, it is for him or her to take the necessary appropriate precautions.

2.DefinitionsU.K.

‘Carcase’: the poultry carcase with bones, cartilage and any additional offal.

‘Offal’: liver, heart, gizzard and neck.

3.PrincipleU.K.

Water and protein contents are determined in accordance with recognised ISO (International Organisation for Standardisation) methods or other methods of analysis approved by the [F6relevant authority].

Textual Amendments

The maximum total water content of the carcase is determined from the protein content of the carcase, which can be related to the physiological water content.

4.Apparatus and reagentsU.K.

4.1.Scales for weighing the carcase and wrappings, accurate to at least 1 g.U.K.

4.2.Meat-axe or saw for cutting carcases into pieces of appropriate size for the mincer.U.K.

4.3.Heavy-duty mincing machine and blender capable of homogenising complete frozen or quick-frozen poultry pieces.U.K.

NB:U.K.

No special mincer is recommended. It should have sufficient power to mince frozen or quick-frozen meat and bones to produce a homogeneous mixture corresponding to that obtained from a mincer fitted with a 4-mm hole disc.

4.4.Apparatus as specified in ISO 1442, for the determination of water content.U.K.

4.5.Apparatus as specified in ISO 937, for the determination of protein content.U.K.

5.MethodU.K.

5.1.Seven carcases are taken at random from the quantity of poultry to be checked and in each case kept frozen until analysis in accordance with points 5.2 to 5.6 begins.U.K.

The analysis may concern either each of the seven carcases separately or a composite sample of the seven carcases.

5.2.The preparation is commenced within the hour following the removal of the carcases from the freezer.U.K.

5.3.

The outside of the pack is wiped to remove superficial ice and water. Each carcase is weighed and removed from any wrapping material. After cutting up of the carcase into smaller pieces, any wrapping material around the edible offal is removed. The total weight of the carcase, including the edible offal and ice adhering to the carcase, is determined to the nearest gram after deduction of the weight of any wrapping material removed, to give ‘P1’.

In the case of a composite sample analysis, the total weight of the seven carcases, prepared in accordance with point 5.3(a), is determined to give ‘P7’.

5.4.

The whole carcase of which the weight is P1 is minced in a mincer as specified under point 4.3 (and, if necessary, mixed with the use of a blender as well) to obtain a homogeneous material from which a sample representative of each carcase may then be taken.

In the case of a composite sample analysis, all seven carcases of which the weight is P7 is minced in a mincer as specified under point 4.3 (and, if necessary, mixed with the use of a blender as well) to obtain a homogeneous material from which two samples representative of the seven carcases may then be taken. The two samples are analysed as described in points 5.5 and 5.6.

5.5.A sample of the homogenised material is taken and used immediately to determine the water content in accordance with ISO 1442 to give the water content ‘a %’.U.K.

5.6.A sample of the homogenised material is also taken and used immediately to determine the nitrogen content in accordance with ISO 937. This nitrogen content is converted to crude protein content ‘b %’ by multiplying it by the factor 6,25.U.K.

[F56. Calculation of results U.K.

6.1.

The weight of water (W) in each carcase is given by aP 1 /100 and the weight of protein (RP) by bP 1 /100, both of which are expressed in grams. The sums of the weights of water (W 7 ) and the weights of protein (RP 7 ) in the seven carcases analysed are determined.

In the case of a composite sample analysis, the average content of water and protein from the two samples analysed is determined to give a % and b %, respectively. The weight of the water (W 7 ) in the seven carcases is given by aP 7 /100, and the weight of protein (RP 7 ) by bP 7 /100, both of which are expressed in grams.

6.2. The average weight of water (W A ) and protein (RP A ) is calculated by dividing W 7 and RP 7 , respectively, by seven. U.K.

6.3. The theoretical physiological water content in grams as determined by this method may be calculated by the following formula: U.K.

6.4.

Air chilling

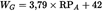

Assuming that the minimum technically unavoidable water content absorbed during preparation amounts to 2 % (1) , the highest permissible limit for the total water content (W G ) in grams as determined by this method is given by the following formula (including confidence interval):

Air-spray chilling

Assuming that the minimum technically unavoidable water content absorbed during preparation amounts to 4,5 % (1) , the highest permissible limit for the total water content (W G ) in grams as determined by this method is given by the following formula (including confidence interval):

Immersion chilling

Assuming a technically unavoidable water absorption during preparation of 7 % (1) the highest permissible limit for the total water content (W G ) in grams as determined by this method is given by the following formula (including confidence interval):

Other chilling methods or a combination of two or more of the methods defined in Article 10

Assuming that the minimum technically unavoidable water content absorbed during preparation amounts to 2 % (1) , the highest permissible limit for the total water content (W G ) in grams as determined by this method is given by the following formula (including confidence interval):

6.5. If the average water content (W A ) of the seven carcases as calculated under point 6.2 does not exceed the value given in point 6.4 (W G ), the quantity of poultry subjected to the check shall be considered up to standard.] U.K.

ANNEX VIIIU.K.DETERMINATION OF THE TOTAL WATER CONTENT OF POULTRY CUTS(Chemical test)

1.Object and scopeU.K.

This method is used to determine the total water content of certain poultry cuts. The method shall involve determination of the water and protein contents of samples from the homogenised poultry cuts. The total water content as determined is compared with the limit value given by the formulae indicated in point 6.4, to determine whether or not excess water has been taken up during processing. If the analyst suspects the presence of any substance which may interfere with the assessment, it is for him or her to take the necessary appropriate precautions.

2.Definitions and sampling proceduresU.K.

The definitions given in point (2) of Article 1 are applicable to the poultry cuts referred to in Article 20. The sample sizes should be at least as follows:

chicken breast: half of the breast,

chicken breast fillet: half of the boned breast without skin,

turkey breast, turkey breast fillet and boned leg meat: portions of about 100 g,

other cuts: as defined in point (2) of Article 1.

In the case of frozen or quick-frozen bulk products (cuts not individually packed) the large packs from which samples are to be taken may be kept at 0 °C until individual cuts can be removed.

3.PrincipleU.K.

Water and protein contents are determined in accordance with recognised ISO (International Organisation for Standardisation) methods or other methods of analysis approved by the [F7relevant authority].

Textual Amendments

The highest permissible total water content of the poultry cuts is determined from the protein content of the cuts, which can be related to the physiological water content.

4.Apparatus and reagentsU.K.

4.1.Scales for weighing the cuts and wrappings, accurate to at least 1 g.U.K.

4.2.Meat-axe or saw for cutting cuts into pieces of appropriate size for the mincer.U.K.

4.3.Heavy-duty mincing machine and blender capable of homogenising poultry cuts or parts thereof.U.K.

NB:U.K.

No special mincer is recommended. It should have sufficient power to mince frozen or quick-frozen meat and bones to produce a homogeneous mixture corresponding to that obtained from a mincer fitted with a 4-mm hole disc.

4.4.Apparatus as specified in ISO 1442, for the determination of water content.U.K.

4.5.Apparatus as specified in ISO 937, for the determination of protein content.U.K.

5.MethodU.K.

5.1.Five cuts are taken at random from the quantity of poultry cuts to be checked and kept frozen or refrigerated as the case may be until analysis in accordance with points 5.2 to 5.6 begins.U.K.

Samples from frozen or quick-frozen bulk products referred to under point 2 may be kept at 0 °C until analysis begins.

The analysis may concern each of the five cuts separately or a composite sample of the five cuts.

5.2.The preparation is commenced within the hour following the removal of the cuts from the freezer or refrigerator.U.K.

5.3.

The outside of the pack is wiped to remove superficial ice and water. Each cut is weighed and removed from any wrapping material. After cutting up the cuts into smaller pieces, the weight of the poultry cut is determined to the nearest gram after deduction of the weight of any wrapping material removed, to give ‘P1’.

In the case of a composite sample analysis, the total weight of the five cuts, prepared in accordance with point 5.3(a), is determined to give ‘P5’.

5.4.

The whole cut of which the weight is P1, is minced in a mincer as specified under point 4.3 (and, if necessary, mixed with the use of a blender as well) to obtain a homogeneous material from which a sample representative of each cut may then be taken.

In the case of a composite sample analysis, all five cuts of which the weight is P5 are minced in a mincer as specified under point 4.3 (and, if necessary, mixed with the use of a blender as well) to obtain a homogeneous material from which two samples representative of the five cuts may then be taken.

The two samples are analysed as described in points 5.5 and 5.6.

5.5.A sample of the homogenised material is taken and used immediately to determine the water content in accordance with ISO 1442 to give the water content ‘a %’.U.K.

5.6.A sample of the homogenised material is also taken and used immediately to determine the nitrogen content in accordance with ISO 937. This nitrogen content is converted to crude protein content ‘b %’ by multiplying it by the factor 6,25.U.K.

[F56. Calculation of results U.K.

6.1.

The weight of water (W) in each cut is given by aP 1 /100 and the weight of protein (RP) by bP 1 /100, both of which are expressed in grams.

The sums of the weights of water (W 5 ) and the weights of protein (RP 5 ) in the five cuts analysed are determined.

In the case of a composite sample analysis, the average content of water and protein from the two samples analysed is determined to give a % and b %, respectively. The weight of the water (W 5 ) in the five cuts is given by aP 5 /100, and the weight of protein (RP 5 ) by bP 5 /100, both of which are expressed in grams.

6.2. The average weight of water (W A ) and protein (RP A ) is calculated by dividing W 5 and RP 5 respectively, by five. U.K.

6.3. The mean physiological W/RP ratio as determined by this method is as follows: U.K.

chicken breast fillet: 3,19 ± 0,12,

chicken legs and leg quarters: 3,78 ± 0,19,

turkey breast fillet: 3,05 ± 0,15,

turkey legs: 3,58 ± 0,15,

deboned turkey leg meat: 3,65 ± 0,17.

6.4. Assuming that the minimum technically unavoidable water content absorbed during preparation amounts to 2 %, 4 % or 6 % (2) depending on the type of products and chilling methods applied, the highest permissible W/RP ratios as determined by this method are as follows: U.K.

| Air chilled | Air-spray chilled | Immersion chilled | |

|---|---|---|---|

| Chicken breast fillet; without skin | 3,4 | 3,4 | 3,4 |

| Chicken breast; with skin | 3,4 | 3,5 | 3,6 |

| Chicken thighs, drumsticks, legs, legs with a portion of the back, leg quarters, with skin | 4,05 | 4,15 | 4,3 |

| Turkey breast fillet; without skin | 3,4 | 3,4 | 3,4 |

| Turkey breast, with skin | 3,4 | 3,5 | 3,6 |

| Turkey thighs, drumsticks, legs, with skin | 3,8 | 3,9 | 4,05 |

| Deboned turkey leg meat, without skin | 3,95 | 3,95 | 3,95 |

In case of other chilling methods or a combination of two or more of the methods defined in Article 10, the unavoidable water content is assumed to amount to 2 % and the highest permissible W/PR ratios are those fixed for the air chilling method in the table above.

If the average W A /RP A ratio of the five cuts as calculated from the values under point 6.2 does not exceed the ratio given in point 6.4, the quantity of poultry cuts subjected to the check is considered up to standard.]

ANNEX IXU.K.CHECK ON ABSORPTION OF WATER IN THE PRODUCTION ESTABLISHMENT(Slaughterhouse test)

1.At least once each working period of eight hours:U.K.

select at random 25 carcases from the evisceration line immediately after evisceration and the removal of the offal and fat and before the first subsequent washing.

2.If necessary, remove the neck by cutting, leaving the neck skin attached to the carcase.U.K.

3.Identify each carcase individually. Weigh each carcase and record its weight to the nearest gram.U.K.

4.Re-hang the test carcases on the evisceration line to continue through the normal processes of washing, chilling, dripping, etc.U.K.

5.Remove identified carcases at the end of the drip line without allowing them any longer time to drip than that allowed normally for poultry from the lot from which the sample was taken.U.K.

6.The sample consists of the first 20 carcases recovered. They are re-weighed. Their weight to the nearest gram is recorded against the weight recorded on first weighing. The test is declared void if less than 20 identified carcases are recovered.U.K.

7.Remove identification from sample carcases and allow the carcases to proceed through normal packing operations.U.K.

8.Determine percentage moisture absorption by subtracting the total weight of these same carcases after washing, chilling and dripping, dividing the difference by the initial weight and multiplying by 100.U.K.

9.Instead of manual weighing as described under points 1 to 8, automatic weighing lines may be used for the determination of the percentage moisture absorption for the same number of carcases and according to the same principles, provided that the automatic weighing line is approved in advance for this purpose by the competent authority.U.K.

10.The result must not exceed the following percentages of the initial weight of the carcase or any other figure allowing compliance with the maximum total extraneous water content:U.K.

:

0 %,

:

2,0 %,

:

4,5 %,

[F811. In cases where carcases are chilled with an other chilling method or a combination of two or more of the methods defined in Article 10, the maximum percentage of water content shall not exceed 0 % of the original weight of the carcase.] U.K.

Textual Amendments

F9ANNEX XU.K.INDICATIONS REFERRED TO IN ARTICLE 16(6)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Textual Amendments

F10ANNEX XIU.K. LIST OF NATIONAL REFERENCE LABORATORIES

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Textual Amendments

ANNEX XIIU.K.

Tasks and organisational structure of the board of experts in monitoring water content in poultrymeatU.K.

The board of experts referred to in Article 19 is responsible for the following tasks:

supplying information on analytical methods and comparative testing regarding the water content of poultrymeat to the national reference laboratories;

coordinating the application by the national reference laboratories of the methods referred to in (a), by organising comparative testing, and proficiency testing in particular;

supporting the national reference laboratories in proficiency testing by providing scientific support for statistical data evaluation and reporting;

coordinating the development of new analytical methods and informing the national reference laboratories of progress made in this area;

providing scientific and technical assistance to the Commission, especially in cases where the results of analyses are contested between Member States.

The board of experts referred to in Article 19 shall be organised as follows:

The board of experts in monitoring water content in poultrymeat shall consist of representatives of the Directorate-General Joint Research Centre (JRC) — Institute for Reference Materials and Measurements (IRMM), of the Directorate-General for Agriculture and Rural Development and of three national reference laboratories. The representative of IRMM shall act as the chairperson of the board and shall appoint the national reference laboratories on a rotational basis. The Member State authority responsible for the national reference laboratory selected shall subsequently appoint individual experts in monitoring water content in food to serve on the board. Through annual rotation, one participating national reference laboratory shall be replaced at a time, so as to ensure a degree of continuity on the board. Expenses incurred by the Member States’ experts and/or the national reference laboratories in the exercise of their functions under this Section of this Annex shall be borne by the respective Member States.

Tasks of national reference laboratoriesU.K.

The national reference laboratories listed in Annex XI are responsible for the following tasks:

coordinating the activities of the national laboratories responsible for analyses of water content in poultrymeat;

assisting the competent authority in the Member State in organising the system for monitoring water content in poultrymeat;

participating in comparative testing (proficiency testing) between the various national laboratories referred to in (a);

ensuring that the information supplied by the board of experts is disseminated to the competent authority in the relevant Member State and to the national laboratories referred to in (a);

collaborating with the board of experts and, if appointed to join the board of experts, preparing the necessary test samples, including homogeneity testing, and arranging appropriate shipping.

F11ANNEX XIIaU.K. [F11Templates referred to in Article 18(1)]

Textual Amendments

F11 Deleted by Commission Regulation (EU) No 557/2010 of 24 June 2010 amending Regulations (EC) No 1518/2003, (EC) No 596/2004, (EC) No 633/2004, (EC) No 1345/2005, (EC) No 2014/2005, (EC) No 239/2007, (EC) No 1299/2007, (EC) No 543/2008, (EC) No 589/2008, (EC) No 617/2008 and (EC) No 826/2008 as regards the notification obligations within the common organisation of agricultural markets.

[ F11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .]

ANNEX XIIIU.K.

Correlation table

| Regulation (EEC) No 1906/90 | Regulation (EEC) No 1538/91 | This Regulation |

|---|---|---|

| Article 1 | Article 1 | |

| Article 1a, introductory phrase | Article 2, introductory phrase | |

| Article 2(2), (3) and (4) | Article 2(a), (b) and (c) | |

| Article 2(8) | Article 2(d) | |

| Article 1a, first and second indents | Article 2(e) and (f) | |

| Article 2 | Article 3(1) to (4) | |

| Article 4 | Article 3(5) | |

| Article 3 | Article 4 | |

| Article 4 | Article 5(1) | |

| Article 5(1) to (4) | Article 5(2) to (5) | |

| Article 6 | Article 5(6) | |

| Article 5 | Article 6 | |

| Article 6(1), introductory phrase | Article 7(1), introductory phrase | |

| Article 6(1), first to sixth indents | Article 7(1), points (a) to (f) | |

| Article 6(2), introductory phrase | Article 7(2), introductory phrase | |

| Article 6(2), first to fourth indents | Article 7(2), points (a) to (d) | |

| Article 7(1) | Article 8(1) | |

| Article 7(3) | Article 8(2) | |

| Article 7(4) | Article 8(3) | |

| Article 7(5) | Article 8(4) | |

| Article 7(6) | Article 8(5) | |

| Article 8(1) | Article 9(1) | |

| Article 8(2) | Article 9(2) | |

| Article 8(3), introductory phrase | Article 9(3), introductory phrase | |

| Article 8(3), first indent | Article 9(3), point (a) | |

| Article 8(3), second indent | Article 9(3), point (b) | |

| Article 8(4), first subparagraph, introductory phrase | Article 9(4), first subparagraph, introductory phrase | |

| Article 8(4), first subparagraph, first to third indents | Article 9(4), first subparagraph, points (a) to (c) | |

| Article 8(4), second subparagraph | Article 9(4), second subparagraph | |

| Article 8(5) to (12) | Article 9(5) to (12) | |

| Article 8(13), first subparagraph | — | |

| Article 8(13), second subparagraph | Article 9(13) | |

| Article 9 | Article 10 | |

| Article 10 | Article 11 | |

| Article 11(1), introductory phrase | Article 12(1), introductory phrase | |

| Article 11(1), first to fourth indents | Article 12(1), points (a) to (d) | |

| Article 11(2) | Article 12(2) | |

| Article 11(2a) | Article 12(3) | |

| Article 11(2b) | Article 12(4) | |

| Article 11(3), introductory phrase | Article 12(5), introductory phrase | |

| Article 11(3), first to fourth indents | Article 12(5), points (a) to (d) | |

| Article 11(4) | Article 12(6) | |

| Article 12 | Article 13 | |

| Article 13 | Article 14 | |

| Article 14a(1) and (2) | Article 15 | |

| Article 14a(3) to (5) | Article 16(1) to (3) | |

| Article 14a(5a) | Article 16(4) | |

| Article 14a(6) | Article 16(5) | |

| Article 14a(7), first subparagraph, introductory phrase | Article 16(6), first subparagraph | |

| Article 14a(7), first subparagraph, indents | Annex X | |

| Article 14a(7), second and third subparagraphs | Article 16(6), second and third subparagraphs | |

| Article 14a(8) to (12) | Article 17(1) to (5) | |

| Article 14a(12a) | Article 18(1) | |

| Article 14a(13) | Article 18(2) | |

| Article 14a(14) | Article 19 | |

| Article 14b(1) | Article 20(1) | |

| Article 14b(2), first subparagraph, introductory phrase | Article 20(2), first subparagraph, introductory phrase | |

| Article 14b(2), first subparagraph, first to third indents | Article 20(2), first subparagraph, points (a) to (c) | |

| Article 14b(2), second subparagraph | Article 20(2), second subparagraph | |

| Article 14b(3) and (4) | Article 20(3) and 4) | |

| Article 15 | — | |

| — | Article 21 | |

| — | Article 22 | |

| Annex I | Annex I | |

| Annex Ia | Annex II | |

| Annex II | Annex III | |

| Annex III | Annex IV | |

| Annex IV | Annex V | |

| Annex V | Annex VI | |

| Annex VI | Annex VII | |

| Annex VIa | Annex VIII | |

| Annex VII | Annex IX | |

| Annex VIII | Annex XI | |

| Annex IX | Annex XII | |

| — | Annex XIII |

Options/Help

Print Options

PrintThe Whole Regulation

PrintThe Annexes only

Mae deddfwriaeth ar gael mewn fersiynau gwahanol:

Y Diweddaraf sydd Ar Gael (diwygiedig):Y fersiwn ddiweddaraf sydd ar gael o’r ddeddfwriaeth yn cynnwys newidiadau a wnaed gan ddeddfwriaeth ddilynol ac wedi eu gweithredu gan ein tîm golygyddol. Gellir gweld y newidiadau nad ydym wedi eu gweithredu i’r testun eto yn yr ardal ‘Newidiadau i Ddeddfwriaeth’.

Gwreiddiol (Fel y’i mabwysiadwyd gan yr UE): Mae'r wreiddiol version of the legislation as it stood when it was first adopted in the EU. No changes have been applied to the text.

Gweler y wybodaeth ychwanegol ochr yn ochr â’r cynnwys

Rhychwant ddaearyddol: Indicates the geographical area that this provision applies to. For further information see ‘Frequently Asked Questions’.

Dangos Llinell Amser Newidiadau: See how this legislation has or could change over time. Turning this feature on will show extra navigation options to go to these specific points in time. Return to the latest available version by using the controls above in the What Version box.

Rhagor o Adnoddau

Gallwch wneud defnydd o ddogfennau atodol hanfodol a gwybodaeth ar gyfer yr eitem ddeddfwriaeth o’r tab hwn. Yn ddibynnol ar yr eitem ddeddfwriaeth sydd i’w gweld, gallai hyn gynnwys:

- y PDF print gwreiddiol y fel adopted version that was used for the EU Official Journal

- rhestr o newidiadau a wnaed gan a/neu yn effeithio ar yr eitem hon o ddeddfwriaeth

- pob fformat o’r holl ddogfennau cysylltiedig

- slipiau cywiro

- dolenni i ddeddfwriaeth gysylltiedig ac adnoddau gwybodaeth eraill

Llinell Amser Newidiadau

Mae’r llinell amser yma yn dangos y fersiynau gwahanol a gymerwyd o EUR-Lex yn ogystal ag unrhyw fersiynau dilynol a grëwyd ar ôl y diwrnod ymadael o ganlyniad i newidiadau a wnaed gan ddeddfwriaeth y Deyrnas Unedig.

Cymerir dyddiadau fersiynau’r UE o ddyddiadau’r dogfennau ar EUR-Lex ac efallai na fyddant yn cyfateb â’r adeg pan ddaeth y newidiadau i rym ar gyfer y ddogfen.

Ar gyfer unrhyw fersiynau a grëwyd ar ôl y diwrnod ymadael o ganlyniad i newidiadau a wnaed gan ddeddfwriaeth y Deyrnas Unedig, bydd y dyddiad yn cyd-fynd â’r dyddiad cynharaf y daeth y newid (e.e. ychwanegiad, diddymiad neu gyfnewidiad) a weithredwyd i rym. Am ragor o wybodaeth gweler ein canllaw i ddeddfwriaeth ddiwygiedig ar Ddeall Deddfwriaeth.

Rhagor o Adnoddau

Defnyddiwch y ddewislen hon i agor dogfennau hanfodol sy’n cyd-fynd â’r ddeddfwriaeth a gwybodaeth am yr eitem hon o ddeddfwriaeth. Gan ddibynnu ar yr eitem o ddeddfwriaeth sy’n cael ei gweld gall hyn gynnwys:

- y PDF print gwreiddiol y fel adopted fersiwn a ddefnyddiwyd am y copi print

- slipiau cywiro

liciwch ‘Gweld Mwy’ neu ddewis ‘Rhagor o Adnoddau’ am wybodaeth ychwanegol gan gynnwys

- rhestr o newidiadau a wnaed gan a/neu yn effeithio ar yr eitem hon o ddeddfwriaeth

- manylion rhoi grym a newid cyffredinol

- pob fformat o’r holl ddogfennau cysylltiedig

- dolenni i ddeddfwriaeth gysylltiedig ac adnoddau gwybodaeth eraill