- Y Diweddaraf sydd Ar Gael (Diwygiedig)

- Pwynt Penodol mewn Amser (31/01/2020)

- Gwreiddiol (Fel y’i mabwysiadwyd gan yr UE)

Commission Implementing Regulation (EU) No 299/2013Dangos y teitl llawn

Commission Implementing Regulation (EU) No 299/2013 of 26 March 2013 amending Regulation (EEC) No 2568/91 on the characteristics of olive oil and olive-residue oil and on the relevant methods of analysis

You are here:

- Rheoliadau yn deillio o’r UE

- 2013 No. 299

- Annexes only

- Dangos Graddfa Ddaearyddol(e.e. Lloegr, Cymru, Yr Alban aca Gogledd Iwerddon)

- Dangos Llinell Amser Newidiadau

Rhagor o Adnoddau

When the UK left the EU, legislation.gov.uk published EU legislation that had been published by the EU up to IP completion day (31 December 2020 11.00 p.m.). On legislation.gov.uk, these items of legislation are kept up-to-date with any amendments made by the UK since then.

Mae hon yn eitem o ddeddfwriaeth sy’n deillio o’r UE

Mae unrhyw newidiadau sydd wedi cael eu gwneud yn barod gan y tîm yn ymddangos yn y cynnwys a chyfeirir atynt gydag anodiadau.Ar ôl y diwrnod ymadael bydd tair fersiwn o’r ddeddfwriaeth yma i’w gwirio at ddibenion gwahanol. Y fersiwn legislation.gov.uk yw’r fersiwn sy’n weithredol yn y Deyrnas Unedig. Y Fersiwn UE sydd ar EUR-lex ar hyn o bryd yw’r fersiwn sy’n weithredol yn yr UE h.y. efallai y bydd arnoch angen y fersiwn hon os byddwch yn gweithredu busnes yn yr UE. EUR-Lex Y fersiwn yn yr archif ar y we yw’r fersiwn swyddogol o’r ddeddfwriaeth fel yr oedd ar y diwrnod ymadael cyn cael ei chyhoeddi ar legislation.gov.uk ac unrhyw newidiadau ac effeithiau a weithredwyd yn y Deyrnas Unedig wedyn. Mae’r archif ar y we hefyd yn cynnwys cyfraith achos a ffurfiau mewn ieithoedd eraill o EUR-Lex. The EU Exit Web Archive legislation_originated_from_EU_p3

Changes over time for: Commission Implementing Regulation (EU) No 299/2013 (Annexes only)

Alternative versions:

Status:

Point in time view as at 31/01/2020.

Changes to legislation:

There are currently no known outstanding effects for the Commission Implementing Regulation (EU) No 299/2013.![]()

Changes to Legislation

Revised legislation carried on this site may not be fully up to date. At the current time any known changes or effects made by subsequent legislation have been applied to the text of the legislation you are viewing by the editorial team. Please see ‘Frequently Asked Questions’ for details regarding the timescales for which new effects are identified and recorded on this site.

ANNEX IU.K.

“ANNEX IX SPECTROPHOTOMETRIC INVESTIGATION IN THE ULTRAVIOLET

FOREWORDU.K.

Spectrophotometric examination in the ultraviolet can provide information on the quality of a fat, its state of preservation and changes brought about in it by technological processes.

The absorption at the wavelengths specified in the method is due to the presence of conjugated diene and triene systems. These absorptions are expressed as specific extinctions E 1 % 1 cm (the extinction of 1 % solution of the fat in the specified solvent, in a thickness of 1 cm) conventionally indicated by K (also referred to as ‘extinction coefficient’).

1.SCOPEU.K.

The method describes the procedure for performing a spectrophotometric examination of olive oil (as described in the Appendix) in the ultraviolet.

2.PRINCIPLE OF THE METHODU.K.

The fat in question is dissolved in the required solvent and the extinction of the solution is then determined at the specified wavelengths with reference to pure solvent. Specific extinctions are calculated from the spectrophotometer readings. The specific absorbance at 232 nm and 268 nm in iso-octane or 232 nm and 270 nm in cyclohexane for a concentration of 1 g per 100 ml in a 10 mm cell is calculated.

3.EQUIPMENTU.K.

3.1.A spectrophotometer for measuring extinction in the ultraviolet between 220 and 360 nm, with the possibility of reading individual nanometric units. Before use it is recommended that the wavelength and absorbance scales of the spectrometer be checked as follows.U.K.

3.1.1. Wavelength scale: This may be checked using a reference material consisting of an optical glass filter containing holmium oxide which has distinct absorption bands. The reference material is designed for the verification and calibration of the wavelength scales of visible and ultraviolet spectrophotometers having nominal spectral bandwidths of 5 nm or less. The holmium glass filter is measured in the absorbance mode against an air blank, over the wavelength range of 640 to 240 nm. For each spectral bandwidth (0,10 – 0,25 – 0,50 – 1,00 – 1,50 – 2,00 and 3,00), a baseline correction is performed with an empty cell holder. The wavelengths of the spectral bandwidth are listed in the certificate of the reference material in ISO 3656.U.K.

3.1.2. Absorbance scale: This may be checked using a reference material consisting of 4 solutions of potassium dichromate in perchloric acid sealed in four UV quartz cells to measure the linearity and photometric accuracy reference in the UV. The potassium dichromate filled cells (40 mg/ml, 60 mg/ml, 80 mg/ml and 100 mg/ml) are measured against a perchloric acid blank. The net absorbance values are listed in the certificate of the reference material in ISO 3656.U.K.

3.2.Rectangular quartz cells, with covers, having an optical length of 1 cm. When filled with water or other suitable solvent the cells should not show differences between them of more than 0,01 extinction units.U.K.

3.3.25 ml graduated flasks.U.K.

3.4.Analytical balance, capable of being read to the nearest 0,0001 g.U.K.

4.REAGENTSU.K.

Use only reagents of recognized analytical grade, unless otherwise stated.

Solvent: Iso-octane (2,2,4-trimethylpentane) for the measurement at 232 nm and 268 nm or cyclohexane for the measurement at 232 nm and 270 nm, having an absorbance less than 0,12 at 232 nm and less than 0,05 at 250 nm against distilled water, measured in a 10 mm cell.

5.PROCEDUREU.K.

5.1.The sample in question must be perfectly homogeneous and without suspected impurities. Oils which are liquid at ambient temperature are to be filtered through paper at a temperature of approximately 30 °C, hard fats are to be homogenized and filtered at a temperature of not more than 10 °C above the melting point.U.K.

5.2.Weigh accurately approximately 0,25 g (to the nearest 1 mg) of the sample so prepared into a 25 ml graduated flask, make up to the mark with the solvent specified and homogenize. The resulting solution must be perfectly clear. If opalescence or turbidity is present filter quickly through paper.U.K.

5.3.Fill a quartz cell with the solution obtained and measure the extinctions at an appropriate wavelength between 232 and 276 nm, using the solvent used as a reference.U.K.

The extinction values recorded must lie within the range 0,1 to 0,8. If not the measurements must be repeated using more concentrated or more dilute solutions as appropriate.

NOTE: It may not be necessary to measure the absorbance over the full wavelength range.U.K.

6.EXPRESSION OF THE RESULTSU.K.

6.1.Record the specific extinctions (extinction coefficients) at the various wavelengths calculated as follows:U.K.

where:

=

specific extinction at wavelength λ,

=

extinction measured at wavelength λ;

=

concentration of the solution in g/100 ml;

=

thickness of the quartz cells in cm.

The results are to be expressed to two decimal places.

6.2. Variation of the specific extinction (ΔΚ) U.K.

Spectrophotometric analysis of olive oil in accordance with the official method in the Union legislation involves also the determination of the variation of the absolute value of the specific extinction (ΔΚ), which is given by:

where Km is the specific extinction at wavelength m, the wavelength for maximum absorption depends on the solvent used: 270 for cyclohexane and 268 for iso-octane.

Appendix

OLIVE OIL CHARACTERISTICS

| a Total isomers which could (or could not) be separated by capillary column. | |||||||||||||

| b Or where the median defect is less than or equal to 3,5 and the fruity median is equal to 0. | |||||||||||||

| c Oils with a wax content of between 300 mg/kg and 350 mg/kg are considered to be lampante olive oil if the total aliphatic alcohol content is less than or equal to 350 mg/kg or if the erythrodiol and uvaol content is less than or equal to 3,5 %. | |||||||||||||

| d Oils with a wax content of between 300 mg/kg and 350 mg/kg are considered to be crude olive-pomace oil if the total aliphatic alcohol content is above 350 mg/kg and if the erythrodiol and uvaol content is greater than 3,5 %. | |||||||||||||

| e K 270 if solvant is cyclohexane, K 268 if solvant is iso-octane.” | |||||||||||||

| Category | Fatty acid methyl esters (FAMES) and fatty acid ethyl esters (FAEEs) | Acidity (%) (*) | Peroxide index mEq 02/kg (*) | Waxes mg/kg (**) | 2 glyceril monopalmitate (%) | Stigmastadiene mg/kga | Difference: ECN42 (HPLC) and ECN42 (theoretical calculation) | K232 (*) | K270 (*) 'K 270 or K 268e' | Delta-K (*)e | Organoleptic evaluation Median defect (Md) (*) | Organoleptic evaluation Fruity median (Mf) (*) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1. | Extra virgin olive oil | Σ FAME + FAEE ≤75 mg/kg or 75 mg/kg <Σ FAME + FAEE ≤150 mg/kg and (FAEE/FAME) ≤1,5 | ≤ 0,8 | ≤ 20 | ≤ 250 | ≤ 0,9 if total palmitic acid % ≤ 14 % | ≤ 0,10 | ≤ 0,2 | ≤ 2,50 | ≤ 0,22 | ≤ 0,01 | Md = 0 | Mf > 0 |

| ≤ 1,0 if total palmitic acid % > 14 % | |||||||||||||

| 2. | Virgin olive oil | — | ≤ 2,0 | ≤ 20 | ≤ 250 | ≤ 0,9 if total palmitic acid % ≤ 14 % | ≤ 0,10 | ≤ 0,2 | ≤ 2,60 | ≤ 0,25 | ≤ 0,01 | Md ≤ 3,5 | Mf > 0 |

| ≤ 1,0 if total palmitic acid % > 14 % | |||||||||||||

| 3. | Lampante olive oil | — | > 2,0 | — | ≤ 300c | ≤ 0,9 if total palmitic acid % ≤ 14 % | ≤ 0,50 | ≤ 0,3 | — | — | — | Md > 3,5b | — |

| ≤ 1,1 if total palmitic acid % > 14 % | |||||||||||||

| 4. | Refined olive oil | — | ≤ 0,3 | ≤ 5 | ≤ 350 | ≤ 0,9 if total palmitic acid % ≤ 14 % | — | ≤ 0,3 | — | ≤ 1,10 | ≤ 0,16 | — | — |

| ≤ 1,1 if total palmitic acid % > 14 % | |||||||||||||

| 5. | Olive oil composed of refined and virgin olive oils | — | ≤ 1,0 | ≤ 15 | ≤ 350 | ≤ 0,9 if total palmitic acid % ≤ 14 % | — | ≤ 0,3 | — | ≤ 0,90 | ≤ 0,15 | — | — |

| ≤ 1,0 if total palmitic acid % > 14 % | |||||||||||||

| 6. | Crude olive-pomace oil | — | — | — | > 350d | ≤ 1,4 | — | ≤ 0,6 | — | — | — | — | — |

| 7. | Refined olive-pomace oil | — | ≤ 0,3 | ≤ 5 | > 350 | ≤ 1,4 | — | ≤ 0,5 | — | ≤ 2,00 | ≤ 0,20 | — | — |

| 8. | Olive-pomace oil | ≤ 1,0 | ≤ 15 | > 350 | ≤ 1,2 | — | ≤ 0,5 | — | ≤ 1,70 | ≤ 0,18 | — | — | |

ANNEX IIU.K.

“ANNEX XVIII DETERMINATION OF THE DIFFERENCE BETWEEN ACTUAL AND THEORETICAL CONTENT OF TRIACYLGLYCEROLS WITH ECN 42

1.SCOPEU.K.

Determination of the absolute difference between the experimental values of triacylglycerols (TAGs) with equivalent carbon number 42 (ECN42HPLC) obtained by determination in the oil by high performance liquid chromatography and the theoretical value of TAGs with an equivalent carbon number of 42 (ECN 42theoretical) calculated from the fatty acid composition.

2.FIELD OF APPLICATIONU.K.

The standard is applicable to olive oils. The method is applicable to the detection of the presence of small amounts of seed oils (rich in linoleic acid) in every class of olive oils.

3.PRINCIPLEU.K.

The content of triacylglycerols with ECN 42 determined by HPLC analysis and the theoretical content of triacylglycerols with ECN 42 (calculated on the basis of GLC determination of fatty acid composition) correspond within a certain limit for genuine olive oils. A difference larger than the values adopted for each type of oil points out that the oil contains seed oils.

4.METHODU.K.

The method for the calculation of the theoretical content of triacylglycerols with ECN 42 and of the difference with respect to the HPLC data is essentially made by the coordination of analytical data obtained by means of other methods. It is possible to distinguish three phases: determination of fatty acid composition by capillary gas chromatography, calculation of theoretical composition of triacylglycerols with ECN 42, HPLC determination of ECN 42 triacylglycerols.

4.1. Apparatus U.K.

4.1.1.Round-bottomed flasks, 250 and 500 ml.U.K.

4.1.2.Beakers 100 ml.U.K.

4.1.3.Glass chromatographic column, 21 mm internal diameter, 450 mm length, with cock and normalised cone (female) at the top.U.K.

4.1.4.Separating funnels, 250 ml, with normalised cone (male) at the bottom, suitable for connection to the top of the column.U.K.

4.1.5.Glass rod, 600 mm length.U.K.

4.1.6.Glass funnel, 80 mm diameter.U.K.

4.1.7.Volumetric flasks, 50 ml.U.K.

4.1.8.Volumetric flasks, 20 ml.U.K.

4.1.9.Rotary evaporator.U.K.

4.1.10.High performance liquid chromatograph, allowing thermostatic control of column temperature.U.K.

4.1.11.Injection units for 10 μl delivery.U.K.

4.1.12.Detector: differential refractometer. The full scale sensitivity should be at least 10–4 units of refractive index.U.K.

4.1.13.Column: stainless steel tube 250 mm length x 4,5 mm internal diameter packed with 5 μm diameter particles of silica with 22 to 23 % carbon in the form of octadecylsilane.U.K.

4.1.14.Data processing software.U.K.

4.1.15.Vials, of about 2 ml volumes, with Teflon-layered septa and screw caps.U.K.

4.2. Reagents U.K.

The reagents should be of analytical purity. Elution solvents should be de-gassed, and may be recycled several times without effect on the separations.

4.2.1.Petroleum ether 40– 60 °C chromatographic grade or hexane.U.K.

4.2.2.Ethyl ether, peroxide-free, freshly distilled.U.K.

4.2.3.Elution solvent for purifying the oil by column chromatography mixture petroleum ether/ethyl ether 87/13 (v/v).U.K.

4.2.4.Silica gel, 70-230 mesh, type Merck 7734, with water content standardised at 5 % (w/w/).U.K.

4.2.5.Glass wool.U.K.

4.2.6.Acetone for HPLC.U.K.

4.2.7.Acetonitrile or propionitrile for HPLC.U.K.

4.2.8.HPLC elution solvent: acetonitrile + acetone (proportions to be adjusted to obtain the desired separation; begin with 50:50 mixture) or propionitrile.U.K.

4.2.9.Solubilisation solvent: acetone.U.K.

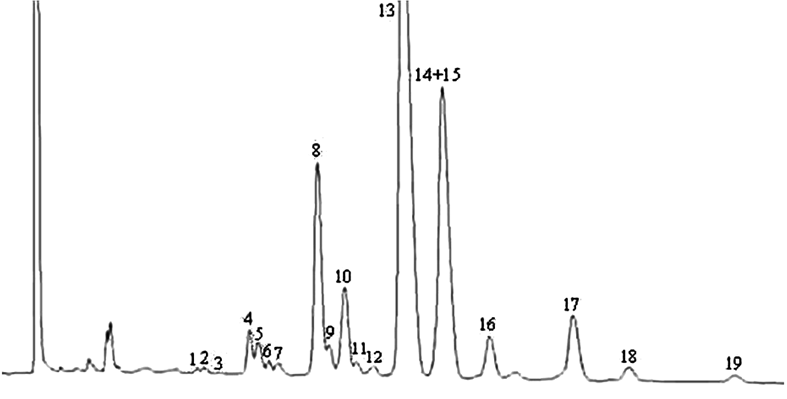

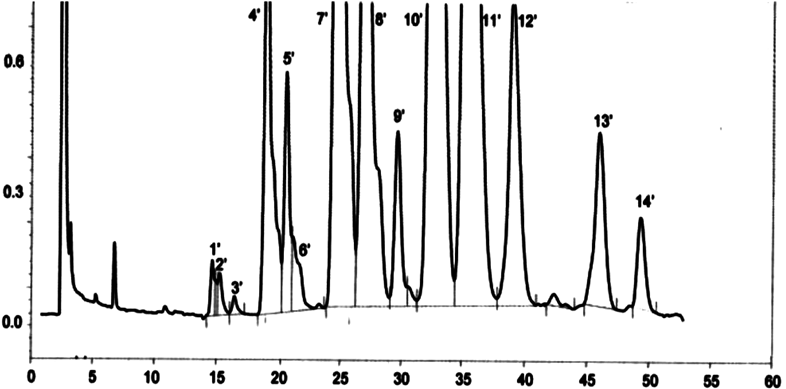

4.2.10.Reference triglycerides: commercial triglycerides (tripalmitin, triolein, etc.) may be used and the retention times then plotted in accordance with the equivalent carbon number, or alternatively reference chromatograms obtained from soya oil, mixture 30:70 soya oil — olive oil and pure olive oil (see notes 1 and 2 and figures 1 to 4).U.K.

4.2.11.Solid phase extraction column with silica phase 1 g, 6 ml.U.K.

4.3. Sample preparation U.K.

As a number of interfering substances can give rise to false positive results, the sample must always be purified according to IUPAC method 2.507, used for the determination of polar compounds in frying fats.

4.3.1. Chromatographic column preparation U.K.

Fill the column (4.1.3) with about 30 ml of elution solvent (4.2.3), then introduce inside the column some glass wool (4.2.5) pushing it to the bottom of the column by means of the glass rod (4.1.5).

In a 100 ml beaker, suspend 25 g of silica gel (4.2.4) in 80 ml of elution mixture (4.2.3), then transfer it to the column by means of a glass funnel (4.1.6).

To ensure the complete transfer of the silica gel to the column, wash the beaker with the elution mixture and transfer the washing portions to the column too.

Open the cock and let the solvent elute from the column until its level is about 1 cm over the silica gel.

4.3.2. Column chromatography U.K.

Weigh with the accuracy of 0,001 g, 2,5 ± 0,1 g of oil, previously filtered, homogenised and anhydrified, if necessary, in a 50 ml volumetric flask (4.1.7).

Dissolve it in about 20 ml of elution solvent (4.2.3). If necessary, slightly heat it to make the dissolution easily. Cool at room temperature and adjust the volume with elution solvent.

By means of a volumetric pipette, introduce 20 ml of solution inside the column prepared according to 4.3.1, open the cock and let the solvent elute to the silica gel layer level.

Then elute with 150 ml of elution solvent (4.2.3), adjusting the solvent rate at about 2 ml/min (150 ml will take about 60-70 minutes to pass through the column).

The eluate is recovered in a 250 ml round-bottomed flask (4.1.1) previously tared in an oven and exactly weighed. Eliminate the solvent at reduced pressure in a rotary evaporator (4.1.9) and weigh the residue that will be used to prepare the solution for HPLC analysis and for methyl ester preparation.

The sample recovery from the column must be 90 % at least for the extra virgin, virgin, ordinary, refined and olive oil categories, and a minimum of 80 % for lampante and olive-pomace oils.

4.3.3. SPE purification U.K.

Silica SPE column is activated by passing 6 ml of hexane (4.2.3) under vacuum, avoiding dryness.

Weigh to an accuracy of 0,001 g, 0,12 g in a 2 ml vial (4.1.15) and dissolve with 0,5 ml of hexane (4.2.3).

Load the SPE column with the solution and elute with 10 ml of hexane-diethyl ether (87:13 v/v) (4.2.3) under vacuum.

The collected fraction is evaporated to dryness in a rotary evaporator (4.1.9) under reduced pressure at room temperature. The residue is dissolved in 2 ml of acetone (4.2.6) for triacylglycerol (TAG) analysis.

4.4. HPLC analysis U.K.

4.4.1. Preparation of the samples for chromatographic analysis U.K.

A 5 % solution of the sample to be analysed is prepared by weighing 0,5 ± 0,001 g of the sample into a 10 ml graduated flask and making up to 10 ml with the solubilisation solvent (4.2.9).

4.4.2. Procedure U.K.

Set up the chromatographic system. Pump elution solvent (4.2.8) at a rate of 1,5 ml/min to purge the entire system. Wait until a stable base line is obtained.

Inject 10 μl of the sample prepared as in point 4.3.

4.4.3. Calculation and expression of results U.K.

Use the area normalisation method, i.e. assume that the sum of the areas of the peaks corresponding to TAGs from ECN 42 up to ECN 52 is equal to 100 %.

Calculate the relative percentage of each triglyceride using the formula:

The results should be given to at least two decimal places.

See notes 1 to 4.

4.5. Calculation of triacylglycerols composition (moles %) from fatty acid composition data (area %) U.K.

4.5.1. Determination of fatty acid composition U.K.

Fatty acid composition is determined by ISO 5508 by means of a capillary column. The methyl esters are prepared according to COI/T.20/Doc. No 24.

4.5.2. Fatty acids for calculation U.K.

Glycerides are grouped by their Equivalent Carbon Number (ECN), taking into account the following equivalencies between ECN and fatty acids. Only fatty acids with 16 and 18 carbon atoms were taken into consideration, because only these are important for olive oil. The fatty acids should be normalised to 100 %.

| Fatty acid (FA) | Abbreviation | Molecular weight(MW) | ECN |

|---|---|---|---|

| Palmitic acid | P | 256,4 | 16 |

| Palmitoleic acid | Po | 254,4 | 14 |

| Stearic acid | S | 284,5 | 18 |

| Oleic acid | O | 282,5 | 16 |

| Linoleic acid | L | 280,4 | 14 |

| Linolenic acid | Ln | 278,4 | 12 |

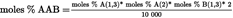

4.5.3. Conversion of area % into moles for all fatty acids (1) U.K.

4.5.4. Normalisation of fatty acid moles to 100 % (2) U.K.

The result gives the percentage of each fatty acid in moles % in the overall (1, 2, 3–) position of the TAGs.

Then the sum of the saturated fatty acids P and S (SFA) and the unsaturated fatty acids Po, O, L and Ln (UFA) are calculated (3):

4.5.5. Calculation of the fatty acid composition in 2- and 1, 3- positions of TAGs U.K.

The fatty acids are distributed to three pools as follows: one for 2- position and two identical for 1- and 3- positions, with different coefficients for the saturated (P and S) and unsaturated acids (Po, O, L and Ln).

4.5.5.1.Saturated fatty acids in 2-position [P(2) and S(2)] (4):U.K.

4.5.5.2.Unsaturated fatty acids in 2-position [Po(2), O(2), L(2) and Ln(2)] (5):U.K.

4.5.5.3.Fatty acids in 1,3-positions [P(1,3), S(1,3), Po(1,3), O(1,3), L(1,3) and Ln(1,3)] (6):U.K.

4.5.6. Calculation of triacylglycerols U.K.

4.5.6.1.TAGs with one fatty acid (AAA, here LLL, PoPoPo) (7)U.K.

4.5.6.2.TAGs with two fatty acids (AAB, here PoPoL, PoLL) (8)U.K.

4.5.6.3.TAGs with three different fatty acids (ABC, here OLLn, PLLn, PoOLn, PPoLn) (9)U.K.

4.5.6.4.Triacylglycerols with ECN42U.K.

The triacylglycerols with ECN42 are calculated according to equations 7, 8 and 9 and are then given in order of expected elution in HPLC (normally only three peaks).

LLL

PoLL and the positional isomer LPoL

OLLn and the positional isomers OLnL and LnOL

PoPoL and the positional isomer PoLPo

PoOLn and the positional isomers OPoLn and OLnPo

PLLn and the positional isomers LLnP and LnPL

PoPoPo

SLnLn and the positional isomer LnSLn

PPoLn and the positional isomers PLnPo and PoPLn

The triacylglycerols with ECN42 are given by the sum of the nine triacylglycerols including their positional isomers. The results should be given to at least two decimal places.

5.EVALUATION OF THE RESULTSU.K.

The calculated theoretical content and the content determined by the HPLC analysis are compared. If the difference in the absolute value of the HPLC data minus the theoretical data is greater than the values stated for the appropriate oil category in the standard, the sample contains seed oil.

Results are given to two decimal figures.

6.EXAMPLE (THE NUMBERS REFER TO THE SECTIONS IN THE TEXT OF THE METHOD)U.K.

— 4.5.1. Calculation of moles % fatty acids from GLC data (normalised area %) U.K.

The following data are obtained for the fatty acid composition by GLC:

| FA | P | S | Po | O | L | Ln |

|---|---|---|---|---|---|---|

| MW | 256,4 | 284,5 | 254,4 | 282,5 | 280,4 | 278,4 |

| Area % | 10,0 | 3,0 | 1,0 | 75,0 | 10,0 | 1,0 |

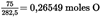

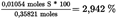

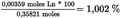

— 4.5.3 Conversion of area % into moles for all fatty acids (see formula (1)) U.K.

=

0,35821 moles TAGs

— 4.5.4 Normalisation of fatty acid moles to 100 % (see formula (2)) U.K.

=

100 %

Sum of the saturated and unsaturated fatty acids in the 1,2,3-position of TAGs (see formula (3)):

— 4.5.5 Calculation of the fatty acid composition in 2- and 1,3-positions of the TAGs U.K.

— 4.5.5.1Saturated fatty acids in 2-position [P(2) and S(2)] (see formula (4))U.K.

— 4.5.5.2Unsaturated fatty acids in 2-position [Po(1,3), O(1,3), L(1,3) and Ln(1,3)] (see formula (5))U.K.

— 4.5.5.3Fatty acids in 1,3-positions [P(1,3), S(1,3), Po(1,3), O(1,3), L(1,3) and Ln(1,3)] (see formula (6))U.K.

— 4.5.6. Calculation of triacylglycerols U.K.

From the calculated fatty acid composition in sn-2- and sn-1,3-positions:

| FA in | 1,3-pos | 2-pos |

|---|---|---|

| P | 16,004 % | 0,653 % |

| S | 4,325 % | 0,177 % |

| Po | 1,015 % | 1,262 % |

| O | 68,526 % | 85,296 % |

| L | 9,204 % | 11,457 % |

| Ln | 0,927 % | 1,153 % |

| Sum | 100,0 % | 100,0 % |

the following triacylglycerols are calculated:

LLL

PoPoPo

PoLL with 1 positional isomer

SLnLn with 1 positional isomer

PoPoL with 1 positional isomer

PPoLn with 2 positional isomers

OLLn with 2 positional isomers

PLLn with 2 positional isomers

PoOLn with 2 positional isomers

— 4.5.6.1.TAGs with one fatty acid (LLL, PoPoPo) (see formula (7))U.K.

— 4.5.6.2TAGs with two fatty acids (PoLL, SLnLn, PoPoL) (see formula (8))U.K.

0,03210 mol PoLL

0,00094 mol SLnLn

0,00354 mol PoPoL

— 4.5.6.3TAGs with three different fatty acids (PoPLn, OLLn, PLLn, PoOLn) See formula (9)U.K.

0,00761 mol PPoLn

0,43655 mol OLLn

0,06907 mol PLLn

0,04812 mol PoOLn

ECN42 = 0,69512 mol TAGs

Note 1: The elution order can be determined by calculating the equivalent carbon numbers, often defined by the relation

where the coefficient do, dl and dln can be calculated by means of the reference triglycerides. Under the conditions specified in this method, the relation obtained will be close to:

Note 2: With several reference triglycerides, it is also possible to calculate the resolution with respect to triolein:U.K.

by use of the reduced retention time

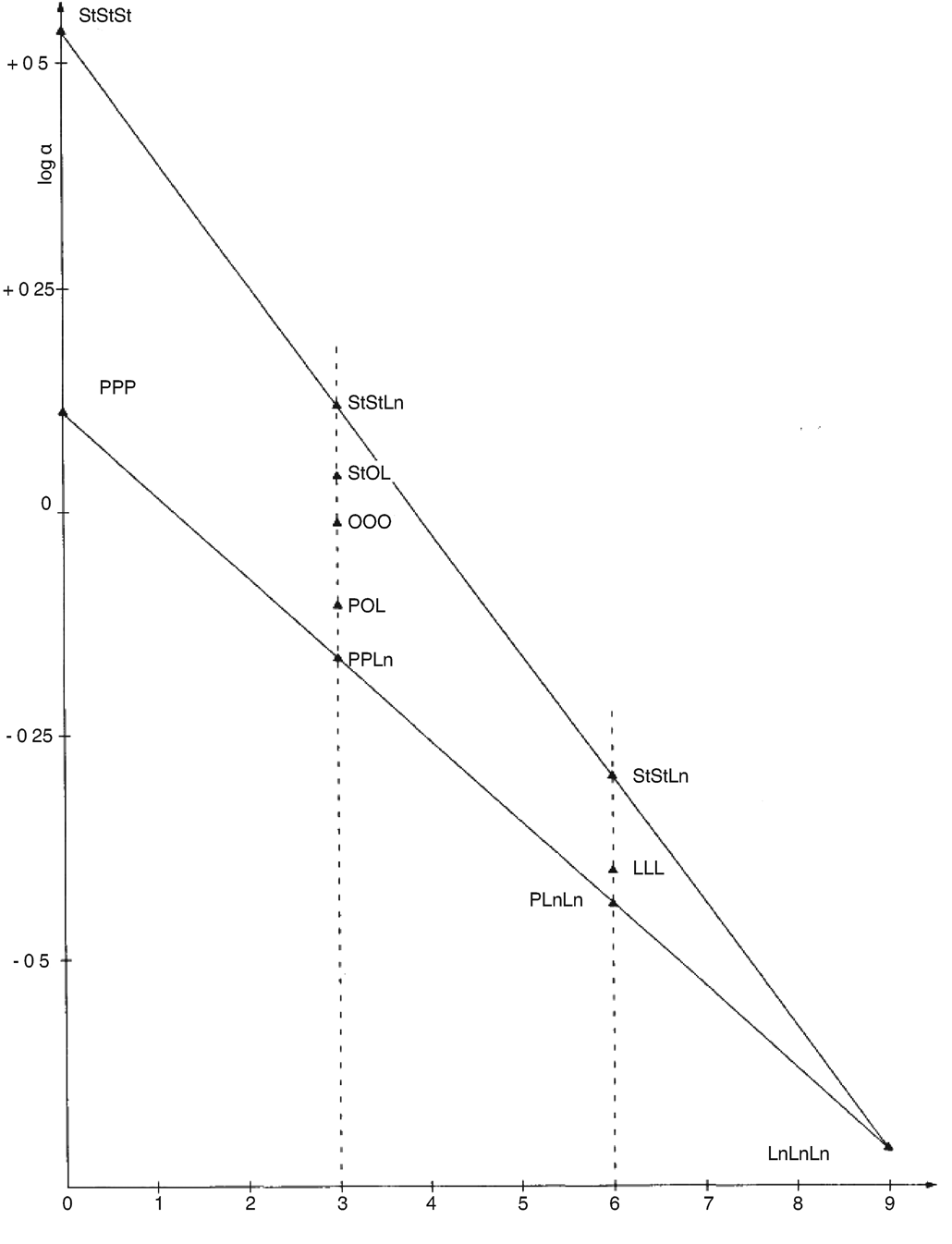

The graph of log α against f (number of double bonds) enables the retention values to be determined for all the triglycerides of fatty acids contained in the reference triglycerides — see Figure 1.

Note 3: The efficiency of the column should permit clear separation of the peak of trilinolein from the peaks of the triglycerides with an adjacent RT. The elution is carried out up to ECN 52 peak.U.K.

Note 4: A correct measure of the areas of all peaks of interest for the present determination is ensured if the second peak corresponding to ECN 50 is 50 % of full scale of the recorder.U.K.

(b)

(b)

ANNEX IIIU.K.

“‘ANNEX XXI

Results of conformity checks carried out on olive oils referred to in Article 8(2)

| a Internal market (mill, bottlers, retail stage), export, import. | |||||||||||||||||

| b Each characteristic of olive oil set out in Annex I shall have a code. | |||||||||||||||||

| c Conform/not conform. | |||||||||||||||||

| d Not required for olive oil and pomace-oil.’” | |||||||||||||||||

| Labelling | Chemical parameters | Organoleptic characteristicsd | Final conclusion | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sample | Category | Country of origin | Place of inspectiona | Legal name | Designation of origin | Storage conditions | Erroneous information | Legibility | C/NCc | Parameters out of limitY/N | If so, please indicate which one(s)b | C/NCc | Median defect | Fruity Median | C/NCc | Required action | Sanction |

Options/Help

Print Options

PrintThe Whole Regulation

PrintThe Annexes only

Mae deddfwriaeth ar gael mewn fersiynau gwahanol:

Y Diweddaraf sydd Ar Gael (diwygiedig):Y fersiwn ddiweddaraf sydd ar gael o’r ddeddfwriaeth yn cynnwys newidiadau a wnaed gan ddeddfwriaeth ddilynol ac wedi eu gweithredu gan ein tîm golygyddol. Gellir gweld y newidiadau nad ydym wedi eu gweithredu i’r testun eto yn yr ardal ‘Newidiadau i Ddeddfwriaeth’.

Gwreiddiol (Fel y’i mabwysiadwyd gan yr UE): Mae'r wreiddiol version of the legislation as it stood when it was first adopted in the EU. No changes have been applied to the text.

Pwynt Penodol mewn Amser: This becomes available after navigating to view revised legislation as it stood at a certain point in time via Advanced Features > Show Timeline of Changes or via a point in time advanced search.

Gweler y wybodaeth ychwanegol ochr yn ochr â’r cynnwys

Rhychwant ddaearyddol: Indicates the geographical area that this provision applies to. For further information see ‘Frequently Asked Questions’.

Dangos Llinell Amser Newidiadau: See how this legislation has or could change over time. Turning this feature on will show extra navigation options to go to these specific points in time. Return to the latest available version by using the controls above in the What Version box.

Rhagor o Adnoddau

Gallwch wneud defnydd o ddogfennau atodol hanfodol a gwybodaeth ar gyfer yr eitem ddeddfwriaeth o’r tab hwn. Yn ddibynnol ar yr eitem ddeddfwriaeth sydd i’w gweld, gallai hyn gynnwys:

- y PDF print gwreiddiol y fel adopted version that was used for the EU Official Journal

- rhestr o newidiadau a wnaed gan a/neu yn effeithio ar yr eitem hon o ddeddfwriaeth

- pob fformat o’r holl ddogfennau cysylltiedig

- slipiau cywiro

- dolenni i ddeddfwriaeth gysylltiedig ac adnoddau gwybodaeth eraill

Llinell Amser Newidiadau

Mae’r llinell amser yma yn dangos y fersiynau gwahanol a gymerwyd o EUR-Lex yn ogystal ag unrhyw fersiynau dilynol a grëwyd ar ôl y diwrnod ymadael o ganlyniad i newidiadau a wnaed gan ddeddfwriaeth y Deyrnas Unedig.

Cymerir dyddiadau fersiynau’r UE o ddyddiadau’r dogfennau ar EUR-Lex ac efallai na fyddant yn cyfateb â’r adeg pan ddaeth y newidiadau i rym ar gyfer y ddogfen.

Ar gyfer unrhyw fersiynau a grëwyd ar ôl y diwrnod ymadael o ganlyniad i newidiadau a wnaed gan ddeddfwriaeth y Deyrnas Unedig, bydd y dyddiad yn cyd-fynd â’r dyddiad cynharaf y daeth y newid (e.e. ychwanegiad, diddymiad neu gyfnewidiad) a weithredwyd i rym. Am ragor o wybodaeth gweler ein canllaw i ddeddfwriaeth ddiwygiedig ar Ddeall Deddfwriaeth.

Rhagor o Adnoddau

Defnyddiwch y ddewislen hon i agor dogfennau hanfodol sy’n cyd-fynd â’r ddeddfwriaeth a gwybodaeth am yr eitem hon o ddeddfwriaeth. Gan ddibynnu ar yr eitem o ddeddfwriaeth sy’n cael ei gweld gall hyn gynnwys:

- y PDF print gwreiddiol y fel adopted fersiwn a ddefnyddiwyd am y copi print

- slipiau cywiro

liciwch ‘Gweld Mwy’ neu ddewis ‘Rhagor o Adnoddau’ am wybodaeth ychwanegol gan gynnwys

- rhestr o newidiadau a wnaed gan a/neu yn effeithio ar yr eitem hon o ddeddfwriaeth

- manylion rhoi grym a newid cyffredinol

- pob fformat o’r holl ddogfennau cysylltiedig

- dolenni i ddeddfwriaeth gysylltiedig ac adnoddau gwybodaeth eraill