- Y Diweddaraf sydd Ar Gael (Diwygiedig)

- Pwynt Penodol mewn Amser (31/12/2020)

- Gwreiddiol (Fel y’i mabwysiadwyd gan yr UE)

Commission Regulation (EU) 2017/2400Dangos y teitl llawn

Commission Regulation (EU) 2017/2400 of 12 December 2017 implementing Regulation (EC) No 595/2009 of the European Parliament and of the Council as regards the determination of the CO2 emissions and fuel consumption of heavy-duty vehicles and amending Directive 2007/46/EC of the European Parliament and of the Council and Commission Regulation (EU) No 582/2011 (Text with EEA relevance)

You are here:

- Rheoliadau yn deillio o’r UE

- 2017 No. 2400

- Annexes only

- Dangos Graddfa Ddaearyddol(e.e. Lloegr, Cymru, Yr Alban aca Gogledd Iwerddon)

- Dangos Llinell Amser Newidiadau

Rhagor o Adnoddau

PDF o Fersiynau Diwygiedig

- ddiwygiedig 01/09/20203.68 MB

- ddiwygiedig 01/03/20193.55 MB

When the UK left the EU, legislation.gov.uk published EU legislation that had been published by the EU up to IP completion day (31 December 2020 11.00 p.m.). On legislation.gov.uk, these items of legislation are kept up-to-date with any amendments made by the UK since then.

Mae hon yn eitem o ddeddfwriaeth sy’n deillio o’r UE

Mae unrhyw newidiadau sydd wedi cael eu gwneud yn barod gan y tîm yn ymddangos yn y cynnwys a chyfeirir atynt gydag anodiadau.Ar ôl y diwrnod ymadael bydd tair fersiwn o’r ddeddfwriaeth yma i’w gwirio at ddibenion gwahanol. Y fersiwn legislation.gov.uk yw’r fersiwn sy’n weithredol yn y Deyrnas Unedig. Y Fersiwn UE sydd ar EUR-lex ar hyn o bryd yw’r fersiwn sy’n weithredol yn yr UE h.y. efallai y bydd arnoch angen y fersiwn hon os byddwch yn gweithredu busnes yn yr UE. EUR-Lex Y fersiwn yn yr archif ar y we yw’r fersiwn swyddogol o’r ddeddfwriaeth fel yr oedd ar y diwrnod ymadael cyn cael ei chyhoeddi ar legislation.gov.uk ac unrhyw newidiadau ac effeithiau a weithredwyd yn y Deyrnas Unedig wedyn. Mae’r archif ar y we hefyd yn cynnwys cyfraith achos a ffurfiau mewn ieithoedd eraill o EUR-Lex. The EU Exit Web Archive legislation_originated_from_EU_p3

Status:

Point in time view as at 31/12/2020.

Changes to legislation:

There are outstanding changes not yet made to Commission Regulation (EU) 2017/2400. Any changes that have already been made to the legislation appear in the content and are referenced with annotations.![]()

Changes to Legislation

Changes and effects yet to be applied by the editorial team are only applicable when viewing the latest version or prospective version of legislation. They are therefore not accessible when viewing legislation as at a specific point in time. To view the ‘Changes to Legislation’ information for this provision return to the latest version view using the options provided in the ‘What Version’ box above.

ANNEX IU.K. CLASSIFICATION OF VEHICLES IN VEHICLE GROUPS

1.Classification of the vehicles for the purpose of this RegulationU.K.

1.1Classification of vehicles of category NU.K.

[F1Table 1

Vehicle groups for vehicles of category N

| a In these vehicle classes tractors are treated as rigid lorries but with specific curb weight of tractor. | ||||||||||

| b Sub-group ‘ v ’ of vehicle groups 4, 5, 9 and 10: these mission profiles are exclusively applicable to vocational vehicles. | ||||||||||

| (*) EMS — European Modular System | ||||||||||

| T = Tractor R = Rigid lorry & standard body T1, T2 = Standard trailers ST = Standard semitrailer D = Standard dolly] | ||||||||||

| Description of elements relevant to the classification in vehicle groups | Vehicle group | Allocation of mission profile and vehicle configuration | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Axle configuration | Chassis configuration | Technically permissible maximum laden mass (tons) | Long haul | Long haul (EMS) | Regional delivery | Regional delivery (EMS) | Urban delivery | Municipal utility | Construction | |

| 4 × 2 | Rigid lorry | > 3,5 –7,5 | (0) | |||||||

| Rigid lorry (or tractor) a | > 7,5 – 10 | 1 | R | R | ||||||

| Rigid lorry (or tractor) a | > 10 – 12 | 2 | R+T1 | R | R | |||||

| Rigid lorry (or tractor) a | > 12 – 16 | 3 | R | R | ||||||

| Rigid lorry | > 16 | 4 | R+T2 | R | R | R | ||||

| Tractor | > 16 | 5 | T+ST | T+ST+T2 | T+ST | T+ST+T2 | T+ST | |||

| Rigid lorry | > 16 | 4v b | R | R | ||||||

| Tractor | > 16 | 5v b | T+ST | |||||||

| 4 × 4 | Rigid lorry | > 7,5 – 16 | (6) | |||||||

| Rigid lorry | > 16 | (7) | ||||||||

| Tractor | > 16 | (8) | ||||||||

| 6 × 2 | Rigid lorry | all weights | 9 | R+T2 | R+D+ST | R | R+D+ST | R | ||

| Tractor | all weights | 10 | T+ST | T+ST+T2 | T+ST | T+ST+T2 | ||||

| Rigid lorry | all weights | 9v b | R | R | ||||||

| Tractor | all weights | 10v b | T+ST | |||||||

| 6 × 4 | Rigid lorry | all weights | 11 | R+T2 | R+D+ST | R | R+D+ST | R | R | |

| Tractor | all weights | 12 | T+ST | T+ST+T2 | T+ST | T+ST+T2 | T+ST | |||

| 6 × 6 | Rigid lorry | all weights | (13) | |||||||

| Tractor | all weights | (14) | ||||||||

| 8 × 2 | Rigid lorry | all weights | (15) | |||||||

| 8 × 4 | Rigid lorry | all weights | 16 | R | ||||||

| 8 × 6 8 × 8 | Rigid lorry | all weights | (17) | |||||||

Textual Amendments

F1 Substituted by Commission Regulation (EU) 2019/318 of 19 February 2019 amending Regulation (EU) 2017/2400 and Directive 2007/46/EC of the European Parliament and of the Council as regards the determination of the CO2 emissions and fuel consumption of heavy-duty vehicles (Text with EEA relevance).

ANNEX IIU.K. REQUIREMENTS AND PROCEDURES RELATED TO THE OPERATION OF THE SIMULATION TOOL

1.The processes to be set up by the vehicle manufacturer with a view to the operation of the simulation toolU.K.

1.1.The manufacturer shall set up at least the following processes:U.K.

A data management system covering sourcing, storing, handling and retrieving of the input information and input data for the simulation tool as well as handling certificates on the CO2 emissions and fuel consumption related properties of a component families, separate technical unit families and system families. The data management system shall at least:

ensure application of correct input information and input data to specific vehicle configurations

ensure correct calculation and application of standard values;

verify by means of comparing cryptographic hashes that the input files of component families, separate technical unit families and system families which are used for the simulation corresponds to the input data of the component families, separate technical unit families and system families for which the certification has been granted;

include a protected database for storing the input data relating to the component families, separate technical unit families or system families and the corresponding certificates of the CO2 emissions and fuel consumption related properties;

ensure correct management of the changes of specification and updates of components, separate technical units and systems;

enable tracing of the components, separate technical units and systems after the vehicle is produced.

A data management system covering retrieving of the input information and input data and calculations by means of the simulation tool and storing of the output data. The data management system shall at least:

ensure a correct application of cryptographic hashes;

include a protected database for storing the output data;

Process for consulting the dedicated electronic distribution platform referred to in Article 5(2) and Article 10(1) and (2), as well as downloading and installing the latest versions of the simulation tool.

Appropriate training of staff working with the simulation tool.

2.Assessment by the approval authorityU.K.

2.1.The approval authority shall verify whether the processes set out in point 1 related to the operation of the simulation tool have been set up.U.K.

The approval authority shall also verify the following:

the functioning of the processes set out in points 1.1.1, 1.1.2 and 1.1.3 and the application of the requirement set out in point 1.1.4;

that the processes used during the demonstration are applied in the same manner in all the production facilities manufacturing the vehicle group concerned;

the completeness of the description of the data and process flows of operations related to the determination of the CO2 emissions and fuel consumption of the vehicles.

For the purpose of point (a) of the second paragraph, The verification shall include determination of the CO2 emissions and fuel consumption of at leaste one vehicle from each of the vehicle groups for which the licence has been applied for.

Appendix 1

MODEL OF AN INFORMATION DOCUMENT FOR THE PURPOSES OF OPERATING THE SIMULATION TOOL WITH A VIEW TO DETERMINING THE CO2 EMISSIONS AND FUEL CONSUMPTION OF NEW VEHICLES U.K.

SECTION IU.K.

1Name and address of manufacturer:U.K.

2Assembly plants for which the processes referred to in point 1 of Annex II of Regulation (EU) 2017/2400 have been set up with a view to the operation of the simulation tool:U.K.

3Vehicle groups covered:U.K.

4Name and address of the manufacturer's representative (if any)U.K.

SECTION IIU.K.

1.Additional informationU.K.

1.1.Data and process flow handling description (e.g. flow chart)U.K.

1.2Description of quality management processU.K.

1.3Additional quality management certificates (if any)U.K.

1.4Description of simulation tool data sourcing, handling and storageU.K.

1.5Additional documents (if any)U.K.

2.Date: …U.K.

3.Signature: …U.K.

Appendix 2

MODEL OF A LICENCE TO OPERATE THE SIMULATION TOOL WITH A VIEW TO DETERMINING CO2 EMISSIONS AND FUEL CONSUMPTION OF NEW VEHICLES U.K.

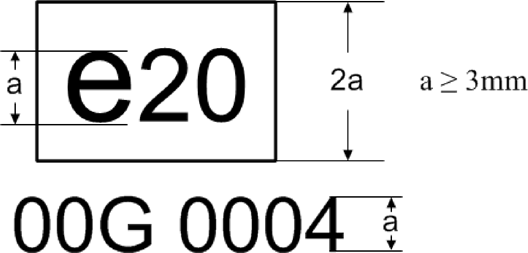

Maximum format: A4 (210 × 297 mm)U.K.

LICENCE TO OPERATE THE SIMULATION TOOL WITH A VIEW TO DETERMINING CO2 EMISSIONS AND FUEL CONSUMPTION OF NEW VEHICLES U.K.

of the licence to operate simulation tool with regard to Regulation (EC) No 595/2009 as implemented by Regulation (EU) 2017/2400.

Licence number:

Reason for extension: …

SECTION IU.K.

0.1Name and address of manufacturer:U.K.

0.2Assembly plants for which the processes referred to in point 1 of Annex II of Commission Regulation (EU) 2017/2400 have been set up with a view to the operation of the simulation toolU.K.

0.3Vehicle groups covered:U.K.

SECTION IIU.K.

1.Additional informationU.K.

1.1Assessment report performed by an approval authorityU.K.

1.2.Data and process flow handling description (e.g. flow chart)U.K.

1.3.Description of quality management processU.K.

1.4.Additional quality management certificates (if any)U.K.

1.5.Description of simulation tool data sourcing, handling and storageU.K.

1.6Additional documents (if any)U.K.

2.Approval authority responsible for carrying out the assessmentU.K.

3.Date of the assessment reportU.K.

4.Number of assessment report reportU.K.

5.Remarks (if any): see AddendumU.K.

6.PlaceU.K.

7.DateU.K.

8.SignatureU.K.

ANNEX IIIU.K. INPUT INFORMATION RELATING TO THE CHARACTERISTIC OF THE VEHICLE

1.IntroductionU.K.

This Annex describes the list of parameters to be provided by the vehicle manufacturer as input to the simulation tool. The applicable XML schema as well as example data are available at the dedicated electronic distribution platform.

2.DefinitionsU.K.

[F1‘ Parameter ID ’ : Unique identifier as used in the simulation tool for a specific input parameter or set of input data]

‘Type’: Data type of the parameter

sequence of characters in ISO8859-1 encoding

sequence of characters in ISO8859-1 encoding, no leading/trailing whitespace

date and time in UTC time in the format: YYYY-MM-DDTHH:MM:SSZ with italic letters denoting fixed characters e.g. ‘2002-05-30T09:30:10Z’

value with an integral data type, no leading zeros, e.g. ‘1800’

fractional number with exactly X digits after the decimal sign (‘.’) and no leading zeros e.g. for ‘double, 2’: ‘2345.67’; for ‘double, 4’: ‘45.6780’

‘Unit’ … physical unit of the parameter

‘corrected actual mass of the vehicle’ shall mean the mass as specified under the ‘actual mass of the vehicle’ in accordance with Commission Regulation (EC) No 1230/2012(1) with an exception for the tank(s) which shall be filled to at least 50 % of its or their capacity/ies, without superstructure and corrected by the additional weight of the non-installed standard equipment as specified in point 4.3 and the mass of a standard body, standard semi-trailer or standard trailer to simulate the complete vehicle or complete vehicle-(semi-)trailer combination.

All parts that are mounted on and above the main frame are regarded as superstructure parts if they are only installed for facilitating a superstructure, independent of the necessary parts for in running order conditions.

3.Set of input parametersU.K.

[F1Table 1

Input parameters ‘ Vehicle/General ’

| a In case of multiple PTOs mounted to the transmission, only the component with the highest losses according to point 3.6 of Annex IX, for its combination of criteria ‘ PTOShaftsGearWheels ’ and ‘ PTOShaftsOtherElements ’ , shall be declared.] | ||||

| Parameter name | Parameter ID | Type | Unit | Description/Reference |

|---|---|---|---|---|

| Manufacturer | P235 | token | [-] | |

| ManufacturerAddress | P252 | token | [-] | |

| Model | P236 | token | [-] | |

| VIN | P238 | token | [-] | |

| Date | P239 | dateTime | [-] | Date and time when the component-hash is created |

| LegislativeClass | P251 | string | [-] | Allowed values: ‘ N2 ’ , ‘ N3 ’ |

| VehicleCategory | P036 | string | [-] | Allowed values: ‘ Rigid Lorry ’ , ‘ Tractor ’ |

| AxleConfiguration | P037 | string | [-] | Allowed values: ‘ 4×2 ’ , ‘ 6×2 ’ , ‘ 6×4 ’ , ‘ 8×4 ’ |

| CurbMassChassis | P038 | int | [kg] | |

| GrossVehicleMass | P041 | int | [kg] | |

| IdlingSpeed | P198 | int | [1/min] | |

| RetarderType | P052 | string | [-] | Allowed values: ‘ None ’ , ‘ Losses included in Gearbox ’ , ‘ Engine Retarder ’ , ‘ Transmission Input Retarder ’ , ‘ Transmission Output Retarder ’ |

| RetarderRatio | P053 | double, 3 | [-] | |

| AngledriveType | P180 | string | [-] | Allowed values: ‘ None ’ , ‘ Losses included in Gearbox ’ , ‘ Separate Angledrive ’ |

| PTOShaftsGearWheels a | P247 | string | [-] | Allowed values: ‘ none ’ , ‘ only the drive shaft of the PTO ’ , ‘ drive shaft and/or up to 2 gear wheels ’ , ‘ drive shaft and/or more than 2 gear wheels ’ , ‘ only one engaged gearwheel above oil level ’ |

| PTOOtherElements a | P248 | string | [-] | Allowed values: ‘ none ’ , ‘ shift claw, synchronizer, sliding gearwheel ’ , ‘ multi-disc clutch ’ , ‘ multi-disc clutch, oil pump ’ |

| CertificationNumberEngine | P261 | token | [-] | |

| CertificationNumberGearbox | P262 | token | [-] | |

| CertificationNumberTorqueconverter | P263 | token | [-] | |

| CertificationNumberAxlegear | P264 | token | [-] | |

| CertificationNumberAngledrive | P265 | token | [-] | |

| CertificationNumberRetarder | P266 | token | [-] | |

| CertificationNumberTyre | P267 | token | [-] | |

| CertificationNumberAirdrag | P268 | token | [-] | |

| ZeroEmissionVehicle | P269 | boolean | [-] | |

| VocationalVehicle | P270 | boolean | [-] | |

| NgTankSystem | P275 | string | [-] | Allowed values: ‘ Compressed ’ , ‘ Liquefied ’ Only relevant for vehicles with engines of fuel type ‘ NG PI ’ (P193) |

| Sleeper cab | P276 | boolean | [-] | |

Table 2

Input parameters ‘Vehicle/AxleConfiguration’ per wheel axle

| Parameter name | Parameter ID | Type | Unit | Description/Reference |

|---|---|---|---|---|

| TwinTyres | P045 | boolean | [-] | |

| AxleType | P154 | string | [-] | Allowed values: ‘VehicleNonDriven’, ‘VehicleDriven’ |

| Steered | P195 | boolean |

Table 3

Input parameters ‘Vehicle/Auxiliaries’

| Parameter name | Parameter ID | Type | Unit | Description/Reference |

|---|---|---|---|---|

| Fan/Technology | P181 | string | [-] | Allowed values: ‘Crankshaft mounted - Electronically controlled visco clutch’, ‘Crankshaft mounted - Bimetallic controlled visco clutch’, ‘Crankshaft mounted - Discrete step clutch’, ‘Crankshaft mounted - On/off clutch’, ‘Belt driven or driven via transm. - Electronically controlled visco clutch’, ‘Belt driven or driven via transm. - Bimetallic controlled visco clutch’, ‘Belt driven or driven via transm. - Discrete step clutch’, ‘Belt driven or driven via transm. - On/off clutch’, ‘Hydraulic driven - Variable displacement pump’, ‘Hydraulic driven - Constant displacement pump’, ‘Electrically driven - Electronically controlled’ |

| SteeringPump/Technology | P182 | string | [-] | Allowed values: ‘Fixed displacement’, ‘Fixed displacement with elec. control’, ‘Dual displacement’, ‘Variable displacement mech. controlled’, ‘Variable displacement elec. controlled’, ‘Electric’ Separate entry for each steered wheel axle required |

| ElectricSystem/Technology | P183 | string | [-] | Allowed values: ‘Standard technology’, ‘Standard technology - LED headlights, all’ |

| PneumaticSystem/Technology | P184 | string | [-] | Allowed values: ‘Small’, ‘Small + ESS’, ‘Small + visco clutch’ , ‘Small + mech. clutch’, ‘Small + ESS + AMS’, ‘Small + visco clutch + AMS’, ‘Small + mech. clutch + AMS’, ‘Medium Supply 1-stage’, ‘Medium Supply 1-stage + ESS’, ‘Medium Supply 1-stage + visco clutch’ , ‘Medium Supply 1-stage + mech. clutch’, ‘Medium Supply 1-stage + ESS + AMS’, ‘Medium Supply 1-stage + visco clutch + AMS’, ‘Medium Supply 1-stage + mech. clutch + AMS’, ‘Medium Supply 2-stage’, ‘Medium Supply 2-stage + ESS’, ‘Medium Supply 2-stage + visco clutch’ , ‘Medium Supply 2-stage + mech. clutch’, ‘Medium Supply 2-stage + ESS + AMS’, ‘Medium Supply 2-stage + visco clutch + AMS’, ‘Medium Supply 2-stage + mech. clutch + AMS’, ‘Large Supply’, ‘Large Supply + ESS’, ‘Large Supply + visco clutch’ , ‘Large Supply + mech. clutch’, ‘Large Supply + ESS + AMS’, ‘Large Supply + visco clutch + AMS’, ‘Large Supply + mech. clutch + AMS’; ‘Vacuum pump’ |

| [F1HVAC/Technology | P185 | string | [-] | Allowed values: ‘ None ’ , ‘ Default ’] |

Table 4

Input parameters ‘Vehicle/EngineTorqueLimits’ per gear (optional)

| Parameter name | Parameter ID | Type | Unit | Description/Reference |

|---|---|---|---|---|

| Gear | P196 | integer | [-] | only gear numbers need to be specified where vehicle related engine torque limits according to point 6 are applicable |

| MaxTorque | P197 | integer | [Nm] |

[F2Table 5

Input parameters for ZE-HDVs, He-HDVs and dual-fuel vehicles

| Parameter name | Parameter ID | Type | Unit | Description/Reference |

|---|---|---|---|---|

| Manufacturer | P235 | token | [-] | |

| ManufacturerAddress | P252 | token | [-] | |

| Model | P236 | token | [-] | |

| VIN | P238 | token | [-] | |

| Date | P239 | dateTime | [-] | Date and time when the component-hash is created |

| LegislativeClass | P251 | string | [-] | Allowed values: ‘ N2 ’ , ‘ N3 ’ |

| VehicleCategory | P036 | string | [-] | Allowed values: ‘ Rigid Lorry ’ , ‘ Tractor ’ |

| CurbMassChassis | P038 | int | [kg] | |

| GrossVehicleMass | P041 | int | [kg] | |

| MaxNetPower1 | P277 | int | [W] | If He-HDV = Y: highest maximum net power of all energy converters, which are linked to the vehicle driveline or the wheels |

| MaxNetPower2 | P278 | int | [W] | If He-HDV = Y: second highest maximum net power of all energy converters, which are linked to the vehicle driveline or the wheels |

| ZE-HDV | P269 | boolean | [-] | |

| He-HDV | P279 | boolean | [-] | |

| DualFuelVehicle | P280 | boolean | [-] | ] |

Textual Amendments

[F2Table 6

Input parameters ‘ Advanced driver assistance systems ’

| Parameter name | Parameter ID | Type | Unit | Description/Reference |

|---|---|---|---|---|

| EngineStopStart | P271 | boolean | [-] | In accordance with point 8.1.1 |

| EcoRollWithoutEngineStop | P272 | boolean | [-] | In accordance with point 8.1.2 |

| EcoRollWithEngineStop | P273 | boolean | [-] | In accordance with point 8.1.3 |

| PredictiveCruiseControl | P274 | string | [-] | In accordance with point 8.1.4, allowed values: ‘ 1,2 ’ , ‘ 1,2,3 ’] |

4.Vehicle massU.K.

4.1The vehicle mass used as input for the simulation tool shall be the corrected actual mass of the vehicle.U.K.

This corrected actual mass shall be based on vehicles equipped in such a way that they are compliant to all regulatory acts of Annex IV and Annex XI to Directive 2007/46/EC applicable to the particular vehicle class.

4.2If not all the standard equipment is installed, the manufacturer shall add the weight of the following construction elements to the corrected actual mass of the vehicle:U.K.

Front under-run protection in accordance with Regulation (EC) No 661/2009 of the European Parliament and of the Council(2)

Rear under-run protection in accordance with Regulation (EC) No 661/2009 of the European Parliament and of the Council

Lateral protection in accordance with Regulation (EC) No 661/2009 of the European Parliament and of the Council

Fifth wheel in accordance with Regulation (EC) No 661/2009 of the European Parliament and of the Council

4.3The weight of the construction elements referred to in point 4.2 shall be the following:U.K.

For vehicles of groups 1, 2 and 3

(a) Front under-ride protection45 kg

(b) Rear under-ride protection40 kg

(c) Lateral protection8,5 kg/m × wheel base [m] – 2,5 kg

[ F3 ]

For vehicles of groups 4, 5, 9 to 12 and 16

(a) Front under-ride protection50 kg

(b) Rear under-ride protection45 kg

(c) Lateral protection14 kg/m × wheel base [m] – 17 kg

(d) Fifth wheel210 kg

Textual Amendments

5.Hydraulically and mechanically driven axlesU.K.

In case of vehicles equipped with:

a hydraulically driven axles, the axle shall be treated as a non-drivable one and the manufacturer shall not take it into consideration for establishing an axle configuration of a vehicle;

a mechanically driven axles, the axle shall be treated as a drivable one and the manufacturer shall take it into consideration for establishing an axle configuration of a vehicle;

6.Gear dependent engine torque limits set by vehicle controlU.K.

For the highest 50 % of the gears (e.g. for gears 7 to 12 of a 12 gear transmission) the vehicle manufacturer may declare a gear dependent maximum engine torque limit which is not higher than 95 % of the maximum engine torque.

7.Vehicle specific engine idling speedU.K.

7.1.The engine idling speed has to be declared in VECTO for each individual vehicle. This declared vehicle engine idling shall be equal or higher than specified in the engine input data approval.U.K.

[F28. Advanced driver assistance systems U.K.

8.1. The following types of advanced driver assistance systems, which are primarily aiming for reduction of fuel consumption and CO 2 emissions, shall be declared in the input to the simulation tool: U.K.

Engine stop-start during vehicle stops: system which automatically shuts down and restarts the internal combustion engine during vehicle stops to reduce engine idling time. For automatic engine shut down the maximum time delay after the vehicle stop shall be not longer than 3 seconds.

Eco-roll without engine stop-start: system which automatically decouples the internal combustion engine from the drivetrain during specific downhill driving conditions with low negative gradients. During these phases the internal combustion engine is operated in engine idling. The system shall be active at least at all cruise control set speeds above 60 km/h.

Eco-roll with engine stop-start: system which automatically decouples the internal combustion engine from the drivetrain during specific downhill driving conditions with low negative slopes. During these phases the internal combustion engine is shut down after a short time delay and keeps shut down during the main share of the eco-roll phase. The system shall be active at least at all cruise control set speeds of above 60 km/h.

Predictive cruise control (PCC): systems which optimise the usage of potential energy during a driving cycle based on an available preview of road gradient data and the use of a GPS system. A PCC system declared in the input to the simulation tool shall have a gradient preview distance longer than 1 000 metres and cover all following functionalities:

Crest coasting

Approaching a crest the vehicle velocity is reduced before the point where the vehicle starts accelerating by gravity alone compared to the set speed of the cruise control so that the braking during the following downhill phase can be reduced.

Acceleration without engine power

During downhill driving with a low vehicle velocity and a high negative slope the vehicle acceleration is performed without any engine power usage so that the downhill braking can be reduced.

Dip coasting

During downhill driving when the vehicle is braking at the overspeed velocity, PCC increases the overspeed for a short period of time to end the downhill event with a higher vehicle velocity. Overspeed is a higher vehicle speed than the set speed of the cruise control system.

A PCC system can be declared as input to the simulation tool if either the functionalities set out in points (1) and (2) or points (1), (2) and (3) are covered.

8.2. The eleven combinations of the advanced driver assistance systems as set out in Table 7 are input parameters into the simulation tool: U.K.

| Table 7 | ||||

| Combinations of advanced driver assistance systems as input parameters into the simulation tool | ||||

| Combination No | Engine stop-start during vehicle stops | Eco-roll without engine stop-start | Eco-roll with engine stop-start | Predictive cruise control |

|---|---|---|---|---|

| 1 | yes | no | no | no |

| 2 | no | yes | no | no |

| 3 | no | no | yes | no |

| 4 | no | no | no | yes |

| 5 | yes | yes | no | no |

| 6 | yes | no | yes | no |

| 7 | yes | no | no | yes |

| 8 | no | yes | no | yes |

| 9 | no | no | yes | yes |

| 10 | yes | yes | no | yes |

| 11 | yes | no | yes | yes |

8.3. Any advanced driver assistance system declared in the input into the simulation tool shall by default be set to fuel economy mode after each key-off/key-on cycle. U.K.

8.4. If an advanced driver assistance system is declared in the input into the simulation tool, it shall be possible to verify the presence of such a system based on real world driving and the system definitions as set out in point 8.1. If a certain combination of systems is declared, also the interaction of functionalities (e.g. predictive cruise control plus eco-roll with engine stop-start) shall be demonstrated. In the verification procedure it shall be taken into consideration, that the systems need certain boundary conditions to be ‘ active ’ (e.g. engine at operation temperature for engine stop-start, certain vehicle speed ranges for PCC, certain ratios of road gradients with vehicle mass for eco-roll). The vehicle manufacturer needs to submit a functional description of boundary conditions when the systems are ‘ inactive ’ or their efficiency is reduced. The approval authority may request the technical justifications of these boundary conditions from the applicant for approval and assess them for compliance.] U.K.

ANNEX IVU.K. MODEL OF THE MANUFACTURER'S RECORDS FILE AND OF THE CUSTOMER INFORMATION FILE

PART IU.K. Vehicle CO2 emissions and fuel consumption – Manufacturer's records file

The manufacturer's records file will be produced by the simulation tool and shall at least contain the following information:

1.Vehicle, component, separate technical unit and systems dataU.K.

1.1.Vehicle dataU.K.

1.1.1.Name and address of manufacturerU.K.

1.1.2.Vehicle modelU.K.

1.1.3.Vehicle identification number (VIN) …U.K.

1.1.4.Vehicle category (N1 N2, N3, M1, M2, M3) …U.K.

1.1.5.Axle configuration …U.K.

1.1.6.Max. gross vehicle weight (t) …U.K.

1.1.7.Vehicle group in accordance with Table 1 …U.K.

1.1.8.Corrected actual curb mass (kg) …U.K.

[F21.1.9. Vocational vehicle (yes/no) … U.K.

1.1.10. Zero emission heavy-duty vehicle (yes/no) … U.K.

1.1.11. Hybrid electric heavy-duty vehicle (yes/no) … U.K.

1.1.12. Dual-fuel vehicle (yes/no) … U.K.

1.1.13. Sleeper cab (yes/no) …] U.K.

1.2.Main engine specificationsU.K.

1.2.1.Engine modelU.K.

1.2.2.Engine certification number …U.K.

1.2.3.Engine rated power (kW) …U.K.

1.2.4.Engine idling speed (1/min) …U.K.

1.2.5.Engine rated speed (1/min) …U.K.

1.2.6.Engine capacity (ltr) …U.K.

[F11.2.7. Fuel type (Diesel CI/CNG PI/LNG PI…) … U.K.

1.2.8. Hash of the engine input data and input information …] U.K.

1.3.Main transmission specificationsU.K.

1.3.1.Transmission modelU.K.

1.3.2.Transmission certification number …U.K.

1.3.3.Main option used for generation of loss maps (Option1/Option2/Option3/Stnadard values) …:U.K.

1.3.4.Transmission type (SMT, AMT, APT-S,APT-P) …U.K.

1.3.5.Nr. of gears …U.K.

1.3.6.Transmission ratio final gear …U.K.

1.3.7.Retarder type …U.K.

1.3.8.Power take off (yes/no) …U.K.

[F11.3.9. Hash of the transmission input data and input information …] U.K.

1.4.Retarder specificationsU.K.

1.4.1.Retarder modelU.K.

1.4.2.Retarder certification number …U.K.

1.4.3.Certification option used for generation of a loss map (standard values/measurement) …U.K.

[F11.4.4. Hash of the other torque transferring components input data and input information …] U.K.

1.5.Torque converter specificationU.K.

1.5.1.Torque converter modelU.K.

1.5.2.Torque converter certification number …U.K.

1.5.3.Certification option used for generation of a loss map (standard values/measurement) …U.K.

[F11.5.4. Hash of the torque converter input data and input information …] U.K.

1.6.Angle drive specificationsU.K.

1.6.1.Angle drive modelU.K.

1.6.2.Axle certification number …U.K.

1.6.3.Certification option used for generation of a loss map (standard values/measurement) …U.K.

1.6.4.Angle drive ratio …U.K.

[F11.6.5. Hash of the additional driveline components input data and input information …] U.K.

1.7.Axle specificationsU.K.

1.7.1.Axle model …U.K.

1.7.2.Axle certification number …U.K.

1.7.3.Certification option used for generation of a loss map (standard values/measurement) …U.K.

1.7.4.Axle type (e.g. standard single driven axle) …U.K.

1.7.5.Axle ratio …U.K.

[F11.7.6. Hash of the axle input data and input information …] U.K.

1.8.AerodynamicsU.K.

1.8.1.ModelU.K.

1.8.2.Certification option used for generation of CdxA (standard values /measurement) …U.K.

1.8.3.CdxA Certification number (if applicable) …U.K.

1.8.4.CdxA value …U.K.

[F11.8.5. Hash of the air drag input data and input information …] U.K.

1.9.Main tyre specificationsU.K.

1.9.1.Tyre dimension axle 1 …U.K.

1.9.2.Tyre certification number …U.K.

1.9.3.Specific RRC of all tyres on axle 1 …U.K.

[F21.9.3a. Hash of the tyre input data and input information axle 1 …] U.K.

1.9.4.Tyre dimension axle 2 …U.K.

1.9.5.Twin axle (yes/no) axle 2 …U.K.

1.9.6.Tyre certification number …U.K.

1.9.7.Specific RRC of all tyres on axle 2 …U.K.

[F21.9.7a. Hash of the tyre input data and input information axle 2 …] U.K.

1.9.8.Tyre dimension axle 3 …U.K.

1.9.9.Twin axle (yes/no) axle 3 …U.K.

1.9.10.Tyre certification number …U.K.

1.9.11.Specific RRC of all tyres on axle 3 …U.K.

[F21.9.11a. Hash of the tyre input data and input information axle 3 …] U.K.

1.9.12.Tyre dimension axle 4 …U.K.

1.9.13.Twin axle (yes/no) axle 4 …U.K.

1.9.14.Tyre certification number …U.K.

1.9.15.Specific RRC of all tyres on axle 4 …U.K.

[F21.9.16. Hash of the tyre input data and input information axle 4 …] U.K.

1.10.Main auxiliary specificationsU.K.

1.10.1.Engine cooling fan technology …U.K.

1.10.2.Steering pump technology …U.K.

1.10.3.Electric system technology …U.K.

1.10.4.Pneumatic system technology …U.K.

1.11.Engine torque limitationsU.K.

1.11.1.Engine torque limit at gear 1 (% of max engine torque) …U.K.

1.11.2.Engine torque limit at gear 2 (% of max engine torque) …U.K.

1.11.3.Engine torque limit at gear 3 (% of max engine torque) …U.K.

1.11.4.Engine torque limit at gear … (% of max engine torque)U.K.

[F21.12. Advanced driver assistance systems (ADAS) U.K.

Engine stop-start during vehicle stops (yes/no) …

Eco-roll without engine stop-start (yes/no) …

Eco-roll with engine stop-start (yes/no) …

Predictive cruise control (yes/no) …]

2.Mission profile and loading dependent valuesU.K.

2.1.Simulation parameters (for each profile/load/fuel combination)U.K.

[F12.1.1. Mission profile (long haul/long haul (EMS)/regional/regional (EMS)/urban/municipal/construction) …] U.K.

2.1.2.Load (as defined in the simulation tool) (kg) …U.K.

2.1.3.Fuel (diesel/petrol/LPG/CNG/…) …U.K.

2.1.4.Total vehicle mass in simulation (kg) …U.K.

2.2.Vehicle driving performance and information for simulation quality checkU.K.

2.2.1.Average speed (km/h) …U.K.

2.2.2.Minimum instantaneous speed (km/h) …U.K.

2.2.3.Maximum instantaneous speed (km/h) …U.K.

2.2.4.Maximum deceleration (m/s2) …U.K.

2.2.5.Maximum acceleration (m/s2) …U.K.

2.2.6.Full load percentage on driving time …U.K.

2.2.7.Total number of gear shifts …U.K.

2.2.8.Total driven distance (km) …U.K.

2.3.Fuel and CO2 resultsU.K.

2.3.1.Fuel consumption (g/km) …U.K.

2.3.2.Fuel consumption (g/t-km) …U.K.

2.3.3.Fuel consumption (g/p-km) …U.K.

2.3.4.Fuel consumption (g/m3-km) …U.K.

2.3.5.Fuel consumption (l/100km) …U.K.

2.3.6.Fuel consumption (l/t-km) …U.K.

2.3.7.Fuel consumption (l/p-km) …U.K.

2.3.8.Fuel consumption (l/m3-km) …U.K.

2.3.9.Fuel consumption (MJ/km) …U.K.

2.3.10.Fuel consumption (MJ/t-km) …U.K.

2.3.11.Fuel consumption (MJ/p-km) …U.K.

2.3.12.Fuel consumption (MJ/m3-km) …U.K.

2.3.13.CO2 (g/km) …U.K.

2.3.14.CO2 (g/t-km) …U.K.

2.3.15.CO2 (g/p-km) …U.K.

2.3.16.CO2 (g/m3-km) …U.K.

3.Software and user informationU.K.

3.1.Software and user informationU.K.

3.1.1.Simulation tool version (X.X.X) …U.K.

3.1.2.Date and time of the simulationU.K.

3.1.3.Hash of simulation tool input information and input data …U.K.

[F13.1.4. Cryptographic hash of the manufacturer's records file …] U.K.

PART IIU.K. Vehicle CO2 emissions and fuel consumption - Customer information file

1.Vehicle, component, separate technical unit and systems dataU.K.

1.1.Vehicle dataU.K.

1.1.1.Vehicle identification number (VIN) …U.K.

1.1.2.Vehicle category (N1 N2, N3, M1, M2, M3) …U.K.

1.1.3.Axle configuration …U.K.

1.1.4.Max. gross vehicle weight (t) …U.K.

1.1.5.Vehicle's group …U.K.

1.1.6.Name and address of manufacturer …U.K.

[F11.1.7. Model …] U.K.

1.1.8.Corrected actual curb mass (kg) …U.K.

[F21.1.9. Vocational vehicle (yes/no) … U.K.

1.1.10. Zero emission heavy-duty vehicle (yes/no) … U.K.

1.1.11. Hybrid electric heavy-duty vehicle (yes/no) … U.K.

1.1.12. Dual-fuel vehicle (yes/no) … U.K.

1.1.13. Sleeper cab (yes/no) …] U.K.

1.2.Component, separate technical unit and systems dataU.K.

1.2.1.Engine rated power (kW) …U.K.

1.2.2.Engine capacity (ltr) …U.K.

[F11.2.3. Fuel type (Diesel CI/CNG PI/LNG PI…) …] U.K.

1.2.4.Transmission values (measured/standard) …U.K.

1.2.5.Transmission type (SMT, AMT, AT-S, AT-S) …U.K.

1.2.6.Nr. of gears …U.K.

1.2.7.Retarder (yes/no) …U.K.

1.2.8.Axle ratio …U.K.

[F11.2.9. Average rolling resistance coefficient (RRC) of all tyres of the motor vehicle: …] U.K.

[F21.2.10. Average fuel efficiency labelling class of all tyres of the motor vehicle in accordance with Regulation (EC) No 1222/2009 … U.K.

1.2.11. Engine stop-start during vehicle stops (yes/no) … U.K.

1.2.12. Eco-roll without engine stop-start (yes/no) … U.K.

1.2.13. Eco-roll with engine stop-start (yes/no) … U.K.

1.2.14. Predictive cruise control (yes/no) …] U.K.

[F22. CO 2 emissions and fuel consumption of the vehicle (for each payload/mission profile) U.K.

2.1. Payload low [kg]: U.K.

| Average vehicle speed | CO 2 emissions | Fuel consumption | |||||

|---|---|---|---|---|---|---|---|

| Long haul | … km/h | … g/km | … g/t-km | … g/m 3 -km | … l/100km | … l/t-km | … l/m 3 -km |

| Long haul (EMS) | … km/h | … g/km | … g/t-km | … g/m 3 -km | … l/100km | … l/t-km | … l/m 3 -km |

| Regional delivery | … km/h | … g/km | … g/t-km | … g/m 3 -km | … l/100km | … l/t-km | … l/m 3 -km |

| Regional delivery (EMS) | … km/h | … g/km | … g/t-km | … g/m 3 -km | … l/100km | … l/t-km | … l/m 3 -km |

| Urban delivery | … km/h | … g/km | … g/t-km | … g/m 3 -km | … l/100km | … l/t-km | … l/m 3 -km |

| Municipal utility | … km/h | … g/km | … g/t-km | … g/m 3 -km | … l/100km | … l/t-km | … l/m 3 -km |

| Construction | … km/h | … g/km | … g/t-km | … g/m 3 -km | … l/100km | … l/t-km | … l/m 3 -km |

2.2. Payload representative [kg]: U.K.

| Average vehicle speed | CO 2 emissions | Fuel consumption | |||||

|---|---|---|---|---|---|---|---|

| Long haul | … km/h | … g/km | … g/t-km | … g/m 3 -km | … l/100km | … l/t-km | … l/m 3 -km |

| Long haul (EMS) | … km/h | … g/km | … g/t-km | …g/m 3 -km | … l/100km | … l/t-km | … l/m 3 -km |

| Regional delivery | …km/h | … g/km | … g/t-km | … g/m 3 -km | … l/100km | … l/t-km | … l/m 3 -km |

| Regional delivery (EMS) | … km/h | … g/km | … g/t-km | … g/m 3 -km | … l/100km | … l/t-km | … l/m 3 -km |

| Urban delivery | … km/h | … g/km | … g/t-km | … g/m 3 -km | … l/100km | … l/t-km | … l/m 3 -km |

| Municipal utility | … km/h | … g/km | … g/t-km | … g/m 3 -km | … l/100km | … l/t-km | … l/m 3 -km |

| Construction | … km/h | … g/km | … g/t-km | … g/m 3 -km | … l/100km | … l/t-km | … l/m 3 -km |

2.3. Specific CO 2 emissions [gCO 2 /tkm] … U.K.

2.4. Average payload value [t] … U.K.

2.5. Software and user information U.K.

| Simulation tool version | [X.X.X] |

| Date and time of the simulation | [-] |

3. Cryptographic hash of the manufacturer's records file …] U.K.

F3PART IIIU.K. CO2 emissions and fuel consumption of the vehicle (for each payload/fuel combination)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ANNEX VU.K. VERIFYING ENGINE DATA

1.IntroductionU.K.

The engine test procedure described in this Annex shall produce input data relating to engines for the simulation tool.

2.DefinitionsU.K.

For the purposes of this Annex the definitions according to UN/ECE Regulation 49 Rev.06 and, in addition to these, the following definitions shall apply:

‘engine CO2-family’ means a manufacturer's grouping of engines, as defined in paragraph 1 of Appendix 3;

‘CO2-parent engine’ means an engine selected from an engine CO2-family as specified in Appendix 3;

‘NCV’ means net calorific value of a fuel as specified in paragraph 3.2;

‘specific mass emissions’ means the total mass emissions divided by the total engine work over a defined period expressed in g/kWh;

‘specific fuel consumption’ means the total fuel consumption divided by the total engine work over a defined period expressed in g/kWh;

‘FCMC’ means fuel consumption mapping cycle;

‘Full load’ means the delivered engine torque/power at a certain engine speed when the engine is operated at maximum operator demand.

The definitions in paragraphs 3.1.5 and 3.1.6. of Annex 4 to UN/ECE Regulation 49 Rev.06 shall not apply.

3.General requirementsU.K.

The calibration laboratory facilities shall comply with the requirements of either ISO/TS 16949, ISO 9000 series or ISO/IEC 17025. All laboratory reference measurement equipment, used for calibration and/or verification, shall be traceable to national or international standards.

Engines shall be grouped into engine CO2-families defined in accordance with Appendix 3. Paragraph 4.1 explains which testruns shall be performed for the purpose of certification of one specific engine CO2-family.

3.1Test conditionsU.K.

All testruns performed for the purpose of certification of one specific engine CO2-family defined in accordance with Appendix 3 to this Annex shall be conducted on the same physical engine and without any changes to the setup of the engine dynamometer and the engine system, apart from the exceptions defined in paragraph 4.2 and Appendix 3.

3.1.1Laboratory test conditionsU.K.

The tests shall be conducted under ambient conditions meeting the following conditions over the whole testrun:

The parameter fa describing the laboratory test conditions, determined in accordance with paragraph 6.1 of Annex 4 to UN/ECE Regulation 49 Rev.06, shall be within the following limits: 0,96 ≤ fa ≤ 1,04.

The absolute temperature (Ta) of the engine intake air expressed in Kelvin, determined in accordance with paragraph 6.1 of Annex 4 to UN/ECE Regulation 49 Rev.06 shall be within the following limits: 283 K ≤ Ta ≤ 303 K.

The atmospheric pressure expressed in kPa, determined in accordance with paragraph 6.1 of Annex 4 to UN/ECE Regulation 49 Rev.06 shall be within the following limits: 90 kPa ≤ ps ≤ 102 kPa.

If tests are performed in test cells that are able to simulate barometric conditions other than those existing in the atmosphere at the specific test site, the applicable fa value shall be determined with the simulated values of atmospheric pressure by the conditioning system. The same reference value for the simulated atmospheric pressure shall be used for the intake air and exhaust path and all other relevant engine systems. The actual value of the simulated atmospheric pressure for the intake air and exhaust path and all other relevant engine systems shall be within the limits specified in subpoint (3).

In cases where the ambient pressure in the atmosphere at the specific test site exceeds the upper limit of 102 kPa, tests in accordance with this Annex may still be performed. In this case tests shall be performed with the specific ambient air pressure in the atmosphere.

In cases where the test cell has the ability to control temperature, pressure and/or humidity of engine intake air independent of the atmospheric conditions the same settings for those parameters shall be used for all testruns performed for the purpose of certification of one specific engine CO2-family defined in accordance with Appendix 3 to this Annex.

3.1.2Engine installationU.K.

The test engine shall be installed in accordance with paragraphs 6.3 to 6.6 of Annex 4 to UN/ECE Regulation 49 Rev.06.

If auxiliaries/equipment necessary for operating the engine system are not installed as required in accordance with paragraph 6.3 of Annex 4 to UN/ECE Regulation 49 Rev.06, all measured engine torque values shall be corrected for the power required for driving these components for the purpose of this Annex in accordance with paragraph 6.3 of Annex 4 to UN/ECE Regulation 49 Rev.06.

The power consumption of the following engine components resulting in the engine torque required for driving these engine components shall be determined in accordance with Appendix 5 to this Annex:

fan

electrically powered auxiliaries/equipment necessary for operating the engine system

3.1.3Crankcase emissionsU.K.

In the case of a closed crankcase, the manufacturer shall ensure that the engine's ventilation system does not permit the emission of any crankcase gases into the atmosphere. If the crankcase is of an open type, the emissions shall be measured and added to the tailpipe emissions, following the provisions set out in paragraph 6.10. of Annex 4 to UN/ECE Regulation 49 Rev.06.

3.1.4Engines with charge air-coolingU.K.

During all testruns the charge air cooling system used on the test bed shall be operated under conditions which are representative for in-vehicle application at reference ambient conditions. The reference ambient conditions are defined as 293 K for air temperature and 101,3 kPa for pressure.

The laboratory charge air cooling for tests according to this regulation should comply with the provisions specified in paragraph 6.2 of Annex 4 to UN/ECE Regulation 49 Rev.06.

3.1.5Engine cooling systemU.K.

During all testruns the engine cooling system used on the test bed shall be operated under conditions which are representative for in-vehicle application at reference ambient conditions. The reference ambient conditions are defined as 293 K for air temperature and 101,3 kPa for pressure.

The engine cooling system should be equipped with thermostats according to the manufacturer specification for vehicle installation. If either a non-operational thermostat is installed or no thermostat is used, subpoint (3) shall apply. The setting of the cooling system shall be performed in accordance with subpoint (4).

If no thermostat is used or a non-operational thermostat is installed, the test bed system shall reflect the behavior of the thermostat under all test conditions. The setting of the cooling system shall be performed in accordance with subpoint (4).

[F1The engine coolant flow rate (or alternatively the pressure difference across the engine side of the heat exchanger) and the engine coolant temperature shall be set to a value representative for in-vehicle application at reference ambient conditions when the engine is operated at rated speed and full load with the engine thermostat in fully open position. This setting defines the coolant reference temperature. For all testruns performed for the purpose of certification of one specific engine within one engine CO 2 -family, the cooling system setting shall not be changed, neither on the engine side nor on the test bed side of the cooling system. The temperature of the test bed side cooling medium shall be kept reasonably constant by good engineering judgement. The cooling medium on the test bed side of the heat exchanger shall not exceed the nominal thermostat opening temperatur downstream of the heat exchanger.]

For all testruns performed for the purpose of certification of one specific engine within one engine CO2-family the engine coolant temperature shall be maintained between the nominal value of the thermostat opening temperature declared by the manufacturer and the coolant reference temperature in accordance with subpoint (4) as soon as the engine coolant has reached the declared thermostat opening temperature after engine cold start.

For the WHTC coldstart test performed in accordance with paragraph 4.3.3, the specific initial conditions are specified in paragraphs 7.6.1. and 7.6.2 of Annex 4 to UN/ECE Regulation 49 Rev.06. If simulation of the thermostat behaviour in accordance with subpoint (3) is applied, there shall be no coolant flow across the heat exchanger as long as the engine coolant has not reached the declared nominal thermostat opening temperature after cold start.

3.2FuelsU.K.

The respective reference fuel for the engine systems under test shall be selected from the fuel types listed in Table 1. The fuel properties of the reference fuels listed in Table 1 shall be those specified in Annex IX to Commission Regulation (EU) No 582/2011.

To ensure that the same fuel is used for all testruns performed for the purpose of certification of one specific engine CO2-family no refill of the tank or switch to another tank supplying the engine system shall occur. Exceptionally a refill or switch may be allowed if it can be ensured that the replacement fuel has exactly the same properties as the fuel used before (same production batch).

The NCV for the fuel used shall be determined by two separate measurements in accordance with the respective standards for each fuel type defined in Table 1. The two separate measurements shall be performed by two different labs independent from the manufacturer applying for certification. The lab performing the measurements shall comply with the requirements of ISO/IEC 17025. The approval authority shall ensure that the fuel sample used for determination of the NCV is taken from the batch of fuel used for all testruns.

If the two separate values for the NCV are deviating by more than 440 Joule per gram fuel, the values determined shall be void and the measurement campaign shall be repeated.

[F1The mean value of the two separate NCV that are not deviating by more than 440 Joule per gram fuel shall be documented in MJ/kg rounded to 2 places to the right of the decimal point in accordance with ASTM E 29-06.]

For gas fuels the standards for determining the NCV according to Table 1 contain the calculation of the calorific value based on the fuel composition. The gas fuel composition for determining the NCV shall be taken from the analysis of the reference gas fuel batch used for the certification tests. For the determination of the gas fuel composition used for determining the NCV only one single analysis by a lab independent from the manufacturer applying for certification shall be performed. For gas fuels the NCV shall be determined based on this single analysis instead of a mean value of two separate measurements.

[F2For gas fuels, switches between fuel tanks of different production batches are allowed exceptionally; in that case, the NCV of each used fuel batch should be calculated and the highest value should be documented.]

Table 1

Reference fuels for testing

| Fuel type / engine type | Reference fuel type | Standard used for determination of NCV |

|---|---|---|

| Diesel / CI | B7 | at least ASTM D240 or DIN 59100-1 (ASTM D4809 is recommended) |

| Ethanol / CI | ED95 | at least ASTM D240 or DIN 59100-1 (ASTM D4809 is recommended) |

| Petrol / PI | E10 | at least ASTM D240 or DIN 59100-1 (ASTM D4809 is recommended) |

| Ethanol / PI | E85 | at least ASTM D240 or DIN 59100-1 (ASTM D4809 is recommended) |

| LPG / PI | LPG Fuel B | ASTM 3588 or DIN 51612 |

| [F1Natural gas / PI | G 25 or G R | ISO 6976 or ASTM 3588] |

3.3LubricantsU.K.

The lubricating oil for all testruns performed in accordance with this Annex shall be a commercially available oil with unrestricted manufacturer approval under normal in-service conditions as defined in paragraph 4.2 of Annex 8 to UN/ECE Regulation 49 Rev.06. Lubricants for which the usage is restricted to certain special operation conditions of the engine system or having an unusually short oil change interval shall not be used for the purpose of testruns in accordance with this Annex. The commercially available oil shall not be modified by any means and no additives shall be added.

All testruns performed for the purpose of certification of the CO2 emissions and fuel consumption related properties of one specific engine CO2-family shall be performed with the same type of lubricating oil.

3.4Fuel flow measurement systemU.K.

All fuel flows consumed by the whole engine system shall be captured by the fuel flow measurement system. Additional fuel flows not directly supplied to the combustion process in the engine cylinders shall be included in the fuel flow signal for all testruns performed. Additional fuel injectors (e.g. cold start devices) not necessary for the operation of the engine system shall be disconnected from the fuel supply line during all testruns performed.

3.5Measurement equipment specificationsU.K.

The measurement equipment shall meet the requirements of paragraph 9 of Annex 4 to UN/ECE Regulation 49 Rev.06.

Notwithstanding the requirements defined in paragraph 9 of Annex 4 to UN/ECE Regulation 49 Rev.06, the measurement systems listed in Table 2 shall meet the limits defined in Table 2.

Table 2

Requirements of measurement systems

| a ‘Accuracy’ means the deviation of the analyzer reading from a reference value which is traceable to a national or international standard. | ||||||

| b ‘Rise time’ means the difference in time between the 10 percent and 90 percent response of the final analyzer reading (t90 – t10). | ||||||

| c The ‘max calibration’ values shall be 1,1 times the maximum predicted value expected during all testruns for the respective measurement system. | ||||||

| Linearity | ||||||

|---|---|---|---|---|---|---|

| Measurement system | Intercept| xmin × (a1 – 1) + a0 | | Slopea1 | Standard error of estimate SEE | Coefficient of determinationr2 | Accuracya | Rise timeb |

| Engine speed | ≤ 0,2 % max calibrationc | 0,999 - 1,001 | ≤ 0,1 % max calibrationc | ≥ 0,9985 | 0,2 % of reading or 0,1 % of max. calibrationc of speed whichever is larger | ≤ 1 s |

| Engine torque | ≤ 0,5 % max calibrationc | 0,995 - 1,005 | ≤ 0,5 % max calibrationc | ≥ 0,995 | 0,6 % of reading or 0,3 % of max. calibrationc of torque whichever is larger | ≤ 1 s |

| Fuel mass flow for liquid fuels | ≤ 0,5 % max calibrationc | 0,995 - 1,005 | ≤ 0,5 % max calibrationc | ≥ 0,995 | 0,6 % of reading or 0,3 % of max. calibrationc of flow whichever is larger | ≤ 2 s |

| Fuel mass flow for gaseous fuels | ≤ 1 % max calibrationc | 0,99 - 1,01 | ≤ 1 % max calibrationc | ≥ 0,995 | 1 % of reading or 0,5 % of max. calibrationc of flow whichever is larger | ≤ 2 s |

| Electrical Power | ≤ 1 % max calibrationc | 0,98 - 1,02 | ≤ 2 % max calibrationc | ≥ 0,990 | n.a. | ≤ 1 s |

| Current | ≤ 1 % max calibrationc | 0,98 - 1,02 | ≤ 2 % max calibrationc | ≥ 0,990 | n.a. | ≤ 1 s |

| Voltage | ≤ 1 % max calibrationc | 0,98 - 1,02 | ≤ 2 % max calibrationc | ≥ 0,990 | n.a. | ≤ 1 s |

‘xmin’, used for calculation of the intercept value in Table 2, shall be 0,9 times the minimum predicted value expected during all testruns for the respective measurement system.

The signal delivery rate of the measurement systems listed in Table 2, except for the fuel mass flow measurement system, shall be at least 5 Hz (≥ 10 Hz recommended). The signal delivery rate of the fuel mass flow measurement system shall be at least 2 Hz.

All measurement data shall be recorded with a sample rate of at least 5 Hz (≥ 10 Hz recommended).

3.5.1Measurement equipment verificationU.K.

A verification of the demanded requirements defined in Table 2 shall be performed for each measurement system. At least 10 reference values between xmin and the ‘max calibration’ value defined in accordance with paragraph 3.5 shall be introduced to the measurement system and the response of the measurement system shall be recorded as measured value.

For the linearity verification the measured values shall be compared to the reference values by using a least squares linear regression in accordance with paragraph A.3.2 of Appendix 3 to Annex 4 to UN/ECE Regulation 49 Rev.06.

4.Testing procedureU.K.

All measurement data shall be determined in accordance with Annex 4 to UN/ECE Regulation 49 Rev.06, unless stated otherwise in this Annex.

4.1Overview of testruns to be performedU.K.

Table 3 gives an overview of all testruns to be performed for the purpose of certification of one specific engine CO2-family defined in accordance with Appendix 3.

The fuel consumption mapping cycle in accordance with paragraph 4.3.5 and the recording of the engine motoring curve in accordance with paragraph 4.3.2 shall be omitted for all other engines except the CO2-parent engine of the engine CO2-family.

In the case that upon request of the manufacturer the provisions defined in Article 15(5) of this Regulation are applied, the fuel consumption mapping cycle in accordance with paragraph 4.3.5 and the recording of the engine motoring curve in accordance with paragraph 4.3.2 shall be performed additionally for that specific engine.

Table 3

Overview of testruns to be performed

| Testrun | Reference to paragraph | Required to be run for CO2-parent engine | Required to be run for other engines within CO2-family |

|---|---|---|---|

| Engine full load curve | 4.3.1 | yes | yes |

| Engine motoring curve | 4.3.2 | yes | no |

| WHTC test | 4.3.3 | yes | yes |

| WHSC test | 4.3.4 | yes | yes |

| Fuel consumption mapping cycle | 4.3.5 | yes | no |

4.2Allowed changes to the engine systemU.K.

Changing of the target value for the engine idle speed controller to a lower value in the electronic control unit of the engine shall be allowed for all testruns in which idle operation occurs, in order to prevent interference between the engine idle speed controller and the test bed speed controller.

4.3TestrunsU.K.

4.3.1Engine full load curveU.K.

The engine full load curve shall be recorded in accordance with paragraphs 7.4.1. to 7.4.5. of Annex 4 to UN/ECE Regulation 49 Rev.06.

4.3.2Engine motoring curveU.K.

The recording of the engine motoring curve in accordance with this paragraph shall be omitted for all other engines except the CO2-parent engine of the engine CO2-family defined in accordance with Appendix 3. In accordance with paragraph 6.1.3 the engine motoring curve recorded for the CO2-parent engine of the engine CO2-family shall also be applicable to all engines within the same engine CO2-family.

In the case that upon request of the manufacturer the provisions defined in Article 15(5) of this Regulation are applied, the recording of the engine motoring curve shall be performed additionally for that specific engine.

The engine motoring curve shall be recorded in accordance with option (b) in paragraph 7.4.7. of Annex 4 to UN/ECE Regulation 49 Rev.06. This test shall determine the negative torque required to motor the engine between maximum and minimum mapping speed with minimum operator demand.

The test shall be continued directly after the full load curve mapping according to paragraph 4.3.1. At the request of the manufacturer, the motoring curve may be recorded separately. In this case the engine oil temperature at the end of the full load curve testrun performed in accordance with paragraph 4.3.1 shall be recorded and the manufacturer shall prove to the satisfaction of the an approval authority, that the engine oil temperature at the starting point of the motoring curve meets the aforementioned temperature within ± 2 K.

At the start of the testrun for the engine motoring curve the engine shall be operated with minimum operator demand at maximum mapping speed defined in paragraph 7.4.3. of Annex 4 to UN/ECE Regulation 49 Rev.06. As soon as the motoring torque value has stabilized within ± 5 % of its mean value for at least 10 seconds, the data recording shall start and the engine speed shall be decreased at an average rate of 8 ± 1 min– 1/s from maximum to minimum mapping speed, which are defined in paragraph 7.4.3. of Annex 4 to UN/ECE Regulation 49 Rev.06.

4.3.3WHTC testU.K.

The WHTC test shall be performed in accordance with Annex 4 to UN/ECE Regulation 49 Rev.06. The weighted emission test results shall meet the applicable limits defined in Regulation (EC) No 595/2009.

The engine full load curve recorded in accordance with paragraph 4.3.1 shall be used for the denormalization of the reference cycle and all calculations of reference values performed in accordance with paragraphs 7.4.6, 7.4.7 and 7.4.8 of Annex 4 to UN/ECE Regulation 49 Rev.06.

4.3.3.1Measurement signals and data recordingU.K.

In addition to the provisions defined in Annex 4 to UN/ECE Regulation 49 Rev.06 the actual fuel mass flow consumed by the engine in accordance with paragraph 3.4 shall be recorded.

4.3.4WHSC testU.K.

The WHSC test shall be performed in accordance with Annex 4 to UN/ECE Regulation 49 Rev.06. The emission test results shall meet the applicable limits defined in Regulation (EC) No 595/2009.

The engine full load curve recorded in accordance with paragraph 4.3.1 shall be used for the denormalization of the reference cycle and all calculations of reference values performed in accordance with paragraphs 7.4.6, 7.4.7 and 7.4.8 of Annex 4 to UN/ECE Regulation 49 Rev.06.

4.3.4.1Measurement signals and data recordingU.K.

In addition to the provisions defined in Annex 4 to UN/ECE Regulation 49 Rev.06 the actual fuel mass flow consumed by the engine in accordance with paragraph 3.4 shall be recorded.

4.3.5Fuel consumption mapping cycle (FCMC)U.K.

The fuel consumption mapping cycle (FCMC) in accordance with this paragraph shall be omitted for all other engines except the CO2-parent engine of the engine CO2-family. The fuel map data recorded for the CO2-parent engine of the engine CO2-family shall also be applicable to all engines within the same engine CO2-family.

In the case that upon request of the manufacturer the provisions defined in Article 15(5) of this Regulation are applied, the fuel consumption mapping cycle shall be performed additionally for that specific engine.

The engine fuel map shall be measured in a series of steady state engine operation points, as defined according to paragraph 4.3.5.2. The metrics of this map are the fuel consumption in g/h depending on engine speed in min-1 and engine torque in Nm.

4.3.5.1Handling of interruptions during the FCMCU.K.

If an after-treatment regeneration event occurs during the FCMC for engines equipped with exhaust after-treatment systems that are regenerated on a periodic basis defined in accordance with paragraph 6.6 of Annex 4 to UN/ECE Regulation 49 Rev.06, all measurements at that engine speed mode shall be void. The regeneration event shall be completed and afterwards the procedure shall be continued as described in paragraph 4.3.5.1.1.

If an unexpected interruption, malfunction or error occurs during the FCMC, all measurements at that engine speed mode shall be void and one of the following options how to continue shall be chosen by the manufacturer:

the procedure shall be continued as described in paragraph 4.3.5.1.1

the whole FCMC shall be repeated in accordance with paragraphs 4.3.5.4 and 4.3.5.5

4.3.5.1.1Provisions for continuing the FCMCU.K.

The engine shall be started and warmed up in accordance with paragraph 7.4.1. of Annex 4 to UN/ECE Regulation 49 Rev.06. After warm-up, the engine shall be preconditioned by operating the engine for 20 minutes at mode 9, as defined in Table 1 of paragraph 7.2.2. of Annex 4 to UN/ECE Regulation 49 Rev.06.

The engine full load curve recorded in accordance with paragraph 4.3.1 shall be used for the denormalization of the reference values of mode 9 performed in accordance with paragraphs 7.4.6, 7.4.7 and 7.4.8 of Annex 4 to UN/ECE Regulation 49 Rev.06.

Directly after completion of preconditioning, the target values for engine speed and torque shall be changed linearly within 20 to 46 seconds to the highest target torque setpoint at the next higher target engine speed setpoint than the particular target engine speed setpoint where the interruption of the FCMC occurred. If the target setpoint is reached within less than 46 seconds, the remaining time up to 46 seconds shall be used for stabilization.

For stabilization the engine operation shall continue from that point in accordance with the test sequence specified in paragraph 4.3.5.5 without recording of measurement values.

When the highest target torque setpoint at the particular target engine speed setpoint where the interruption occurred is reached, the recording of measurement values shall be continued from that point on in accordance with the test sequence specified in paragraph 4.3.5.5.

4.3.5.2Grid of target setpointsU.K.

The grid of target setpoints is fixed in a normalized way and consists of 10 target engine speed setpoints and 11 target torque setpoints. Conversion of the normalized setpoint definition to the actual target values of engine speed and torque setpoints for the individual engine under test shall be based on the engine full load curve of the CO2-parent engine of the engine CO2-family defined in accordance with Appendix 3 to this Annex and recorded in accordance with paragraph 4.3.1.

4.3.5.2.1Definition of target engine speed setpointsU.K.

The 10 target engine speed setpoints are defined by 4 base target engine speed setpoints and 6 additional target engine speed setpoints.

The engine speeds nidle, nlo, npref, n95h and nhi shall be determined from the engine full load curve of the CO2-parent engine of the engine CO2-family defined in accordance with Appendix 3 to this Annex and recorded in accordance with paragraph 4.3.1 by applying the definitions of characteristic engine speeds in accordance with paragraph 7.4.6. of Annex 4 to UN/ECE Regulation 49 Rev.06.

The engine speed n57 shall be determined by the following equation:

n57 = 0,565 × (0,45 × nlo + 0,45 × npref + 0,1 × nhi – nidle) × 2,0327 + nidle

The 4 base target engine speed setpoints are defined as follows:

Base engine speed 1: nidle

Base engine speed 2: nA = n57 – 0,05 × (n95h – nidle)

Base engine speed 3: nB = n57 + 0,08 × (n95h – nidle)

Base engine speed 4: n95h

The potential distances between the speed setpoints shall be determined by the following equations:

dnidleA_44 = (nA – nidle) / 4

dnB95h_44 = (n95h – nB) / 4

dnidleA_35 = (nA – nidle) / 3

dnB95h_35 = (n95h – nB) / 5

dnidleA_53 = (nA – nidle) / 5

dnB95h_53 = (n95h – nB) / 3

The absolute values of potential deviations between the two sections shall be determined by the following equations:

dn44 = ABS(dnidleA_44 – dnB95h_44)

dn35 = ABS(dnidleA_35 – dnB95h_35)

dn53 = ABS(dnidleA_53 – dnB95h_53)

[F1The 6 additional target engine speed setpoints shall be determined in accordance with the following provisions:

If dn 44 is smaller than or equal to (dn 35 + 5) and also smaller than or equal to (dn 53 + 5), the 6 additional target engine speeds shall be determined by dividing each of the two ranges, one from n idle to n A and the other from n B to n 95h , into 4 equidistant sections.

If (dn 35 + 5) is smaller than dn 44 and also dn 35 is smaller than dn 53 , the 6 additional target engine speeds shall be determined by dividing the range from n idle to n A into 3 equidistant sections and the range from n B to n 95h , into 5 equidistant sections.

If (dn 53 + 5) is smaller than dn 44 and also dn 53 is smaller than dn 35 , the 6 additional target engine speeds shall be determined by dividing the range from n idle to n A into 5 equidistant sections and the range from n B to n 95h , into 3 equidistant sections.]

Figure 1 exemplarily illustrates the definition of the target engine speed setpoints according to subpoint (1) above.

4.3.5.2.2Definition of target torque setpointsU.K.

The 11 target torque setpoints are defined by 2 base target torque setpoints and 9 additional target torque setpoints. The 2 base target torque setpoints are defined by zero engine torque and the maximum engine full load of the CO2-parent engine determined in accordance with paragraph 4.3.1. (overall maximum torque Tmax_overall). The 9 additional target torque setpoints are determined by dividing the range from zero torque to overall maximum torque, Tmax_overall, into 10 equidistant sections.

[F1All target torque setpoints at a particular target engine speed setpoint that exceed the limit value defined by the full load torque value at this particular target engine speed setpoint minus 5 percent of T max_overall , shall be replaced by one single target torque setpoint at full load torque at this particular target engine speed setpoint. Each of these replacement setpoints shall be measured only once during the FCMC test sequence defined in accordance with paragraph 4.3.5.5. Figure 2 exemplarily illustrates the definition of the target torque setpoints.]

4.3.5.3Measurement signals and data recordingU.K.

The following measurement data shall be recorded:

engine speed

engine torque corrected in accordance with paragraph 3.1.2

fuel mass flow consumed by the whole engine system in accordance with paragraph 3.4

Gaseous pollutants according to the definitions in UN/ECE Regulation 49 Rev.06. Particulate pollutants and ammonia emissions are not required to be monitored during the FCMC testrun.

The measurement of gaseous pollutants shall be carried out in accordance with paragraphs 7.5.1, 7.5.2, 7.5.3, 7.5.5, 7.7.4, 7.8.1, 7.8.2, 7.8.4 and 7.8.5 of Annex 4 to UN/ECE Regulation 49 Rev.06.

For the purpose of paragraph 7.8.4 of Annex 4 to UN/ECE Regulation 49 Rev.06, the term ‘test cycle’ in the paragraph referred to shall be the complete sequence from preconditioning in accordance with paragraph 4.3.5.4 to ending of the test sequence in accordance with paragraph 4.3.5.5.

4.3.5.4Preconditioning of the engine systemU.K.

The dilution system, if applicable, and the engine shall be started and warmed up in accordance with paragraph 7.4.1. of Annex 4 to UN/ECE Regulation 49 Rev.06.

After warm-up is completed, the engine and sampling system shall be preconditioned by operating the engine for 20 minutes at mode 9, as defined in Table 1 of paragraph 7.2.2. of Annex 4 to UN/ECE Regulation 49 Rev.06, while simultaneously operating the dilution system.

The engine full load curve of the CO2-parent engine of the engine CO2-family and recorded in accordance with paragraph 4.3.1 shall be used for the denormalization of the reference values of mode 9 performed in accordance with paragraphs 7.4.6, 7.4.7 and 7.4.8 of Annex 4 to UN/ECE Regulation 49 Rev.06.

Directly after completion of preconditioning, the target values for engine speed and torque shall be changed linearly within 20 to 46 seconds to match the first target setpoint of the test sequence according to paragraph 4.3.5.5. If the first target setpoint is reached within less than 46 seconds, the remaining time up to 46 seconds shall be used for stabilization.

4.3.5.5Test sequenceU.K.

The test sequence consists of steady state target setpoints with defined engine speed and torque at each target setpoint in accordance with paragraph 4.3.5.2 and defined ramps to move from one target setpoint to the next.

The highest target torque setpoint at each target engine speed shall be operated with maximum operator demand.

The first target setpoint is defined at the highest target engine speed setpoint and highest target torque setpoint.

The following steps shall be performed to cover all target setpoints:

The engine shall be operated for 95 ± 3 seconds at each target setpoint. The first 55 ± 1 seconds at each target setpoint are considered as a stabilization period,. During the following period of 30 ± 1 seconds the engine speed mean value shall be controlled as follows:

The engine speed mean value shall be held at the target engine speed setpoint within ± 1 percent of the highest target engine speed.

Except for the points at full load, the engine torque mean value shall be held at the target torque setpoint within a tolerance of ± 20 Nm or ± 2 percent of the overall maximum torque, Tmax_overall, whichever is greater.

The recorded values in accordance with paragraph 4.3.5.3 shall be stored as averaged value over the period of 30 ± 1 seconds. The remaining period of 10 ± 1 seconds may be used for data post-processing and storage if necessary. During this period the engine target setpoint shall be kept.

After the measurement at one target setpoint is completed, the target value for engine speed shall be kept constant within ± 20 min– 1 of the target engine speed setpoint and the target value for torque shall be decreased linearly within 20±1 seconds to match the next lower target torque setpoint. Then the measurement shall be performed according to subpoint (1).

After the zero torque setpoint has been measured in subpoint (1), the target engine speed shall be decreased linearly to the next lower target engine speed setpoint while at the same time the target torque shall be increased linearly to the highest target torque setpoint at the next lower target engine speed setpoint within 20 to 46 seconds. If the next target setpoint is reached within less than 46 seconds, the remaining time up to 46 seconds shall be used for stabilization. Then the measurement shall be performed by starting the the stabilization procedure according to subpoint (1) and afterwards the target torque setpoints at constant target engine speed shall be adjusted according to subpoint (2).

Figure 3 illustrates the three different steps to be performed at each measurement setpoint for the test according to subpoint (1) above.

Figure 4 exemplarily illustrates the sequence of steady state measurement setpoints to be followed for the test.

4.3.5.6Data evaluation for emission monitoringU.K.

Gaseous pollutants in accordance with paragraph 4.3.5.3 shall be monitored during the FCMC. The definitions of characteristic engine speeds in accordance with paragraph 7.4.6. of Annex 4 to UN/ECE R.49.06 shall apply.

4.3.5.6.1Definition of control areaU.K.

The control area for emission monitoring during the FCMC shall be determined in accordance with paragraphs 4.3.5.6.1.1 and 4.3.5.6.1.2.

4.3.5.6.1.1Engine speed range for the control areaU.K.

The engine speed range for the control area shall be defined based on the engine full load curve of the CO2-parent engine of the engine CO2-family defined in accordance with Appendix 3 to this Annex and recorded in accordance with paragraph 4.3.1.

The control area shall include all engine speeds greater than or equal to the 30th percentile cumulative speed distribution, determined from all engine speeds including idle speed sorted in ascending order, over the hotstart WHTC test cycle performed in accordance with paragraph 4.3.3 (n30) for the engine full load curve referred to the subpoint (1).

The control area shall include all engine speeds lower than or equal to nhi determined from the engine full load curve referred to in the subpoint (1)

4.3.5.6.1.2Engine torque and power range for the control areaU.K.

The lower boundary of the engine torque range for the control area shall be defined based on the engine full load curve of the engine with the lowest rating of all engines within the engine CO2-family and recorded in accordance with paragraph 4.3.1.

The control area shall include all engine load points with a torque value greater than or equal to 30 percent of the maximum torque value determined from the engine full load curve referred to in subpoint (1).

Notwithstanding the provisions of subpoint (2), speed and torque points below 30 percent of the maximum power value, determined from the engine full load curve referred to in subpoint (1), shall be excluded from the control area.

Notwithstanding the provisions of subpoints (2) and (3), the upper boundary of the control area shall be based on the engine full load curve of the CO2-parent engine of the engine CO2-family defined in accordance with Appendix 3 to this Annex and recorded in accordance with paragraph 4.3.1. The torque value for each engine speed determined from the engine full load curve of the CO2-parent engine shall be increased by 5 percent of the overall maximum torque, Tmax_overall, defined in accordance with paragraph 4.3.5.2.2. The modified increased engine full load curve of the CO2-parent engine shall be used as upper boundary of the control area.

Figure 5 exemplarily illustrates the definition of the engine speed, torque and power range for the control area.

4.3.5.6.2Definition of the grid cellsU.K.

The control area defined in accordance with paragraph 4.3.5.6.1 shall be divided into a number of grid cells for emission monitoring during the FCMC.

The grid shall comprise of 9 cells for engines with a rated speed less than 3 000 min– 1 and 12 cells for engines with a rated speed greater than or equal to 3 000 min– 1. The grids shall be defined in accordance with the following provisions:

The outer boundaries of the grids are aligned to the control area defined according to paragraph 4.3.5.6.1.

2 vertical lines spaced at equal distance between engine speeds n30 and 1,1 times n95h for 9 cell grids, or 3 vertical lines spaced at equal distance between engine speeds n30 and 1,1 times n95h for 12 cell grids.

2 lines spaced at equal distance of engine torque (i.e. 1/3) at each vertical line of engine speed defined by subpoints (1) and (2)

All engine speed values in min-1 and all torque values in Newtonmeters defining the boundaries of the grid cells shall be rounded to 2 places to the right of the decimal point in accordance with ASTM E 29-06.

Figure 6 exemplarily illustrates the definition of the grid cells for the control area in the case of 9 cell grid.

4.3.5.6.3Calculation of specific mass emissionsU.K.

The specific mass emissions of the gaseous pollutants shall be determined as average value for each grid cell defined in accordance with paragraph 4.3.5.6.2. The average value for each grid cell shall be determined as arithmetical mean value of the specific mass emissions over all engine speed and torque points measured during the FCMC located within the same grid cell.

The specific mass emissions of the single engine speed and torque measured during the FCMC shall be determined as averaged value over the 30 ± 1 seconds measurement period defined in accordance with subpoint (1) of paragraph 4.3.5.5.