- Latest available (Revised)

- Point in Time (13/06/2002)

- Original (As adopted by EU)

Commission Regulation (EC) No 1360/2002 (repealed)Show full title

Commission Regulation (EC) No 1360/2002 of 13 June 2002 adapting for the seventh time to technical progress Council Regulation (EEC) No 3821/85 on recording equipment in road transport (Text with EEA relevance) (repealed)

You are here:

- Regulations originating from the EU

- 2002 No. 1360

- Annexes only

- Show Geographical Extent(e.g. England, Wales, Scotland and Northern Ireland)

- Show Timeline of Changes

More Resources

Revised version PDFs

- Revised 02/03/20160.44 MB

- Revised 25/08/20022.30 MB

When the UK left the EU, legislation.gov.uk published EU legislation that had been published by the EU up to IP completion day (31 December 2020 11.00 p.m.). On legislation.gov.uk, these items of legislation are kept up-to-date with any amendments made by the UK since then.

This item of legislation originated from the EU

Legislation.gov.uk publishes the UK version. EUR-Lex publishes the EU version. The EU Exit Web Archive holds a snapshot of EUR-Lex’s version from IP completion day (31 December 2020 11.00 p.m.).

Changes over time for: Commission Regulation (EC) No 1360/2002 (repealed) (Annexes only)

Version Superseded: 25/08/2002

Alternative versions:

Status:

Point in time view as at 13/06/2002.

Changes to legislation:

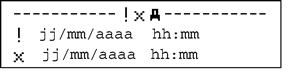

There are currently no known outstanding effects for the Commission Regulation (EC) No 1360/2002 (repealed).![]()

Changes to Legislation

Revised legislation carried on this site may not be fully up to date. At the current time any known changes or effects made by subsequent legislation have been applied to the text of the legislation you are viewing by the editorial team. Please see ‘Frequently Asked Questions’ for details regarding the timescales for which new effects are identified and recorded on this site.

ANNEXU.K.

‘ANNEX I BREQUIREMENTS FOR CONSTRUCTION, TESTING, INSTALLATION AND INSPECTION

I.DEFINITIONS

In this Annex:

:

phase where the recording equipment becomes fully operational and implements all functions, including security functions;

Activating a recording equipment requires the use of a workshop card and the entry of its PIN code;

:

a function intended to establish and verify a claimed identity;

:

the property that an information is coming from a party whose identity can be verified;

:

tests run at request, triggered by the operator or by an external equipment;

:

a day ranging from 00.00 hours to 24.00 hours. All calendar days relate to UTC time (universal time coordinated);

:

updating or confirming vehicle parameters to be held in the data memory. Vehicle parameters include vehicle identification (VIN, VRN and registering Member State) and vehicle characteristics (w, k, l, tyre size, speed limiting device setting (if applicable), current UTC time, current odometer value);

calibrating a recording equipment requires the use of a workshop card;

:

a 16 alpha-numerical characters number that uniquely identifies a tachograph card within a Member State. The card number includes a consecutive index (if applicable), a replacement index and a renewal index;

a card is therefore uniquely identified by the code of the issuing Member State and the card number;

:

the 14th alpha-numerical character of a card number that is used to differentiate the different cards issued to a company or a body entitled to be issued several tachograph cards. The company or the body is uniquely identified by the 13 first characters of the card number;

:

the 16th alpha-numerical character of a card number which is incremented each time a tachograph card is renewed;

:

the 15th alpha-numerical character of a card number which is incremented each time a tachograph card is replaced;

:

the numerical characteristic giving the value of the output signal emitted by the part of the vehicle linking it with the recording equipment (gearbox output shaft or axle) while the vehicle travels a distance of one kilometre under standard test conditions (see Chapter VI(5)). The characteristic coefficient is expressed in impulses per kilometre (w = … imp/km);

:

a tachograph card issued by the authorities of a Member State to the owner or holder of vehicles fitted with recording equipment;

the company card identifies the company and allows for displaying, downloading and printing of the data stored in the recording equipment which has been locked by this company;

:

the numerical characteristic giving the value of the input signal required to show and record a distance travelled of one kilometre; this constant shall be expressed in impulses per kilometre (k = … imp/km);

:

the continuous driving time is computed as the current accumulated driving times of a particular driver, since the end of his last AVAILABILITY or BREAK/REST or UNKNOWN(2)

:

a tachograph card issued by the authorities of a Member State to a national competent control authority;

the control card identifies the control body and possibly the control officer and allows for getting access to the data stored in the data memory or in the driver cards for reading, printing and/or downloading;

:

the cumulative break from driving time is computed as the current accumulated AVAILABILITY or BREAK/REST or UNKNOWN(2) times of 15 minutes or more of a particular driver, since the end of his last AVAILABILITY or BREAK/REST or UNKNOWN(2) period of 45 minutes or more (this period may have been split in several periods of 15 minutes or more).

The computations involved take into account, as needed, past activities stored on the driver card. Unknown periods of negative duration (start of unknown period > end of unknown period) due to time overlaps between two different recording equipments, are not taken into account for the computation.

When the driver has not inserted his card, the computations involved are based on the data memory recordings related to the current period where no card was inserted and related to the relevant slot;

:

an electronic data storage device built into the recording equipment;

:

data appended to, or a cryptographic transformation of, a block of data that allows the recipient of the block of data to prove the authenticity and integrity of the block of data;

:

copying together with digital signature of a part or of a complete set of data stored in the data memory of the vehicle or in the memory of a tachograph card;

downloading may not alter or delete any stored data;

:

a tachograph card issued by the authorities of a Member State to a particular driver;

the driver card identifies the driver and allows for storage of driver activity data;

:

the average of the distances travelled by each of the wheels moving the vehicle (driving wheels) in the course of one complete rotation. The measurement of these distances shall be made under standard test conditions (Chapter VI(5)) and is expressed in the form “l = … mm“. Vehicle manufacturers may replace the measurement of these distances by a theoretical calculation which takes into account the distribution of the weight on the axles, vehicle unladen in normal running order(3). The methods for such theoretical calculation will be approved by a competent Member State authority;

:

abnormal operation detected by the recording equipment which may come from a fraud attempt;

:

abnormal operation detected by the recording equipment which may come from an equipment malfunction or failure;

:

mounting of the recording equipment in a vehicle;

:

part of the recording equipment, providing a signal representative of vehicle speed and/or distance travelled;

:

a card detected as faulty, or which initial authentication failed, or which start of validity date is not yet reached, or which expiry date has passed;

:

when the use of the recording equipment is not required, according to the provisions of Council Regulation (EEC) No 3820/85;

:

exceeding the authorised speed of the vehicle, defined as any period of more than 60 seconds during which the vehicle's measured speed exceeds the limit for setting the speed limitation device laid down in Council Directive 92/6/EEC of 10 February 1992 on the installation and use of speed limitation devices for certain categories of motor vehicles in the Community(4);

:

set of operations performed to control that the recording equipment works properly and that its settings correspond to the vehicle parameters;

:

component of the recording equipment which provides printouts of stored data;

:

the total equipment intended for installation in road vehicles to show, record and store automatically or semi-automatically details of the movement of such vehicles and of certain work periods of their drivers;

:

issue of a new tachograph card when an existing card reaches its expiry date, or is malfunctioning and has been returned to the issuing authority. Renewal always implies the certainty that two valid cards do not co-exist;

:

any repair of a motion sensor or of a vehicle unit that requires disconnection of its power supply, or disconnection from other recording equipment components, or opening of it;

:

issue of a tachograph card in replacement of an existing card, which has been declared lost, stolen or malfunctioning and has not been returned to the issuing authority. Replacement always implies a risk that two valid cards may co-exist;

:

process to certify, by an ITSEC(5) certification body, that the recording equipment (or component) or the tachograph card under investigation fulfils the security requirements defined in Appendix 10 Generic security targets;

:

tests run cyclically and automatically by the recording equipment to detect faults;

:

smart card intended for use with the recording equipment. Tachograph cards allow for identification by the recording equipment of the identity (or identity group) of the cardholder and allow for data transfer and storage. A tachograph card may be of the following types:

driver card,

control card,

workshop card,

company card;

:

process to certify, by a Member State, that the recording equipment (or component) or the tachograph card under investigation fulfils the requirements of this regulation;

:

the designation of the dimensions of the tyres (external driving wheels) in accordance with Directive 92/23/EEC of 31 march 1992(6);

:

numbers identifying the vehicle: vehicle registration number (VRN) with indication of the registering Member State and vehicle identification number (VIN)(7);

:

the recording equipment excluding the motion sensor and the cables connecting the motion sensor. The vehicle unit may either be a single unit or be several units distributed in the vehicle, as long as it complies with the security requirements of this regulation;

:

the period between 00.00 hours UTC on Monday and 24.00 UTC on Sunday;

:

a tachograph card issued by the authorities of a Member State to a recording equipment manufacturer, a fitter, a vehicle manufacturer or workshop, approved by that Member State.

The workshop card identifies the cardholder and allows for testing, calibration and/or downloading of the recording equipment;

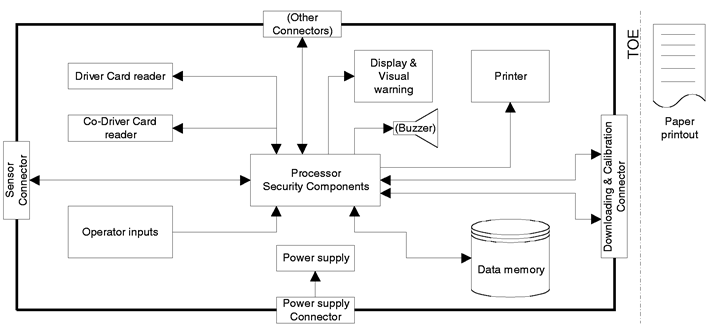

II.GENERAL CHARACTERISTICS AND FUNCTIONS OF THE RECORDING EQUIPMENT

[000] Any vehicle fitted with the recording equipment complying with the provisions of this Annex, must include a speed display and an odometer. These functions may be included within the recording equipment.

1.General characteristics

The purpose of the recording equipment is to record, store, display, print, and output data related to driver activities.

[001] The recording equipment includes cables, a motion sensor, and a vehicle unit.

[002] The vehicle unit includes a processing unit, a data memory, a real time clock, two smart card interface devices (driver and co-driver), a printer, a display, a visual warning, a calibration/downloading connector, and facilities for entry of user's inputs.

The recording equipment may be connected to other devices through additional connectors.

[003] Any inclusion in or connection to the recording equipment of any function, device, or devices, approved or otherwise, shall not interfere with, or be capable of interfering with, the proper and secure operation of the recording equipment and the provisions of the Regulation.

Recording equipment users identify themselves to the equipment via tachograph cards.

[004] The recording equipment provides selective access rights to data and functions according to user's type and/or identity.

The recording equipment records and stores data in its data memory and in tachograph cards.

This is done in accordance with Directive 95/46/EC of 24 October 1995 on the protection of individuals with regard to the processing of personal data and on the free movement of such data(8).

2.Functions

[005] The recording equipment shall ensure the following functions:

monitoring cards insertions and withdrawals,

speed and distance measurement,

time measurement,

monitoring driver activities,

monitoring driving status,

drivers manual entries:

entry of places where daily work periods begin and/or end,

manual entry of driver activities,

entry of specific conditions,

company locks management,

monitoring control activities,

detection of events and/or faults,

built-in and self tests,

reading from data memory,

recording and storing in data memory,

reading from tachograph cards,

recording and storing in tachograph cards,

displaying,

printing,

warning,

data downloading to external media,

output data to additional external devices,

calibration,

time adjustment.

3.Modes of operation

[006] The recording equipment shall possess four modes of operation:

operational mode,

control mode,

calibration mode,

company mode.

[007] The recording equipment shall switch to the following mode of operation according to the valid tachograph cards inserted into the card interface devices:

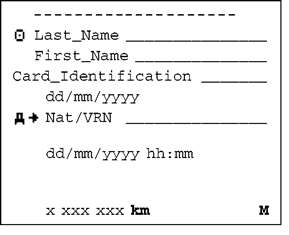

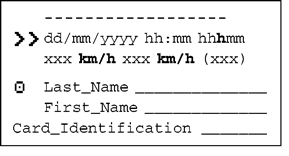

| a [008] In these situations the recording equipment shall use only the tachograph card inserted in the driver slot. | ||||||

| Mode of operation | Driver slot | |||||

|---|---|---|---|---|---|---|

| No card | Driver card | Control card | Workshop card | Company card | ||

| Co-driver slot | No card | Operational | Operational | Control | Calibration | Company |

| Driver card | Operational | Operational | Control | Calibration | Company | |

| Control card | Control | Control | Controla | Operational | Operational | |

| Workshop card | Calibration | Calibration | Operational | Calibrationa | Operational | |

| Company card | Company | Company | Operational | Operational | Companya | |

[009] The recording equipment shall ignore non-valid cards inserted, except displaying, printing or downloading data held on an expired card which shall be possible.

[010] All functions listed in II.2. shall work in any mode of operation with the following exceptions:

the calibration function is accessible in the calibration mode only,

the time adjustment function is limited when not in the calibration mode,

the driver manual entries functions are accessible in operational or calibration modes only,

the company locks management function is accessible in the company mode only,

the monitoring of control activities function is operational in the control mode only,

the downloading function is not accessible in the operational mode (except as provided for in Requirement 150).

[011] The recording equipment can output any data to display, printer or external interfaces with the following exceptions:

in the operational mode, any personal identification (surname and first name(s)) not corresponding to a tachograph card inserted shall be blanked and any card number not corresponding to a tachograph card inserted shall be partially blanked (every odd character — from left to right — shall be blanked),

in the company mode, driver related data (requirements 081, 084 and 087) can be output only for periods not locked by another company (as identified by the first 13 digits of the company card number),

when no card is inserted in the recording equipment, driver related data can be output only for the current and eight previous calendar days.

4.Security

The system security aims at protecting the data memory in such a way as to prevent unauthorised access to and manipulation of the data and detecting any such attempts, protecting the integrity and authenticity of data exchanged between the motion sensor and the vehicle unit, protecting the integrity and authenticity of data exchanged between the recording equipment and the tachograph cards, and verifying the integrity and authenticity of data downloaded.

[012] In order to achieve the system security, the recording equipment shall meet the security requirements specified in the motion sensor and vehicle unit generic security targets (Appendix 10).

III.CONSTRUCTION AND FUNCTIONAL REQUIREMENTS FOR RECORDING EQUIPMENT

1.Monitoring cards insertion and withdrawal

[013] The recording equipment shall monitor the card interface devices to detect card insertions and withdrawals.

[014] Upon card insertion the recording equipment shall detect whether the card inserted is a valid tachograph card and in such a case identify the card type.

[015] The recording equipment shall be so designed that the tachograph cards are locked in position on their proper insertion into the card interface devices.

[016] The release of tachograph cards may function only when the vehicle is stopped and after the relevant data have been stored on the cards. The release of the card shall require positive action by the user.

2.Speed and distance measurement

[017] This function shall continuously measure and be able to provide the odometer value corresponding to the total distance travelled by the vehicle.

[018] This function shall continuously measure and be able to provide the speed of the vehicle.

[019] The speed measurement function shall also provide the information whether the vehicle is moving or stopped. The vehicle shall be considered as moving as soon as the function detects more than 1 imp/sec for at least five seconds from the motion sensor, otherwise the vehicle shall be considered as stopped.

Devices displaying speed (speedometer) and total distance travelled (odometer) installed in any vehicle fitted with a recording equipment complying with the provisions of this Regulation, shall comply with the requirements relating to maximum tolerances laid down in this Annex (Chapters III(2)(1) and III(2)(2)).

2.1.Measurement of distance travelled

[020] The distance travelled may be measured either:

so as to cumulate both forward and reverse movements, or

so as to include only forward movement.

[021] The recording equipment shall measure distance from 0 to 9 999 999,9 km.

[022] Distance measured shall be within the following tolerances (distances of at least 1 000 m):

± 1 % before installation,

± 2 % on installation and periodic inspection,

± 4 % in use.

[023] Distance measured shall have a resolution better than or equal to 0,1 km.

2.2.Measurement of speed

[024] The recording equipment shall measure speed from 0 to 220 km/h.

[025] To ensure a maximum tolerance on speed displayed of ± 6 km/h in use, and taking into account:

a ± 2 km/h tolerance for input variations (tyre variations, …),

a ± 1 km/h tolerance in measurements made during installation or periodic inspections,

the recording equipment shall, for speeds between 20 and 180 km/h, and for characteristic coefficients of the vehicle between 4 000 and 25 000 imp/km, measure the speed with a tolerance of ± 1 km/h (at constant speed).

Note: The resolution of data storage brings an additional tolerance of ± 0,5 km/h to speed stored by the recording equipment.

[025a] The speed shall be measured correctly within the normal tolerances within 2 seconds of the end of a speed change when the speed has changed at a rate up to 2 m/s2.

[026] Speed measurement shall have a resolution better than or equal to 1 km/h.

3.Time measurement

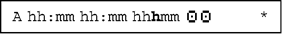

[027] The time measurement function shall measure permanently and digitally provide UTC date and time.

[028] UTC date and time shall be used for dating throughout the recording equipment (recordings, printouts, data exchange, display, …).

[029] In order to visualise the local time, it shall be possible to change the offset of the time displayed, in half hour steps.

[030] Time drift shall be within ± 2 seconds per day in type approval conditions.

[031] Time measured shall have a resolution better than or equal to 1 second.

[032] Time measurement shall not be affected by an external power supply cut-off of less than 12 months in type approval conditions.

4.Monitoring driver activities

[033] This function shall permanently and separately monitor the activities of one driver and one co-driver.

[034] Driver activity shall be DRIVING, WORK, AVAILABILITY, or BREAK/REST.

[035] It shall be possible for the driver and/or the co-driver to manually select WORK, AVAILABILITY, or BREAK/REST.

[036] When the vehicle is moving, DRIVING shall be selected automatically for the driver and AVAILABILITY shall be selected automatically for the co-driver.

[037] When the vehicle stops, WORK shall be selected automatically for the driver.

[038] The first change of activity arising within 120 seconds of the automatic change to WORK due to the vehicle stop shall be assumed to have happened at the time of vehicle stop (therefore possibly cancelling the change to WORK).

[039] This function shall output activity changes to the recording functions at a resolution of one minute.

[040] Given a calendar minute, if any DRIVING activity has occurred within the minute, the whole minute shall be regarded as DRIVING.

[041] Given a calendar minute, if any DRIVING activity has occurred within both the immediately preceding and the immediately succeeding minute, the whole minute shall be regarded as DRIVING.

[042] Given a calendar minute that is not regarded as DRIVING according to previous requirements, the whole minute shall be regarded to be of the same type of activity as the longest continuous activity within the minute (or the latest of the equally longest).

[043] This function shall also permanently monitor the continuous driving time and the cumulative break time of the driver.

5.Monitoring driving status

[044] This function shall permanently and automatically monitor the driving status.

[045] The driving status CREW shall be selected when two valid driver cards are inserted in the equipment, the driving status SINGLE shall be selected in any other case.

6.Drivers manual entries

6.1.Entry of places where daily work periods begin and/or end

[046] This function shall allow for the entry of places where the daily work periods begin and/or end for a driver and/or a co-driver.

[047] Places are defined as the country and, in addition where applicable, the region.

[048] At the time of a driver (or workshop) card withdrawal, the recording equipment shall prompt the (co-)driver to enter a “place where the daily work period ends“.

[049] The recording equipment shall allow this request to be disregarded.

[050] It shall be possible to input places where daily work periods begin and/or end without card or at times other than card insertion or withdrawal.

6.2.Manual entry of driver activities

[050a] Upon driver (or workshop) card insertion, and only at this time, the recording equipment shall:

remind the cardholder the date and time of his last card withdrawal, and

ask the cardholder to identify if the current insertion of the card represents a continuation of the current daily work period.

The recording equipment shall allow the cardholder to disregard the question without answering, or to answer positively, or to answer negatively:

in the case where the cardholder disregards the question, the recording equipment shall prompt the cardholder for a “place where the daily work period begins“. The recording equipment shall allow this request to be disregarded. If a location is entered, then it shall be recorded, in the data memory and in the tachograph card, and related to the card insertion time,

in the case of a negative or positive answer, the recording equipment shall invite the cardholder to enter activities manually, with their dates and times of beginning and end, among WORK, AVAILABILITY, or BREAK/REST only, strictly included within the period last card withdrawal — current insertion only, and without allowing such activities to overlap mutually. This shall be done in accordance with the following procedures:

in the case where the cardholder answers positively to the question, the recording equipment shall invite the cardholder to enter activities manually, in chronological order, for the period last card withdrawal — current insertion. The process shall end when the end time of a manually entered activity equals the card insertion time.

in the case where the cardholder answers negatively to the question, the recording equipment shall:

invite the card holder to enter manually activities in chronological order from the card withdrawal time up to the time of end of the related daily work period (or of the activities related to that vehicle in the case where the daily work period continues on a record sheet). The recording equipment shall therefore, before allowing the cardholder to enter manually each activity, invite the cardholder to identify if the time of end of the last recorded activity represents the end of a previous work period (see note below),

Notes: in the case where the cardholder fails to declare when the previous work period ended, and manually enters an activity of which end time equals the card insertion time, the recording equipment shall:

assume that the daily work period ended at the start of the first REST (or remaining UNKNOWN) period after card withdrawal or at the time of card withdrawal if no rest period has been entered (and if no period remains UNKNOWN),

assume that the start time (see below) equals the card insertion time,

proceed through the steps below;

then, if the time of end of the related work period is different from the time of card withdrawal, or if no place of end of daily work period had been entered at that time, prompt the cardholder to “confirm or enter the place where the daily work period ended“ (the recording equipment shall allow this request to be disregarded). If a location is entered, it shall be recorded in the tachograph card only and only if different from the one entered at card withdrawal (if one was entered), and related to the time of end of the work period,

then invite the cardholder to “enter a start time“ of the current daily work period (or of the activities related to the current vehicle in the case where the card holder previously used a record sheet during this period), and prompt the cardholder for a “place where the daily work period begins“ (the recording equipment shall allow this request to be disregarded). If a location is entered, it shall be recorded in the tachograph card and related to this start time. If this start time is equal to the card insertion time, the location shall also be recorded in the data memory,

then, if this start time is different from the card insertion time, invite the cardholder to enter manually activities in chronological order from this start time up to the time of card insertion. The process shall end when the end time of a manually entered activity equals the card insertion time,

the recording equipment shall then allow the card holder to modify any activity manually entered, until validation by selection of a specific command, and thereafter forbid any such modification,

such answers to the initial question followed by no activity entries, shall be interpreted by the recording equipment as if the cardholder had disregarded the question.

During this whole process, the recording equipment shall wait for entries no longer than the following time-outs:

if no interaction with the equipment's human machine interface is happening during one minute (with a visual, and possibly audible, warning after 30 seconds) or,

if the card is withdrawn or another driver (or workshop) card is inserted or,

as soon as the vehicle is moving,

in this case the recording equipment shall validate any entries already made.

6.3.Entry of specific conditions

[050b] The recording equipment shall allow the driver to enter, in real time, the following two specific conditions:

“OUT OF SCOPE“ (begin, end)

“FERRY/TRAIN CROSSING“

A “FERRY/TRAIN CROSSING“ may not occur if an “OUT OF SCOPE“ condition is opened.

An opened “OUT OF SCOPE“ condition must be automatically closed, by the recording equipment, if a driver card is inserted or withdrawn.

7.Company locks management

[051] This function shall allow the management of the locks placed by a company to restrict data access in company mode to itself.

[052] Company locks consist in a start date/time (lock-in) and an end date/time (lock-out) associated with the identification of the company as denoted by the company card number (at lock-in).

[053] Locks may be turned “in“ or “out“ in real time only.

[054] Locking-out shall only be possible for the company whose lock is “in“ (as identified by the first 13 digits of the company card number), or,

[055] locking-out shall be automatic if another company locks in.

[055a] In the case where a company locks in and where the previous lock was for the same company, then it will be assumed that the previous lock has not been turned “out“ and is still “in“.

8.Monitoring control activities

[056] This function shall monitor DISPLAYING, PRINTING, VU and card DOWNLOADING activities carried while in control mode.

[057] This function shall also monitor OVER SPEEDING CONTROL activities while in control mode. An over speeding control is deemed to have happened when, in control mode, the “over speeding“ printout has been sent to the printer or to the display, or when “events and faults“ data have been downloaded from the VU data memory.

9.Detection of events and/or faults

[058] This function shall detect the following events and/or faults:

9.1.Insertion of a non-valid card““ event

[059] This event shall be triggered at the insertion of any non-valid card and/or when an inserted valid card expires.

[060] This event shall be triggered when any of the valid cards combination noted X in the following table arise:

9.2.

“Card conflict“ event

| Card conflict | Driver slot | |||||

|---|---|---|---|---|---|---|

| No card | Driver card | Control card | Workshop card | Company card | ||

| Co-driver slot | No card | |||||

| Driver card | X | |||||

| Control card | X | X | X | |||

| Workshop card | X | X | X | X | ||

| Company card | X | X | X | |||

9.3.“Time overlap“ event

[061] This event shall be triggered when the date/time of last withdrawal of a driver card, as read from the card, is later than the current date/time of the recording equipment in which the card is inserted.

9.4.“Driving without an appropriate card“ event

[062] This event shall be triggered for any tachograph cards combination noted X in the following table, when driver activity changes to DRIVING, or when there is a change of the mode of operation while driver activity is DRIVING:

| Driving without an appropriate card | Driver slot | |||||

|---|---|---|---|---|---|---|

| No (or non-valid) card | Driver card | Control card | Workshop card | Company card | ||

| Co-driver slot | No (or non-valid) card | X | X | X | ||

| Driver card | X | X | X | X | ||

| Control card | X | X | X | X | X | |

| Workshop card | X | X | X | X | ||

| Company card | X | X | X | X | X | |

9.5.“Card insertion while driving“ event

[063] This event shall be triggered when a tachograph card is inserted in any slot, while driver activity is DRIVING.

9.6.“Last card session not correctly closed“ event

[064] This event shall be triggered when at card insertion the recording equipment detects that, despite the provisions laid down in paragraph III(1), the previous card session has not been correctly closed (the card has been withdrawn before all relevant data have been stored on the card). This event shall be triggered by driver and workshop cards only.

9.7.“Over speeding“ event

[065] This event shall be triggered for each over speeding.

9.8.“Power supply interruption“ event

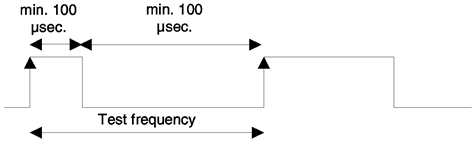

[066] This event shall be triggered, while not in calibration mode, in case of any interruption exceeding 200 milliseconds of the power supply of the motion sensor and/or of the vehicle unit. The interruption threshold shall be defined by the manufacturer. The drop in power supply due to the starting of the engine of the vehicle shall not trigger this event.

9.9.“Motion data error“ event

[067] This event shall be triggered in case of interruption of the normal data flow between the motion sensor and the vehicle unit and/or in case of data integrity or data authentication error during data exchange between the motion sensor and the vehicle unit.

9.10.“Security breach attempt“ event

[068] This event shall be triggered for any other event affecting the security of the motion sensor and/or of the vehicle unit as specified within the generic security targets of these components, while not in calibration mode.

9.11.“Card“ fault

[069] This fault shall be triggered when a tachograph card failure occurs during operation.

9.12.“Recording equipment“ fault

[070] This fault shall be triggered for any of these failures, while not in calibration mode:

VU internal fault,

printer fault,

display fault,

downloading fault,

sensor fault.

10.Built-in and self tests

[071] The recording equipment shall self-detect faults through self tests and built-in-tests, according to the following table:

| Sub-assembly to test | Self test | Built-in-test |

|---|---|---|

| Software | Integrity | |

| Data memory | Access | Access, data integrity |

| Card interface devices | Access | Access |

| Keyboard | Manual check | |

| Printer | (up to manufacturer) | Printout |

| Display | Visual check | |

| Downloading (performed only during downloading) | Proper operation | |

| Sensor | Proper operation | Proper operation |

11.Reading from data memory

[072] The recording equipment shall be able to read any data stored in its data memory.

12.Recording and storing in the data memory

For the purpose of this paragraph,

“365 days“ is defined as 365 calendar days of average drivers activity in a vehicle. The average activity per day in a vehicle is defined as at least six drivers or co-drivers, six card insertion withdrawal cycles, and 256 activity changes. “365 days“ therefore include at least 2 190 (co-)drivers, 2 190 card insertion withdrawal cycles, and 93 440 activity changes,

times are recorded with a resolution of one minute, unless otherwise specified,

odometer values are recorded with a resolution of one kilometre,

speeds are recorded with a resolution of 1 km/h.

[073] Data stored into the data memory shall not be affected by an external power supply cut-off of less than twelve months in type approval conditions.

[074] The recording equipment shall be able to record and store implicitly or explicitly in its data memory the following:

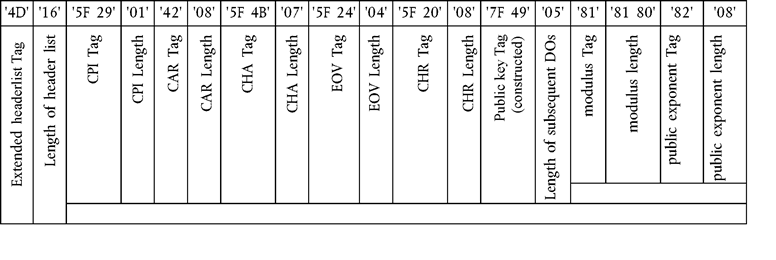

12.1.Equipment identification data

12.1.1.Vehicle unit identification data

[075] The recording equipment shall be able to store in its data memory the following vehicle unit identification data:

name of the manufacturer,

address of the manufacturer,

part number,

serial number,

software version number,

software version installation date,

year of equipment manufacture,

approval number.

[076] Vehicle unit identification data are recorded and stored once and for all by the vehicle unit manufacturer, except the software-related data and the approval number which may be changed in case of software upgrade.

12.1.2.Motion sensor identification data

[077] The motion sensor shall be able to store in its memory the following identification data:

name of the manufacturer,

part number,

serial number,

approval number,

embedded security component identifier (e.g. internal chip/processor part number),

operating system identifier (e.g. software version number).

[078] Motion sensor identification data are recorded and stored once and for all in the motion sensor, by the motion sensor manufacturer.

[079] The vehicle unit shall be able to record and store in its data memory the following currently paired motion sensor identification data:

serial number,

approval number,

first pairing date.

12.2.Security elements

[080] The recording equipment shall be able to store the following security elements:

European public key,

Member State certificate,

equipment certificate,

equipment private key.

Recording equipment security elements are inserted in the equipment by the vehicle unit manufacturer.

12.3.Driver card insertion and withdrawal data

[081] For each insertion and withdrawal cycle of a driver or workshop card in the equipment, the recording equipment shall record and store in its data memory:

the card holder's surname and first name(s) as stored in the card,

the card's number, issuing Member State and expiry date as stored in the card,

the insertion date and time,

the vehicle odometer value at card insertion,

the slot in which the card is inserted,

the withdrawal date and time,

the vehicle odometer value at card withdrawal,

the following information about the previous vehicle used by the driver, as stored in the card:

VRN and registering Member State,

card withdrawal date and time,

a flag indicating whether, at card insertion, the card holder has manually entered activities or not.

[082] The data memory shall be able to hold these data for at least 365 days.

[083] When storage capacity is exhausted, new data shall replace oldest data.

12.4.Driver activity data

[084] The recording equipment shall record and store in its data memory whenever there is a change of activity for the driver and/or the co-driver, and/or whenever there is a change of driving status, and/or whenever there is an insertion or withdrawal of a driver or workshop card:

the driving status (CREW, SINGLE),

the slot (DRIVER, CO-DRIVER),

the card status in the relevant slot (INSERTED, NOT INSERTED) (see Note),

the activity (DRIVING, AVAILABILITY, WORK, BREAK/REST),

the date and time of the change.

Note: INSERTED means that a valid driver or workshop card is inserted in the slot. NOT INSERTED means the opposite, i.e. no valid driver or workshop card is inserted in the slot (e.g. a company card is inserted or no card is inserted).

Note: Activity data manually entered by a driver are not recorded in the data memory.

[085] The data memory shall be able to hold driver activity data for at least 365 days.

[086] When storage capacity is exhausted, new data shall replace oldest data.

12.5.Places where daily work periods start and/or end

[087] The recording equipment shall record and store in its data memory whenever a (co-)driver enters the place where a daily work period begins and/or ends:

if applicable, the (co-)driver card number and card issuing Member State,

the date and time of the entry (or the date/time related to the entry when the entry is made during the manual entry procedure),

the type of entry (begin or end, condition of entry),

the country and region entered,

the vehicle odometer value.

[088] The data memory shall be able to hold daily work periods start and/or end data for at least 365 days (with the assumption that one driver enters two records per day).

[089] When storage capacity is exhausted, new data shall replace oldest data.

12.6.Odometer data

[090] The recording equipment shall record in its data memory the vehicle odometer value and the corresponding date at midnight every calendar day.

[091] The data memory shall be able to store midnight odometer values for at least 365 calendar days.

[092] When storage capacity is exhausted, new data shall replace oldest data.

12.7.Detailed speed data

[093] The recording equipment shall record and store in its data memory the instantaneous speed of the vehicle and the corresponding date and time at every second of at least the last 24 hours that the vehicle has been moving.

12.8.Events data

For the purpose of this subparagraph, time shall be recorded with a resolution of one second.

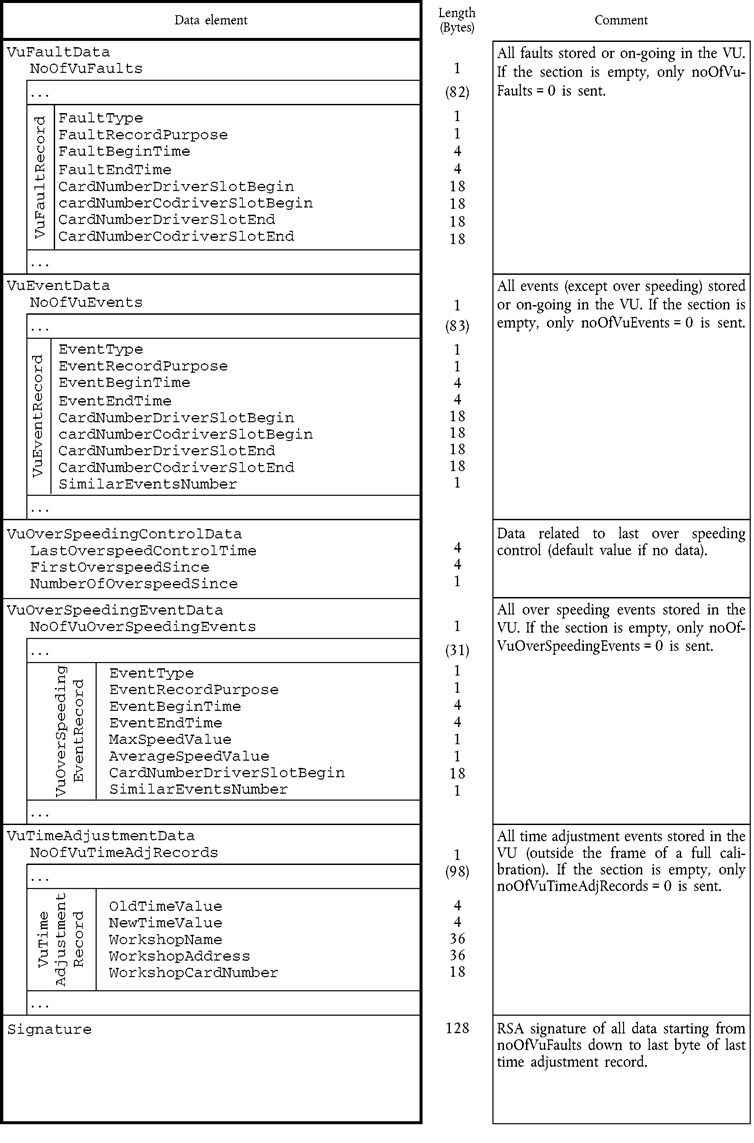

[094] The recording equipment shall record and store in its data memory the following data for each event detected according to the following storage rules:

| a [095] The recording equipment shall also record and store in its data memory:

| ||

| b These data may be recorded at power supply reconnection only, times may be known with an accuracy to the minute. | ||

| Event | Storage rules | Data to be recorded per event |

|---|---|---|

| Card conflict |

|

|

| Driving without an appropriate card |

|

|

| Card insertion while driving |

|

|

| Last card session not correctly closed |

|

|

| Over speedinga |

|

|

| Power supply interruptionb |

|

|

| Motion data error |

|

|

| Security breach attempt |

|

|

12.9.Faults data

For the purpose of this subparagraph, time shall be recorded with a resolution of one second.

[096] The recording equipment shall attempt to record and store in its data memory the following data for each fault detected according to the following storage rules:

| Fault | Storage rules | Data to be recorded per fault |

|---|---|---|

| Card fault |

|

|

| Recording equipment faults |

|

|

12.10.Calibration data

[097] The recording equipment shall record and store in its data memory data relevant to:

known calibration parameters at the moment of activation,

its very first calibration following its activation,

its first calibration in the current vehicle (as identified by its VIN),

the five most recent calibrations (If several calibrations happen within one calendar day, only the last one of the day shall be stored).

[098] The following data shall be recorded for each of these calibrations:

purpose of calibration (activation, first installation, installation, periodic inspection),

workshop name and address,

workshop card number, card issuing Member State and card expiry date,

vehicle identification,

parameters updated or confirmed: w, k, l, tyre size, speed limiting device setting, odometer (old and new values), date and time (old and new values).

[099] The motion sensor shall record and store in its memory the following motion sensor installation data:

first pairing with a VU (date, time, VU approval number, VU serial number),

last pairing with a VU (date, time, VU approval number, VU serial number).

12.11.Time adjustment data

[100] The recording equipment shall record and store in its data memory data relevant to:

the most recent time adjustment,

the five largest time adjustments, since last calibration,

performed in calibration mode outside the frame of a regular calibration (definition (f)).

[101] The following data shall be recorded for each of these time adjustments:

date and time, old value,

date and time, new value,

workshop name and address,

workshop card number, card issuing Member State and card expiry date.

12.12.Control activity data

[102] The recording equipment shall record and store in its data memory the following data relevant to the 20 most recent control activities:

date and time of the control,

control card number and card issuing Member State,

type of the control (displaying and/or printing and/or VU downloading and/or card downloading).

[103] In case of downloading, the dates of the oldest and of the most recent days downloaded shall also be recorded.

12.13.Company locks data

[104] The recording equipment shall record and store in its data memory the following data relevant to the 20 most recent company locks:

lock-in date and time,

lock-out date and time,

company card number and card issuing Member State,

company name and address.

12.14.Download activity data

[105] The recording equipment shall record and store in its data memory the following data relevant to the last data memory downloading to external media while in company or in calibration mode:

date and time of downloading,

company or workshop card number and card issuing Member State,

company or workshop name.

12.15.Specific conditions data

[105a] The recording equipment shall record in its data memory the following data relevant to specific conditions:

date and time of the entry,

type of specific condition.

[105b] The data memory shall be able to hold specific conditions data for at least 365 days (with the assumption that on average, one condition is opened and closed per day). When storage capacity is exhausted, new data shall replace oldest data.

13.Reading from tachograph cards

[106] The recording equipment shall be able to read from tachograph cards, where applicable, the necessary data:

to identify the card type, the card holder, the previously used vehicle, the date and time of the last card withdrawal and the activity selected at that time,

to check that last card session was correctly closed,

to compute the driver's continuous driving time, cumulative break time and cumulated driving times for the previous and the current week,

to print requested printouts related to data recorded on a driver card,

to download a driver card to external media.

[107] In case of a reading error, the recording equipment shall try again, three times maximum, the same read command, and then if still unsuccessful, declare the card faulty and non-valid.

14.Recording and storing on tachograph cards

[108] The recording equipment shall set the “card session data“ in the driver or workshop card right after the card insertion.

[109] The recording equipment shall update data stored on valid driver, workshop and/or control cards with all necessary data relevant to the period while the card is inserted and relevant to the card holder. Data stored on these cards are specified in Chapter IV.

[109a] The recording equipment shall update driver activity and location data (as specified in Chapter IV, paragraphs 5.2.5 and 5.2.6), stored on valid driver and/or workshop cards, with activity and location data manually entered by the cardholder.

[110] Tachograph cards data update shall be such that, when needed and taking into account card actual storage capacity, most recent data replace oldest data.

[111] In the case of a writing error, the recording equipment shall try again, three times maximum, the same write command, and then if still unsuccessful, declare the card faulty and non valid.

[112] Before releasing a driver card, and after all relevant data have been stored on the card, the recording equipment shall reset the card session data.

15.Displaying

[113] The display shall include at least 20 characters.

[114] The minimum character size shall be 5 mm high and 3,5 mm wide.

[114a] The display shall support the Latin 1 and Greek character sets defined by ISO 8859 parts 1 and 7, as specified in Appendix 1 Chapter 4 “Character sets“. The display may use simplified glyphs (e.g. accented characters may be displayed without accent, or lower case letters may be shown as upper case letters).

[115] The display shall be provided with adequate non-dazzling lighting.

[116] Indications shall be visible from outside the recording equipment.

[117] The recording equipment shall be able to display:

default data,

data related to warnings,

data related to menu access,

other data requested by a user.

Additional information may be displayed by the recording equipment, provided that it is clearly distinguishable from information required above.

[118] The display of the recording equipment shall use the pictograms or pictogram combinations listed in Appendix 3. Additional pictograms or pictogram combinations may also be provided by the display, if clearly distinguishable from the aforementioned pictogram or pictogram combinations.

[119] The display shall always be ON when the vehicle is moving.

[120] The recording equipment may include a manual or automatic feature to turn the display OFF when the vehicle is not moving.

Displaying format is specified in Appendix 5.

15.1.Default display

[121] When no other information needs to be displayed, the recording equipment shall display, by default, the following:

the local time (as a result of UTC time + offset as set by the driver),

the mode of operation,

the current activity of the driver and the current activity of the co-driver,

information related to the driver:

if his current activity is DRIVING, his current continuous driving time and his current cumulative break time,

if his current activity is not DRIVING, the current duration of this activity (since it was selected) and his current cumulative break time,

information related to the co-driver:

the current duration of his activity (since it was selected).

[122] Display of data related to each driver shall be clear, plain and unambiguous. In the case where the information related to the driver and the co-driver cannot be displayed at the same time, the recording equipment shall display by default the information related to the driver and shall allow the user to display the information related to the co-driver.

[123] In the case where the display width does not allow to display by default the mode of operation, the recording equipment shall briefly display the new mode of operation when it changes.

[124] The recording equipment shall briefly display the card holder name at card insertion.

[124a] When an “OUT OF SCOPE“ condition is opened, then the default display must show using the relevant pictogram that the condition is opened (It is acceptable that the driver's current activity may not be shown at the same time).

15.2.Warning display

[125] The recording equipment shall display warning information using primarily the pictograms of Appendix 3, completed where needed by an additional numerically coded information. A literal description of the warning may also be added in the driver's preferred language.

15.3.Menu access

[126] The recording equipment shall provide necessary commands through an appropriate menu structure.

15.4.Other displays

[127] It shall be possible to display selectively on request:

the UTC date and time,

the mode of operation (if not provided by default),

the continuous driving time and cumulative break time of the driver,

the continuous driving time and cumulative break time of the co-driver,

the cumulated driving time of the driver for the previous and the current week,

the cumulated driving time of the co-driver for the previous and the current week,

the content of any of the six printouts under the same formats as the printouts themselves.

[128] Printout content display shall be sequential, line by line. If the display width is less than 24 characters the user shall be provided with the complete information through an appropriate mean (several lines, scrolling, …). Printout lines devoted to hand-written information may be omitted for display.

16.Printing

[129] The recording equipment shall be able to print information from its data memory and/or from tachograph cards in accordance with the six following printouts:

driver activities from card daily printout,

driver activities from Vehicle Unit daily printout,

events and faults from card printout,

events and faults from Vehicle Unit printout,

technical data printout,

over speeding printout.

The detailed format and content of these printouts are specified in Appendix 4.

Additional data may be provided at the end of the printouts

Additional printouts may also be provided by the recording equipment, if clearly distinguishable from the six aforementioned printouts.

[130] The “driver activities from card daily printout“ and “events and faults from card printout“ shall be available only when a driver card or a workshop card is inserted in the recording equipment. The recording equipment shall update data stored on the relevant card before starting printing.

[131] In order to produce the “driver activities from card daily printout“ or the “events and faults from card printout“, the recording equipment shall:

either automatically select the driver card or the workshop card if one only of these cards is inserted,

or provide a command to select the source card or select the card in the driver slot if two of these cards are inserted in the recording equipment.

[132] The printer shall be able to print 24 characters per line.

[133] The minimum character size shall be 2,1 mm high and 1,5 mm wide.

[133a] The printer shall support the Latin 1 and Greek character sets defined by ISO 8859 parts 1 and 7, as specified in Appendix 1 Chapter 4 “Character sets“.

[134] Printers shall be so designed as to produce these printouts with a degree of definition likely to avoid any ambiguity when they are read.

[135] Printouts shall retain their dimensions and recordings under normal conditions of humidity (10 to 90 %) and temperature.

[136] The paper for use by the recording equipment shall bear the relevant type approval mark and the indication of the type(s) of recording equipment with which it may be used. Printouts shall remain clearly legible and identifiable under normal conditions of storage, in terms of light intensity, humidity and temperature, for at least one year.

[137] It shall also be possible to add handwritten notes, such as the driver's signature, to these documents.

[138] The recording equipment shall manage “paper out“ events while printing by, once paper has been re-loaded, restarting printing from printout beginning or by continuing printing and providing an unambiguous reference to previously printed part.

17.Warnings

[139] The recording equipment shall warn the driver when detecting any event and/or fault.

[140] Warning of a power supply interruption event may be delayed until the power supply is reconnected.

[141] The recording equipment shall warn the driver 15 minutes before and at the time of exceeding 4 h 30 min. continuous driving time.

[142] Warnings shall be visual. Audible warnings may also be provided in addition to visual warnings.

[143] Visual warnings shall be clearly recognisable by the user, shall be situated in the driver's field of vision and shall be clearly legible both by day and by night.

[144] Visual warnings may be built into the recording equipment and/or remote from the recording equipment.

[145] In the latter case it shall bear a “T“ symbol and shall be amber or orange.

[146] Warnings shall have a duration of at least 30 seconds, unless acknowledged by the user by hitting any key of the recording equipment. This first acknowledgement shall not erase warning cause display referred to in next paragraph.

[147] Warning cause shall be displayed on the recording equipment and remain visible until acknowledged by the user using a specific key or command of the recording equipment.

[148] Additional warnings may be provided, as long as they do not confuse drivers in relation to previously defined ones.

18.Data downloading to external media

[149] The recording equipment shall be able to download on request data from its data memory or from a driver card to external storage media via the calibration/downloading connector. The recording equipment shall update data stored on the relevant card before starting downloading.

[150] In addition and as an optional feature, the recording equipment may, in any mode of operation, download data through another connector to a company authenticated through this channel. In such a case, company mode data access rights shall apply to this download.

[151] Downloading shall not alter or delete any stored data.

The calibration/downloading connector electrical interface is specified in Appendix 6.

Downloading protocols are specified in Appendix 7.

19.Output data to additional external devices

[152] When the recording equipment does not include speed and/or odometer display functions, the recording equipment shall provide output signal(s) to allow for displaying the speed of the vehicle (speedometer) and/or the total distance travelled by the vehicle (odometer).

[153] The vehicle unit shall also be able to output the following data using an appropriate dedicated serial link independent from an optional CAN bus connection (ISO 11898 Road vehicles — Interchange of digital information — Controller Area Network (CAN) for high speed communication), to allow their processing by other electronic units installed in the vehicle:

current UTC date and time,

speed of the vehicle,

total distance travelled by the vehicle (odometer),

currently selected driver and co-driver activity,

information if any tachograph card is currently inserted in the driver slot and in the co-driver slot and (if applicable) information about the corresponding cards identification (card number and issuing Member State).

Other data may also be output in addition to this minimum list.

When the ignition of the vehicle is ON, these data shall be permanently broadcast. When the ignition of the vehicle is OFF, at least any change of driver or co-driver activity and/or any insertion or withdrawal of a tachograph card shall generate a corresponding data output. In the event that data output has been withheld whilst the ignition of the vehicle is OFF, that data shall be made available once the ignition of the vehicle is ON again.

20.Calibration

[154] The calibration function shall allow:

to automatically pair the motion sensor with the VU,

to digitally adapt the constant of the recording equipment (k) to the characteristic coefficient of the vehicle (w) (vehicles with two or more axle ratios shall be fitted with a switch device whereby these various ratios will automatically be brought into line with the ratio for which the equipment has been adapted to the vehicle),

to adjust (without limitation) the current time,

to adjust the current odometer value,

to update motion sensor identification data stored in the data memory,

to update or confirm other parameters known to the recording equipment: vehicle identification, w, l, tyre size and speed limiting device setting if applicable.

[155] Pairing the motion sensor to the VU shall consist, at least, in:

updating motion sensor installation data held by the motion sensor (as needed),

copying from the motion sensor to the VU data memory necessary motion sensor identification data.

[156] The calibration function shall be able to input necessary data through the calibration/downloading connector in accordance with the calibration protocol defined in Appendix 8. The calibration function may also input necessary data through other connectors.

21.Time adjustment

[157] The time adjustment function shall allow for adjusting the current time in amounts of one minute maximum at intervals of not less than seven days.

[158] The time adjustment function shall allow for adjusting the current time without limitation, in calibration mode.

22.Performance characteristics

[159] The Vehicle Unit shall be fully operational in the temperature range − 20 °C to 70 °C, and the motion sensor in the temperature range − 40 °C to 135 °C. Data memory content shall be preserved at temperatures down to − 40 °C.

[160] The recording equipment shall be fully operational in the humidity range 10 % to 90 %.

[161] The recording equipment shall be protected against over-voltage, inversion of its power supply polarity, and short circuits.

[162] The recording equipment shall conform to Commission Directive 95/54/EC of 31 October 1995(9) adapting to technical progress Council Directive 72/245/EEC(10), related to electromagnetic compatibility, and shall be protected against electrostatic discharges and transients.

23.Materials

[163] All the constituent parts of the recording equipment shall be made of materials of sufficient stability and mechanical strength and with stable electrical and magnetic characteristics.

[164] For normal conditions of use, all the internal parts of the equipment shall be protected against damp and dust.

[165] The Vehicle Unit shall meet the protection grade IP 40 and the motion sensor shall meet the protection grade IP 64, as per standard IEC 529.

[166] The recording equipment shall conform to applicable technical specifications related to ergonomic design.

[167] The recording equipment shall be protected against accidental damage.

24.Markings

[168] If the recording equipment displays the vehicle odometer value and speed, the following details shall appear on its display:

near the figure indicating the distance, the unit of measurement of distance, indicated by the abbreviation “km“,

near the figure showing the speed, the entry “km/h“.

The recording equipment may also be switched to display the speed in miles per hour, in which case the unit of measurement of speed shall be shown by the abbreviation “mph“.

[169] A descriptive plaque shall be affixed to each separate component of the recording equipment and shall show the following details:

name and address of the manufacturer of the equipment,

manufacturer's part number and year of manufacture of the equipment,

equipment serial number,

approval mark for the equipment type.

[170] When physical space is not sufficient to show all abovementioned details, the descriptive plaque shall show at least: the manufacturer's name or logo, and the equipment's part number.

IV.CONSTRUCTION AND FUNCTIONAL REQUIREMENTS FOR TACHOGRAPH CARDS

1.Visible data

The front page will contain:

[171] the words “Driver card“ or “Control card“ or “Workshop card“ or “Company card“ printed in large type in the official language or languages of the Member State issuing the card, according to the type of the card;

[172] the same words in the other official languages of the Community, printed to form the background of the card:

ES TARJETA DEL CONDUCTOR

TARJETA DE CONTROL

TARJETA DEL CENTRO DE ENSAYO

TARJETA DE LA EMPRESA

DK FØRERKORT

KONTROLKORT

VÆRKSTEDSKORT

VIRKSOMHEDSKORT

DE FAHRERKARTE

KONTROLLKARTE

WERKSTATTKARTE

UNTERNEHMENSKARTE EL ΚΑΡΤΑ ΟΔΗΟΥ

ΚΑΡΤΑ ΕΛΕΓΧΟΥ

ΚΑΡΤΑ ΚΕΝΤΡΟΥ ΔΟΚΙΜΩΝ

ΚΑΡΤΑ ΕΠΙΧΕΙΡΗΣΗΣ

EN DRIVER CARD

CONTROL CARD

WORKSHOP CARD

COMPANY CARD

FR CARTE DE CONDUCTEUR

CARTE DE CONTROLEUR

CARTE D'ATELIER

CARTE D'ENTREPRISE

GA CÁRTA TIOMÁNAÍ

CÁRTA STIÚRTHA

CÁRTA CEARDLAINNE

CÁRTA COMHLACHTA

IT CARTA DEL CONDUCENTE

CARTA DI CONTROLLO

CARTA DELL'OFFICINA

CARTA DELL'AZIENDA

NL BESTUURDERS KAART

CONTROLEKAART

WERKPLAATSKAART

BEDRIJFSKAART

PT CARTÃO DE CONDUTOR

CARTÃO DE CONTROLO

CARTÃO DO CENTRO DE ENSAIO

CARTÃO DE EMPRESA

FI KULJETTAJA KORTTILLA

VALVONTA KORTILLA

TESTAUSASEMA KORTILLA

YRITYSKORTILLA

SV FÖRARKORT

KONTROLLKORT

VERKSTADSKORT

FÖRETAGSKORT

[173] the name of the Member State issuing the card (optional);

[174] the distinguishing sign of the Member State issuing the card, printed in negative in a blue rectangle and encircled by 12 yellow stars. The distinguishing signs shall be as follows:

BBelgium

DKDenmark

DGermany

GRGreece

ESpain

FFrance

IRLIreland

IItaly

LLuxembourg

NLThe Netherlands

AAustria

PPortugal

FINFinland

SSweden

UKThe United Kingdom;

[175] information specific to the card issued, numbered as follows:

Driver card Control card Company or workshop card 1. Surname of the driver Control body name Company or workshop card 2. First name(s) of the driver Surname of the controller

(if applicable)

Surname of card holder

(if applicable)

3. Birth date of the driver First name(s) of the controller

(if applicable)

First name(s) of card holder

(if applicable)

4.(a) Card start of validity date (b) Card expiry date (if any) (c) The name of the issuing authority (may be printed on page 2) (d) A different number from the one under heading 5, for administrative purposes (optional) 5.(a) Driving licence number

(at the date of issue of the driver card)

5.(b) Card number 6. Photograph of the driver Photograph of the controller

(optional)

— 7. Signature of the driver Signature of the holder (optional) 8. Normal place of residence, or postal address of the holder (optional) Postal address of control body Postal address of company or workshop [176] dates shall be written using a “dd/mm/yyyy“ or “dd.mm.yyyy“ format (day, month, year);

the reverse page will contain:

[177] an explanation of the numbered items which appear on the front page of the card;

[178] with the specific written agreement of the holder, information which is not related to the administration of the card may also be added, such addition will not alter in any way the use of the model as a tachograph card.

[179] Tachograph cards shall be printed with the following background predominant colours:

driver card: white,

control card: blue,

workshop card: red,

company card: yellow.

[180] Tachograph cards shall bear at least the following features for protection of the card body against counterfeiting and tampering:

a security design background with fine guilloche patterns and rainbow printing,

in the area of the photograph, the security design background and the photograph shall overlap,

at least one two-coloured microprint line.

[181] After consulting the Commission, Member States may add colours or markings, such as national symbols and security features, without prejudice to the other provisions of this Annex.

2.Security

The system security aims at protecting integrity and authenticity of data exchanged between the cards and the recording equipment, protecting the integrity and authenticity of data downloaded from the cards, allowing certain write operations onto the cards to recording equipment only, ruling out any possibility of falsification of data stored in the cards, preventing tampering and detecting any attempt of that kind.

[182] In order to achieve the system security, the tachograph cards shall meet the security requirements defined in the tachograph cards generic security target (Appendix 10).

[183] Tachograph cards shall be readable by other equipment such as personal computers.

3.Standards

[184] The tachograph cards shall comply with the following standards:

ISO/IEC 7810 Identification cards — Physical characteristics,

ISO/IEC 7816 Identification cards — Integrated circuits with contacts:

Part 1: Physical characteristics,

Part 2: Dimensions and location of the contacts,

Part 3: Electronic signals and transmission protocols,

Part 4: Inter-industry commands for interchange,

Part 8: Security related inter-industry commands,

ISO/IEC 10373 Identification cards — Test methods.

4.Environmental and electrical specifications

[185] The tachograph cards shall be capable of operating correctly in all the climatic conditions normally encountered in Community territory and at least in the temperature range − 25 °C to + 70 °C with occasional peaks of up to + 85 °C, “occasional“ meaning not more than 4 hours each time and not over 100 times during the lifetime of the card.

[186] The tachograph cards shall be capable of operating correctly in the humidity range 10 % to 90 %.

[187] The tachograph cards shall be capable of operating correctly for a five-year period if used within the environmental and electrical specifications.

[188] During operation, the tachograph cards shall conform to Commission Directive 95/54/EC of 31 October 1995(11), related to electromagnetic compatibility, and shall be protected against electrostatic discharges.

5.Data storage

For the purpose of this paragraph,

times are recorded with a resolution of one minute, unless otherwise specified,

odometer values are recorded with a resolution of one kilometre,

speeds are recorded with a resolution of 1 km/h.

The tachograph cards functions, commands and logical structures, fulfilling data storage requirements are specified in Appendix 2.

[189] This paragraph specifies minimum storage capacity for the various application data files. The tachograph cards shall be able to indicate to the recording equipment the actual storage capacity of these data files.

Any additional data that may be stored on tachograph cards, related to other applications eventually borne by the card, shall be stored in accordance with Directive 95/46/EC of 24 October 1995 on the protection of individuals with regard to the processing of personal data and on the free movement of such data(12).

5.1.Card identification and security data

5.1.1.Application identification

[190] The tachograph cards shall be able to store the following application identification data:

tachograph application identification,

type of tachograph card identification.

5.1.2.Chip identification

[191] The tachograph cards shall be able to store the following integrated circuit (IC) identification data:

IC serial number,

IC manufacturing references.

5.1.3.IC card identification

[192] The tachograph cards shall be able to store the following smart card identification data:

card serial number (including manufacturing references),

card type approval number,

card personaliser identification (ID),

embedder ID,

IC identifier.

5.1.4.Security elements

[193] The tachograph cards shall be able to store the following security elements data:

European public key,

Member State certificate,

card certificate,

card private key.

5.2.Driver card

5.2.1.Card identification

[194] The driver card shall be able to store the following card identification data:

card number,

issuing Member State, issuing authority name, issue date,

card beginning of validity date, card expiry date.

5.2.2.Card holder identification

[195] The driver card shall be able to store the following card holder identification data:

surname of the holder,

first name(s) of the holder,

date of birth,

preferred language.

5.2.3.Driving licence information

[196] The driver card shall be able to store the following driving licence data:

issuing Member State, issuing authority name,

driving licence number (at the date of the issue of the card).

5.2.4.Vehicles used data

[197] The driver card shall be able to store, for each calendar day where the card has been used, and for each period of use of a given vehicle that day (a period of use includes all consecutive insertion/withdrawal cycle of the card in the vehicle, as seen from the card point of view), the following data:

date and time of first use of the vehicle (i.e. first card insertion for this period of use of the vehicle, or 00.00 if the period of use is on-going at that time),

vehicle odometer value at that time,

date and time of last use of the vehicle, (i.e. last card withdrawal for this period of use of the vehicle, or 23.59 if the period of use is on-going at that time),

vehicle odometer value at that time,

VRN and registering Member State of the vehicle.

[198] The driver card shall be able to store at least 84 such records.

5.2.5.Driver activity data

[199] The driver card shall be able to store, for each calendar day where the card has been used or for which the driver has entered activities manually, the following data:

the date,

a daily presence counter (increased by one for each of these calendar days),

the total distance travelled by the driver during this day,

a driver status at 00.00,

whenever the driver has changed of activity, and/or has changed of driving status, and/or has inserted or withdrawn his card:

the driving status (CREW, SINGLE),

the slot (DRIVER, CO-DRIVER),

the card status (INSERTED, NOT INSERTED),

the activity (DRIVING, AVAILABILITY, WORK, BREAK/REST),

the time of the change.

[200] The driver card memory shall be able to hold driver activity data for at least 28 days (the average activity of a driver is defined as 93 activity changes per day).

[201] The data listed under requirements 197 and 199 shall be stored in a way allowing the retrieval of activities in the order of their occurrence, even in case of a time overlap situation.

5.2.6.Places where daily work periods start and/or end

[202] The driver card shall be able to store the following data related to places where daily work periods begin and/or end, entered by the driver:

the date and time of the entry (or the date/time related to the entry if the entry is made during the manual entry procedure),

the type of entry (begin or end, condition of entry),

the country and region entered,

the vehicle odometer value.

[203] The driver card memory shall be able to hold at least 42 pairs of such records.

5.2.7.Events data

For the purpose of this subparagraph, time shall be stored with a resolution of one second.

[204] The driver card shall be able to store data related to the following events detected by the recording equipment while the card was inserted:

time overlap (where this card is the cause of the event),

card insertion while driving (where this card is the subject of the event),

last card session not correctly closed (where this card is the subject of the event),

power supply interruption,

motion data error,

security breach attempts.

[205] The driver card shall be able to store the following data for these events:

event code,

date and time of beginning of the event (or of card insertion if the event was on-going at that time),

date and time of end of the event (or of card withdrawal if the event was on-going at that time),

VRN and registering Member State of vehicle in which the event happened.

Note: For the “time overlap“ event:

date and time of beginning of the event shall correspond to the date and time of the card withdrawal from the previous vehicle,

date and time of end of the event shall correspond to the date and time of card insertion in current vehicle,

vehicle data shall correspond to the current vehicle raising the event.

Note: For the “last card session not correctly closed“ event:

date and time of beginning of event shall correspond to the card insertion date and time of the session not correctly closed,

date and time of end of event shall correspond to the card insertion date and time of the session during which the event was detected (current session),

vehicle data shall correspond to the vehicle in which the session was not correctly closed.

[206] The driver card shall be able to store data for the six most recent events of each type (i.e. 36 events).

5.2.8.Faults data

For the purpose of this subparagraph, time shall be recorded with a resolution of one second.

[207] The driver card shall be able to store data related to the following faults detected by the recording equipment while the card was inserted:

card fault (where this card is the subject of the event),

recording equipment fault.

[208] The driver card shall be able to store the following data for these faults:

fault code,

date and time of beginning of the fault (or of card insertion if the fault was on-going at that time),

date and time of end of the fault (or of card withdrawal if the fault was on-going at that time),

VRN and registering Member State of vehicle in which the fault happened.

[209] The driver card shall be able to store data for the twelve most recent faults of each type (i.e. 24 faults).

5.2.9.Control activity data