- Latest available (Revised)

- Point in Time (22/02/2017)

- Original (As adopted by EU)

Commission Regulation (EU) No 142/2011Show full title

Commission Regulation (EU) No 142/2011 of 25 February 2011 implementing Regulation (EC) No 1069/2009 of the European Parliament and of the Council laying down health rules as regards animal by-products and derived products not intended for human consumption and implementing Council Directive 97/78/EC as regards certain samples and items exempt from veterinary checks at the border under that Directive (Text with EEA relevance)

You are here:

- Regulations originating from the EU

- 2011 No. 142

- Annexes only

- Show Geographical Extent(e.g. England, Wales, Scotland and Northern Ireland)

- Show Timeline of Changes

More Resources

Revised version PDFs

- Revised 08/12/20209.59 MB

- Revised 30/06/20209.58 MB

- Revised 23/06/20209.54 MB

- Revised 08/03/20209.54 MB

- Revised 14/12/20199.44 MB

- Revised 31/07/20199.44 MB

- Revised 16/07/20199.44 MB

- Revised 20/03/20199.75 MB

- Revised 02/08/201710.18 MB

- Revised 01/07/201710.16 MB

- Revised 29/05/20179.92 MB

- Revised 22/02/20179.91 MB

- Revised 23/02/20159.85 MB

- Revised 15/07/20149.35 MB

- Revised 19/03/20149.30 MB

- Revised 01/12/20138.38 MB

- Revised 01/07/20139.54 MB

- Revised 15/03/20139.53 MB

- Revised 14/12/20129.27 MB

- Revised 04/12/20129.27 MB

- Revised 19/08/20118.01 MB

When the UK left the EU, legislation.gov.uk published EU legislation that had been published by the EU up to IP completion day (31 December 2020 11.00 p.m.). On legislation.gov.uk, these items of legislation are kept up-to-date with any amendments made by the UK since then.

This item of legislation originated from the EU

Legislation.gov.uk publishes the UK version. EUR-Lex publishes the EU version. The EU Exit Web Archive holds a snapshot of EUR-Lex’s version from IP completion day (31 December 2020 11.00 p.m.).

Changes over time for: Commission Regulation (EU) No 142/2011 (Annexes only)

Version Superseded: 29/05/2017

Alternative versions:

- 25/02/2011- Amendment

- 19/08/2011- Amendment

- 04/12/2012- Amendment

- 15/03/2013- Amendment

- 01/12/2013- Amendment

- 15/07/2014- Amendment

- 23/02/2015- Amendment

- 22/02/2017- Amendment

- 22/02/2017

Point in time - 29/05/2017- Amendment

- 01/07/2017- Amendment

- 02/08/2017- Amendment

- 20/03/2019- Amendment

- 16/07/2019- Amendment

- 31/07/2019- Amendment

- Exit day: start of implementation period31/01/2020 11pm- Amendment

- 08/03/2020- Amendment

- 23/06/2020- Amendment

- 30/06/2020- Amendment

- 08/12/2020- Amendment

- End of implementation period31/12/2020- Amendment

Status:

Point in time view as at 22/02/2017.

Changes to legislation:

There are currently no known outstanding effects by UK legislation for Commission Regulation (EU) No 142/2011.![]()

Changes to Legislation

Revised legislation carried on this site may not be fully up to date. At the current time any known changes or effects made by subsequent legislation have been applied to the text of the legislation you are viewing by the editorial team. Please see ‘Frequently Asked Questions’ for details regarding the timescales for which new effects are identified and recorded on this site.

ANNEX IU.K. DEFINITIONS AS REFERRED TO IN ARTICLE 2

For the purpose of this Regulation, the following definitions shall apply:

‘fur animals’ means animals kept or reared for the production of fur and not used for human consumption;

‘blood’ means fresh whole blood;

‘feed material’ means those feed materials, as defined in Article 3(2)(g) of Regulation (EC) No 767/2009, that are of animal origin, including processed animal proteins, blood products, rendered fats, egg products, fish oil, fat derivatives, collagen, gelatine and hydrolysed proteins, dicalcium phosphate, tricalcium phosphate, milk, milk-based products, milk-derived products, colostrum, colostrum products and centrifuge or separator sludge;

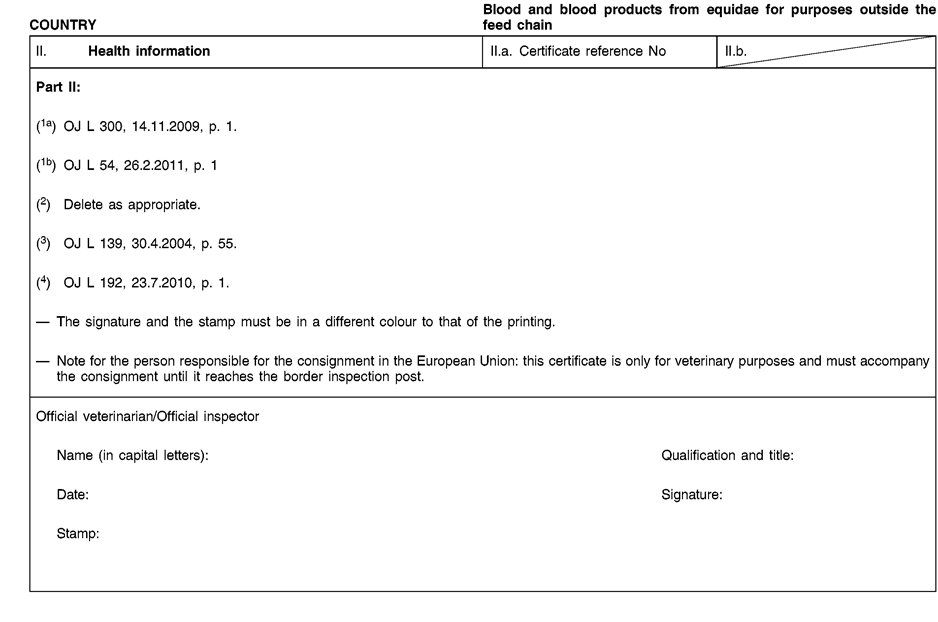

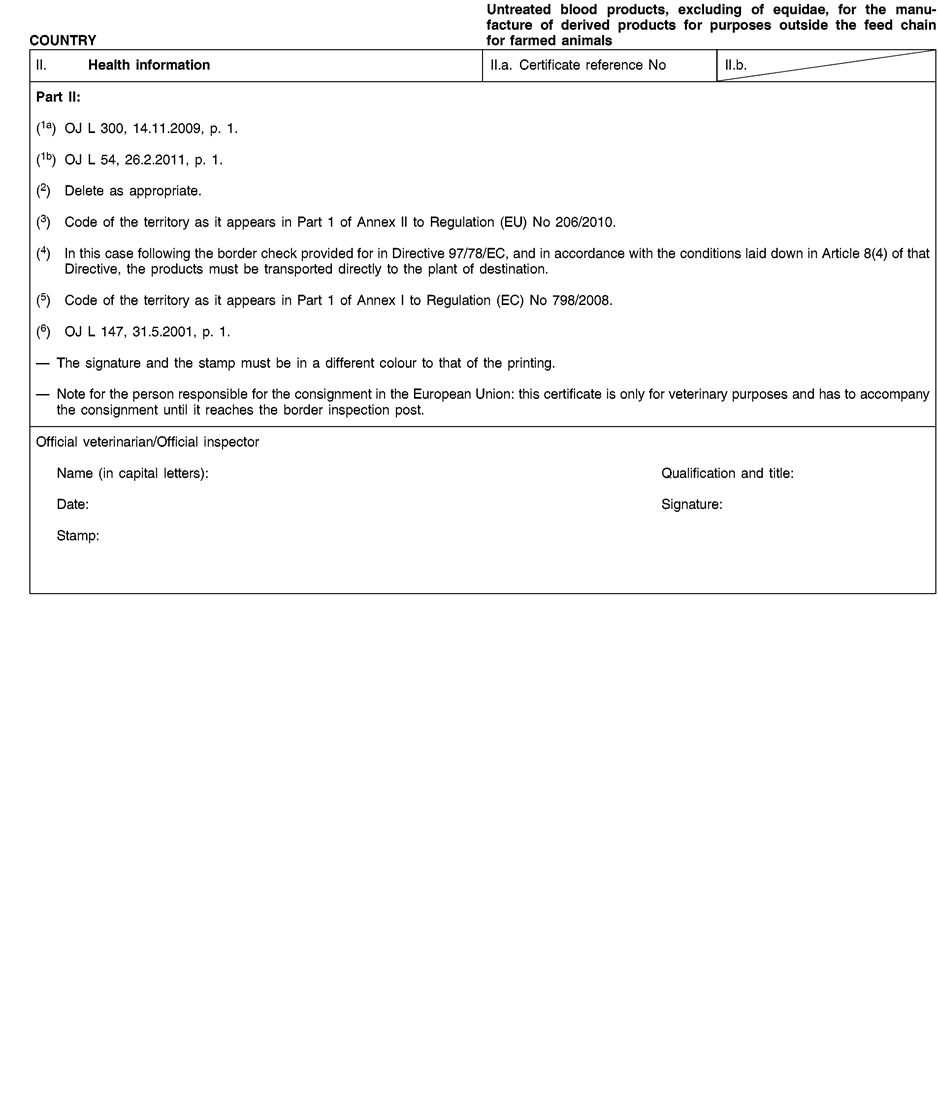

‘blood products’ means derived products from blood or fractions of blood, excluding blood meal; they include dried/frozen/liquid plasma, dried whole blood, dried/frozen/liquid red cells or fractions thereof and mixtures;

‘processed animal protein’ means animal protein derived entirely from Category 3 material, which have been treated in accordance with Section 1 of Chapter II of Annex X (including blood meal and fishmeal) so as to render them suitable for direct use as feed material or for any other use in feedingstuffs, including petfood, or for use in organic fertilisers or soil improvers; however, it does not include blood products, milk, milk-based products, milk-derived products, colostrum, colostrum products, centrifuge or separator sludge, gelatine, hydrolysed proteins and dicalcium phosphate, eggs and egg-products, including eggshells, tricalcium phosphate and collagen;

‘blood meal’ means processed animal protein derived from the heat treatment of blood or fractions of blood in accordance with Section 1 of Chapter II of Annex X;

‘fishmeal’ means processed animal protein derived from aquatic animals, except sea mammals;

‘rendered fats’ means either fats derived from the processing of:

animal by-products; or

products for human consumption, which an operator has destined for purposes other than human consumption;

‘fish oil’ means oil derived from the processing of aquatic animals or oil from the processing of fish for human consumption, which an operator has destined for purposes other than human consumption;

‘apiculture by-products’ means honey, beeswax, royal jelly, propolis or pollen not intended for human consumption;

‘collagen’ means protein-based products derived from hides, skins, bones and tendons of animals;

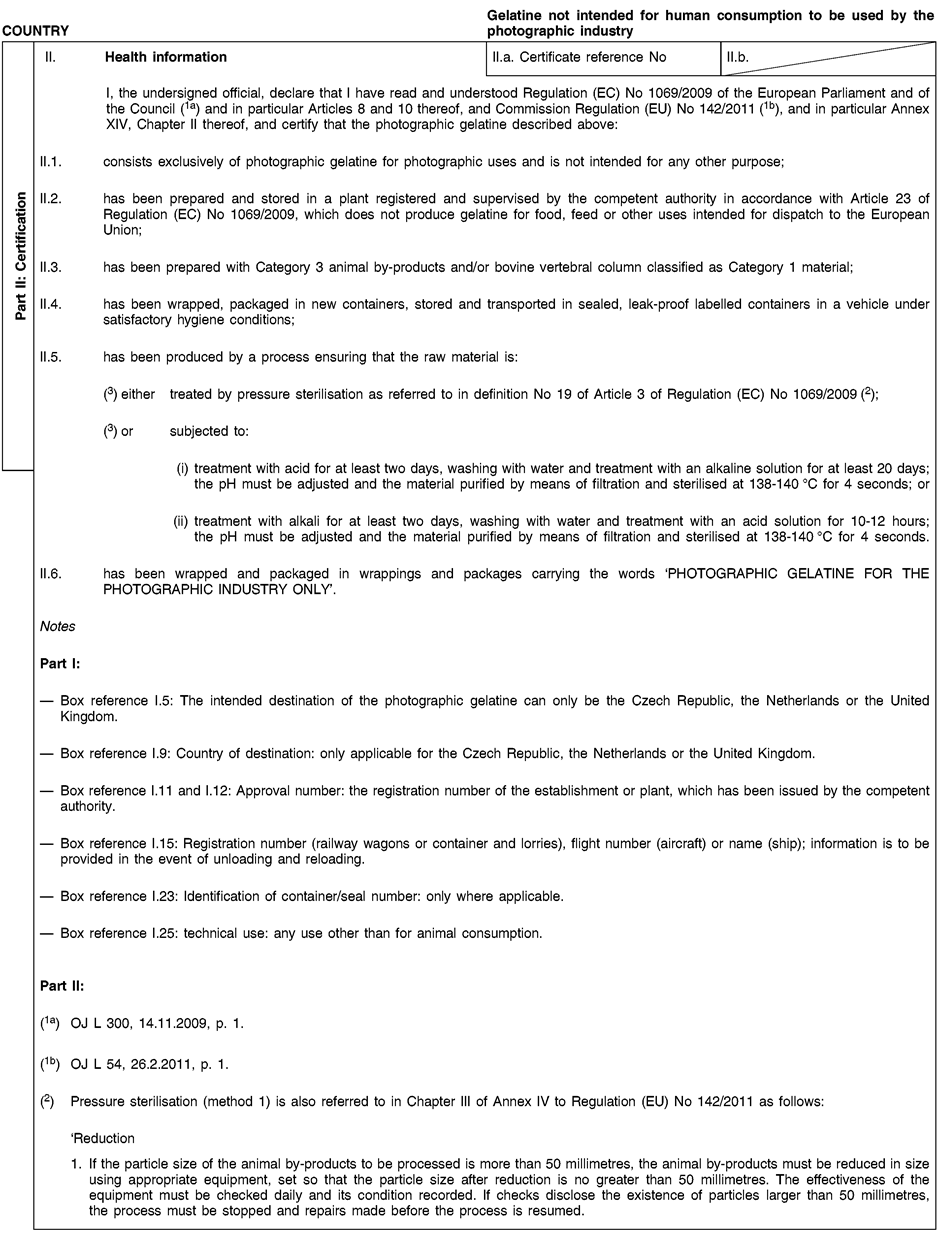

‘gelatine’ means natural, soluble protein, gelling or non-gelling, obtained by the partial hydrolysis of collagen produced from bones, hides and skins, tendons and sinews of animals;

‘greaves’ means the protein-containing residue of rendering, after partial separation of fat and water;

‘hydrolysed proteins’ means polypeptides, peptides and aminoacids, and mixtures thereof, obtained by the hydrolysis of animal by-products;

‘white water’ means a mixture of milk, milk-based products or products derived thereof with water which is collected during the rinsing of dairy equipment including containers used for dairy products, prior to their cleaning and disinfection;

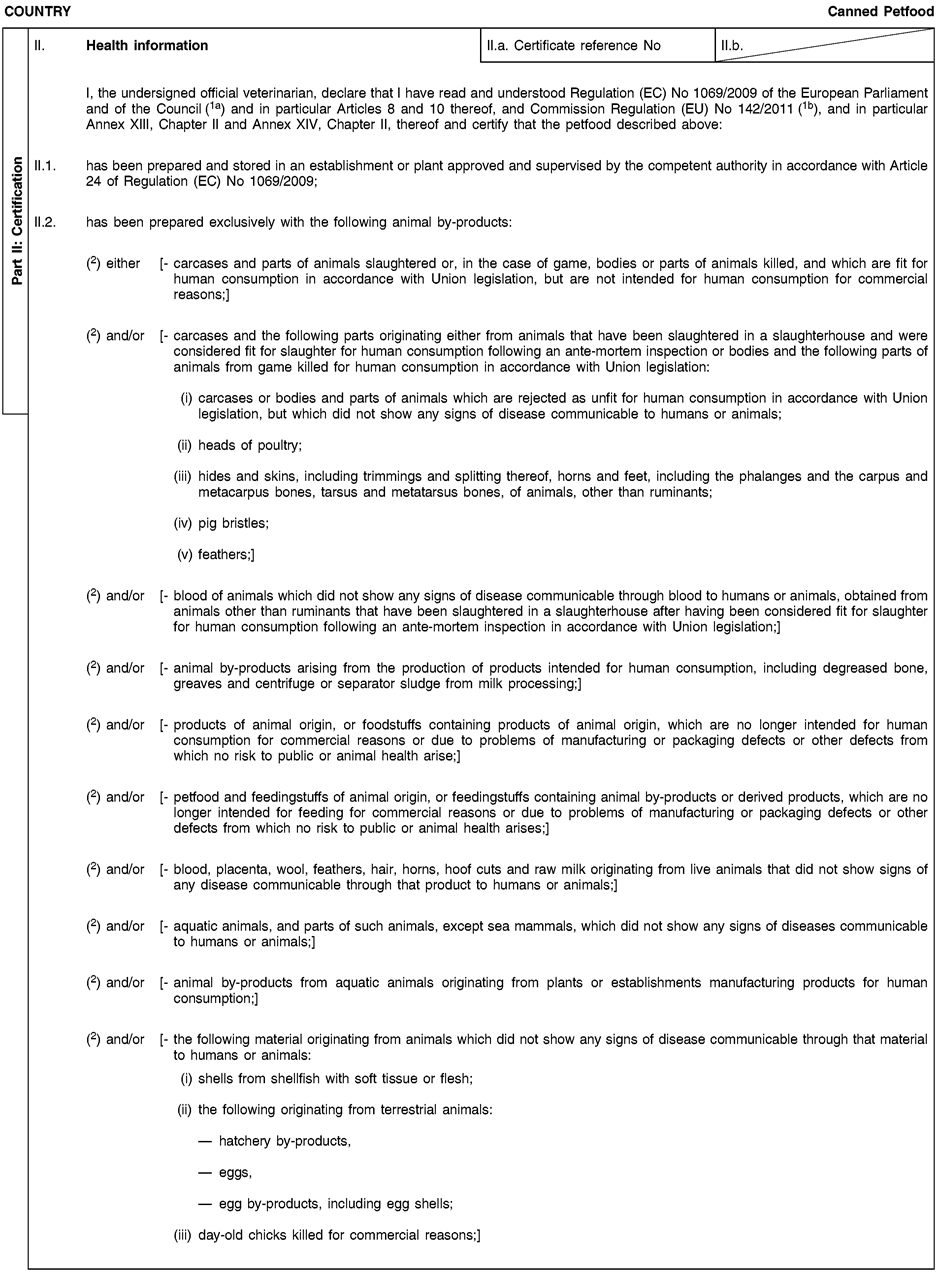

‘canned petfood’ means heat-processed petfood contained within a hermetically sealed container;

‘dogchews’ means products for pet animals to chew, produced from untanned hides and skins of ungulates or from other material of animal origin;

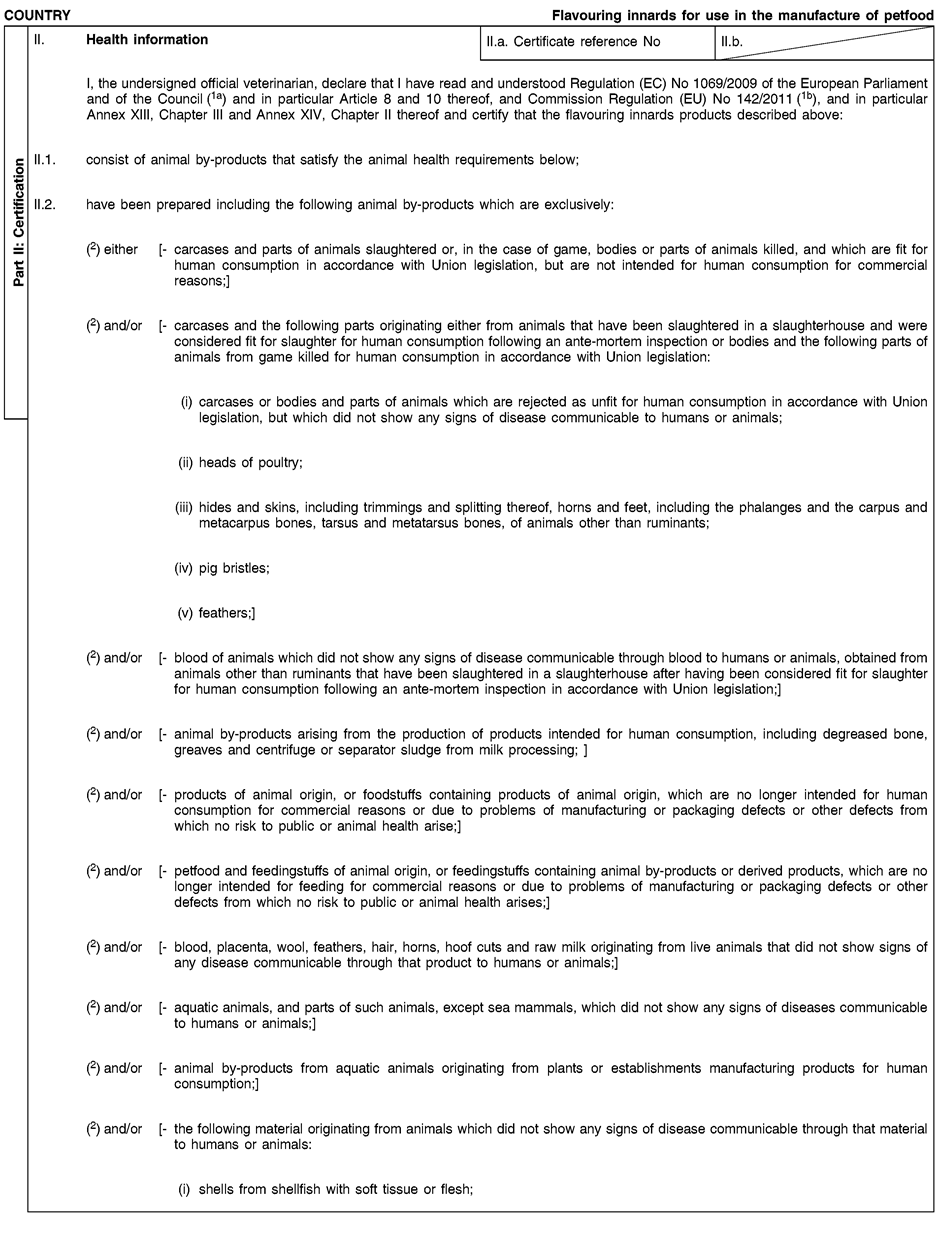

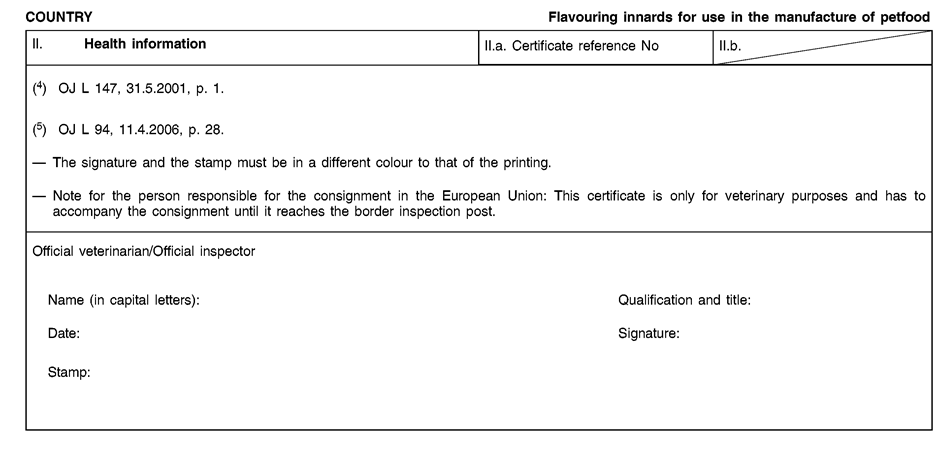

‘flavouring innards’ means a liquid or dehydrated derived product of animal origin used to enhance the palatability values of petfood;

‘ [F1petfood ’ means feed, other than material referred to in Article 24(2), for use as feed for pet animals, and dogchews consisting of animal by-products or derived products which:

contain Category 3 material, other than material referred to in Article 10(n), (o) and (p) of Regulation (EC) No 1069/2009; and

may contain imported Category 1 material comprising of animal by-products derived from animals which have been submitted to illegal treatment as defined in Article 1(2)(d) of Directive 96/22/EC or Article 2(b) of Directive 96/23/EC;]

‘processed petfood’ means petfood, other than raw petfood, which has been processed in accordance with point 3 of Chapter II of Annex XIII;

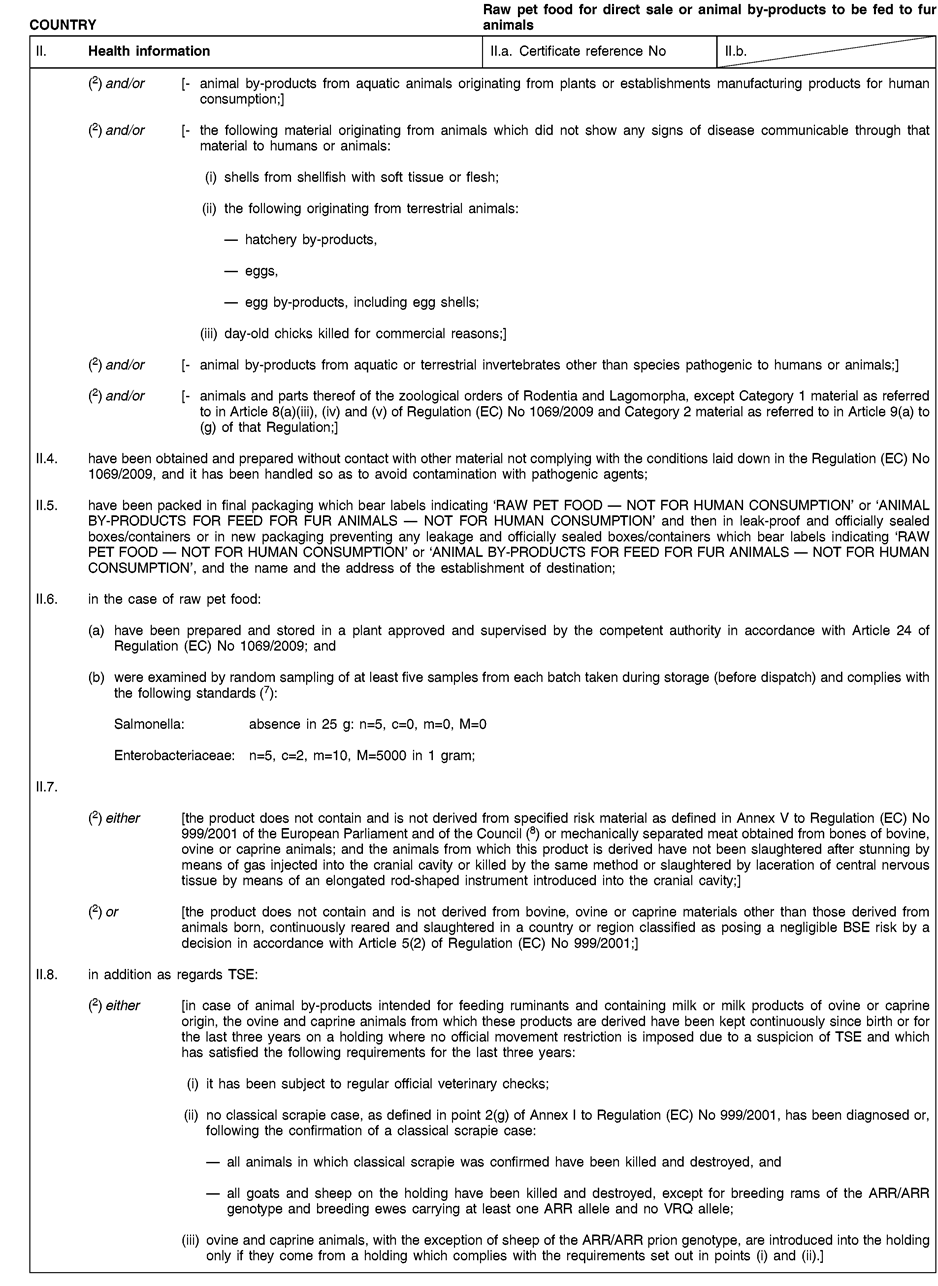

‘raw petfood’ means petfood containing certain Category 3 material which has not undergone any preserving process other than chilling or freezing;

‘catering waste’ means all waste food, including used cooking oil originating in restaurants, catering facilities and kitchens, including central kitchens and household kitchens;

‘ [F1digestion residues ’ means residues, including the liquid fraction, resulting from the transformation of animal by-products in a biogas plant;]

‘digestive tract content’ means the content of the digestive tract of mammals and ratites;

‘fat derivatives’ means derived products from rendered fats, which, as regards rendered fats of Category 1 or Category 2 material, have been processed in accordance with Chapter XI of Annex XIII;

‘guano’ means a natural product which has been collected from the excrements of bats or wild sea birds and which is not mineralised;

‘meat-and-bone meal’ means animal protein derived from the processing of Category 1 or Category 2 materials in accordance with one of the processing methods set out in Chapter III of Annex IV;

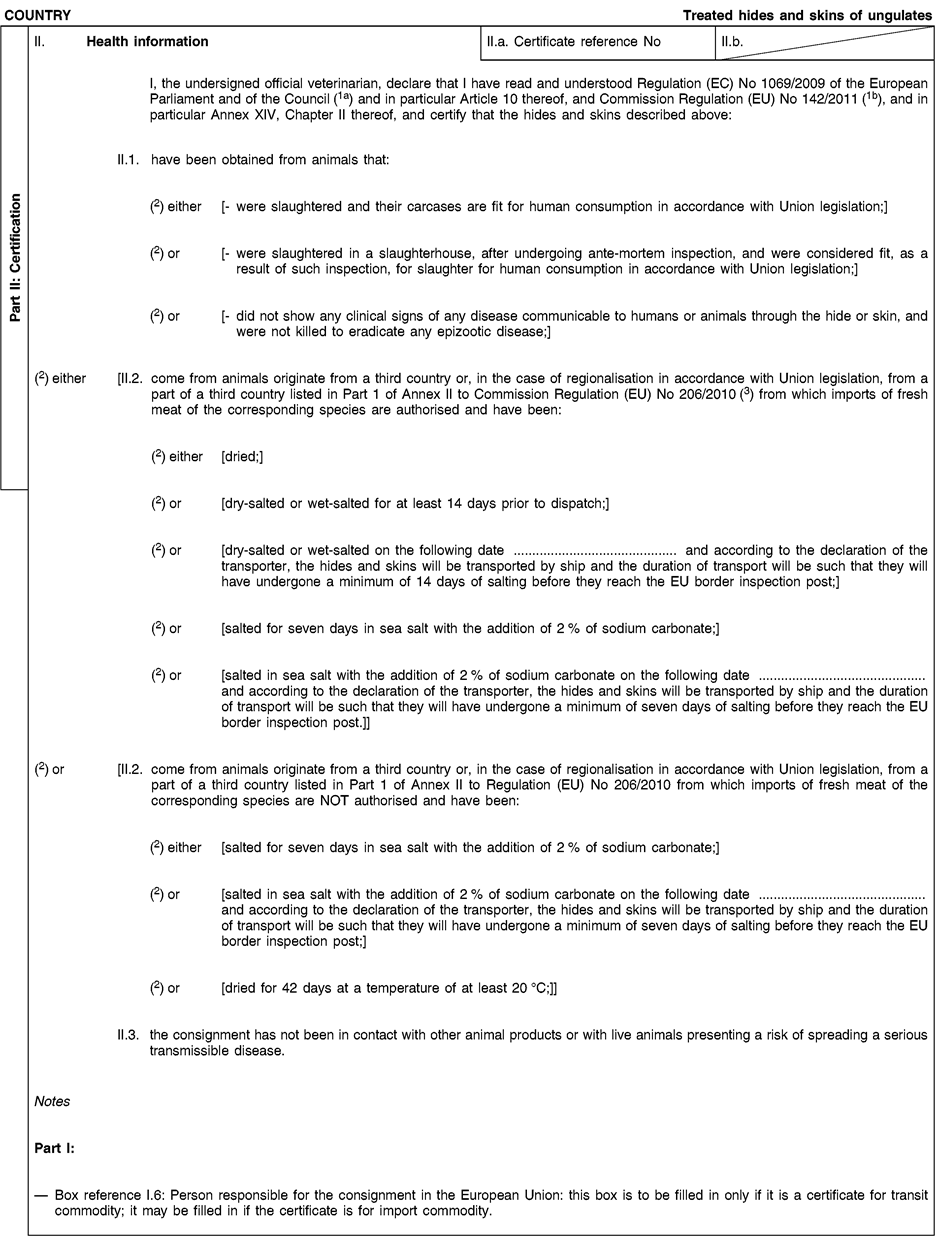

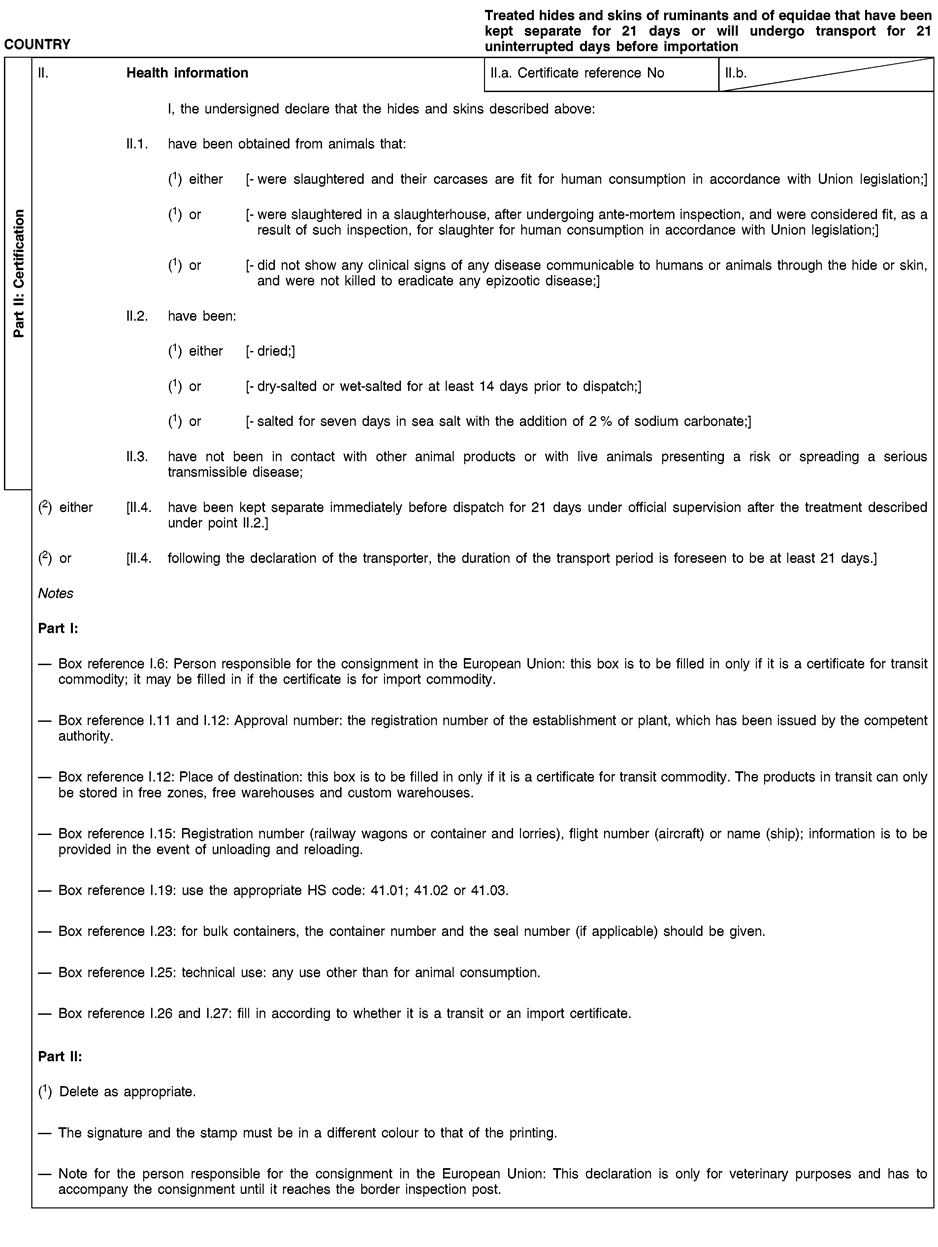

‘treated hides and skins’ means derived products from untreated hides and skins, other than dogchews, that have been:

dried;

dry-salted or wet-salted for a period of at least 14 days prior to dispatch;

salted for a period of at least seven days in sea salt with the addition of 2 % of sodium carbonate;

dried for a period of at least 42 days at a temperature of at least 20 °C; or

subject to a preservation process other than tanning;

‘untreated hides and skins’ means all cutaneous and subcutaneous tissues that have not undergone any treatment, other than cutting, chilling or freezing;

‘untreated feathers and parts of feathers’ means feathers and parts of feathers, other than feathers or parts of feathers, which have been treated:

with a steam current; or

by another method that ensures that no unacceptable risks remain;

‘ [F2untreated wool ’ means wool, other than wool which has:

undergone factory washing;

been obtained from tanning;

been treated by another method that ensures that no unacceptable risks remain;

been produced from animals other than those of the porcine species, and has undergone factory-washing which consisting of the immersion of the wool in series of baths of water, soap and sodium hydroxide or potassium hydroxide; or

been produced from animals other than those of the porcine species, is intended for being dispatched directly to a plant producing derived products from wool for the textile industry and has undergone at least one of the following treatments:

chemical depilation by means of slaked lime or sodium sulphide;

fumigation in formaldehyde in a hermetically sealed chamber for at least 24 hours;

industrial scouring which consists of the immersion of wool in a water-soluble detergent held at 60–70 °C;

storage, which may include the journey time, at 37 °C for eight days, 18 °C for 28 days or 4 °C for 120 days;

‘ untreated hair ’ means hair, other than hair which has:

undergone factory washing;

been obtained from tanning;

been treated by another method that ensures that no unacceptable risks remain;

been produced from animals other than those of the porcine species, and has undergone factory-washing which consisting of the immersion of the hair in series of baths of water, soap and sodium hydroxide or potassium hydroxide; or

been produced from animals other than those of the porcine species, is intended for being dispatched directly to a plant producing derived products from hair for the textile industry and has undergone at least one of the following treatments:

chemical depilation by means of slaked lime or sodium sulphide;

fumigation in formaldehyde in a hermetically sealed chamber for at least 24 hours;

industrial scouring which consists of the immersion of hair in a water-soluble detergent held at 60–70 °C;

storage, which may include the journey time, at 37 °C for eight days, 18 °C for 28 days or 4 °C for 120 days;]

‘untreated pig bristles’ means pig bristles, other than pig bristles which have:

undergone factory washing;

been obtained from tanning; or

been treated by another method that ensures that no unacceptable risks remain;

‘display item’ means animal by-products or derived products intended for exhibitions or artistic activities;

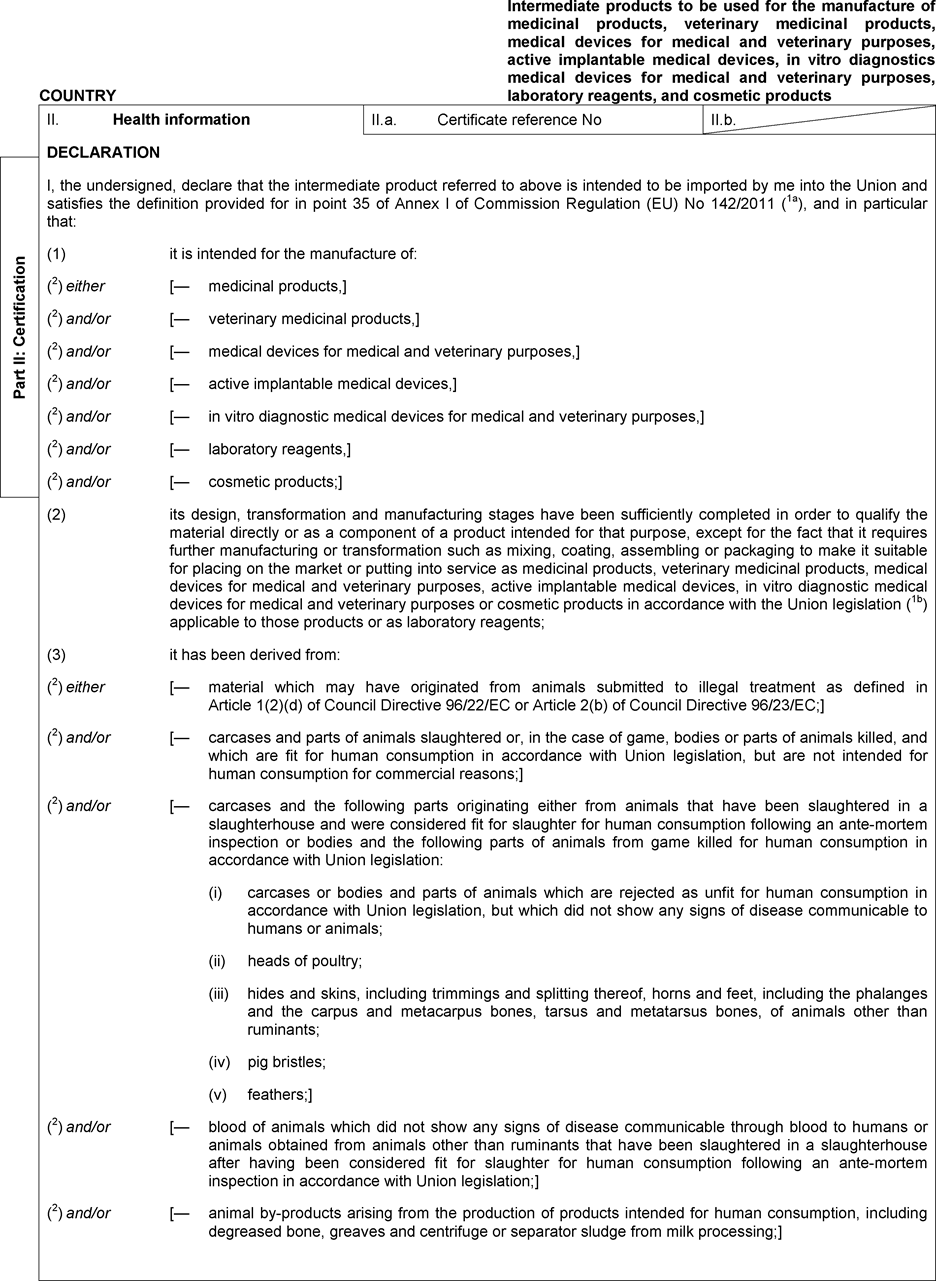

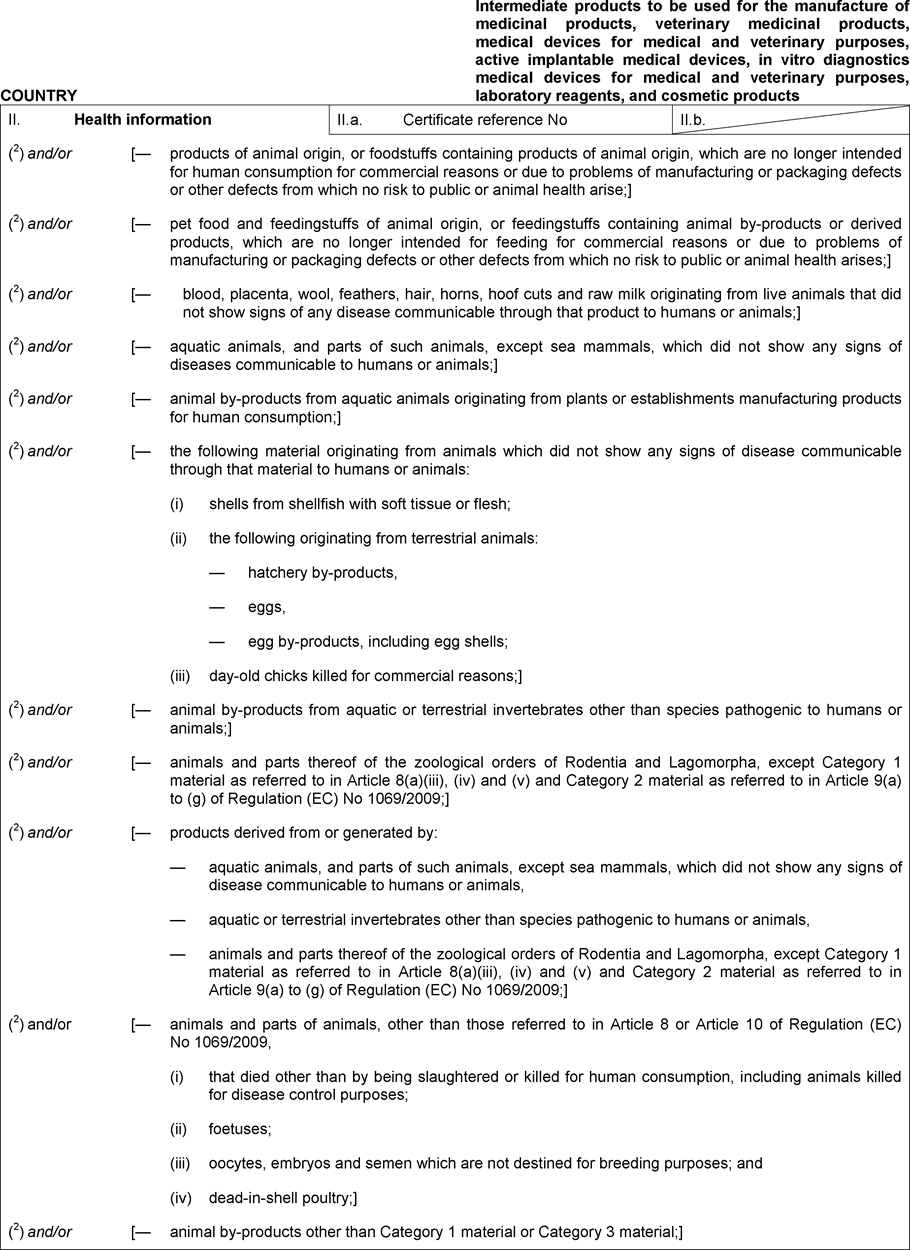

‘ [F3intermediate product ’ means a derived product:

which is intended for uses within the manufacturing of medicinal products, veterinary medicinal products, medical devices for medical and veterinary purposes, active implantable medical devices, in vitro diagnostic medical devices for medical and veterinary purposes, laboratory reagents or cosmetic products as follows:

as material in a manufacturing process or in the final production of a finished product;

in validation or verification during a manufacturing process; or

in quality control of a finished product;

whose design, transformation and manufacturing stages have been sufficiently completed in order to be regarded as a derived product and to qualify the material directly or as a component of a product for the purposes referred to in point (a);

which however requires some further manufacturing or transformation, such as mixing, coating, assembling or packaging to make it suitable for placing on the market or putting into service, as applicable, a medicinal product, veterinary medicinal product, medical device for medical and veterinary purposes, active implantable medical device, in vitro diagnostic medical devices for medical and veterinary purposes, laboratory reagent or cosmetic products;]

‘laboratory reagent’ means a packaged product, ready for use, containing animal by-products or derived products and intended as such or in combination with substances of non-animal origin for specific laboratory use as a reagent or reagent product, calibrator or control material to detect, measure, examine or produce other substances;

‘product used for in vitro diagnosis’ means a packaged product, ready for use, containing a blood product or another animal by-product, and used as a reagent, reagent product, calibrator, kit or any other system, whether used alone or in combination, intended to be used in vitro for the examination of samples of human or animal origin, solely or principally with a view to the diagnosis of a physiological state, state of health, disease or genetic abnormality or to determine safety and compatibility with reagents; it does not include donated organs or blood;

‘research and diagnostic samples’ means animal by-products and derived products intended for the following purposes: examination in the context of diagnostic activities or analysis for the promotion of progress in science and technology, in the context of educational or research activities;

‘ [F3trade samples ’ means animal by-products or derived products intended for particular studies or analyses authorised by the competent authority in accordance with Article 17(1) of Regulation (EC) No 1069/2009 with a view to carrying out a production process, including the processing of animal by-products or derived products, the development of feedingstuff, pet food or derived products, or the testing of machinery or equipment;]

‘co-incineration’ means the recovery or disposal of animal by-products or derived products, if they are waste, in a co-incineration plant;

‘combustion’ means a process involving the oxidisation of fuel in order to use the energy value of the animal by-products or derived products, if they are not waste;

‘incineration’ means the disposal of animal by-products or derived products as waste, in an incineration plant, as defined in point 4 of Article 3 of Directive 2000/76/EC;

‘incineration and co-incineration residues’ means any residues as defined in point 13 of Article 3 of Directive 2000/76/EC, which are generated by incineration or co-incineration plants treating animal by-products or derived products;

‘colour-coding’ means the systematic use of colours as set out in point 1(c) of Chapter II of Annex VIII for displaying information as provided for in this Regulation on the surface or on part of the surface of a packaging, container or vehicle, or on a label or symbol applied to them;

‘intermediate operations’ means the operations, other than storage, referred to in Article 19(b);

‘tanning’ means the hardening of hides, using vegetable tanning agents, chromium salts or other substances such as aluminium salts, ferric salts, silicic salts, aldehydes and quinones, or other synthetic hardening agents;

‘taxidermy’ means the art of preparing, stuffing and mounting the skins of animals with lifelike effect, so that no unacceptable risks to public and animal health may be transmitted through the mounted skin;

‘trade’ means trade in goods between Member States as referred to in Article 28 of the Treaty on the Functioning of the European Union;

‘processing methods’ means the methods listed in Chapters III and IV of Annex IV;

‘batch’ means a unit of production produced in a single plant using uniform production parameters, such as the origin of the materials, or a number of such units, when produced in continuous order in a single plant and stored together as a shipping unit;

‘hermetically sealed container’ means a container that is designed and intended to be secure against the entry of micro-organisms;

‘biogas plant’ means a plant in which animal by-products or derived products are at least part of the material which is submitted to biological degradation under anaerobic conditions;

‘collection centres’ means premises other than processing plants in which the animal by-products referred to in Article 18(1) of Regulation (EC) No 1069/2009 are collected with the intention to be used for feeding to the animals referred to in the same Article;

‘composting plant’ means a plant in which animal by-products or derived products are at least part of the material which is submitted to biological degradation under aerobic conditions;

‘co-incineration plant’ means any stationary or mobile plant whose main purpose is the generation of energy or the production of material products as defined in point 5 of Article 3 of Directive 2000/76/EC;

‘incineration plant’ means any stationary or mobile technical unit and equipment dedicated to the thermal treatment of waste as defined in point 4 of Article 3 of Directive 2000/76/EC;

‘petfood plant’ means premises or facilities for the production of petfood or flavouring innards, as referred to in Article 24(1)(e) of Regulation (EC) No 1069/2009;

‘ [F3processing plant ’ means premises or facilities for the processing of animal by-products as referred to in Article 24(1)(a) of Regulation (EC) No 1069/2009, in which animal by-products are processed in accordance with Annex IV and/or Annex X;]

‘ [F4growing media ’ means materials, including potting soil, other than soil in situ , in which plants are grown and which is used independently from soil in situ .]

Textual Amendments

F1 Substituted by Commission Regulation (EU) No 294/2013 of 14 March 2013 amending and correcting Regulation (EU) No 142/2011 implementing Regulation (EC) No 1069/2009 of the European Parliament and of the Council laying down health rules as regards animal by-products and derived products not intended for human consumption and implementing Council Directive 97/78/EC as regards certain samples and items exempt from veterinary checks at the border under that Directive (Text with EEA relevance).

F2 Substituted by Commission Regulation (EU) No 1063/2012 of 13 November 2012 amending Regulation (EU) No 142/2011 implementing Regulation (EC) No 1069/2009 of the European Parliament and of the Council laying down health rules as regards animal by-products and derived products not intended for human consumption and implementing Council Directive 97/78/EC as regards certain samples and items exempt from veterinary checks at the border under that Directive (Text with EEA relevance).

F3 Substituted by Commission Regulation (EU) 2015/9 of 6 January 2015 amending Regulation (EU) No 142/2011 implementing Regulation (EC) No 1069/2009 of the European Parliament and of the Council laying down health rules as regards animal by-products and derived products not intended for human consumption and implementing Council Directive 97/78/EC as regards certain samples and items exempt from veterinary checks at the border under that Directive (Text with EEA relevance).

F4 Inserted by Commission Regulation (EU) 2015/9 of 6 January 2015 amending Regulation (EU) No 142/2011 implementing Regulation (EC) No 1069/2009 of the European Parliament and of the Council laying down health rules as regards animal by-products and derived products not intended for human consumption and implementing Council Directive 97/78/EC as regards certain samples and items exempt from veterinary checks at the border under that Directive (Text with EEA relevance).

ANNEX IIU.K. RESTRICTIONS ON THE USE OF ANIMAL BY-PRODUCTS

CHAPTER IU.K. Intra-species recycling of fur animals

1.In Estonia, Latvia and Finland, the following fur animals may be fed with meat-and-bone meal or other products which have been processed in accordance with Chapter III of Annex IV and which are derived from bodies or parts of bodies of animals of the same species:U.K.

[F5foxes ( Vulpes vulpes and Alopex lagopus );]

raccoon dogs (Nyctereutes procyonides).

Textual Amendments

F5 Substituted by Commission Regulation (EU) No 749/2011 of 29 July 2011 amending Regulation (EU) No 142/2011 implementing Regulation (EC) No 1069/2009 of the European Parliament and of the Council laying down health rules as regards animal by-products and derived products not intended for human consumption and implementing Council Directive 97/78/EC as regards certain samples and items exempt from veterinary checks at the border under that Directive (Text with EEA relevance).

2.In Estonia and Latvia, fur animals of the species American mink (Mustela vison) may be fed with meat-and-bone meal or other products which have been processed in accordance with the processing methods set out in Chapter III of Annex IV and which are derived from bodies or parts of bodies of animals of the same species.U.K.

3.The feeding referred to in points 1 and 2 shall take place under the following conditions:U.K.

Feeding shall only take place in farms:

which have been registered by the competent authority on the basis of an application that is accompanied by documentation proving that there is no reason to suspect the presence of the TSE agent in the population of the species covered by the application;

where an appropriate surveillance system for transmissible spongiform encephalopathies (TSEs) in fur animals is in place on the farm and includes regular laboratory testing of samples for TSE;

which have provided appropriate guarantees that no animal by-product or meat-and-bone meal or other products which have been processed in accordance with Chapter III of Annex IV and which are derived from those animals or their offspring may enter the food or feed chain of other animals than fur animals;

which have had no known contact with any farm with a suspected or confirmed outbreak of TSE;

where the operator of the registered farm ensures that:

the carcases of fur animals intended for feeding to animals of the same species are handled and processed separately from carcases not authorised for that purpose,

fur animals fed with meat-and-bone meal or other products which have been processed in accordance with Chapter III of Annex IV and which are derived from animals of the same species are kept separate from animals not being fed with products derived from animals of the same species,

the farm complies with the requirements set out in point 2 of Section 1 of Chapter II of Annex VI and point (2)(b)(ii) of Chapter II of Annex VIII.

The operator of the farm shall ensure that meat-and-bone meal or other products derived from one species and intended for the feeding of the same species must:

have been processed in a processing plant approved under Article 24(1)(a) of Regulation (EC) No 1069/2009 and using only processing methods 1 to 5 or processing method 7 as set out in Chapter III of Annex IV to this Regulation;

have been produced from healthy animals killed for the production of fur.

In the event of any known or suspected contact with any farm with a suspected or confirmed outbreak of TSE, the operator of the farm must immediately:

inform the competent authority of such contact;

cease the dispatch of fur animals to any destination without a written authorisation of the competent authority.

CHAPTER IIU.K. Feeding of farmed animals with herbage

The following conditions shall apply to the feeding of farmed animals with herbage from land, either by direct access of the animals to that land or by using cut herbage as feed, provided that organic fertilisers or soil improvers have been applied to that land:

The waiting period of at least 21 days referred to in Article 11(1)(c) of Regulation (EC) No 1069/2009 must have been observed,

Only organic fertilisers and soil improvers have been used which comply with Article 32(1) and (2) of Regulation (EC) No 1069/2009 and with Chapter II of Annex XI hereto.

However, those conditions shall not apply, provided only the following organic fertilisers or soil improvers have been applied to land:

manure and guano;

digestive tract content, milk, milk-based products, milk-derived products, colostrum and colostrum products, which the competent authority does not consider to present a risk for the spread of any serious animal disease.

[F6ANNEX III U.K. DISPOSAL, RECOVERY AND USE AS A FUEL]

Textual Amendments

CHAPTER IU.K. GENERAL REQUIREMENTS FOR INCINERATION AND CO-INCINERATION

Section 1 U.K. General conditions

1.Operators of incineration and co-incineration plants referred to in Article 6(1)(b) of this Regulation shall ensure that the following hygiene conditions are met in the plants under their control:U.K.

Animal by-products and derived products must be disposed of as soon as possible after arrival, in accordance with conditions laid down by the competent authority. They shall be stored properly until disposal, in accordance with conditions laid down by the competent authority.

Plants must have appropriate arrangements for the cleaning and disinfection of containers and vehicles in place, in particular in a designated area from which wastewater is disposed of in accordance with Union legislation, to avoid risks of contamination.

Plants must be located on a well-drained hardstanding.

Plants must have appropriate arrangements for protection against pests, such as insects, rodents and birds. A documented pest control programme must be used for that purpose.

Staff must have access to adequate facilities for personal hygiene such as lavatories, changing rooms and washbasins, if necessary to prevent risks of contamination.

Cleaning procedures must be established and documented for all parts of the premises. Suitable equipment and cleaning agents must be provided for cleaning.

Hygiene control must include regular inspections of the environment and equipment. Inspection schedules and results must be documented and maintained for at least two years.

2.The operator of an incineration or co-incineration plant shall take all necessary precautions concerning the reception of animal by-products or derived products to prevent, or limit as far as practicable, direct risks to human or animal health.U.K.

3.Animals must not have access to the plants, animal by-products and derived products that are awaiting incineration or co-incineration or to ash resulting from the incineration or co-incineration of animal by-products.U.K.

4.If the incineration or co-incineration plant is located on a livestock holding:U.K.

there must be total physical separation between the incineration or co-incineration equipment and the livestock and their feed and bedding, with fencing where necessary;

equipment must be dedicated entirely to the operation of the incinerator and not used elsewhere on the holding or, alternatively, cleaned and disinfected before such use;

personnel working in the plant must change their outer clothing and footwear before handling livestock or livestock feed.

5.The storage of animal by-products and derived products that are awaiting incineration or co-incineration and of ashes must be in covered, correctly identified and, if appropriate, leak proof containers.U.K.

6.Incompletely incinerated animal by-products must be reincinerated or disposed of by other means, other than by disposal in an authorised landfill, in accordance with Articles 12, 13 and 14, as applicable, of Regulation (EC) No 1069/2009.U.K.

Section 2 U.K. Operating conditions

Incineration or co-incineration plants shall be designed, equipped, built and operated in such a way that the gas resulting from the process is raised in a controlled and homogeneous fashion, even under the most unfavourable conditions, to a temperature of 850 °C for at least 2 seconds or to a temperature of 1 100 °C for 0.2 seconds, as measured near the inner wall or at another representative point of the chamber where the incineration or the co-incineration is carried out, as authorised by the competent authority.

Section 3 U.K. Incineration and co-incineration residues

1.Incineration and co-incineration residues shall be minimised in their amount and harmfulness. Such residues must be recovered, where appropriate, directly in the plant or outside it in accordance with relevant Union legislation or disposed of in an authorised landfill.U.K.

2.Transport and intermediate storage of dry residues, including dust, shall take place in such a way as to prevent dispersal in the environment, such as in closed containers.U.K.

Section 4 U.K. Measurement of temperature and of other parameters

1.Techniques shall be used to monitor the parameters and conditions relevant to the incineration or co-incineration process.U.K.

2.The approval issued by the competent authority, or conditions attached to it, shall lay down temperature measurement requirements.U.K.

3.The functioning of any automated monitoring equipment shall be subject to control and to an annual surveillance test.U.K.

4.Temperature measurement results shall be recorded and presented in an appropriate fashion to enable the competent authority to verify compliance with the permitted operating conditions laid down in this Regulation in accordance with procedures to be decided upon by that authority.U.K.

Section 5 U.K. Abnormal operating

In the case of a breakdown, or abnormal operating conditions of an incineration plant or a co-incineration plant, the operator shall reduce or close down operations as soon as practicable until normal operations can be resumed.

CHAPTER IIU.K. HIGH-CAPACITY INCINERATION AND CO-INCINERATION PLANTS

Section 1 U.K. Specific operating conditions

Incineration or co-incineration plants treating only animal by-products and derived products with a capacity of more than 50 kg per hour (high-capacity plants) and which are not required to have a permit to operate in accordance with Directive 2000/76/EC shall comply with the following conditions:

The plants must be equipped for each line with at least one auxiliary burner. This burner shall be switched on automatically when the temperature of the combustion gases after the last injection of combustion air falls below 850 °C or 1 100 °C, as applicable. It must also be used during plant start-up and shut-down operations to ensure that the temperature of 850 °C or of 1 100 °C, as applicable, is maintained at all times during these operations and as long as unburned material is in the chamber where the incineration or co-incineration is carried out.

When animal by-products or derived products are introduced into the chamber where the incineration or co-incineration is carried out by a continuous process, the plant must operate an automatic system to prevent the introduction of animal by-products or derived products at start-up, until the temperature of 850 °C or of 1 100 °C, as applicable, has been reached, and whenever the temperature is not maintained.

The operator must operate the incineration plant in such manner that a level of incineration is achieved such that the slag and bottom ashes total organic carbon content is less than 3 % or their loss on ignition is less than 5 % of the dry weight of the material. If necessary, appropriate techniques of pre-treatment shall be used.

Section 2 U.K. Water discharges

1.Sites of high capacity plants, including associated storage areas for animal by-products, shall be designed in such a way as to prevent unauthorised and accidental release of any polluting substances into soil, surface water and groundwater.U.K.

2.Storage capacity shall be provided for contaminated rainwater run-off from the plant site or for contaminated water arising from spillage or firefighting operations.U.K.

The operator shall, if necessary, ensure that such rainwater and such water can be tested and treated before discharge, when necessary.

CHAPTER IIIU.K. LOW-CAPACITY INCINERATION AND CO-INCINERATION PLANTS

Incineration and co-incineration plants treating only animal by-products and derived products with a maximum capacity of less than 50 kg of animal by-products per hour or per batch (low-capacity plants) and which are not required to have a permit to operate in accordance with Directive 2000/76/EC shall:

[F3only be used for the disposal of:

dead pet animals referred to in Article 8(a)(iii) of Regulation (EC) No 1069/2009;

Category 1 materials referred to in Article 8(b), (e) and (f), Category 2 materials referred to in Article 9 or Category 3 materials referred to in Article 10 of that Regulation; and

dead individually identified equine animals from holdings not subject to health restrictions in accordance with Article 4(5) or 5 of Directive 2009/156/EC, if authorised by the Member State;]

when Category 1 materials referred to in Article 8(b) of Regulation (EC) No 1069/2009 are introduced into the low-capacity plant, be equipped with an auxiliary burner;

operate in such way that the animal by-products are completely reduced to ash.

[F7CHAPTER IV U.K. GENERAL REQUIREMENTS FOR THE USE OF ANIMAL BY-PRODUCTS AND DERIVED PRODUCTS AS A FUEL

Section 1 U.K. General requirements regarding the combustion of animal by-products and derived products as a fuel

1. Operators of combustion plants referred to in Article 6(6) shall ensure that the following conditions are met in the combustion plants under their control: U.K.

Animal by-products and derived products intended to be used as a fuel must be utilised for that purpose as soon as possible or safely stored until used.

The combustion plants must have in place appropriate measures to ensure that cleaning and disinfection of containers and vehicles are carried out in a designated area of their premises from which the wastewater can be collected and disposed of in accordance with Union legislation, to avoid risks of contamination of the environment.

By way of derogation from the requirements set out in the first subparagraph, containers and vehicles used for the transport of rendered fats may be cleaned and disinfected at the plant of loading or at any other plant approved or registered under Regulation (EC) No 1069/2009.

The combustion plants must be located on a well-drained hard standing.

The combustion plants must have appropriate measures in place for the protection against pests. A documented pest control programme must be used for that purpose.

Staff must have access to adequate facilities for personal hygiene such as lavatories, changing rooms and washbasins, if necessary, to prevent risks of contamination of equipment for handling of farmed animals or their feedstuffs.

Cleaning and disinfection procedures, must be established and documented for all parts of the combustion plant. Suitable equipment and cleaning agents must be provided for cleaning.

Hygiene control must include regular inspections of the environment and equipment. Inspection schedules and results must be documented and retained for a period of at least two years.

Where rendered fats are used as a fuel for combustion in stationary internal combustion engines located within approved or registered food or feed processing plants, the processing of food or feed on the same site must take place under strict conditions of separation.

2. Operators of the combustion plants shall take all necessary precautions concerning the reception of animal by-products or derived products to prevent or limit as far as practicable, risks to human or animal health and the environment. U.K.

3. Animals must not have access to the combustion plant or to the animal by-products and derived products awaiting combustion or the ash resulting from the combustion. U.K.

4. Where the combustion plant is located on a holding keeping animals of food producing species: U.K.

there must be total physical separation between the combustion equipment and the animals including their feed and bedding;

equipment must be dedicated entirely to the operation of the combustion plant and not used elsewhere on the holding unless it had been effectively cleaned and disinfected before such use;

personnel working in the combustion plant must change their outer clothing and footwear and take personal hygiene measures before handling animals on this or any other holding or their feed or bedding material.

5. The animal by-products and derived products that are awaiting combustion as a fuel and the combustion residues must be stored in a closed and covered dedicated area, or in covered and leak-proof containers. U.K.

6. The combustion of animal by-products or derived products shall be carried out under conditions which prevent cross-contamination of feed for animals. U.K.

Section 2 U.K. Operating conditions of combustion plants

1. Combustion plants must be designed, built, equipped and operated in such a way that even under the most unfavourable conditions the animal by-products and derived products are treated for at least for 2 seconds at a temperature of 850 °C or for at least 0,2 seconds at a temperature of 1 100 °C. U.K.

2. The gas resulting from the process is raised in a controlled and homogeneous fashion for 2 seconds to a temperature of 850 °C or for 0,2 seconds to a temperature of 1 100 °C. U.K.

The temperature must be measured near the inner wall or at another representative point of the combustion chamber, as authorised by the competent authority.

3. Automated techniques shall be used to monitor the parameters and conditions relevant to the combustion process. U.K.

4. Temperature measurement results shall be recorded automatically and presented in an appropriate fashion to enable the competent authority to verify compliance with the permitted operating conditions referred to in points 1 and 2 in accordance with procedures to be decided upon by the relevant authority. U.K.

5. The operator of a combustion plant shall ensure that the fuel is combusted in such a way that the total organic carbon content of the slags and bottom ashes is less than 3 % or their loss on ignition is less than 5 % of the dry weight of the material. U.K.

Section 3 U.K. Combustion residues

1. Combustion residues shall be minimised in their amount and harmfulness. Such residues must be recovered, or where it is not appropriate, disposed of or used in accordance with relevant Union legislation. U.K.

2. The transport and intermediate storage of dry residues, including dust, shall take place in closed containers or in another way which prevents dispersal into the environment. U.K.

Section 4 U.K. Breakdown or abnormal operating conditions

1. The combustion plant shall be equipped with facilities which automatically shut down operations in the case of a breakdown or abnormal operating conditions until normal operations can be resumed. U.K.

2. Incompletely combusted animal by-products and derived products must be combusted again or disposed of by means referred to in Articles 12, 13 and 14 of Regulation (EC) No 1069/2009 other than disposal in an authorised landfill. U.K.

Textual Amendments

CHAPTER V U.K. TYPES OF PLANTS AND FUELS THAT MAY BE USED FOR COMBUSTION AND SPECIFIC REQUIREMENTS FOR PARTICULAR TYPES OF PLANTS

A. Stationary internal combustion engines U.K.

1. Starting material: U.K.

For this process, a fat fraction derived from animal by-products of all categories may be used provided it meets the following conditions:

unless fish oil or rendered fat is used which has been produced in accordance with Section VIII or XII of Annex III to Regulation (EC) No 853/2004, respectively, the fat fraction derived from animal by-products must first be processed using:

in the case of a fat fraction of Category 1 and 2 materials, any of the processing methods 1 to 5 as set out in Chapter III of Annex IV.

Where this fat is moved by a closed conveyer system, which may not be by-passed, and provided such a system has been authorised by the competent authority, from the processing plant for immediate direct combustion the permanent marking with glyceroltriheptanoate (GTH) referred to in point 1 of Chapter V of Annex VIII shall not be required;

in the case of a fat fraction of Category 3 material, any of the processing methods 1 to 5 or processing method 7 as set out in Chapter III of Annex IV;

in the case of the materials derived from fish, any of the processing methods 1 to 7 as set out in Chapter III of Annex IV;

the fat fraction must be separated from the protein and in the case of fat from ruminant origin which is intended to be combusted in another plant, insoluble impurities in excess of 0,15 % by weight must be removed.

2. Methodology: U.K.

Combustion of animal fat as a fuel in a stationary internal combustion engine shall be carried out as follows:

the fat fractions referred to in points 1(a) and (b) must be combusted:

under the conditions laid down in Section 2(1) of Chapter IV; or

using process parameters achieving an equivalent outcome as the conditions under (i) and which are authorised by the competent authority;

the combustion of material of animal origin other than animal fat must not be permitted;

the animal fat derived from Category 1 or Category 2 combusted in premises approved or registered in accordance with Regulations (EC) No 852/2004, (EC) No 853/2004, 183/2005, or in public places must have been processed with processing method 1 as set out in Chapter III of Annex IV;

the combustion of animal fat must be carried out in accordance with Union legislation for the protection of the environment, in particular, with reference to the standards and requirements of that legislation and the requirements regarding best available techniques for the control and monitoring of emissions.

3. Operating conditions: U.K.

By way of derogation from the requirements set out in the first paragraph of point 2 of Section 2 of Chapter IV, requirements based on other process parameters, which ensure an equivalent environmental outcome may be authorised by the competent authority responsible for environmental issues.

B. On-farm combustion plants in which poultry manure is used as a fuel U.K.

1. Type of plant: U.K.

On-farm combustion plant with a total rated thermal input not exceeding 5 MW.

2. Starting material and scope: U.K.

Exclusively unprocessed poultry manure, as referred to in Article 9(a) of Regulation (EC) No 1069/2009, to be used as a fuel for combustion in accordance with the requirements set out in point 3 to 5.

The combustion of other animal by-products or derived products and of manure of other species or generated outside the holding shall not be allowed for use as a fuel in on-farm combustion plants referred to in point 1.

3. Specific requirements for poultry manure used as a fuel for combustion: U.K.

The manure shall be stored securely in a closed storage area to minimise the need for further handling and to prevent cross contamination with other areas on a holding keeping animals of food producing species.

The on-farm combustion plant must be equipped with:

an automatic fuel management system to place the fuel directly in the combustion chamber without further handling;

an auxiliary burner which must be used during start-up and shut-down operations to ensure that the temperature requirements set out in Section 2(2) of Chapter IV are met at all times during those operations and as long as unburned material is in the combustion chamber.

4. Emission limit values and monitoring requirements: U.K.

The emissions of sulphur dioxide, nitrogen oxides (namely the sum of nitrogen monoxide and nitrogen dioxide, expressed as nitrogen dioxide) and particulate matter shall not exceed the following emission limit values, expressed in mg/Nm 3 at a temperature of 273,15 K, a pressure of 101,3 kPa and an oxygen content of 11 per cent, after correction for the water vapour content of the waste gases:

| Pollutant | Emission limit value in mg/Nm 3 |

|---|---|

| Sulphur dioxide | 50 |

| Nitrogen oxides (as NO 2 ) | 200 |

| Particulate matter | 10 |

The operator of the on-farm combustion plant shall carry out at least annual measurements of sulphur dioxide, nitrogen oxides and particulate matter.

As an alternative to the measurements referred to in the first subparagraph, other procedures, verified and approved by the competent authority, may be used to determine the emissions of sulphur dioxide.

Monitoring shall be carried out by or on behalf of the operator in accordance with CEN standards. Where CEN standards are not available, ISO, national or other international standards which ensure the provision of data of an equivalent scientific quality shall apply.

All results shall be recorded, processed and presented in such a way as to enable the competent authority to verify compliance with the emission limit values.

For on-farm combustion plants applying secondary abatement equipment in order to meet the emission limit values, the effective operation of that equipment shall be monitored continuously and the results thereof recorded.

In the event of non-compliance with the emission limit values referred to in point (a) or where an on-farm combustion plant does not meet the requirements of point 1 of Section 2 of Chapter IV, operators shall immediately inform the competent authority and take the measures necessary to ensure that compliance is restored within the shortest possible time. Where compliance cannot be restored, the competent authority shall suspend the operation of the plant and withdraw its approval.

5. Changes of operation and breakdowns: U.K.

The operator shall notify the competent authority of any planned change of the on-farm combustion plant which would affect its emissions at least one month before the date on which the change takes place.

The operator shall take the necessary measures to ensure that the periods of start-up and shut-down of the on-farm combustion plant and of any malfunctions are kept as short as possible. In the case of a malfunction or a breakdown of secondary abatement equipment, the operator shall immediately inform the competent authority.]

ANNEX IVU.K. PROCESSING

CHAPTER IU.K. REQUIREMENTS FOR PROCESSING PLANTS AND CERTAIN OTHER PLANTS AND ESTABLISHMENTS

Section 1 U.K. General conditions

1.Processing plants shall meet the following requirements, for processing by pressure sterilisation or in accordance with the processing methods referred to in Article 15(1)(b) of Regulation (EC) No 1069/2009:U.K.

Processing plants must not be situated on the same site as slaughterhouses or other establishments which have been approved or registered in accordance with Regulation (EC) No 852/2004 or Regulation (EC) No 853/2004, unless the risks to public and animal health resulting from the processing of animal by-products, which originate from such slaughterhouses or other establishments, are mitigated by compliance with at least the following conditions:

the processing plant must be physically separated from the slaughterhouse or other establishment, where appropriate by locating the processing plant in a building that is completely separated from the slaughterhouse or other establishment;

the following must be installed and operated in the processing plant:

a conveyer system which links the processing plant to the slaughterhouse or other establishment and which may not be by-passed,

separate entrances, reception bays, equipment and exits for both the processing plant and the slaughterhouse or establishment;

measures must be taken to prevent the spreading of risks through the operation of personnel which is employed in the processing plant and in the slaughterhouse or other establishment;

unauthorised persons and animals must not have access to the processing plant.

By way of derogation from points (i) to (iv), in the case of processing plants processing Category 3 material, the competent authority may authorise other conditions instead of those set out in those points, aimed at mitigating the risks to public and animal health, including the risks arising from the processing of Category 3 material, which originates from off-site establishments approved or registered in accordance with Regulation (EC) No 852/2004 or Regulation (EC) No 853/2004.

Member States shall inform the Commission and the other Member States in the framework of the Standing Committee on the Food Chain and Animal Health referred to in Article 52(1) of Regulation (EC) No 1069/2009 of the use made of this derogation by their competent authorities;

The processing plant must have a clean and unclean sector, adequately separated. The unclean sector must have a covered place to receive animal by-products and must be constructed in such a way that it is easy to clean and disinfect. Floors must be laid in such a way as to facilitate the draining of liquids;

The processing plant must have adequate facilities including lavatories, changing rooms and washbasins for staff;

The processing plant must have sufficient production capacity for hot water and steam for the processing of animal by-products;

The unclean sector must, if appropriate, contain equipment to reduce the size of animal by-products and equipment for loading the crushed animal by-products into the processing unit;

Where heat treatment is required, all installations must be equipped with:

measuring equipment to monitor temperature against time and, if applicable for the processing method used, pressure at critical points;

recording devices to record continuously the results of these measurements in a way so that they remain accessible for the purpose of checks and official controls;

an adequate safety system to prevent insufficient heating;

To prevent recontamination of the derived product by the introduction of animal by-products, there must be a clear separation between the area of the plant where incoming material for processing is unloaded and the areas set aside for the processing of that product and the storage of the derived product.

2.The processing plant must have adequate facilities for cleaning and disinfecting the containers or receptacles in which animal by-products are received and the means of transport, other than ships, in which they are transported.U.K.

3.Adequate facilities must be provided for the disinfecting of vehicle wheels and the other parts of the vehicle, as appropriate, on leaving the unclean sector of the processing plant.U.K.

4.All processing plants must have a waste-water disposal system meeting the requirements set out by the competent authority in accordance with Union legislation.U.K.

5.The processing plant must have its own laboratory or make use of the services of an external laboratory. The laboratory must be equipped to carry out necessary analyses and be approved by the competent authority on the basis of an assessment of the capacity of the laboratory to carry out those analyses, be accredited according to internationally recognised standards or be subject to regular controls by the competent authority, to assess the capacity of the laboratory to carry out those analyses.U.K.

6.If on the basis of a risk assessment, the volume of products treated requires the regular or permanent presence of the competent authority, the processing plants must have an adequately equipped lockable room for the exclusive use of the inspection service.U.K.

Section 2 U.K. Wastewater treatment

1.Processing plants processing Category 1 material and other premises where specified risk material is removed, slaughterhouses and processing plants processing Category 2 material shall have a pre-treatment process for the retention and collection of animal material as an initial step in the treatment of wastewater.U.K.

The equipment used in the pre-treatment process shall consist of drain traps or screens with apertures with a filter pore or a mesh size of no more than 6 mm in the downstream end of the process or equivalent systems that ensure that the solid particles in the wastewater passing through them are no more than 6 mm.

2.Wastewater from the premises as referred to in point 1 must enter a pre-treatment process which shall ensure that all wastewater has been filtered through the process before being drained off the premises. No grinding, maceration or any other processing or application of pressure shall be carried out which could facilitate the passage of solid animal material through the pre-treatment process.U.K.

3.All animal material retained in the pre-treatment process in premises as referred to in point 1 shall be collected and transported as Category 1 or Category 2 material, as appropriate, and disposed of in accordance with Regulation (EC) No 1069/2009.U.K.

4.Wastewater having passed the pre-treatment process in premises referred to in point 1 and wastewater from other premises handling or processing animal by-products shall be treated in accordance with Union legislation, without restrictions in accordance with this Regulation.U.K.

5.In addition to the requirements laid down in point 4, the competent authority may oblige operators to treat wastewater originating in the unclean sector of processing plants and in plants or establishments carrying out intermediate operations with Category 1 material or Category 2 material or storing Category 1 material or Category 2 material, in accordance with conditions which ensure that risks from pathogens are mitigated.U.K.

6.Without prejudice to points 1 to 5, the disposal of animal by-products, including blood and milk, or derived products through the wastewater stream shall be prohibited.U.K.

However, Category 3 material comprising of centrifuge or separator sludge may be disposed of through the wastewater stream, provided that it has been subject to one of the treatments for centrifuge or separator sludge set out in Part III of Section 4 of Chapter II of Annex X hereto.

Section 3 U.K. Specific requirements for the processing of Category 1 and Category 2 materials

The layout of processing plants processing Category 1 and Category 2 materials must ensure the total separation of Category 1 material from Category 2 material from reception of the raw material until dispatch of the resulting derived product, unless a mixture of Category 1 material and Category 2 material is processed as Category 1 material.

Section 4 U.K. Specific requirements for the processing of Category 3 materials

The following requirements shall apply in addition to the general conditions set out in Section 1:

Processing plants processing Category 3 materials shall not be located at the same site as processing plants processing Category 1 or Category 2 materials, unless located in a completely separate building.

However, the competent authority may authorise the processing of Category 3 material on a site where handling or processing of Category 1 or Category 2 material takes place, if cross-contamination is prevented due to:

the layout of the premises, in particular the arrangements for the reception, and by way of the further handling of raw materials;

the layout and the management of the equipment used for processing, including the layout and the management of separate processing lines or of cleaning procedures which are excluding the propagation of any possible risks to public and animal health; and

the layout and the management of the areas for the temporary storage of the end products.

Processing plants processing Category 3 material shall have in place an installation to check the presence of foreign bodies, such as packaging material or metallic pieces, in the animal by-products or derived products, if they are processing materials which are destined for feeding. Such foreign bodies shall be removed before or during processing.

CHAPTER IIU.K. HYGIENE AND PROCESSING REQUIREMENTS

Section 1 U.K. General hygiene requirements

In addition to the general hygiene requirements provided for in Article 25 of Regulation (EC) No 1069/2009, processing plants shall have a documented pest control programme in place for the implementation of the arrangements for protection against pests, such as insects, rodents and birds, referred to in Article 25(1)(c) of that Regulation.

Section 2 U.K. General processing requirements

1.Accurately calibrated gauges/recorders must be used to monitor continuously the processing conditions. Records must be kept to show the date of calibration of gauges/recorders.U.K.

2.Material that may not have received the specified heat treatment, such as material discharged at start up or leakage from cookers, must be recirculated through the heat treatment or collected and reprocessed or disposed of in accordance with Regulation (EC) No 1069/2009.U.K.

Section 3 U.K. Processing methods for Category 1 and Category 2 material

Unless the competent authority requires the application of pressure sterilisation (method 1), Category 1 and Category 2 material shall be processed in accordance with processing methods 2, 3, 4 or 5 as referred to in Chapter III.

Section 4 U.K. Processing of Category 3 material

1.The critical control points that determine the extent of the heat treatments applied in processing shall include for each processing method as specified in Chapter III:U.K.

raw material particle size;

temperature achieved in the heat treatment process;

pressure, if applied to the raw material;

duration of the heat treatment process or feed rate to a continuous system. Minimum processing standards must be specified for each applicable critical control point.

2.In the case of chemical treatments which have been authorised by the competent authority as processing method 7 in accordance with point G of Chapter III, the critical control points that determine the extent of the chemical treatments applied shall include the pH adjustment achieved.U.K.

3.Records shall be maintained for at least two years to show that the minimum process values for each critical control point are applied.U.K.

4.Category 3 material shall be processed in accordance with any of the processing methods 1 to 5 or processing method 7, or, in the case of material originating from aquatic animals, with any of the processing methods 1 to 7, as referred to in Chapter III.U.K.

CHAPTER IIIU.K. STANDARD PROCESSING METHODS

A.Processing method 1 (pressure sterilisation)U.K.

ReductionU.K.

1.If the particle size of the animal by-products to be processed is more than 50 millimetres, the animal by-products must be reduced in size using appropriate equipment, set so that the particle size after reduction is no greater than 50 millimetres. The effectiveness of the equipment must be checked daily and its condition recorded. If checks disclose the existence of particles larger than 50 millimetres, the process must be stopped and repairs made before the process is resumed.U.K.

Time, temperature and pressureU.K.

2.The animal by-products with the particle size of no greater than 50 millimetres must be heated to a core temperature of more than 133 °C for at least 20 minutes without interruption at a pressure (absolute) of at least 3 bars. The pressure must be produced by the evacuation of all air in the sterilisation chamber and the replacement of the air by steam (‘saturated steam’); the heat treatment may be applied as the sole process or as a pre- or post-process sterilisation phase.U.K.

3.The processing may be carried out in batch or continuous systems.U.K.

B.Processing method 2U.K.

ReductionU.K.

1.If the particle size of the animal by-products to be processed is more than 150 millimetres, the animal by-products must be reduced in size using appropriate equipment, set so that the particle size after reduction is no greater than 150 millimetres. The effectiveness of the equipment must be checked daily and its condition recorded. If checks disclose the existence of particles larger than 150 millimetres, the process must be stopped and repairs made before the process is resumed.U.K.

Time, temperature and pressureU.K.

2.After reduction the animal by-products must be heated in a manner which ensures that a core temperature greater than 100 °C is achieved for at least 125 minutes, a core temperature greater than 110 °C is achieved for at least 120 minutes and a core temperature greater that 120 °C is achieved for at least 50 minutes.U.K.

The core temperatures may be achieved consecutively or through a coincidental combination of the time periods indicated.

3.The processing must be carried out in a batch system.U.K.

C.Processing method 3U.K.

ReductionU.K.

1.If the particle size of the animal by-products to be processed is more than 30 millimetres, the animal by-products must be reduced in size using appropriate equipment, set so that the particle size after reduction is no greater than 30 millimetres. The effectiveness of the equipment must be checked daily and its condition recorded. If checks disclose the existence of particles larger than 30 millimetres, the process must be stopped and repairs made before the process is resumed.U.K.

Time, temperature and pressureU.K.

2.After reduction the animal by-products must be heated in a manner which ensures that a core temperature greater than 100 °C is achieved for at least 95 minutes, a core temperature greater than 110 °C is achieved for at least 55 minutes and a core temperature greater that 120 °C is achieved for at least 13 minutes.U.K.

The core temperatures may be achieved consecutively or through a coincidental combination of the time periods indicated.

3.The processing may be carried out in batch or continuous systems.U.K.

D.Processing method 4U.K.

ReductionU.K.

1.If the particle size of the animal by-products to be processed is more than 30 millimetres, the animal by-products must be reduced in size using appropriate equipment, set so that the particle size after reduction is no greater than 30 millimetres. The effectiveness of the equipment must be checked daily and its condition recorded. If checks disclose the existence of particles larger than 30 millimetres, the process must be stopped and repairs made before the process is resumed.U.K.

Time, temperature and pressureU.K.

2.After reduction the animal by-products must be placed in a vessel with added fat and heated in a manner which ensures that a core temperature greater than 100 °C is achieved for at least 16 minutes, a core temperature greater than 110 °C is achieved for at least 13 minutes, a core temperature greater than 120 °C is achieved for at least eight minutes and a core temperature greater that 130 °C is achieved for at least three minutes.U.K.

The core temperatures may be achieved consecutively or through a coincidental combination of the time periods indicated.

3.The processing may be carried out in batch or continuous systems.U.K.

E.Processing method 5U.K.

ReductionU.K.

1.If the particle size of the animal by-products to be processed is more than 20 millimetres, the animal by-products must be reduced in size using appropriate equipment, set so that the particle size after reduction is no greater than 20 millimetres. The effectiveness of the equipment must be checked daily and its condition recorded. If checks disclose the existence of particles larger than 20 millimetres, the process must be stopped and repairs made before the process is resumed.U.K.

Time, temperature and pressureU.K.

2.After reduction the animal by-products must be heated until they coagulate and then pressed so that fat and water are removed from the proteinaceous material. The proteinaceous material must then be heated in a manner which ensures that a core temperature greater than 80 °C is achieved for at least 120 minutes and a core temperature greater that 100 °C is achieved for at least 60 minutes.U.K.

The core temperatures may be achieved consecutively or through a coincidental combination of the time periods indicated.

3.The processing may be carried out in batch or continuous systems.U.K.

F.Processing method 6 (for Category 3 animal by-products originating from aquatic animal or aquatic invertebrates only)U.K.

ReductionU.K.

1.The animal by-products must be reduced to a particle size which is no greater than:U.K.

50 mm, in case of heat treatment in accordance with point 2(a); or

30 mm, in case of heat treatment in accordance with point 2(b).

They must then be mixed with formic acid to reduce and maintain the pH to 4,0 or lower. The mixture must be stored for at least 24 hours pending further treatment.

Time, temperature and pressureU.K.

2.After reduction, the mixture must be heated to:U.K.

a core temperature of at least 90 °C for at least 60 minutes; or

a core temperature of at least 70 °C for at least 60 minutes.

When using a continuous flow system, the progression of the product through the heat converter must be controlled by means of mechanical commands limiting its displacement in such way that at the end of the heat treatment operation the product has undergone a cycle which is sufficient in both time and temperature.

3.The processing may be carried out in batch or continuous systems.U.K.

G.Processing method 7U.K.

1.Any processing method authorised by the competent authority where the following have been demonstrated by the operator to that authority:U.K.

the identification of relevant hazards in the starting material, in view of the origin of the material, and of the potential risks in view of the animal health status of the Member State or the area or zone where the method is to be used;

the capacity of the processing method to reduce those hazards to a level which does not pose any significant risks to public and animal health;

the sampling of the final product on a daily basis over a period of 30 production days in compliance with the following microbiological standards:

Samples of material taken directly after the treatment:

Clostridium perfringens absent in 1 g of the products

Samples of material taken during or upon withdrawal from storage:

Salmonella: absence in 25g: n=5, c=0, m=0, M=0

Enterobacteriaceae: n=5, c=2; m=10; M=300 in 1 g

where:

=

number of samples to be tested;

=

threshold value for the number of bacteria; the result is considered satisfactory if the number of bacteria in all samples does not exceed m;

=

maximum value for the number of bacteria; the result is considered unsatisfactory if the number of bacteria in one or more samples is M or more; and

=

number of samples the bacterial count of which may be between m and M, the samples still being considered acceptable if the bacterial count of the other samples is m or less.

2.Details of the critical control points under which each processing plant satisfactorily complies with the microbiological standards must be recorded and maintained so that the operator and the competent authority can monitor the operation of the processing plant. The information to be recorded and monitored must include the particle size, and, as appropriate, the critical temperature, the absolute time, pressure profile, raw material feed rate and fat recycling rate.U.K.

3.By way of derogation from point 1, the competent authority may authorise the use of processing methods which have been approved prior to the date of entry into application of this Regulation, in accordance with Chapter III of Annex V to Regulation (EC) No 1774/2002.U.K.

4.The competent authority shall permanently or temporarily suspend the application of processing methods referred to in points 1 and 3, if it obtains evidence that any of the circumstances specified in point 1(a) or (b) have substantially changed.U.K.

5.The competent authority shall inform the competent authority of another Member State upon request about the information at its disposal under points 1 and 2 in relation to an authorised processing method.U.K.

CHAPTER IVU.K. ALTERNATIVE PROCESSING METHODS

Section 1 U.K. General provisions

[F51. Materials resulting from the processing of Category 1 and 2 materials shall be permanently marked in accordance with the requirements for the marking of certain derived products set out in Chapter V of Annex VIII. U.K.

However, such marking shall not be required for the following materials referred to in Section 2:

biodiesel produced in accordance with point D;

hydrolysed materials referred to in point H;

mixtures of pig and poultry manure with quick lime produced in accordance with point I;

renewable fuels produced from rendered fats, which are derived from Category 2 materials, in accordance with point J.]

2.The competent authority of a Member State shall make the results of official controls available to the competent authority of another Member State upon request, when an alternative method is used for the first time in that Member State, in order to facilitate the introduction of the new alternative method.U.K.

Section 2 U.K. Processing standards

A.Alkaline hydrolysis processU.K.

1.Starting materialU.K.

For this process, animal by-products of all categories may be used.

2.Processing methodU.K.

Alkaline hydrolysis shall be carried out according to the following processing standards:

Either a sodium hydroxide (NaOH) or potassium hydroxide (KOH) solution (or a combination thereof) must be used in an amount that assures approximate molar equivalency to the weight, type and composition of the animal by-products to be digested.

In the case of high fat in the animal by-products that neutralises the base, the added base must be adjusted so that the molar equivalency referred to is achieved.

Animal by-products must be placed in a steel alloy container. The measured amount of alkali must be added either in solid form or as a solution as referred to in point (a).

The container must be closed and the animal by-products and alkali mixture must be heated to a core temperature of at least 150 °C and at a pressure (absolute) of at least 4 bars for at least:

three hours without interruption;

six hours without interruption in case of treatment of animal by-products referred to in Article 8(a)(i) and (ii) of Regulation (EC) No 1069/2009.

However, materials derived from Category 1 materials comprising of animals killed in the context of TSE eradication measures which are either ruminants not requiring TSE testing or ruminants which have been tested with a negative result in accordance with Article 6(1) of Regulation (EC) No 999/2001 may be processed in accordance with point 2(c)(i) of this Section; or

one hour without interruption in the case of animal by-products consisting of fish or of poultry materials.

The process must be carried out in a batch system and the material in the vessel must be constantly mixed in order to facilitate the digestion process until the tissues are dissolved and bones and teeth are softened; and

The animal by-products must be treated in such way that the requirements regarding time, temperature and pressure are achieved at the same time.

B.High pressure high temperature hydrolysis processU.K.

1.Starting materialU.K.

For this process, Category 2 and Category 3 materials may be used.

2.Processing methodU.K.

High pressure high temperature hydrolysis shall be carried out according to the following processing standards:

The animal by-products must be heated to a core temperature of at least 180 °C for at least 40 minutes without interruption at a pressure (absolute) of at least 12 bar, heated by indirect steam application to the biolytic reactor;

The process must be carried out in a batch and the material in the vessel must be constantly mixed; and

The animal by-products must be treated in such a manner that the requirements regarding time, temperature and pressure are achieved at the same time.

C.High pressure hydrolysis biogas processU.K.

1.Starting materialU.K.

For this process, animal by-products of all categories may be used.

2.Processing methodU.K.

The high pressure hydrolysis biogas process shall be carried out according to the following processing standards:

The animal by-products must be first processed using processing method 1 (pressure sterilisation) as set out in Chapter III in an approved processing plant;

Following the process referred to in point (a), the defatted materials must be treated at a temperature of at least 220 °C for at least 20 minutes at a pressure (absolute) of at least 25 bar, heated in a two-step procedure, first by direct steam injection, secondly indirect in a coaxial heat exchanger;

The process must be carried out in a batch or continuous system and the material is constantly mixed;

The animal by-products must be treated in such a manner that the requirements regarding time, temperature and pressure are achieved at the same time;

The resulting material must then be mixed with water and anaerobically fermented (biogas transformation) in a biogas reactor;

In the case of starting material of Category 1, the entire process must take place on the same site and in a closed system and the biogas produced during the process must be combusted rapidly in the same plant at a minimum of 900 °C followed by rapid chilling (‘quenching’).

D.Biodiesel production processU.K.

1.Starting materialU.K.

For this process, a fat fraction derived from animal by-products of all categories may be used.

2.Processing methodU.K.

Biodiesel production shall be carried out according to the following processing standards:

Unless fish oil or rendered fat are used which have been produced in accordance with Sections VIII or XII of Annex III to Regulation (EC) No 853/2004, respectively, the fat fraction derived from animal by-products must be first processed using:

in the case of Category 1 or 2 materials, processing method 1 (pressure sterilisation) as set out in Chapter III; and

in the case of Category 3 materials, any of the processing methods 1 to 5 or processing method 7 or, in the case of material derived from fish, processing methods 1 to 7 as set out in Chapter III;

The processed fat must then be processed further using one of the following methods:

a process whereby the processed fat must be separated from the protein and in the case of fat from ruminant origin, insoluble impurities in excess of 0,15 % by weight must be removed, and the processed fat must be subsequently submitted to esterfication and transesterfication.

However, esterfication is not required for processed fat derived from Category 3 material. For esterfication the pH must be reduced to less than 1 by adding sulphuric acid (H2SO4) or an equivalent acid and the mixture must be heated to 72 °C for at least two hours during which it must be intensely mixed.

Transesterfication must be carried out by increasing the pH to about 14 with potassium hydroxide or with an equivalent base at 35 °C to 50 °C for at least 15 minutes. Transesterfication shall be carried out twice under the conditions described in this point using a new base solution. This process must be followed by refinement of the products including vacuum distillation at 150 °C, leading to biodiesel;

a process using equivalent process parameters authorised by the competent authority.

E.Brookes’ gasification processU.K.

1.Starting materialU.K.

For this process, Category 2 and Category 3 material may be used.

2.Processing methodU.K.

Brookes’ gasification shall be carried out according to the following processing standards:

The afterburner chamber must be warmed up using natural gas;

The animal by-products must be loaded into the primary chamber of the gasificator and the door must be closed. The primary chamber must have no burners and must be heated instead by the transfer of heat by conduction from the afterburner, which must be underneath the primary chamber. The only air admitted to the primary chamber must be via three inlet valves mounted on the main door to enhance the efficiency of the process;

The animal by-products must be volatilised into complex hydrocarbons and the resultant gases must pass from the primary chamber via a narrow opening at the top of the back wall to the mixing and cracking zones, where they must be broken down into their constituent elements. Finally the gases must pass into the afterburner chamber where they must be burned in the flame of a natural gas fired burner in the presence of excess air;

Each process unit must have two burners and two secondary air fans for back-up in case of burner or fan failure. The secondary chamber must be designed to give a minimum residence time of two seconds at a temperature of at least 950 °C under all conditions of combustion;