- Latest available (Revised)

- Original (As adopted by EU)

Commission Regulation (EU) No 1230/2012Show full title

Commission Regulation (EU) No 1230/2012 of 12 December 2012 implementing Regulation (EC) No 661/2009 of the European Parliament and of the Council with regard to type-approval requirements for masses and dimensions of motor vehicles and their trailers and amending Directive 2007/46/EC of the European Parliament and of the Council (Text with EEA relevance)

You are here:

- Show Geographical Extent(e.g. England, Wales, Scotland and Northern Ireland)

- Show Timeline of Changes

More Resources

Revised version PDFs

- Revised 02/12/20191.95 MB

- Revised 27/07/20171.11 MB

When the UK left the EU, legislation.gov.uk published EU legislation that had been published by the EU up to IP completion day (31 December 2020 11.00 p.m.). On legislation.gov.uk, these items of legislation are kept up-to-date with any amendments made by the UK since then.

This item of legislation originated from the EU

Legislation.gov.uk publishes the UK version. EUR-Lex publishes the EU version. The EU Exit Web Archive holds a snapshot of EUR-Lex’s version from IP completion day (31 December 2020 11.00 p.m.).

Changes to legislation:

There are currently no known outstanding effects by UK legislation for Commission Regulation (EU) No 1230/2012, ANNEX I.![]()

Changes to Legislation

Revised legislation carried on this site may not be fully up to date. At the current time any known changes or effects made by subsequent legislation have been applied to the text of the legislation you are viewing by the editorial team. Please see ‘Frequently Asked Questions’ for details regarding the timescales for which new effects are identified and recorded on this site.

ANNEX IU.K. TECHNICAL REQUIREMENTS

PART AU.K.Vehicles of category M1 and N1

1.Maximum authorised dimensionsU.K.

1.1.The dimensions shall not exceed the following values:U.K.

Textual Amendments

F1Words in Annex 1 Pt. A point 1.1.2 substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(a)(i)

F2Annex 1 Pt. A point 1.1.3 omitted (E.W.S.) (31.12.2022 at 11.00 p.m.) by virtue of The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(a)(ii)

1.2.For the purposes of measurement of the [F3length and width], the vehicle shall be at its mass in running order, placed on a horizontal and flat surface with tyres inflated at the pressure recommended by the manufacturer.U.K.Textual Amendments

F3Words in Annex 1 Pt. A point 1.2 substituted (E.W.S.) (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(a)(iii)

Textual Amendments

F3Words in Annex 1 Pt. A point 1.2 substituted (E.W.S.) (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(a)(iii)

[F41.3.The devices and equipment referred to in Appendix 1 shall not be taken into account for the determination of the [F5length and width].]U.K.Textual Amendments

F5Words in Annex 1 Pt. A point 1.3 substituted (E.W.S.) (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(a)(iii)

Textual Amendments

F5Words in Annex 1 Pt. A point 1.3 substituted (E.W.S.) (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(a)(iii)

Textual Amendments

F4Substituted by Commission Regulation (EU) 2019/1892 of 31 October 2019 amending Regulation (EU) No 1230/2012 as regards type-approval requirements for certain motor vehicles fitted with elongated cabs and for aerodynamic devices and equipment for motor vehicles and their trailers (Text with EEA relevance).

2.Mass distributionU.K.

2.1.The sum of the technically permissible maximum mass on the axles shall not be less than the technically permissible maximum laden mass of the vehicle.U.K.

2.2.The technically permissible maximum laden mass of the vehicle shall not be less than the mass of the vehicle in running order plus the mass of the passengers plus the mass of the optional equipment plus the mass of the coupling if not included in the mass in running order.U.K.

2.3.Where the vehicle is laden to the technically permissible maximum laden mass, the mass on each axle shall not exceed the technically permissible maximum mass on that axle.U.K.

2.4.Where the vehicle is laden to the technically permissible maximum laden mass, the mass on the front axle shall in no event be less than 30 % of the technically permissible maximum laden mass of the vehicle.U.K.

2.4.1.Where the vehicle is laden to the technically permissible maximum laden mass plus the technically permissible maximum mass at the coupling point, the mass on the front axle shall in no event be less than 20 % of the technically permissible maximum laden mass of the vehicle.U.K.

2.5.Where a vehicle is equipped with removable seats, the verification procedure shall be limited to the condition with the maximum number of seating positions.U.K.

2.6.For the purposes of verifying the requirements laid down in points 2.2, 2.3 and 2.4:U.K.

The seats shall be adjusted as prescribed in point 2.6.1

the masses of the passengers, the pay-mass and the mass of the optional equipment shall be distributed as prescribed in points 2.6.2 to 2.6.4.2.3.

2.6.1.Seat adjustmentU.K.

2.6.1.1.The seats where adjustable shall be moved to their rearmost position.U.K.

2.6.1.2.Where there are other possibilities for adjusting the seat (vertical, angled, seat back, etc.) the adjusted positions shall be as specified by the vehicle manufacturer.U.K.

2.6.1.3.In the case of suspension seats, the seat shall be locked in the position specified by the manufacturer.U.K.

2.6.2.Distribution of the mass of passengersU.K.

2.6.2.1.The mass representing each passenger shall be 75 kg.U.K.

2.6.2.2.The mass for each passenger shall be located at the seating reference point (i.e. the ‘R point’ of the seat)U.K.

2.6.2.3.In the case of special purpose vehicle, the requirement of point 2.6.2.2 shall apply mutatis mutandis (for example, mass of an injured person lying on the stretcher in the case of an ambulance).U.K.

2.6.3.Distribution of the mass of the optional equipmentU.K.

2.6.3.1.The mass of the optional equipment shall be distributed in accordance with the manufacturer’s specifications.U.K.

2.6.4Distribution of the pay-massU.K.

2.6.4.1.M1 vehiclesU.K.

2.6.4.1.1.As regards M1 vehicles, the pay-mass shall be distributed in accordance with the manufacturer’s specifications in agreement with the technical service.U.K.

2.6.4.1.2.As regards motor caravans the minimum pay-mass (PM) shall meet the following requirement:U.K.

Where

is the maximum number of passengers plus the driver and

is the overall length of the vehicle in metre

2.6.4.2.N1 vehiclesU.K.

2.6.4.2.1.As regards vehicles with bodywork, the pay-mass shall be distributed uniformly on the cargo bed;U.K.

2.6.4.2.2.As regards vehicles without bodywork (e.g. chassis-cab), the manufacturer shall state the extreme permissible positions of the centre of gravity of the pay-mass increased by the mass of the equipment intended to accommodate goods (e.g. bodywork, tank, etc.) (for instance: from 0,50 m to 1,30 m in front of the first rear axle);U.K.

2.6.4.2.3.As regards vehicles intended to be fitted with a fifth wheel coupling, the manufacturer shall state the minimum and maximum fifth wheel lead.U.K.

2.7.Additional requirements where the vehicle is capable of towing a trailerU.K.

2.7.1.The requirements referred to in points 2.2, 2.3 and 2.4 shall apply taking into account the mass of the coupling and the technically permissible maximum mass at the coupling point.U.K.

2.7.2.Without prejudice to the requirements of point 2.4, the technically permissible maximum mass on the rear axle(s) may be exceeded by not more than 15 %.U.K.

2.7.2.1.Where the technically permissible maximum mass on the rear axle(s) is exceeded by not more than 15 %, the requirements of point 5.2 of Annex II to Commission Regulation (EU) No 458/2011(1) shall apply.U.K.

2.7.2.2.F6...U.K.Textual Amendments

F6Annex 1 Pt. A point 2.7.2.2 omitted (31.12.2022 at 11.00 p.m.) by virtue of The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(a)(iv)

Textual Amendments

F6Annex 1 Pt. A point 2.7.2.2 omitted (31.12.2022 at 11.00 p.m.) by virtue of The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(a)(iv)

3.Towable mass and mass at the couplingU.K.

3.1.As regards the technically permissible maximum towable mass, the following requirements shall apply:U.K.

3.1.1.Trailer fitted with a service braking systemU.K.

3.1.1.1.The technically permissible maximum towable mass of the vehicle shall be the lowest of the following values:U.K.

the technically permissible maximum towable mass based on the construction features of the vehicle and the strength of the coupling;

the technically permissible maximum laden mass of the towing vehicle;

1,5 times the technically permissible maximum laden mass of the towing vehicle in the case of an off-road vehicle as defined in [F7Annex I to Regulation (EU) 2018/858].

Textual Amendments

F7Words in Annex 1 Pt. A point 3.1.1.1(c) substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(a)(v)

3.1.1.2.However, the technically permissible maximum towable mass shall in no case exceed 3 500 kg.U.K.

3.1.2.Trailer without a service braking systemU.K.

3.1.2.1.The permissible towable mass shall be the lowest of the following values:U.K.

the technically permissible maximum towable mass based on the construction features of the vehicle and the strength of the coupling;

half of the mass in running order of the towing vehicle.

3.1.2.2.The technically permissible maximum towable mass shall in no case exceed 750 kg.U.K.

3.2.The technically permissible maximum mass at the coupling point shall not be less than 4 % of the maximum permissible towable mass and not be less than 25 kg.U.K.

3.3.The manufacturer shall specify in the owner’s manual the technically permissible maximum mass at the coupling point, the mounting points of the coupling on the towing vehicle and the maximum permissible rear overhang for the coupling point.U.K.

3.4.The technically permissible maximum towable mass shall not be defined by reference to the number of passengers.U.K.

4.Mass of the combinationU.K.

The technically permissible maximum laden mass of the combination shall not exceed the sum of the technically permissible maximum laden mass plus the technically permissible maximum towable mass.

MC ≤ M + TM

5.Hill starting abilityU.K.

5.1.The towing vehicle shall be able to start the vehicle combination five times on an uphill gradient of at least 12 % within five minutes.U.K.

5.2.In order to conduct the test described in point 5.1, the towing vehicle and the trailer shall be laden as to equal the technically permissible maximum laden mass of the combination.U.K.

PART BU.K.Vehicles of category M2 and M3

1.Maximum authorised dimensionsU.K.

1.1.The dimensions shall not exceed the following values:U.K.

Length

Vehicle with two axles and one section: 13,50 m

Vehicle with three or more axles and one section: 15,00 m

Articulated vehicle: 18,75 m

Width: 2,55 m;

Height: [F84.57 m]

Textual Amendments

F8Words in Annex 1 Pt. B point 1.1.3 substituted (E.W.S.) (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(b)(i)

1.2.For the purposes of measurement of the length, width and height, the vehicle shall be at its mass in running order, placed on a horizontal and flat surface with tyres inflated at the pressure recommended by the manufacturer.U.K.

[F41.3.The devices and equipment referred to in Appendix 1 shall not be taken into account for the determination of the length, width and height.]U.K.

[F91.3.1.Additional requirements for aerodynamic devices referred to in Appendix 1U.K.

Textual Amendments

F9Inserted by Commission Regulation (EU) 2019/1892 of 31 October 2019 amending Regulation (EU) No 1230/2012 as regards type-approval requirements for certain motor vehicles fitted with elongated cabs and for aerodynamic devices and equipment for motor vehicles and their trailers (Text with EEA relevance).

1.3.1.1.Aerodynamic devices and equipment not exceeding 500 mm in length in the in-use position shall not increase the overall usable cargo space. They shall be constructed in such a way as to make it possible to lock them in the retracted or folded and the in-use positions. Such devices and equipment shall furthermore be constructed so as to be retractable or foldable when the vehicle is at stand-still in such a way that the maximum authorised width of the vehicle referred to in point 1.1.2. is not exceeded by more than 25 mm on each side of the vehicle and the maximum authorised length of the vehicle referred to in point 1.1.1. is not exceeded by more than 200 mm as permitted only from a height above the ground of at least 1 050 mm so that they do not impair the capability of the vehicle to be used for intermodal transport. In addition, the requirements set out in points 1.3.1.1.1 and 1.3.1.1.3. shall be met.U.K.

1.3.1.1.1.The devices and equipment shall be type-approved in accordance with this Regulation.U.K.

1.3.1.1.2.It shall be possible for the operator to vary the position of the aerodynamic device and equipment, and to retract or fold it, by applying a manual force not exceeding 40 daN. In addition, this may be done automatically as well.U.K.

1.3.1.1.3.It is not required for devices and equipment to be retractable or foldable if the maximum dimensional requirements are fully complied with under all conditions.U.K.

1.3.1.2.Aerodynamic devices and equipment exceeding 500 mm in length in the in-use position shall not increase the overall usable cargo space. They shall be constructed in such a way as to make it possible to lock them in both the retracted or folded and the in-use positions. Such devices shall furthermore be constructed so as to be retractable or foldable when the vehicle is at stand-still in such a way that the maximum authorised width of the vehicle referred to in point 1.1.2. is not exceeded by more than 25 mm on each side of the vehicle and the maximum authorised length of the vehicle referred to in point 1.1.1. is not exceeded by more than 200 mm as permitted only from a height above the ground of at least 1 050 mm so that they do not impair the capability of the vehicle to be used for intermodal transport. In addition, the requirements set out in points 1.3.1.2.1. to 1.3.1.2.4. shall be met.U.K.

1.3.1.2.1.The devices and equipment shall be type-approved in accordance with this Regulation.U.K.

1.3.1.2.2.It shall be possible for the operator to vary the position of the aerodynamic device and equipment, and to retract or fold it, by applying a manual force not exceeding 40 daN. In addition, this may be done automatically as well.U.K.

1.3.1.2.3.Each main vertical element or combination of elements and main horizontal element or combination of elements forming the devices and equipment shall, when installed on the vehicle and in the in-use position, withstand vertical and horizontal traction and push forces, applied sequentially in up, down, left and right direction, of 200 daN ± 10 % applied statically to the geometric centre of the relevant perpendicular projected surface, at a maximum pressure of 2,0 MPa. The devices and equipment may deform, but the system for adjustment and locking shall not release as a result of the applied forces. The deformation shall be limited to ensure that the maximum authorised width of the vehicle is not exceeded by more than 25 mm on each side of the vehicle, during and after the test.U.K.

1.3.1.2.4.Each main vertical element or combination of elements and main horizontal element or combination of elements forming the devices and equipment shall also, when in the retracted or folded position, withstand a horizontal traction force applied in longitudinal rearward direction, of 200 daN ± 10 % applied statically to the geometric centre of the relevant perpendicular projected surface, at a maximum pressure of 2,0 MPa. The devices and equipment may deform, but the system for adjustment and locking shall not release as a result of the applied forces. The deformation shall be limited to ensure that the maximum authorised width of the vehicle is not exceeded by more than 25 mm on each side of the vehicle and the maximum authorised length of the vehicle is not exceeded by more than 200 mm.U.K.

1.3.1.3. It shall be verified by the technical service, to the satisfaction of the type-approval authority that aerodynamic devices and equipment positioned in both, the in-use and the retracted or folded positions, do not significantly impair cooling and ventilation of the powertrain, exhaust system and passenger cabin. All other applicable requirements relating to the vehicle systems shall be fully complied with when the devices and equipment are placed in both their in-use and retracted or folded positions. U.K.

By way of derogation concerning the applicable requirements relating to rear underrun protection, the horizontal distances between the rear of the rear underrun protection device and the rear extremity of the vehicle as fitted with aerodynamic devices and equipment may be measured without taking the devices and equipment into account on condition that they exceed 200 mm in length, they are in the in-use condition and the fundamental sections of the elements placed at a height ≤ 2,0 m above the ground measured in unladen condition are made of material having a hardness of < 60 Shore (A). Narrow ribs, tubing and metal wire forming a frame or substrate to support the fundamental sections of the elements shall not be taken into account when determining the hardness. However, in order to eliminate the risk of injuries and penetration of other vehicles in the event of a collision, any ends of such ribs, tubing and metal wire shall not be directed rearward, with the device and equipment both in the retracted or folded and the in-use positions.

As alternative to the derogation referred to in the previous paragraph, the horizontal distances between the rear of the rear underrun protection device and the rear extremity of the vehicle as fitted with aerodynamic devices and equipment may be measured without taking the aerodynamic devices and equipment into account provided that they exceed 200 mm in length, they are in the in-use condition and those devices or equipment comply with the test provisions set out in Appendix 4.

The horizontal distances between the rear of the rear underrun protection device and the rear extremity of the vehicle shall however be measured with the aerodynamic devices and equipment positioned in the retracted or folded position or take into account the resulting projection length in accordance with point 1.6.1 of Appendix 4, if this length exceeds that of the retracted or folded position.]

2.Mass distribution for vehicles fitted with bodyworkU.K.

2.1.Calculation procedureU.K.

Notations:

technically permissible maximum laden mass;

technically permissible maximum towable mass;

technically permissible maximum laden mass of the combination;

technically permissible maximum laden mass on the solo axle designated ‘i’, where ‘i’ varies from 1 to the total number of axles of the vehicle;

technically permissible maximum mass at the coupling point;

the technically permissible maximum mass on the group of axles designated ‘j’, where j varies from 1 to the total number of groups of axles.

2.1.1.Suitable calculations shall be carried out in order to make sure that the following requirements are fulfilled for each technical configuration within the type.U.K.

2.1.2.In the case of vehicles fitted with loadable axles, the following calculations shall be carried out with the suspension of the axles loaded in the normal operating configuration.U.K.

[F92.1.3.In the case of alternatively fuelled or zero-emission motor vehicles:U.K.

2.1.3.1.[F10Any increase in the maximum authorised weight of a vehicle that is permitted for alternative fuel or zero-emission technology in accordance with regulation 4 of the Road Vehicles (Authorised Weight) Regulations 1998 must be determined] on the basis of the documentation provided by the manufacturer. The correctness of the declared information shall be verified by the Technical Service, to the satisfaction of the Type-Approval Authority.U.K.Textual Amendments

F10Words in Annex 1 Pt. B point 2.1.3.1 substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(b)(ii)

Textual Amendments

F10Words in Annex 1 Pt. B point 2.1.3.1 substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(b)(ii)

2.1.3.2. The manufacturer shall indicate [F11one or both of the following additional symbols] as well as the value of the [F12increase in weight] below or to the side of the mandatory inscriptions on the manufacturer’s statutory plate, outside a clearly marked rectangle which shall enclose only the mandatory information. U.K.

‘96/53/EC ARTICLE 10B COMPLIANT – XXXX KG’ [F13, or]

[F14‘AWR REGULATION 4 COMPLIANT – XXXX KG’]

Textual Amendments

F13Word in Annex 1 Pt. B point 2.1.3.2 inserted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(b)(iii)(cc)

F14Words in Annex 1 Pt. B point 2.1.3.2 inserted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(b)(iii)(dd)

The height of the symbol’s characters and stated value shall not be less than 4 mm.

In addition, until the introduction of a dedicated entry in the Certificate of Conformity, the value of the [F12increase in weight] shall be stated under ‘remarks’ in the Certificate of Conformity as to allow inclusion of this information in on-board vehicle registration papers.]

Textual Amendments

F11Words in Annex 1 Pt. B point 2.1.3.2 substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(b)(iii)(aa)

F12Words in Annex 1 Pt. B point 2.1.3.2 substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(b)(iii)(bb)

2.2.General requirementsU.K.

2.2.1.The sum of the technically permissible maximum mass on the solo axles plus the sum of the technically permissible maximum mass on the groups of axles shall not be less than the technically permissible maximum laden mass of the vehicle.U.K.

2.2.2.The mass of the vehicle in running order, plus the mass of the optional equipment, the mass of the passengers, the masses ‘WP’ and ‘B’ referred to in point 2.2.3, plus the mass of the coupling if not included in the mass in running order, plus the technical permissible maximum mass at the coupling point shall not exceed the technically permissible maximum laden mass.U.K.

2.2.3.Load distributionU.K.

2.2.3.1.NotationsU.K.

number of seating positions, not including the driver and crew member(s);

mass of one passenger in kg;

mass of one crew member in kg;

area in m2 for standing passengers;

number of standing passengers stated by the manufacturer;

rated space for one standing passenger in m2;

number of wheelchair spaces multiplied by 250 kg representing the mass of a wheelchair and user;

total volume of baggage compartments in m3 including luggage compartments, racks and ski-box;

maximum permissible mass of the luggage in kg stated by the manufacturer, including the maximum permissible mass (B’) that may be transported in the ski-box if any.

2.2.3.2.The mass Q and Qc of the seated passengers shall be located at the seating reference points (i.e. the ‘R point’ of the seat).U.K.

2.2.3.3.The mass corresponding to the number SP of standing passengers of mass Q shall be uniformly distributed over the surface available for standing passenger S1.U.K.

2.2.3.4.Where appropriate, the mass WP shall be uniformly distributed over each wheelchair space.U.K.

2.2.3.5.A mass equal to B (kg) shall be uniformly distributed in the luggage compartments.U.K.

2.2.3.6.A mass equal to B’ (kg) shall be located at the centre of gravity of the ski-box.U.K.

2.2.3.7.The technically permissible maximum mass at the coupling point shall be located at the coupling point the rear overhang of which is stated by the vehicle manufacturer.U.K.

2.2.3.8.Values of Q and Ssp valuesU.K.

| Vehicle class | Q (kg) | Ssp (m2) |

|---|---|---|

| Class I and A | 68 | 0,125 m2 |

| Class II | 71 | 0,15 m2 |

| Class III and B | 71 | Not applicable |

The mass of each crew member shall be 75 kg.

2.2.3.9.The number of standing passengers shall not exceed the value S1/Ssp, where Ssp is the rated space provided for one standing passenger as specified in the table in point 2.2.3.8.U.K.

2.2.3.10.The value of the maximum permissible mass of the luggage shall be not less than: B = 100 × VU.K.

2.2.4.CalculationsU.K.

2.2.4.1The requirements of point 2.2.2 shall be verified in all interior arrangement configurations.U.K.

2.2.4.2.In the conditions specified in point 2.2.3 the mass on each solo axle and on each group of axles shall not exceed the technically permissible maximum mass on that axle or group of axles.U.K.

2.2.4.3.In the case of a vehicle equipped with a variable seating capacity, with an area available for standing passengers (S1) and equipped for the carriage of wheelchairs, compliance with the requirements of points 2.2.2 and 2.2.4.2 shall be verified for each of the following conditions as applicable:U.K.

with all possible seats occupied followed by the remaining area for standing passengers (up to the standing capacity limit declared by the manufacturer, if reached) and, if space remains, any wheelchair spaces occupied;

with all possible standing areas occupied (up to the standing capacity limit stated by the manufacturer) followed by the remaining seats available for seated passengers and, if space remains, any wheelchair spaces occupied;

with all possible wheelchair spaces occupied followed by the remaining area for standing passengers (up to the standing capacity limit stated by the manufacturer, if reached) and then the remaining seats available for use occupied.

2.2.5.Where the vehicle is laden as specified in point 2.2.2 the mass corresponding to the load on the front steering axle(s) shall in no case be less than 20 % of the technically permissible maximum laden mass ‘M’.U.K.

[F92.2.5.1In the case of an articulated vehicle with at least 4 axles of class I having two steered axles, the mass corresponding to the load on the front steering axle(s) shall in no case be less than 15 % of the technically permissible maximum laden mass ‘M’.]U.K.

2.2.6.Where a vehicle is to be type-approved to more than one class, the requirements of Section 2 shall apply to each class.U.K.

3.Towing capacityU.K.

3.1.The technically permissible maximum laden mass of the combination shall not exceed the sum of the technically permissible maximum laden mass plus the technically permissible maximum towable mass.U.K.

MC ≤ M + TM

3.2.The technically permissible maximum towable mass shall not exceed 3 500 kg.U.K.

4.Technically permissible maximum mass at the coupling pointU.K.

4.1.The technically permissible maximum mass at the coupling point shall be at least equal to 4 % of its technically permissible maximum towable mass, or 25 kg, whichever is the greater.U.K.

4.2.The manufacturer shall specify in the owner’s manual the conditions for the attachment of the coupling to the motor vehicle.U.K.

4.2.1.Where appropriate the conditions referred to in point 4.2 shall include the technically permissible maximum mass at the coupling point of the towing vehicle, the maximum permissible mass of the coupling device, the mounting points of the coupling and the maximum permissible rear overhang of the coupling.U.K.

5.Hill-starting abilityU.K.

5.1.Vehicles designed to tow a trailer shall be capable of starting five times within five minutes at an up-hill gradient of at least 12 %.U.K.

5.2.For performing the test described in point 5.1, the towing vehicle and the trailer shall be laden so as to equal the technically permissible maximum laden mass of the combination.U.K.

6.Engine powerU.K.

6.1.The engine shall provide a power output of at least 5 kW per tonne of the technically permissible maximum laden mass of the combination or of the technically permissible maximum laden mass of the solo vehicle where the vehicle is not designed to tow a trailer. [F9The requirements in this point shall not apply to the electric-only driving mode of hybrid electric vehicles.]U.K.

[F46.2.The engine power shall be measured in accordance with UNECE Regulation No 85(2).]U.K.

7.ManoeuvrabilityU.K.

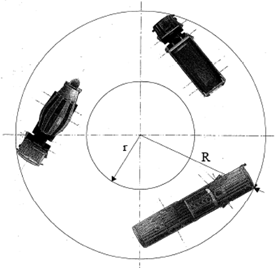

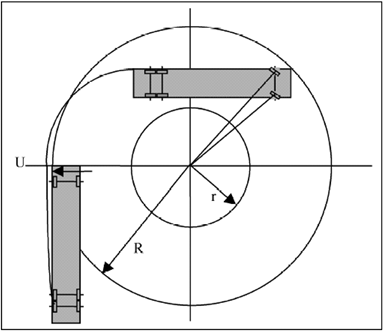

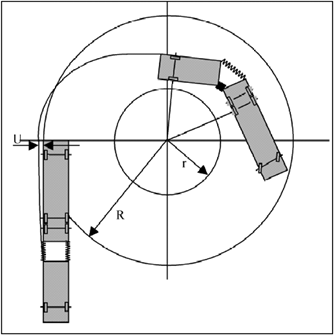

7.1.The vehicle shall be capable of manoeuvring on either side of a complete trajectory of 360° as shown in Figure 1 in Appendix 3 to this Annex without any of the vehicle’s outermost points protruding beyond the outer circle or intruding inside the inner circle as the case may be.U.K.

7.1.1.The test shall be conducted with the vehicle in both the unladen conditions (i.e. at its mass in running order) and loaded to its technically maximum permissible laden mass. [F9If the vehicle is equipped with aerodynamic devices or equipment referred to in points 1.3.1.1 and 1.3.1.2, the devices and equipment shall be in the deployed and in-use position.]U.K.

7.1.2.For the purposes of point 7.1, the parts permitted to protrude beyond the vehicle width referred to in Appendix 1 to this Annex shall not be taken into account.U.K.

7.2.For vehicles fitted with a loadable axle, the requirement of point 7.1 shall also apply where the loadable axle(s) is in service.U.K.

7.3.The requirements of section 7.1 shall be verified as follows:U.K.

The vehicle shall manoeuvre inside a circular area defined by two concentric circles, the outer circle having a radius of 12,50 m and the inner circle having a radius of 5,30 m

The outermost front point of the motor vehicle shall be guided along the contour of the outer circle (see Figure 1 in Appendix 3 to this Annex).

[F97.4With the agreeement of the Technical Service and the Type-Approval Authority, the manoeuvrability requirements may be proved by numerical simulation in accordance with [F15Annex VIII to Regulation (EU) 2018/858]. In case of doubt, the Technical Service or Type-Approval Authority may require a physical full-scale test to be carried out.]U.K.Textual Amendments

F15Words in Annex 1 Pt. B point 7.4 substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(b)(iv)

Textual Amendments

F15Words in Annex 1 Pt. B point 7.4 substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(b)(iv)

8.Rear swing-outU.K.

8.1.Vehicle with one sectionU.K.

8.1.1.The vehicle shall be tested in accordance with the drive-in test method described in point 8.1.2. [F9If the vehicle is equipped with aerodynamic devices or equipment referred to in points 1.3.1.1 and 1.3.1.2, the devices and equipment shall be in the deployed and in-use position.]U.K.

8.1.2.Drive-in test methodU.K.

The vehicle shall be stationary, a vertical plane tangential to the side of the vehicle and facing outwards from the circle shall be established by marking a line on the ground.

The vehicle shall be moved from a straight line approach into the circular area described in Figure 1 with its front wheels turned such as the front outermost point follows the contour of the outer circle (see Figure 2a of Appendix 3 to this Annex).

8.1.3.The vehicle shall be set to its mass in running order.U.K.

8.1.4.The maximum rear swing-out shall not exceed 0,60 m.U.K.

8.2.Vehicles with two or more sectionsU.K.

8.2.1.The requirements of point 8.1 shall apply mutatis mutandis as regards vehicles with two or more sections.U.K.

In such a case, the two or more rigid sections shall be aligned with the plane as shown in Figure 2b of Appendix 3 to this Annex.

[F98.3. With the agreement of the Technical Service and the Type-Approval Authority, the maximum rear swing-out requirements may be proved by numerical simulation in accordance with [F16Annex VIII to Regulation (EU) 2018/858]. In case of doubt, the Technical Service or Type-Approval Authority may require a physical full-scale test to be carried out.]U.K.

Textual Amendments

F16Words in Annex 1 Pt. B point 8.3 substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(b)(v)

PART CU.K.Vehicles of category N2 and N3

1.Maximum authorised dimensionsU.K.

1.1.The dimensions shall not exceed the following values:U.K.

Textual Amendments

F17Words in Annex 1 Pt. C point 1.1.2(b) substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(c)(i)

F18Annex 1 Pt. C point 1.1.3 omitted (E.W.S.) (31.12.2022 at 11.00 p.m.) by virtue of The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(c)(ii)

1.2.For the purposes of measurement of the [F19length and width], the vehicle shall be at its mass in running order, placed on a horizontal and flat surface with tyres inflated at the pressure recommended by the manufacturer.U.K.Textual Amendments

F19Words in Annex 1 Pt. C point 1.2 substituted (E.W.S.) (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(c)(iii)

Textual Amendments

F19Words in Annex 1 Pt. C point 1.2 substituted (E.W.S.) (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(c)(iii)

[F41.3.The devices and equipment referred to in Appendix 1 shall not be taken into account for the determination of the [F20length and width].]U.K.Textual Amendments

F20Words in Annex 1 Pt. C point 1.3 substituted (E.W.S.) (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(c)(iii)

Textual Amendments

F20Words in Annex 1 Pt. C point 1.3 substituted (E.W.S.) (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(c)(iii)

[F91.3.1.Additional requirements for aerodynamic devices referred to in Appendix 1U.K.

1.3.1.1.Aerodynamic devices and equipment not exceeding 500 mm in length in the in-use position shall not increase the usable length of the loading area. They shall be constructed in such a way as to make it possible to lock them in both the retracted or folded and the in-use positions. Such devices and equipment shall furthermore be constructed so as to be retractable or foldable when the vehicle is at stand-still in such a way that the maximum authorised width of the vehicle is not exceeded by more than 25 mm on each side of the vehicle and the maximum authorised length of the vehicle is not exceeded by more than 200 mm as permitted only from a height above the ground of at least 1 050 mm so that they do not impair the capability of the vehicle to be used for intermodal transport. In addition, the requirements set out in points 1.3.1.1.1 and 1.3.1.1.3. shall be met.U.K.

1.3.1.1.1.The devices and equipment shall be type-approved in accordance with this Regulation.U.K.

1.3.1.1.2.It shall be possible for the operator to vary the position of the aerodynamic device and equipment, and to retract or fold it, by applying a manual force not exceeding 40 daN. In addition, this may be done automatically as well.U.K.

1.3.1.1.3.It is not required for devices and equipment to be retractable or foldable if the maximum dimensional requirements are fully complied with under all conditions.U.K.

1.3.1.2.Aerodynamic devices and equipment exceeding 500 mm in length in the in-use position shall not increase the usable length of the loading area. They shall be constructed in such a way as to make it possible to lock them in both the retracted or folded and in-use positions. Such devices shall furthermore be constructed so as to be retractable or foldable when the vehicle is at stand-still in such a way that the maximum authorised width of the vehicle is not exceeded by more than 25 mm on each side of the vehicle and the maximum authorised length of the vehicle is not exceeded by more than 200 mm as permitted only from a height above the ground of at least 1 050 mm so that they do not impair the capability of the vehicle to be used for intermodal transport. In addition, the requirements set out in points 1.3.1.2.1. to 1.3.1.2.4. below shall be met.U.K.

1.3.1.2.1.The devices and equipment shall be type-approved in accordance with this Regulation.U.K.

1.3.1.2.2.It shall be possible for the operator to vary the position of the aerodynamic device and equipment, and retract or fold it, by applying a manual force not exceeding 40 daN. In addition, this may be done automatically as well.U.K.

1.3.1.2.3.Each main vertical element or combination of elements and main horizontal element or combination of elements forming the devices and equipment shall, when installed on the vehicle and in the in-use position, withstand vertical and horizontal traction and push forces, applied sequentially in up, down, left and right direction, of 200 daN ± 10 % applied statically to the geometric centre of the relevant perpendicular projected surface, at a maximum pressure of 2,0 MPa. The devices and equipment may deform, but the system for adjustment and locking shall not release as a result of the applied forces. The deformation shall be limited to ensure that the maximum authorised width of the vehicle is not exceeded by more than 25 mm on each side of the vehicle, during and after the test.U.K.

1.3.1.2.4.Each main vertical element or combination of elements and main horizontal element or combination of elements forming the devices and equipment shall also, when in the retracted or folded position, withstand a horizontal traction force applied in longitudinal rearward direction, of 200 daN ± 10 % applied statically to the geometric centre of the relevant perpendicular projected surface, at a maximum pressure of 2,0 MPa. The devices and equipment may deform, but the system for adjustment and locking shall not release as a result of the applied forces. The deformation shall be limited to ensure that the maximum authorised width of the vehicle is not exceeded by more than 25 mm on each side of the vehicle and the maximum authorised length of the vehicle is not exceeded by more than 200 mm.U.K.

1.3.1.3.Aerodynamic devices and equipment of cabs, both in the retracted or folded and in-use position, where applicable, shall be constructed in such a way that the maximum authorised width of the vehicle is not exceeded by more than 25 mm on each side of the vehicle and that they do not impair the capability of the vehicle to be used for intermodal transport. In addition, the requirements set out in points 1.3.1.3.1. to 1.3.1.3.4. below shall be met.U.K.

1.3.1.3.1.Aerodynamic devices and equipment for cabs shall be type-approved in accordance with this Regulation.U.K.

1.3.1.3.2.When installed on a vehicle and both in the retracted or folded and in-use positions, where applicable, no part of the device and equipment shall be above the lower windscreen edge, unless it is not directly visible to the driver due to the instrument panel or other standard interior fittings.U.K.

1.3.1.3.3.The device and equipment shall be covered with energy absorbing material. Alternatively, the device and equipment shall consist of material having a hardness of < 60 Shore (A) in accordance with point 1.3.1.4..U.K.

1.3.1.3.4.The device and equipment shall not be constructed of material that is prone to breakage into sharp fragments or jagged edges.U.K.

1.3.1.4. It shall be verified by the technical service, to the satisfaction of the type-approval authority that aerodynamic devices and equipment referred to in points 1.3.1.1, 1.3.1.2 and 1.3.1.3 positioned in both, the in-use and retracted or folded positions, do not impair the driver’s forward field of vision and the windscreen wash and wipe functions, as well as do not significantly impair the cooling and ventilation of the powertrain, exhaust system, braking system, occupant cabin and loading area. All other applicable requirements relating to the vehicle systems shall be fully complied with when the devices and equipment are placed in both their in-use and retracted or folded positions. U.K.

By way of derogation concerning the applicable requirements relating to front underrun protection, the horizontal distances between the foremost part of the vehicle as fitted with aerodynamic devices and equipment and its front underrun protective device as well as the rear of the rear underrun protection device and the rear extremity of the vehicle as fitted with aerodynamic devices and equipment may be measured without taking the devices and equipment into account on condition that at the rear they exceed 200 mm in length and they are in the in-use condition and that at the front and rear the fundamental sections of the elements placed at a height ≤ 2,0 m above the ground measured in unladen condition are made of material having a hardness of < 60 Shore (A). Narrow ribs, tubing and metal wire forming a frame or substrate to support the fundamental sections of the elements shall not be taken into account when determining the hardness. However, in order to eliminate the risk of injuries and penetration of other vehicles in the event of a collision, any ends of such ribs, tubing and metal wire shall not be directed forward at the front and rearward at the rear of the vehicle, with the device and equipment both in the retracted or folded and the in-use positions.

As alternative to the derogation concerning the rear underrun protection device referred to in the previous paragraph, the horizontal distances between the rear of the rear underrun protection device and the rear extremity of the vehicle as fitted with aerodynamic devices and equipment may be measured without taking the aerodynamic devices and equipment into account provided that they exceed 200 mm in length, they are in the in-use condition and those devices or equipment comply with the test provisions set out in Appendix 4.

The horizontal distances between the rear of the rear underrun protection device and the rear extremity of the vehicle shall however be measured with the aerodynamic devices and equipment positioned in the retracted or folded position or take into account the resulting projection length in accordance with point 1.6.1 of Appendix 4, if this length exceeds that of the retracted or folded position.

1.4.Elongated cabsU.K.

1.4.1.Where the front fascia of the motor vehicle’s cab location, including all external projections of for example the chassis, bumper, wheel guards and wheels, fully conforms to parameters of the three-dimensional envelope as set out in Appendix 5 and the length of the loading area does not exceed 10,5 m, the vehicle may exceed the maximum authorised length set out in point 1.1.1.U.K.

1.4.2. In the case referred to in point 1.4.1, the manufacturer shall indicate [F21one or both of the following additional symbols] below or to the side of the mandatory inscriptions on the manufacturer’s statutory plate, outside a clearly marked rectangle which shall enclose only the mandatory information. U.K.

‘96/53/EC ARTICLE 9A COMPLIANT’ [F22, or]

[F23‘C&U REGULATION 7(3D) COMPLIANT’]

Textual Amendments

F22Word in Annex 1 Pt. C point 1.4.2 inserted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(c)(iv)(bb)

F23Words in Annex 1 Pt. C point 1.4.2 inserted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(c)(iv)(cc)

The height of the symbol’s characters shall not be less than 4 mm. The [F24symbols above] shall also be added to the ‘remarks’ in the Certificate of Conformity as to allow inclusion of this information in on-board vehicle registration papers.]

Textual Amendments

F24Words in Annex 1 Pt. C point 1.4.2 substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(c)(iv)(dd)

Textual Amendments

F21Words in Annex 1 Pt. C point 1.4.2 substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(c)(iv)(aa)

2.Mass distribution for vehicles fitted with bodyworkU.K.

2.1.Calculation procedureU.K.

Notations:

technically permissible maximum laden mass;

technically permissible maximum towable mass;

technically permissible maximum laden mass of the combination;

the technically permissible maximum mass on the solo axle designated ‘i’, where i varies from 1 to the total number of axles of the vehicle;

technically permissible maximum mass at the coupling point;

the technically permissible maximum mass on the group of axles designated ‘j’, where j varies from 1 to the total number of groups of axles.

2.1.1.Suitable calculations shall be carried out in order to make sure that the requirements set out in points 2.2 and 2.3 are fulfilled for each technical configuration within the type.U.K.

2.1.2.In the case of vehicles fitted with loadable axles, the calculations required under points 2.2 and 2.3 shall be carried out with the suspension of loadable axles in the normal running configuration.U.K.

2.1.3.In the case of vehicles fitted with lift axles, the calculations required under points 2.2 and 2.3 shall be carried out with the axles lowered.U.K.

[F92.1.4.In the case of alternatively fuelled or zero-emission motor vehicles:U.K.

2.1.4.1.[F25Any increase in the maximum authorised weight of a vehicle that is permitted for alternative fuel or zero-emission technology in accordance with regulation 4 of the Road Vehicles (Authorised Weight) Regulations 1998 must be determined] on the basis of the documentation provided by the manufacturer. The correctness of the declared information shall be verified by the Technical Service, to the satisfaction of the Type-Approval Authority.U.K.Textual Amendments

F25Words in Annex 1 Pt. C point 2.1.4.1 substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(c)(v)

Textual Amendments

F25Words in Annex 1 Pt. C point 2.1.4.1 substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(c)(v)

2.1.4.2. The manufacturer shall indicate [F26one or both of the following additional symbols] as well as the value of the [F27increase in weight] below or to the side of the mandatory inscriptions on the manufacturer’s statutory plate, outside a clearly marked rectangle which shall enclose only the mandatory information. U.K.

‘96/53/EC ARTICLE 10B COMPLIANT – XXXX KG’ [F28or

‘AWR REGULATION 4 COMPLIANT – XXXX KG’]

Textual Amendments

F28Words in Annex 1 Pt. C point 2.1.4.2 inserted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(c)(vi)(cc)

The height of the symbol’s characters and stated value shall not be less than 4 mm.

In addition, until the introduction of a dedicated entry in the Certificate of Conformity, the value of the [F27increase in weight] shall be stated under ‘remarks’ in the Certificate of Conformity as to allow inclusion of this information in on-board vehicle registration papers.]

Textual Amendments

F26Words in Annex 1 Pt. C point 2.1.4.2 substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(c)(vi)(aa)

F27Words in Annex 1 Pt. C point 2.1.4.2 substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(c)(vi)(bb)

2.2.General requirementsU.K.

2.2.1.The sum of the technically permissible maximum mass on the solo axles plus the sum of the technically permissible maximum mass on the groups of axles shall not be less than the technically permissible maximum laden mass of the vehicle.U.K.

2.2.2.For each group of axles designated ‘j’, the sum of the technically permissible maximum mass on its axles shall not be less than the technically permissible maximum mass on the group of axles.U.K.

In addition, each of the masses mi shall not be less than the part of μj applying on the axle ‘i’ as determined by the mass distribution for that group of axles.

2.3.Specific requirementsU.K.

2.3.1.The mass of the vehicle in running order, plus the mass of the optional equipment plus the mass of the passengers, plus the mass of the coupling if not included in the mass in running order plus the technically permissible maximum mass at the coupling point shall not exceed the technically permissible maximum laden mass of the vehicle.U.K.

2.3.2.Where the vehicle is laden to its technically permissible maximum laden mass, the mass distributed on an axle ‘i’ shall not exceed the mass mi on that axle, and the mass on the group of axles ‘j’ shall not exceed the mass μj.U.K.

2.3.3.The requirements of point 2.3.2 shall be complied with in the following load configurations:U.K.

Uniform distribution of the pay-mass:

the vehicle shall be at its mass in running order plus the mass of the optional equipment plus the mass of the passengers located at the seating reference points, plus the mass of the coupling (if not included in the mass in running order), plus the maximum permissible mass at the coupling point, plus the pay-mass being distributed uniformly on the cargo area.

Non-uniform distribution of pay-mass:

the vehicle shall be at its mass in running order plus the mass of the optional equipment plus the mass of the passengers located at the seating reference points, plus the mass of the coupling (if not included in the mass in running order), plus the maximum permissible mass at the coupling point, plus the pay-mass located in accordance with the manufacturers specifications.

For such purposes the manufacturer shall state the extreme permissible possible positions of the centre of gravity of the pay-mass and/or body and/or equipment or interior fittings (for instance: from 0,50 m to 1,30 m in front of the first rear axle).

Combination of uniform and non-uniform distribution:

The requirements of points 2.3.3.1 and 2.3.3.2 shall be fulfilled simultaneously.

Example, a tipper lorry (distributed load) equipped with an additional crane (localised load).

Mass transferred by the fifth wheel coupling (tractor unit for semi-trailer):

the vehicle shall be at its mass in running order plus the mass of the optional equipment plus the mass of the passengers located at the seating reference points, plus the mass of the coupling if not included in the mass in running order, plus the maximum permissible mass at the fifth wheel coupling point located in accordance with the manufacturers’ specifications (minimum and maximum fifth-wheel lead).

The requirements of points 2.3.3.1 shall always be fulfilled where the vehicle is fitted with a flat cargo area.

2.3.4.Where the vehicle is laden to its technically permissible maximum laden mass, plus the mass of the coupling if not included in the mass in running order, plus the maximum permissible mass at the coupling point in such a way that the maximum permissible maximum mass on the rear group of axle (μ) or the maximum permissible maximum on the rear axle (m) is reached, the mass on the front steering axle(s) shall not be less than 20 % of the technically permissible maximum laden mass of the vehicle.U.K.

2.3.5.As regards special purposes vehicles of category N2 and N3, the technical service shall check compliance with the requirements of Section 2 in agreement with the manufacturer, taking into account the specific design of the vehicle (for example, mobile cranes).U.K.

3.Towing capacityU.K.

3.1.The technically permissible maximum laden mass of the combination shall not exceed the sum of the technically permissible maximum laden mass plus the technically permissible maximum towable mass.U.K.

MC ≤ M + TM

4.Hill-starting ability and gradeabilityU.K.

4.1.Vehicles designed to tow a trailer and laden to their technically permissible maximum laden mass of the combination shall be capable of starting five times within five minutes at an up-hill gradient of at least 12 %.U.K.

4.2.As regard gradeability, off road vehicles shall be tested against the technical requirements of Annex II.U.K.

4.2.1.The requirements of Section 5 of Appendix 1 to [F29Annex I to Regulation (EU) 2018/858] shall also apply.U.K.Textual Amendments

F29Words in Annex 1 Pt. C point 4.2.1 substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(c)(vii)

Textual Amendments

F29Words in Annex 1 Pt. C point 4.2.1 substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(c)(vii)

5.Engine powerU.K.

5.1.Vehicles shall provide an engine power output of at least 5 kW per tonne of the technically permissible maximum laden mass of the combination.U.K.

5.1.1.In the case of a road tractor, or a tractor unit for semi-trailer intended for the transport of indivisible loads, the engine power shall be at least 2 kW per tonne of the technically permissible maximum laden mass of the combination.U.K.

[F95.1.2.The requirements in points 5.1 and 5.1.1 shall not apply to the electric-only driving mode of hybrid electric vehicles.]U.K.

[F45.2.The engine power shall be measured in accordance with UNECE Regulation No 85.]U.K.

6.ManoeuvrabilityU.K.

6.1.The vehicle shall be capable of manoeuvring on either side of a complete trajectory of 360° as shown in Figure 1 of Appendix 3 to this Annex without any of the vehicle’s outermost points protruding beyond the outer circle or intruding inside the inner circle as the case may be.U.K.

6.1.1.The test shall be conducted with the vehicle in both the unladen conditions (i.e. at its mass in running order) and loaded to its technically maximum permissible laden mass. [F9If the vehicle is equipped with aerodynamic devices or equipment referred to in points 1.3.1.1, 1.3.1.2 and 1.3.1.3, the devices and equipment shall be in the deployed and in-use position or in the fixed in-use position where applicable for devices and equipment covered by point 1.3.1.3.]U.K.

6.1.2.For the purposes of point 6.1, the parts permitted to protrude beyond the vehicle width referred to in Appendix 1 to this Annex shall not be taken into account.U.K.

6.2.For vehicles fitted with axle-lift devices, the requirement of point 6.1 shall also apply with the lift axle(s) in the lifted position and where the loadable axle(s) is in service.U.K.

6.3.The requirements of point 6.1 shall be verified as followsU.K.

The vehicle shall manoeuvre inside an area defined by two concentric circles, the outer circle having a radius of 12,50 m and the inner circle having a radius of 5,30 m

The outermost front point of the motor vehicle shall be guided along the contour of the outer circle (see Figure 1 of Appendix 3 to this Annex)

[F96.4With the agreement of the Technical Service and the Type-Approval Authority, the manoeuvrability requirements may be proved by numerical simulation in accordance with [F30Annex VIII to Regulation (EU) 2018/858]. In case of doubt, the Technical Service or Type-Approval Authority may require a physical full-scale test to be carried out.]U.K.Textual Amendments

F30Words in Annex 1 Pt. C point 6.4 substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(c)(viii)

Textual Amendments

F30Words in Annex 1 Pt. C point 6.4 substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(c)(viii)

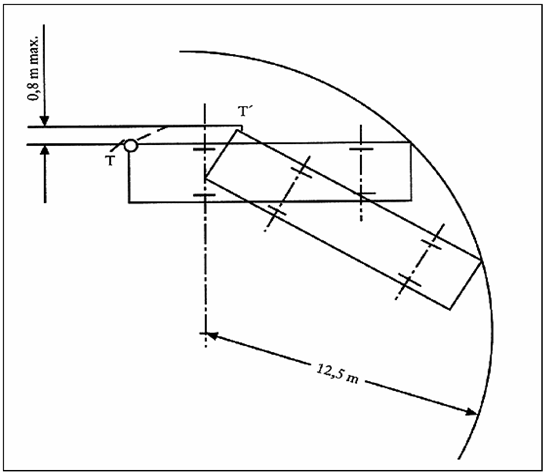

7.Maximum rear swing-outU.K.

7.1.The vehicle shall be tested in accordance with the steady-state test method described in point 7.1.1. [F9If the vehicle is equipped with aerodynamic devices or equipment referred to in points 1.3.1.1, 1.3.1.2 and 1.3.1.3, the devices and equipment shall be in the deployed and in-use position.]U.K.

7.1.1.Steady-state test methodU.K.

7.1.1.2.The vehicle shall be stationary and shall have its front steered wheels so directed that if the vehicle moves, its outermost point would describe a circle of 12,50 m radius.U.K.

A vertical plane tangential to the side of the vehicle and facing outwards from the circle shall be established by marking a line on the ground.

The vehicle shall move forward such as the front outermost point follows the contour of the outer circle of 12,50 m radius.

7.2.The maximum rear swing-out shall not exceed: (see Figure 3 of Appendix 3 to this Annex)U.K.

0,80 m;

1,00 m where the vehicle if fitted with an axle-lift device and the axle is cleared off the ground;

1,00 m where the rearmost axle is a steered axle.

[F97.3. With the agreement of the Technical Service and the Type-Approval Authority, the maximum rear swing-out requirements may be proved by numerical simulation in accordance with [F31Annex VIII to Regulation (EU) 2018/858]. In case of doubt, the Technical Service or Type-Approval Authority may require a physical full-scale test to be carried out.]U.K.

Textual Amendments

F31Words in Annex 1 Pt. C point 7.3 substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(c)(ix)

PART DU.K.Vehicles of category O

1.Maximum authorised dimensionsU.K.

1.1.The dimensions shall not exceed the following values:U.K.

Length

Trailer: 12,00 m including drawbar;

Semi-trailer: 12,00 m plus the front overhang.

Width

F33...

Front fitting radius of semi-trailer: 2,04 m.

Textual Amendments

F32Words in Annex 1 Pt. D point 1.1.2 substituted (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(d)(i)

F33Annex 1 Pt. D point 1.1.3 omitted (E.W.S.) (31.12.2022 at 11.00 p.m.) by virtue of The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(d)(ii)

1.2.For the purposes of measurement of the [F34length and width], the vehicle shall be at its mass in running order, placed on a horizontal and flat surface with tyres inflated at the pressure recommended by the manufacturer.U.K.Textual Amendments

F34Words in Annex 1 Pt. D point 1.2 substituted (E.W.S.) (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(d)(iii)

Textual Amendments

F34Words in Annex 1 Pt. D point 1.2 substituted (E.W.S.) (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(d)(iii)

1.3.The measurement of the lengthF35... and front fitting radius shall be conducted where the loading surface or the reference surface referred to in point 1.2.1 second subparagraph of Annex 7 to UNECE Regulation No 55 is horizontal.U.K.

Adjustable drawbars shall be horizontal and aligned with the centre-line of the vehicle. They shall be set at their horizontal most elongated position.

Textual Amendments

F35Word in Annex 1 Pt. D point 1.1.3 omitted (E.W.S.) (31.12.2022 at 11.00 p.m.) by virtue of The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(d)(iv)

[F41.4.The devices and equipment referred to in Appendix 1 shall not be taken into account for the determination of the [F36length and width].]U.K.Textual Amendments

F36Words in Annex 1 Pt. D point 1.4 substituted (E.W.S.) (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(d)(iii)

Textual Amendments

F36Words in Annex 1 Pt. D point 1.4 substituted (E.W.S.) (31.12.2022 at 11.00 p.m.) by The Road Vehicles and Non-Road Mobile Machinery (Type-Approval) (Amendment and Transitional Provisions) (EU Exit) Regulations 2022 (S.I. 2022/1273), regs. 1(2), 72(2)(d)(iii)

[F91.4.1.Additional requirements for aerodynamic devices referred to in Appendix 1U.K.

1.4.1.1.Aerodynamic devices and equipment not exceeding 500 mm in length in the in-use position shall not increase the usable length of the loading area. They shall be constructed in such a way as to make it possible to lock them in both the retracted or folded and the in-use positions. Such devices and equipment shall furthermore be constructed so as to be retractable or foldable when the vehicle is at stand-still in such a way that the maximum authorised width of the vehicle is not exceeded by more than 25 mm on each side of the vehicle and the maximum authorised length of the vehicle is not exceeded by more than 200 mm as permitted only from a height above the ground of at least 1 050 mm so that they do not impair the capability of the vehicle to be used for intermodal transport. In addition, the requirements set out in points 1.4.1.1.1 to 1.4.1.1.3. shall be met.U.K.

1.4.1.1.1.The devices and equipment shall be type-approved in accordance with this Regulation.U.K.

1.4.1.1.2.It shall be possible for the operator to vary the position of the aerodynamic device and equipment, and to retract and fold it, by applying a manual force not exceeding 40 daN. In addition, this may be done automatically as well.U.K.

1.4.1.1.3.It is not required for devices and equipment to be retractable or foldable if the maximum dimensional requirements are fully complied with under all conditions.U.K.

1.4.1.2.Aerodynamic devices and equipment exceeding 500 mm in length in the in-use position shall not increase the usable length of the loading area. They shall be constructed in such a way to make it possible to lock them in both the retracted or folded and the in-use positions. Such devices shall furthermore be constructed so as to be retractable or foldable when the vehicle is at stand-still in such a way that the maximum authorised width of the vehicle is not exceeded by more than 25 mm on each side of the vehicle and the maximum authorised length of the vehicle is not exceeded by more than 200 mm as permitted only from a height above the ground of at least 1 050 mm so that they do not impair the capability of the vehicle to be used for intermodal transport. In addition, the requirements set out in points 1.4.1.2.1. to 1.4.1.2.4. shall be met.U.K.

1.4.1.2.1.The devices and equipment shall be type-approved in accordance with this Regulation.U.K.

1.4.1.2.2.It shall be possible for the operator to vary the position of the aerodynamic device and equipment, and retract or fold it, by applying a manual force not exceeding 40 daN. In addition, this may be done automatically as well.U.K.

1.4.1.2.3.Each main vertical element or combination of elements and main horizontal element or combination of elements forming the devices and equipment shall, when installed on the vehicle and in the in-use position, withstand vertical and horizontal traction and push forces, applied sequentially in up, down, left and right direction, of 200 daN ± 10 % applied statically to the geometric centre of the relevant perpendicular projected surface, at a maximum pressure of 2,0 MPa. The devices and equipment may deform, but the system for adjustment and locking shall not release as a result of the applied forces. The deformation shall be limited to ensure that the maximum authorised width of the vehicle is not exceeded by more than 25 mm on each side of the vehicle, during and after the test.U.K.

1.4.1.2.4.Each main vertical element or combination of elements and main horizontal element or combination of elements forming the devices and equipment shall also, when in the retracted or folded position, withstand a horizontal traction force applied in longitudinal rearward direction, of 200 daN ± 10 % applied statically to the geometric centre of the relevant perpendicular projected surface, at a maximum pressure of 2,0 MPa. The devices and equipment may deform, but the system for adjustment and locking shall not release as a result of the applied forces. The deformation shall be limited to ensure that the maximum authorised width of the vehicle is not exceeded by more than 25 mm on each side of the vehicle and the maximum authorised length of the vehicle is not exceeded by more than 200 mm.U.K.

1.4.1.3. It shall be verified by the technical service, to the satisfaction of the type-approval authority that aerodynamic devices and equipment positioned in both, the in-use and the retracted or folded positions, do not completely block the ventilation of the loading area. All other applicable requirements relating to the vehicle systems shall be fully complied with when the devices and equipment are placed in both their in-use and retracted or folded positions. U.K.

By way of derogation concerning the applicable requirements relating to rear underrun protection, the horizontal distances between the rear of the rear underrun protection device and the rear extremity of the vehicle as fitted with aerodynamic devices and equipment may be measured without taking the devices and equipment into account on condition that they exceed 200 mm in length, they are in the in-use condition and the fundamental sections of the elements placed at a height ≤ 2,0 m above the ground measured in unladen condition are made of material having a hardness of < 60 Shore (A). Narrow ribs, tubing and metal wire forming a frame or substrate to support the fundamental sections of the elements shall not be taken into account when determining the hardness. However, in order to eliminate the risk of injuries and penetration of other vehicles in the event of a collision, any ends of such ribs, tubing and metal wire shall not be directed rearward at the rear of the vehicle, with the device and equipment both in the retractable or folded and the in-use positions.

As alternative to the derogation referred to in the previous paragraph, the horizontal distances between the rear of the rear underrun protection device and the rear extremity of the vehicle as fitted with aerodynamic devices and equipment may be measured without taking the aerodynamic devices and equipment into account provided that they exceed 200 mm in length, they are in the in-use condition and those devices or equipment comply with the test provisions set out in Appendix 4.

The horizontal distances between the rear of the rear underrun protection device and the rear extremity of the vehicle shall however be measured with the aerodynamic devices and equipment positioned in the retracted or folded position or take into account the resulting projection length in accordance with point 1.6.1 of Appendix 4, if this length exceeds that of the retracted or folded position.]

2.Mass distribution for vehicles fitted with bodyworkU.K.

2.1.Calculation procedureU.K.

Notations:

technically permissible maximum laden mass;

technically permissible maximum mass at the front coupling point;

the technically permissible maximum mass on the axle designated ‘i’, where i varies from 1 to the total number of axles of the vehicle;

technically permissible maximum mass at the rear coupling point;

the technically permissible maximum mass on the group of axles designated ‘j’, where j varies from 1 to the total number of groups of axles.

2.1.1.Suitable calculations shall be carried out in order to make sure that the requirements set out in points 2.2 and 2.3 are fulfilled for each technical configuration within the type.U.K.

2.1.2.In the case of vehicles fitted with loadable axles, the calculations required under points 2.2 and 2.3 shall be carried out with the suspension of loadable axles in the normal running configuration.U.K.

2.1.3.In the case of vehicles fitted with lift axles, the calculations required under points 2.2 and 2.3 shall be carried out with the axles lowered.U.K.

2.2.General requirementsU.K.

[F42.2.1.The sum of the technically permissible maximum mass at the front coupling point plus the technically permissible maximum mass on the solo axles and/or group(s) of axles plus the technically permissible maximum mass at the rear coupling point shall be not less than the technically permissible maximum laden mass of the vehicle.U.K.

M ≤ Σ [m 0 + m i + m c ] or M ≤ Σ [m 0 + μ j + m c ].]

2.2.2.For each group of axles designated ‘j’, the sum of the masses mi on its axles shall not be less than the mass μj.U.K.

In addition, each of the masses mi shall not be less than the part of μj applying on the axle ‘i’ as determined by the mass distribution for that group of axles.

2.3.Specific requirementsU.K.

2.3.1.The mass of the vehicle in running order, plus the mass of the optional equipment plus the technically permissible maximum mass at the coupling point(s) shall not exceed the technically permissible maximum laden mass of the vehicle.U.K.

2.3.2.Where the vehicle is laden to its technically permissible maximum laden mass, the mass distributed on a solo axle ‘i’ shall neither exceed the mass mi on that axle, nor the mass μj on the group of axles, nor the technically permissible maximum mass at the coupling point m0.U.K.

2.3.3.The requirements of point 2.3.2 shall be complied with in the following load configurations:U.K.

2.3.3.1.Uniform distribution of the pay-massU.K.

The vehicle shall be at its mass in running order plus the mass of the optional equipment plus the pay-mass being distributed uniformly on the cargo area;

2.3.3.2.Non-uniform distribution of the pay-massU.K.

The vehicle shall be at its mass in running order plus the mass of the optional equipment plus the pay-mass located in accordance with the manufacturer’s specifications.

For such purposes the manufacturer shall state the extreme permissible possible positions of the centre of gravity of the pay-mass and/or body and/or equipment or interior fittings (for instance: from 0,50 m to 1,30 m in front of the first rear axle);

2.3.3.3.Combination of uniform and non-uniform distribution:U.K.

The requirements of points 2.3.3.1 and 2.3.3.2 shall be fulfilled simultaneously.

2.3.3.4.The requirements of points 2.3.3.1 shall always be fulfilled where the vehicle is fitted with a flat cargo area.U.K.

2.3.4.Specific requirements for trailer caravansU.K.

2.3.4.1.The minimum pay-mass (PM) shall meet the following requirement:U.K.

Where

is the maximum number of berths and

is the overall length of the body length as defined in point 6.1.2 of Standard ISO 7237:1981.

3.Manoeuvrability requirementsU.K.

3.1.Trailers and semi-trailers shall be so designed that, when coupled to a towing vehicle, the combination is capable of manoeuvring on either side of a complete trajectory of 360° made up of two concentric circles, the outer circle having a radius of 12,50 m and the inner circle having a radius of 5,30 m without any of the vehicle’s outermost points of the towing vehicle protruding beyond the outer circle or any of the outermost points of the trailer or semi-trailer intruding inside the inner circle. [F9If the trailer or semi-trailer is equipped with aerodynamic devices or equipment referred to in points 1.4.1.1 or 1.4.1.2, the devices and equipment shall be in the in-use and deployed position.]U.K.

[F43.2. A semi-trailer not equipped with aerodynamic devices or equipment referred to in points 1.4.1.1 or 1.4.1.2 shall be deemed to comply with the requirement set out in point 3.1. if its reference wheelbase ‘RWB’ meets the following requirement: U.K.

RWB ≤ [(12,50 – 2,04) 2 - (5,30 + ½ W) 2 ] 1/2

where:

is the distance between the king-pin axis and the centre line of the non-steering axles.

is the semi-trailer’s width.]

3.3.Where one or more of the non-steering axles has an axle lift device the reference wheelbase with the axle lowered or the axle lifted — whichever is the longest — shall be taken into account.U.K.

Appendix 1

List of devices and equipment that are not required to be taken into account for the determination of the outermost dimensions U.K.

[F41. Subject to the additional restrictions provided in the following tables, the devices and equipment listed in Tables I, II and III are not required to be taken into account for the determination and calculation of the outermost dimensions where the following requirements are fulfilled: U.K.

where devices are fitted at the front, with the exception of aerodynamic devices and equipment of cabs, the total protrusion of those devices shall not exceed 250 mm;

the total protrusion of devices and equipment added to the length of the vehicle, with the exception of aerodynamic devices and equipment, shall not exceed 750 mm;

the total protrusion of devices and equipment added to the width of the vehicle shall not exceed 100 mm.

2. The requirements set out in points (a), (b) and (c) of point 1 shall not apply to devices for indirect vision.] U.K.

Table I

Vehicle length

| Item | Vehicles categories | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| M1 | M2 | M3 | N1 | N2 | N3 | O1 | O2 | O3 | O4 | ||

| 1. | Devices for indirect vision as defined in point 2.1 of UNECE Regulation No 46a | x | x | x | x | x | x | x | x | x | x |

| 2. | Wiper and washer devices | x | x | x | x | x | x | ||||