- Latest available (Revised)

- Point in Time (03/08/2012)

- Original (As adopted by EU)

Commission Regulation (EU) No 748/2012Show full title

Commission Regulation (EU) No 748/2012 of 3 August 2012 laying down implementing rules for the airworthiness and environmental certification of aircraft and related products, parts and appliances, as well as for the certification of design and production organisations (recast) (Text with EEA relevance)

You are here:

- Regulations originating from the EU

- 2012 No. 748

- Whole Regulation

- Previous

- Next

- Show Geographical Extent(e.g. England, Wales, Scotland and Northern Ireland)

- Show Timeline of Changes

More Resources

Revised version PDFs

- Revised 24/03/20201.75 MB

- Revised 23/03/20201.75 MB

- Revised 23/06/20191.62 MB

- Revised 01/01/20181.40 MB

- Revised 26/01/20161.41 MB

- Revised 01/01/20161.33 MB

- Revised 21/07/20151.35 MB

- Revised 17/02/20141.81 MB

- Revised 29/01/20131.49 MB

When the UK left the EU, legislation.gov.uk published EU legislation that had been published by the EU up to IP completion day (31 December 2020 11.00 p.m.). On legislation.gov.uk, these items of legislation are kept up-to-date with any amendments made by the UK since then.

This item of legislation originated from the EU

Legislation.gov.uk publishes the UK version. EUR-Lex publishes the EU version. The EU Exit Web Archive holds a snapshot of EUR-Lex’s version from IP completion day (31 December 2020 11.00 p.m.).

Status:

Point in time view as at 03/08/2012.

Changes to legislation:

There are currently no known outstanding effects by UK legislation for Commission Regulation (EU) No 748/2012.![]()

Changes to Legislation

Revised legislation carried on this site may not be fully up to date. At the current time any known changes or effects made by subsequent legislation have been applied to the text of the legislation you are viewing by the editorial team. Please see ‘Frequently Asked Questions’ for details regarding the timescales for which new effects are identified and recorded on this site.

Commission Regulation (EU) No 748/2012

of 3 August 2012

laying down implementing rules for the airworthiness and environmental certification of aircraft and related products, parts and appliances, as well as for the certification of design and production organisations

(recast)

(Text with EEA relevance)

THE EUROPEAN COMMISSION,

Having regard to the Treaty on the Functioning of the European Union,

Having regard to Regulation (EC) No 216/2008 of the European Parliament and of the Council of 20 February 2008 on common rules in the field of civil aviation and establishing a European Aviation Safety Agency, and repealing Council Directive 91/670/EEC, Regulation (EC) No 1592/2002 and Directive 2004/36/EC(1), and in particular Articles 5(5) and 6(3) thereof,

Whereas:

(1) Commission Regulation (EC) No 1702/2003 of 24 September 2003 laying down implementing rules for the airworthiness and environmental certification of aircraft and related products, parts and appliances, as well as for the certification of design and production organisations(2) has been substantially amended several times(3). Since further amendments are to be made, it should be recast in the interests of clarity.

(2) Regulation (EC) No 216/2008 establishes common essential requirements to provide for a high uniform level of civil aviation safety and environmental protection. It requires the Commission to adopt the necessary implementing rules to ensure their uniform application. It establishes the ‘European Aviation Safety Agency’ (hereinafter referred to as the ‘Agency’) to assist the Commission in the development of such implementing rules.

(3) It is necessary to lay down common technical requirements and administrative procedures to ensure the airworthiness and environmental compatibility of aeronautical products, parts and appliances, subject to Regulation (EC) No 216/2008. Such requirements and procedures should specify the conditions to issue, maintain, amend, suspend or revoke the appropriate certificates.

(4) Organisations involved in the design and production of products, parts and appliances should be required to comply with certain technical requirements in order to demonstrate their capability and means to discharge their obligations and associated privileges. The Commission is required to lay down measures to specify conditions to issue, maintain, amend, suspend or revoke certificates attesting such compliance.

(5) In laying down measures for the implementation of common essential requirements in the field of airworthiness, the Commission must take care that they reflect the state of the art and the best practices, take into account worldwide aircraft experience and scientific and technical progress and allow for immediate reaction to established causes of accidents and serious incidents.

(6) The need to ensure uniformity in the application of common airworthiness and environmental requirements for aeronautical products, parts and appliances requires that common procedures be followed by the competent authorities of the Member States and, where applicable, the Agency to assess compliance with these requirements. The Agency should develop certification specifications and guidance material to facilitate the necessary regulatory uniformity.

(7) It is necessary to recognise the continuing validity of certificates issued before the entry into force of Regulation (EC) No 1702/2003, in accordance with Article 69 of Regulation (EC) No 216/2008.

(8) In order to maintain a high uniform level of aviation safety in Europe, it is necessary to introduce changes to requirements and procedures for the certification of aircraft and related products, parts and appliances and of design and production organisations, in particular to elaborate the rules related to the demonstration of compliance with the type-certification basis and environmental protection requirements and to introduce the possibility to choose to comply with later standards for changes to type-certificates.

(9) The concept and complexity of auxiliary power units (APU) resembles that of aircraft engines and in some cases APU designs are even derived from engine designs. Changes to provisions for repairs to APU are therefore needed to restore consistency with repairs process to engines.

(10) In order to subject non-complex motor-powered aircraft, recreational aircraft and related products, parts and appliances to measures that are proportionate to their simple design and type of operation, while maintaining a high uniform level of aviation safety in Europe, it is necessary to introduce changes to requirements and procedures for the certification of those aircraft and related products, parts and appliances and of design and production organisations and in particular, for the owners of European Light Aircraft below 2 000 kg (ELA2) or below 1 200 kg (ELA1), to introduce the possibility to accept certain not safety critical parts for installation without an EASA Form 1.

(11) The Agency prepared draft implementing rules and submitted them as opinions No 01/2009 on ‘Possibility to deviate from airworthiness code in case of design changes’, No 02/2009 on ‘Repair and design changes to European Technical Standard Order’, No 01/2010 on ‘SubPart J DOA’ and Opinion No 01/2011 on ‘ELA Process and “standard changes and repairs” ’ to the Commission in accordance with Article 19(1) of Regulation (EC) No 216/2008.

(12) The measures provided for in this Regulation are in accordance with the opinion of the European Aviation Safety Agency Committee established by Article 65(1) of Regulation (EC) No 216/2008,

HAS ADOPTED THIS REGULATION:

Article 1U.K.Scope and definitions

1.This Regulation lays down, in accordance with Article 5(5) and Article 6(3) of Regulation (EC) No 216/2008, common technical requirements and administrative procedures for the airworthiness and environmental certification of products, parts and appliances specifying:

(a)the issue of type-certificates, restricted type-certificates, supplemental type-certificates and changes to those certificates;

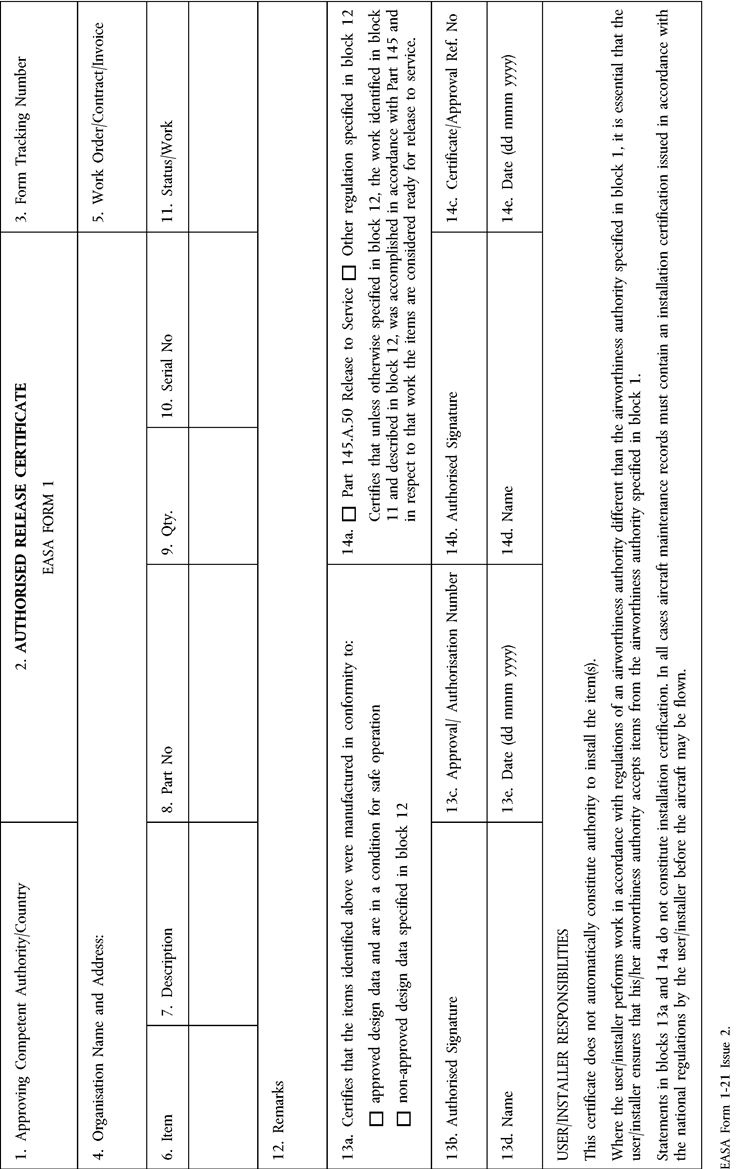

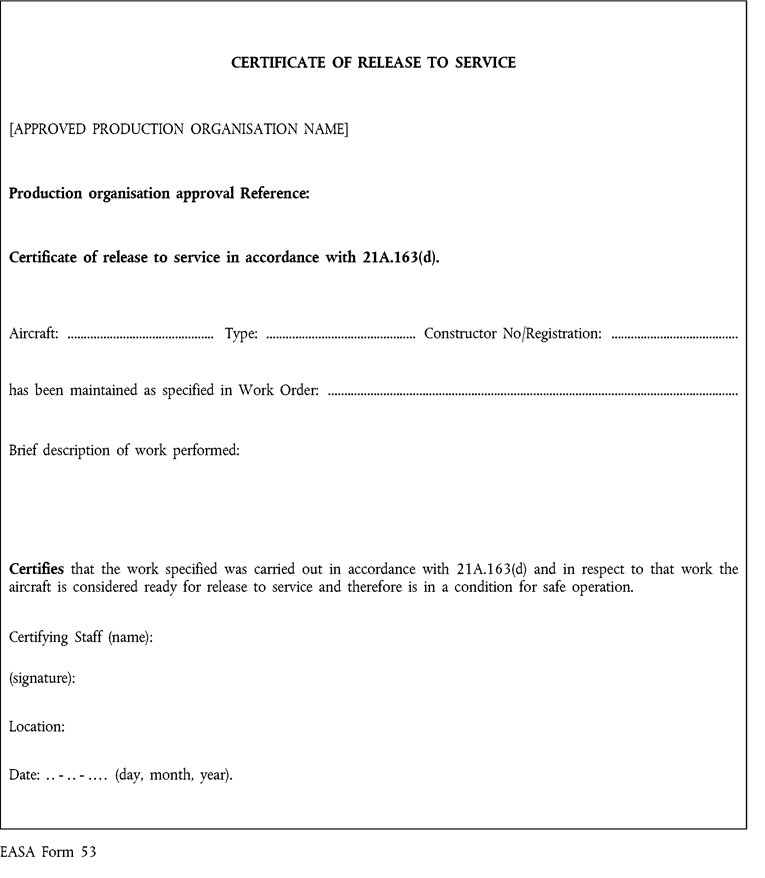

(b)the issue of certificates of airworthiness, restricted certificates of airworthiness, permits to fly and authorised release certificates;

(c)the issue of repair design approvals;

(d)the showing of compliance with environmental protection requirements;

(e)the issue of noise certificates;

(f)the identification of products, parts and appliances;

(g)the certification of certain parts and appliances;

(h)the certification of design and production organisations;

(i)the issue of airworthiness directives.

2.For the purpose of this Regulation, the following definitions shall apply:

(a)‘JAA’ means the ‘Joint Aviation Authorities’;

(b)‘JAR’ means ‘Joint Aviation Requirements’;

(c)‘Part 21’ means the requirements and procedures for the certification of aircraft and related products, parts and appliances, and of design and production organisations laid down in Annex I to this Regulation;

(d)‘Part M’ means the applicable continuing airworthiness requirements adopted in pursuance of Regulation (EC) No 216/2008;

(e)‘principal place of business’ means the head office or registered office of the undertaking within which the principal financial functions and operational control of the activities referred to in this Regulation are exercised;

(f)‘article’ means any part and appliance to be used on civil aircraft;

(g)‘ETSO’ means European Technical Standard Order. The European Technical Standard Order is a detailed airworthiness specification issued by the European Aviation Safety Agency (the ‘Agency’) to ensure compliance with the requirements of this Regulation as a minimum performance standard for specified articles;

(h)‘EPA’ means European Part Approval. European Part Approval of an article means the article has been produced in accordance with approved design data not belonging to the type-certificate holder of the related product, except for ETSO articles;

(i)‘ELA1 aircraft’ means the following manned European Light Aircraft:

an aeroplane with a Maximum Take-off Mass (MTOM) of 1 200 kg or less that is not classified as complex motor-powered aircraft;

a sailplane or powered sailplane of 1 200 kg MTOM or less;

a balloon with a maximum design lifting gas or hot air volume of not more than 3 400 m3 for hot air balloons, 1 050 m3 for gas balloons, 300 m3 for tethered gas balloons;

an airship designed for not more than 4 occupants and a maximum design lifting gas or hot air volume of not more than 3 400 m3 for hot air airships and 1 000 m3 for gas airships;

(j)‘ELA2 aircraft’ means the following manned European Light Aircraft:

an aeroplane with a Maximum Take-off Mass (MTOM) of 2 000 kg or less that is not classified as complex motor-powered aircraft;

a sailplane or powered sailplane of 2 000 kg MTOM or less;

a balloon;

a hot air airship;

a gas airship complying with all of the following characteristics:

3 % maximum static heaviness,

Non-vectored thrust (except reverse thrust),

Conventional and simple design of: structure, control system and ballonet system,

Non-power assisted controls;

a Very Light Rotorcraft.

Article 2U.K.Products, parts and appliances certification

1.Products, parts and appliances shall be issued certificates as specified in Annex I (Part 21).

2.By way of derogation from point 1, aircraft, including any installed product, part and appliance, which are not registered in a Member State shall be exempted from the provisions of Subparts H and I of Annex I (Part 21). They shall also be exempted from the provisions of Subpart P of Annex I (Part 21) except when aircraft identification marks are prescribed by a Member State.

Article 3U.K.Continued validity of type-certificates and related certificates of airworthiness

1.With regard to products which had a type-certificate, or a document allowing the issuing of a certificate of airworthiness, issued before 28 September 2003 by a Member State, the following provisions shall apply:

(a)the product shall be deemed to have a type-certificate issued in accordance with this Regulation when:

its type-certification basis was:

the JAA type-certification basis, for products that have been certificated under JAA procedures, as defined in their JAA data sheet, or

for other products, the type-certification basis as defined in the type-certificate data sheet of the State of design, if that State of design was:

a Member State, unless the Agency determines, taking into account, in particular, airworthiness codes used and service experience, that such type-certification basis does not provide for a level of safety equivalent to that required by Regulation (EC) No 216/2008 and this Regulation, or

a State with which a Member State had concluded a bilateral airworthiness agreement or similar arrangement under which such products have been certificated on the basis of the airworthiness codes of that State of design, unless the Agency determines that such airworthiness codes or service experience or the safety system of that State of design do not provide for a level of safety equivalent to that required by Regulation (EC) No 216/2008 and this Regulation.

The Agency shall make a first evaluation of the implication of the provisions of the second indent in view of producing an opinion to the Commission including possible amendments to this Regulation;

the environmental protection requirements were those laid down in Annex 16 to the Chicago Convention, as applicable to the product;

the applicable airworthiness directives were those of the State of design;

(b)the design of an individual aircraft, which was on the register of a Member State before 28 September 2003, shall be deemed to have been approved in accordance with this Regulation when:

its basic type design was part of a type-certificate referred to in point (a);

all changes to this basic type design, which were not under the responsibility of the type-certificate holder, had been approved; and

the airworthiness directives issued or adopted by the Member State of registry before 28 September 2003 were complied with, including any variations to the airworthiness directives of the State of design agreed by the Member State of registry.

2.With regard to products for which a type-certification process was proceeding through the JAA or a Member State on 28 September 2003, the following shall apply:

(a)if a product is under certification by several Member States, the most advanced project shall be used as the reference;

(b)points 21.A.15(a), (b) and (c) of Annex I (Part 21) shall not apply;

(c)by way of derogation from point 21.A.17(a) of Annex I (Part 21), the type-certification basis shall be that established by the JAA or, where applicable, the Member State at the date of application for the approval;

(d)compliance findings made under JAA or Member State procedures shall be deemed to have been made by the Agency for the purpose of complying with points 21.A.20(a) and (b) of Annex I (Part 21).

3.With regard to products that have a national type-certificate, or equivalent, and for which the approval process of a change carried out by a Member State was not finalised at the time when the type-certificate had to be in accordance with this Regulation, the following shall apply:

(a)if an approval process is being carried out by several Member States, the most advanced project shall be used as the reference;

(b)point 21.A.93 of Annex I (Part 21) shall not apply;

(c)the applicable type-certification basis shall be that established by the JAA or, where applicable, the Member State at the date of application for the approval of change;

(d)compliance findings made under JAA or Member State procedures shall be deemed to have been made by the Agency for the purpose of complying with points 21.A.103(a)(2) and (b) of Annex I (Part 21).

4.With regard to products that had a national type-certificate, or equivalent, and for which the approval process of a major repair design carried out by a Member State was not finalised at the time when the type-certificate had to be determined in accordance with this Regulation, compliance findings made under JAA or Member State procedures shall be deemed to have been made by the Agency for the purpose of complying with point 21.A.433(a) of Annex I (Part 21).

5.A certificate of airworthiness issued by a Member State attesting conformity with a type-certificate determined in accordance with point 1 shall be deemed to comply with this Regulation.

Article 4U.K.Continued validity of supplemental type-certificates

1.With regard to supplemental type-certificates issued by a Member State under JAA procedures or applicable national procedures and with regard to changes to products proposed by persons other than the type-certificate holder of the product, which were approved by a Member State under applicable national procedures, if the supplemental type-certificate, or change, was valid on 28 September 2003, the supplemental type-certificate, or change shall be deemed to have been issued under this Regulation.

2.With regard to supplemental type-certificates for which a certification process was being carried out by a Member State on 28 September 2003 under applicable JAA supplemental type-certificate procedures and with regard to major changes to products, proposed by persons other than the type-certificate holder of the product, for which a certification process was being carried out by a Member State on 28 September 2003 under applicable national procedures, the following shall apply:

(a)if a certification process was being carried out by several Member States, the most advanced project shall be used as the reference;

(b)point 21.A.113 (a) and (b) of Annex I (Part 21) shall not apply;

(c)the applicable certification basis shall be that established by the JAA or, where applicable, the Member State at the date of application for the supplemental type-certificate or the major change approval;

(d)the compliance findings made under JAA or Member State procedures shall be deemed to have been made by the Agency for the purpose of complying with point 21.A.115(a) of Annex I (Part 21).

Article 5U.K.Continued operation of certain aircraft registered by Member States

With regard to an aircraft that cannot be deemed to have a type-certificate issued in accordance with Article 3(1)(a) of this Regulation, that has been issued a certificate of airworthiness by a Member State before Regulation (EC) No 1702/2003 became applicable in that Member State(4), was on its register on that date, and was still on the register of a Member State on 28 March 2007, the combination of the following shall be deemed to constitute the applicable specific airworthiness specifications issued in accordance with this Regulation:

the type-certificate data sheet and type-certificate data sheet for noise, or equivalent documents, of the State of design, provided that the State of design has concluded the appropriate working arrangement in accordance with Article 27(2) of Regulation (EC) No 216/2008 with the Agency covering the continued airworthiness of the design of such an aircraft;

the environmental protection requirements laid down in Annex 16 to the Chicago Convention, as applicable to that aircraft; and

the mandatory continuing airworthiness information of the State of design.

Article 6U.K.Continued validity of parts and appliances certificates

1.Approvals of parts and appliances issued by a Member State and valid on 28 September 2003 shall be deemed to have been issued in accordance with this Regulation.

2.With regard to parts and appliances for which an approval or authorisation process was being carried out by a Member State on 28 September 2003, the following shall apply:

(a)if an authorisation process was being carried out by several Member States, the most advanced project shall be used as the reference;

(b)point 21.A.603 of Annex I (Part 21) shall not apply;

(c)the applicable data requirements laid down in point 21.A.605 of Annex I (Part 21) shall be those established by the relevant Member State, at the date of application for the approval or authorisation;

(d)compliance findings made by the relevant Member State shall be deemed to have been made by the Agency for the purpose of complying with point 21.A.606(b) of Annex I (Part 21).

Article 7U.K.Permit to fly

The conditions determined before 28 March 2007 by the Member States for permits to fly or other airworthiness certificate issued for aircraft which did not hold a certificate of airworthiness or restricted certificate of airworthiness issued under this Regulation, are deemed to have been determined in accordance with this Regulation, unless the Agency has determined before 28 March 2008 that such conditions do not provide for a level of safety equivalent to that required by Regulation (EC) No 216/2008 or this Regulation.

Article 8U.K.Design organisations

1.An organisation responsible for the design of products, parts and appliances or for changes or repairs thereto shall demonstrate its capability in accordance with Annex I (Part 21).

2.By way of derogation from point 1, an organisation whose principal place of business is in a non-member State may demonstrate its capability by holding a certificate issued by that State for the product, part and appliance for which it applies, provided:

(a)that State is the State of design; and

(b)the Agency has determined that the system of that State includes the same independent level of checking of compliance as provided by this Regulation, either through an equivalent system of approvals of organisations or through direct involvement of the competent authority of that State.

3.Design organisation approvals issued or recognised by a Member State in accordance with the JAA requirements and procedures and valid before 28 September 2003 shall be deemed to comply with this Regulation.

Article 9U.K.Production organisations

1.An organisation responsible for the manufacture of products, parts and appliances shall demonstrate its capability in accordance with the provisions of Annex I (Part 21).

2.By way of derogation from point 1, a manufacturer whose principal place of business is in a non-member State may demonstrate its capability by holding a certificate issued by that State for the product, part and appliance for which it applies, provided:

(a)that State is the State of manufacture; and

(b)the Agency has determined that the system of that State includes the same independent level of checking of compliance as provided by this Regulation, either through an equivalent system of approvals of organisations or through direct involvement of the competent authority of that State.

3.Production organisation approvals issued or recognised by a Member State in accordance with the JAA requirements and procedures and valid before 28 September 2003 shall be deemed to comply with this Regulation.

Article 10U.K.Agency measures

1.The Agency shall develop acceptable means of compliance (hereinafter called ‘AMC’) that competent authorities, organisations and personnel may use to demonstrate compliance with the provisions of the Annex I (Part 21) to this Regulation.

2.The AMC issued by the Agency shall neither introduce new requirements nor alleviate the requirements of the Annex I (Part 21) to this Regulation.

3.Without prejudice to Articles 54 and 55 of Regulation (EC) No 216/2008, when the acceptable means of compliance issued by the Agency are used, the related requirements of the Annex I (Part 21) to this Regulation shall be considered as met without further demonstration.

Article 11U.K.Repeal

Regulation (EC) No 1702/2003 is repealed.

References to the repealed Regulation shall be construed as references to this Regulation and shall be read in accordance with the correlation table in Annex III.

Article 12U.K.Entry into force

This Regulation shall enter into force on the twentieth day following that of its publication in the Official Journal of the European Union.

This Regulation shall be binding in its entirety and directly applicable in all Member States.

Done at Brussels, 3 August 2012.

For the Commission

The President

José Manuel Barroso

ANNEX IU.K.

PART 21 U.K. Certification of aircraft and related products, parts and appliances, and of design and production organisations

21.1 General U.K.

For the purpose of this Annex I (Part 21), ‘competent authority’ shall be:

for organisations having their principal place of business in a Member State, the authority designated by that Member State; or the Agency if so requested by that Member State; or

for organisations having their principal place of business in a non-member State, the Agency.

SECTION A U.K. TECHNICAL REQUIREMENTS

SUBPART A —GENERAL PROVISIONSU.K.

21.A.1 Scope U.K.

This Section establishes general provisions governing the rights and obligations of the applicant for, and holder of, any certificate issued or to be issued in accordance with this Section.

21.A.2 Undertaking by another person than the applicant for, or holder of, a certificate U.K.

The actions and obligations required to be undertaken by the holder of, or applicant for, a certificate for a product, part or appliance under this Section may be undertaken on its behalf by any other natural or legal person, provided the holder of, or applicant for, that certificate can show that it has made an agreement with the other person such as to ensure that the holder’s obligations are and will be properly discharged.

21.A.3A Failures, malfunctions and defects U.K.

(a)System for Collection, Investigation and Analysis of DataU.K.

The holder of a type-certificate, restricted type-certificate, supplemental type-certificate, European Technical Standard Order (ETSO) authorisation, major repair design approval or any other relevant approval deemed to have been issued under this Regulation shall have a system for collecting, investigating and analysing reports of and information related to failures, malfunctions, defects or other occurrences which cause or might cause adverse effects on the continuing airworthiness of the product, part or appliance covered by the type-certificate, restricted type-certificate, supplemental type-certificate, ETSO authorisation, major repair design approval or any other relevant approval deemed to have been issued under this Regulation. Information about this system shall be made available to all known operators of the product, part or appliance and, on request, to any person authorised under other associated implementing Regulations.

(b)Reporting to the AgencyU.K.

The holder of a type-certificate, restricted type-certificate, supplemental type-certificate, ETSO authorisation, major repair design approval or any other relevant approval deemed to have been issued under this Regulation shall report to the Agency any failure, malfunction, defect or other occurrence of which it is aware related to a product, part, or appliance covered by the type-certificate, restricted type-certificate, supplemental type-certificate, ETSO authorisation, major repair design approval or any other relevant approval deemed to have been issued under this Regulation, and which has resulted in or may result in an unsafe condition.

These reports shall be made in a form and manner established by the Agency, as soon as practicable and in any case dispatched not later than 72 hours after the identification of the possible unsafe condition, unless exceptional circumstances prevent this.

(c)Investigation of Reported OccurrencesU.K.

When an occurrence reported under point (b), or under points 21.A.129(f)(2) or 21.A.165(f)(2) results from a deficiency in the design, or a manufacturing deficiency, the holder of the type-certificate, restricted type-certificate, supplemental type-certificate, major repair design approval, ETSO authorisation, or any other relevant approval deemed to have been issued under this Regulation, or the manufacturer as appropriate, shall investigate the reason for the deficiency and report to the Agency the results of its investigation and any action it is taking or proposes to take to correct that deficiency.

If the Agency finds that an action is required to correct the deficiency, the holder of the type-certificate, restricted type-certificate, supplemental type-certificate, major repair design approval, ETSO authorisation, or any other relevant approval deemed to have been issued under this Regulation, or the manufacturer as appropriate, shall submit the relevant data to the Agency.

21.A.3B Airworthiness directives U.K.

(a)An airworthiness directive means a document issued or adopted by the Agency which mandates actions to be performed on an aircraft to restore an acceptable level of safety, when evidence shows that the safety level of this aircraft may otherwise be compromised.U.K.

(b)The Agency shall issue an airworthiness directive when:U.K.

an unsafe condition has been determined by the Agency to exist in an aircraft, as a result of a deficiency in the aircraft, or an engine, propeller, part or appliance installed on this aircraft; and

that condition is likely to exist or develop in other aircraft.

(c)When an airworthiness directive has to be issued by the agency to correct the unsafe condition referred to in point (b), or to require the performance of an inspection, the holder of the type-certificate, restricted type-certificate, supplemental type-certificate, major repair design approval, ETSO authorisation or any other relevant approval deemed to have been issued under this Regulation, shall:U.K.

propose the appropriate corrective action or required inspections, or both, and submit details of these proposals to the Agency for approval;

following the approval by the Agency of the proposals referred to under point (1), make available to all known operators or owners of the product, part or appliance and, on request, to any person required to comply with the airworthiness directive, appropriate descriptive data and accomplishment instructions.

(d)An airworthiness directive shall contain at least the following information:U.K.

an identification of the unsafe condition;

an identification of the affected aircraft;

the action(s) required;

the compliance time for the required action(s);

the date of entry into force.

21.A.4 Coordination between design and production U.K.

Each holder of a type-certificate, restricted type-certificate, supplemental type-certificate, ETSO authorisation, approval of a change to type design or approval of a repair design, shall collaborate with the production organisation as necessary to ensure:

the satisfactory coordination of design and production required by point 21.A.122 or point 21.A.133 or point 21.A.165(c)(2) as appropriate; and

the proper support of the continued airworthiness of the product, part or appliance.

SUBPART B —TYPE-CERTIFICATES AND RESTRICTED TYPE-CERTIFICATESU.K.

21.A.11 Scope U.K.

This Subpart establishes the procedure for issuing type-certificates for products and restricted type-certificates for aircraft, and establishes the rights and obligations of the applicants for, and holders of, those certificates.

21.A.13 Eligibility U.K.

Any natural or legal person that has demonstrated, or is in the process of demonstrating, its capability in accordance with point 21.A.14 shall be eligible as an applicant for a type-certificate or a restricted type-certificate under the conditions laid down in this Subpart.

21.A.14 Demonstration of capability U.K.

(a)Any organisation applying for a type-certificate or restricted type-certificate shall demonstrate its capability by holding a design organisation approval, issued by the Agency in accordance with Subpart J.U.K.

(b)By way of derogation from point (a), as an alternative procedure to demonstrate its capability, an applicant may seek the agreement of the Agency for the use of procedures setting out the specific design practices, resources and sequence of activities necessary to comply with this Annex I (Part 21), when the product is one of the following:U.K.

an ELA2 aircraft;

an engine or propeller installed in ELA2 aircraft;

a piston engine;

a fixed or adjustable pitch propeller.

(c)By way of derogation from point (a), an applicant may choose for demonstration of capability by providing the Agency with the certification programme required by point 21.A.20(b) when the product is one of the following:U.K.

an ELA1 aircraft;

an engine or propeller installed in an ELA1 aircraft.

21.A.15 Application U.K.

(a)An application for a type-certificate or restricted type-certificate shall be made in a form and manner established by the Agency.U.K.

(b)An application for an aircraft type-certificate or restricted type-certificate shall be accompanied by a three-view drawing of that aircraft and preliminary basic data, including the proposed operating characteristics and limitations.U.K.

(c)An application for an engine or propeller type-certificate shall be accompanied by a general arrangement drawing, a description of the design features, the operating characteristics, and the proposed operating limitations, of the engine, or propeller.U.K.

21.A.16A Airworthiness codes U.K.

The Agency shall issue in accordance with Article 19 of Regulation (EC) No 216/2008 airworthiness codes as standard means to show compliance of products, parts and appliances with the essential requirements of Annex I (Part 21) to Regulation (EC) No 216/2008. Such codes shall be sufficiently detailed and specific to indicate to applicants the conditions under which certificates will be issued.

21.A.16B Special conditions U.K.

(a)The Agency shall prescribe special detailed technical specifications, named special conditions, for a product, if the related airworthiness code does not contain adequate or appropriate safety standards for the product, because:U.K.

the product has novel or unusual design features relative to the design practices on which the applicable airworthiness code is based; or

the intended use of the product is unconventional; or

experience from other similar products in service or products having similar design features, has shown that unsafe conditions may develop.

(b)The special conditions contain such safety standards as the Agency finds necessary to establish a level of safety equivalent to that established in the applicable airworthiness code.U.K.

21.A.17 Type-certification basis U.K.

(a)The type-certification basis to be notified for the issuance of a type-certificate or a restricted type-certificate shall consist of:U.K.

the applicable airworthiness code established by the Agency that is effective on the date of application for that certificate unless:

otherwise specified by the Agency; or

compliance with certification specifications of later effective amendments is chosen by the applicant or required under points (c) and (d);

any special condition prescribed in accordance with point 21.A.16B(a).

(b)An application for type-certification of large aeroplanes and large rotorcraft shall be effective for five years and an application for any other type-certificate shall be effective for three years, unless an applicant shows at the time of application that its product requires a longer period of time for design, development, and testing, and the Agency approves a longer period.U.K.

(c)In the case where a type-certificate has not been issued, or it is clear that a type-certificate will not be issued, within the time limit established under point (b), the applicant may:U.K.

file a new application for a type-certificate and comply with all the provisions of point (a) applicable to an original application; or

file for an extension of the original application and comply with the applicable airworthiness codes that were effective on a date, to be selected by the applicant, not earlier than the date which precedes the date of issue of the type-certificate by the time limit established under point (b) for the original application.

(d)If an applicant chooses to comply with a certification specification of an amendment to the airworthiness codes that is effective after the filing of the application for a type-certificate, the applicant shall also comply with any other certification specification that the Agency finds is directly related.U.K.

21.A.18 Designation of applicable environmental protection requirements and certification specifications U.K.

(a)The applicable noise requirements for the issue of a type-certificate for an aircraft are prescribed according to the provisions of Chapter 1 of Annex 16, Volume I, Part II to the Chicago Convention and:U.K.

for subsonic jet aeroplanes, in Volume I, Part II, Chapters 2, 3 and 4, as applicable;

for propeller-driven aeroplanes, in Volume I, Part II, Chapters 3, 4, 5, 6 and 10, as applicable;

for helicopters, in Volume I, Part II, Chapters 8 and 11, as applicable; and

for supersonic aeroplanes, in Volume I, Part II, Chapter 12, as applicable.

(b)The applicable emission requirements for the issue of a type-certificate for an aircraft and engine are prescribed in Annex 16 to the Chicago Convention:U.K.

for prevention of intentional fuel venting, in Volume II, Part II, Chapter 2;

for emissions of turbo-jet and turbofan engines intended for propulsion only at subsonic speeds, in Volume II, Part III, Chapter 2; and

for emissions of turbo-jet and turbofan engines intended for propulsion only at supersonic speeds, in Volume II, Part III, Chapter 3.

(c)The Agency shall issue, in accordance with Article 19 of Regulation (EC) No 216/2008, certification specifications providing for acceptable means to demonstrate compliance with the noise and the emission requirements laid down in points (a) and (b) respectively.U.K.

21.A.19 Changes requiring a new type-certificate U.K.

Any natural or legal person proposing to change a product shall apply for a new type-certificate if the Agency finds that the change in design, power, thrust, or mass is so extensive that a substantially complete investigation of compliance with the applicable type-certification basis is required.

21.A.20 Compliance with the type-certification basis and environmental protection requirements U.K.

(a)The applicant for a type-certificate or a restricted type-certificate shall demonstrate compliance with the applicable type-certification basis and environmental protection requirements and shall provide the Agency with the means by which such compliance has been demonstrated.U.K.

(b)The applicant shall provide the Agency with a certification programme detailing the means for compliance demonstration. This document shall be updated as necessary during the certification process.U.K.

(c)The applicant shall record justification of compliance within compliance documents according to the certification programme established under point (b).U.K.

(d)The applicant shall declare that it has demonstrated compliance with the applicable type-certification basis and environmental protection requirements, according to the certification programme established under point (b).U.K.

(e)Where the applicant holds an appropriate design organisation approval, the declaration of point (d) shall be made according to the provisions of Subpart J.U.K.

21.A.21 Issue of a type-certificate U.K.

The applicant shall be entitled to have a product type-certificate issued by the Agency after:

demonstrating its capability in accordance with point 21.A.14;

submitting the declaration referred to in point 21.A.20(d); and

it is shown that:

the product to be certificated meets the applicable type-certification basis and environmental protection requirements designated in accordance with points 21.A.17 and 21.A.18;

any airworthiness provisions not complied with are compensated for by factors that provide an equivalent level of safety;

no feature or characteristic makes it unsafe for the uses for which certification is requested; and

the type-certificate applicant has expressly stated that it is prepared to comply with point 21.A.44.

In the case of an aircraft type-certificate, the engine or propeller, or both, if installed in the aircraft, have a type-certificate issued or determined in accordance with this Regulation.

21.A.23 Issue of a restricted type-certificate U.K.

(a)For an aircraft that does not meet the provisions of point 21.A.21(c), the applicant shall be entitled to have a restricted type-certificate issued by the Agency after:U.K.

complying with the appropriate type-certification basis established by the Agency ensuring adequate safety with regard to the intended use of the aircraft, and with the applicable environmental protection requirements;

expressly stating that it is prepared to comply with point 21.A.44.

(b)The engine or propeller installed in the aircraft, or both, shall:U.K.

have a type-certificate issued or determined in accordance with this Regulation; or

have been shown to be in compliance with the certification specifications necessary to ensure safe flight of the aircraft.

21.A.31 Type design U.K.

(a)The type design shall consist of:U.K.

the drawings and specifications, and a listing of those drawings and specifications, necessary to define the configuration and the design features of the product shown to comply with the applicable type-certification basis and environmental protection requirements;

information on materials and processes and on methods of manufacture and assembly of the product necessary to ensure the conformity of the product;

an approved airworthiness limitations section of the instructions for continued airworthiness as defined by the applicable airworthiness code; and

any other data necessary to allow by comparison, the determination of the airworthiness, the characteristics of noise, fuel venting, and exhaust emissions (where applicable) of later products of the same type.

(b)Each type design shall be adequately identified.U.K.

21.A.33 Inspection and tests U.K.

(a)The applicant shall perform all inspections and tests necessary to demonstrate compliance with the applicable type-certification basis and environmental protection requirements.U.K.

(b)Before each test required by point (a) is undertaken, the applicant shall have determined:U.K.

for the test specimen:

that materials and processes adequately conform to the specifications for the proposed type design;

that parts of the products adequately conform to the drawings in the proposed type design;

that the manufacturing processes, construction and assembly adequately conform to those specified in the proposed type design; and

that the test equipment and all measuring equipment used for tests are adequate for the test and are appropriately calibrated.

(c)The applicant shall allow the Agency to make any inspection necessary to check compliance with point (b).U.K.

(d)The applicant shall allow the Agency to review any report and make any inspection and to perform or witness any flight and ground test necessary to check the validity of the declaration of compliance submitted by the applicant under point 21.A.20(d) and to determine that no feature or characteristic makes the product unsafe for the uses for which certification is requested.U.K.

(e)For tests performed or witnessed by the Agency under point (d):U.K.

the applicant shall submit to the Agency a statement of compliance with point (b); and

no change relating to the test that would affect the statement of compliance may be made to a product, part or appliance between the time compliance with point (b) is shown and the time it is presented to the Agency for test.

21.A.35 Flight Tests U.K.

(a)Flight testing for the purpose of obtaining a type-certificate shall be conducted in accordance with conditions for such flight testing specified by the Agency.U.K.

(b)The applicant shall make all flight tests that the Agency finds necessary:U.K.

to determine compliance with the applicable type-certification basis and environmental protection requirements; and

to determine whether there is reasonable assurance that the aircraft, its parts and appliances are reliable and function properly for aircraft to be certificated under this Annex I (Part 21), except for,

sailplanes and powered sailplanes;

balloons and airships defined in ELA1 or ELA2;

aeroplanes of 2 722 kg or less maximum take-off mass (MTOM).

(c)(Reserved)U.K.

(d)(Reserved)U.K.

(e)(Reserved)U.K.

(f)The flight tests prescribed in point (b)(2) shall include:U.K.

for aircraft incorporating turbine engines of a type not previously used in a type-certificated aircraft, at least 300 hours of operation with a full complement of engines that conform to a type-certificate; and

for all other aircraft, at least 150 hours of operation.

21.A.41 Type-certificate U.K.

The type-certificate and restricted type-certificate are both considered to include the type design, the operating limitations, the type-certificate data sheet for airworthiness and emissions, the applicable type-certification basis and environmental protection requirements with which the Agency records compliance, and any other conditions or limitations prescribed for the product in the applicable certification specifications and environmental protection requirements. The aircraft type-certificate and restricted type-certificate, in addition, both include the type-certificate data sheet for noise. The engine type-certificate data sheet includes the record of emission compliance.

21.A.44 Obligations of the holder U.K.

Each holder of a type-certificate or restricted type-certificate shall:

undertake the obligations laid down in points 21.A.3A, 21.A.3B, 21.A.4, 21.A.55, 21.A.57 and 21.A.61; and, for this purpose, shall continue to meet the qualification requirements for eligibility under point 21.A.14; and

specify the marking in accordance with Subpart Q.

21.A.47 Transferability U.K.

Transfer of a type-certificate or restricted type-certificate may only be made to a natural or legal person that is able to undertake the obligations under point 21.A.44, and, for this purpose, has demonstrated its ability to qualify under the criteria of point 21.A.14.

21.A.51 Duration and continued validity U.K.

(a)A type-certificate and restricted type-certificate shall be issued for an unlimited duration. They shall remain valid subject to:U.K.

the holder remaining in compliance with this Annex 1 (Part 21); and

the certificate not being surrendered or revoked under the applicable administrative procedures established by the Agency.

(b)Upon surrender or revocation, the type-certificate and restricted type-certificate shall be returned to the Agency.U.K.

21.A.55 Record-keeping U.K.

All relevant design information, drawings and test reports, including inspection records for the product tested, shall be held by the type-certificate or restricted type-certificate holder at the disposal of the Agency and shall be retained in order to provide the information necessary to ensure the continued airworthiness and compliance with applicable environmental protection requirements of the product.

21.A.57 Manuals U.K.

The holder of a type-certificate or restricted type-certificate shall produce, maintain and update master copies of all manuals required by the applicable type-certification basis and environmental protection requirements for the product, and provide copies, on request, to the Agency.

21.A.61 Instructions for continued airworthiness U.K.

(a)The holder of the type-certificate or restricted type-certificate shall furnish at least one set of complete instructions for continued airworthiness, comprising descriptive data and accomplishment instructions prepared in accordance with the applicable type-certification basis, to each known owner of one or more aircraft, engine or propeller upon its delivery or upon issue of the first certificate of airworthiness for the affected aircraft, whichever occurs later and thereafter make those instructions available on request to any other person required to comply with any of the terms of those instructions. The availability of some manual or portion of the instructions for continued airworthiness, dealing with overhaul or other forms of heavy maintenance, may be delayed until after the product has entered into service, but shall be available before any of the products reaches the relevant age or flight-hours/cycles.U.K.

(b)In addition, changes to the instructions for continued airworthiness shall be made available to all known operators of the product and shall be made available on request to any person required to comply with any of those instructions. A programme showing how changes to the instructions for continued airworthiness are distributed shall be submitted to the Agency.U.K.

(SUBPART C — NOT APPLICABLE)U.K.

SUBPART D —CHANGES TO TYPE-CERTIFICATES AND RESTRICTED TYPE-CERTIFICATESU.K.

21.A.90A Scope U.K.

This Subpart establishes the procedure for the approval of changes to type designs and type-certificates, and establishes the rights and obligations of the applicants for, and holders of, those approvals. This Subpart also defines standard changes that are not subject to an approval process under this Subpart. In this Subpart, references to type-certificates include type-certificate and restricted type-certificate.

21.A.90B Standard changes U.K.

(a)Standard changes are changes to a type design:U.K.

in relation to:

aeroplanes of 5 700 kg Maximum Take-Off Mass (MTOM) or less;

rotorcraft of 3 175 kg MTOM or less;

sailplanes, powered sailplanes, balloons and airships, as defined in ELA1 or ELA2,

that follow design data included in certification specifications issued by the Agency, containing acceptable methods, techniques and practices for carrying out and identifying standard changes, including the associated instructions for continuing airworthiness; and

that are not in conflict with TC holders data.

(b)Points 21.A.91 to 21.A.109 are not applicable to standard changes.U.K.

21.A.91 Classification of changes in type design U.K.

Changes in type design are classified as minor and major. A ‘minor change’ is one that has no appreciable effect on the mass, balance, structural strength, reliability, operational characteristics, noise, fuel venting, exhaust emission, or other characteristics affecting the airworthiness of the product. Without prejudice to point 21.A.19, all other changes are ‘major changes’ under this Subpart. Major and minor changes shall be approved in accordance with points 21.A.95 or 21.A.97 as appropriate, and shall be adequately identified.

21.A.92 Eligibility U.K.

(a)Only the type-certificate holder may apply for approval of a major change to a type design under this Subpart; all other applicants for a major change to a type design shall apply under Subpart E.U.K.

(b)Any natural or legal person may apply for approval of a minor change to a type design under this Subpart.U.K.

21.A.93 Application U.K.

An application for approval of a change to a type design shall be made in a form and manner established by the Agency and shall include:

A description of the change identifying:

all parts of the type design and the approved manuals affected by the change; and

the certification specifications and environmental protection requirements with which the change has been designed to comply in accordance with point 21.A.101.

Identification of any re-investigations necessary to show compliance of the changed product with the applicable certification specifications and environmental protection requirements.

21.A.95 Minor changes U.K.

Minor changes in a type design shall be classified and approved either:

by the Agency; or

by an appropriately approved design organisation under a procedure agreed with the Agency.

21.A.97 Major changes U.K.

(a)An applicant for approval of a major change shall:U.K.

submit to the Agency substantiating data together with any necessary descriptive data for inclusion in the type design;

demonstrate that the changed product complies with applicable certification specifications and environmental protection requirements, as specified in point 21.A.101;

comply with points 21.A.20(b), (c) and (d); and

where the applicant holds an appropriate design organisation approval, make the declaration referred to in point 21.A.20(d) according to the provisions of Subpart J;

comply with point 21.A.33 and, where applicable, point 21.A.35.

(b)Approval of a major change in a type design is limited to that or those specific configuration(s) in the type design upon which the change is made.U.K.

21.A.101 Designation of applicable certification specifications and environmental protection requirements U.K.

(a)An applicant for a change to a type-certificate shall demonstrate that the changed product complies with the airworthiness code that is applicable to the changed product and that is in effect at the date of the application for the change, unless compliance with certification specifications of later effective amendments is chosen by the applicant or required under points (e) and (f), and with the applicable environmental protection requirements laid down in point 21.A.18.U.K.

(b)By derogation from point (a), an applicant may show that the changed product complies with an earlier amendment of the airworthiness code defined in point (a), and of any other certification specification the Agency finds is directly related. However, the earlier amended airworthiness code may not precede the corresponding airworthiness code incorporated by reference in the type-certificate. The applicant may show compliance with an earlier amendment of an airworthiness code for any of the following:U.K.

A change that the Agency finds not to be significant. In determining whether a specific change is significant, the Agency considers the change in context with all previous relevant design changes and all related revisions to the applicable certification specifications incorporated in the type-certificate for the product. Changes that meet one of the following criteria are automatically considered significant:

the general configuration or the principles of construction are not retained;

the assumptions used for certification of the product to be changed do not remain valid.

Each area, system, part or appliance that the Agency finds is not affected by the change.

Each area, system, part or appliance that is affected by the change, for which the Agency finds that compliance with an airworthiness code described in point (a) would not contribute materially to the level of safety of the changed product or would be impractical.

(c)An applicant for a change to an aircraft (other than a rotorcraft) of 2 722 kg (6 000 lbs) or less maximum weight or to a non-turbine rotorcraft of 1 361 kg (3 000 lbs) or less maximum weight may show that the changed product complies with the type-certification basis incorporated by reference in the type-certificate. However, if the Agency finds that the change is significant in an area, the Agency may designate compliance with an amendment to the type-certification basis incorporated by reference in the type-certificate, in effect at the date of the application, and any certification specification that the Agency finds is directly related, unless the Agency also finds that compliance with that amendment or certification specification would not contribute materially to the level of safety of the changed product or would be impractical.U.K.

(d)If the Agency finds that the airworthiness code in effect at the date of the application for the change does not provide adequate standards with respect to the proposed change, the applicant shall also comply with any special conditions, and amendments to those special conditions, prescribed under the provisions of point 21.A.16B, to provide a level of safety equivalent to that established in the airworthiness code in effect at the date of the application for the change.U.K.

(e)An application for a change to a type-certificate for large aeroplanes and large rotorcraft is effective for five years, and an application for a change to any other type-certificate is effective for three years. In a case where the change has not been approved, or it is clear that it will not be approved under the time limit established under this point, the applicant may:U.K.

file a new application for a change to the type-certificate and comply with all the provisions of point (a) applicable to an original application for a change; or

file for an extension of the original application and comply with the provisions of point (a) for an effective date of application, to be selected by the applicant, not earlier than the date which precedes the date of approval of the change by the time period established under this point for the original application for the change.

(f)If an applicant chooses to comply with a certification specification of an amendment to the airworthiness codes that is effective after the filing of the application for a change to a type, the applicant shall also comply with any other certification specification that the Agency finds is directly related.U.K.

21.A.103 Issue of approval U.K.

(a)The applicant shall be entitled to have a major change to a type design approved by the Agency after:U.K.

submitting the declaration referred to in point 21.A.20(d); and

it is demonstrated that:

the changed product meets the applicable certification specifications and environmental protection requirements, as specified in point 21.A.101;

any airworthiness provisions not complied with are compensated for by factors that provide an equivalent level of safety; and

no feature or characteristic makes the product unsafe for the uses for which certification is requested.

(b)A minor change to a type design shall only be approved in accordance with point 21.A.95 if it is shown that the changed product meets the applicable certification specifications, as specified in point 21.A.101.U.K.

21.A.105 Record-keeping U.K.

For each change, all relevant design information, drawings and test reports, including inspection records for the changed product tested, shall be held by the applicant at the disposal of the Agency and shall be retained in order to provide the information necessary to ensure the continued airworthiness and compliance with applicable environmental protection requirements of the changed product.

21.A.107 Instructions for continued airworthiness U.K.

(a)The holder of a minor change approval to type design shall furnish at least one set of the associated variations, if any, to the instructions for continued airworthiness of the product on which the minor change is to be installed, prepared in accordance with the applicable type-certification basis, to each known owner of one or more aircraft, engine, or propeller incorporating the minor change, upon its delivery, or upon issuance of the first certificate of airworthiness for the affected aircraft, whichever occurs later, and thereafter make those variations in instructions available, on request, to any other person required to comply with any of the terms of those instructions.U.K.

(b)In addition, changes to those variations of the instructions for continued airworthiness shall be made available to all known operators of a product incorporating the minor change and shall be made available, on request, to any person required to comply with any of those instructions.U.K.

21.A.109 Obligations and EPA marking U.K.

The holder of a minor change approval to type design shall:

undertake the obligations laid down in points 21.A.4, 21.A.105 and 21.A.107; and

specify the marking, including EPA (‘European Part Approval’) letters, in accordance with point 21.A.804(a).

SUBPART E —SUPPLEMENTAL TYPE-CERTIFICATESU.K.

21.A.111 Scope U.K.

This Subpart establishes the procedure for the approval of major changes to the type design under supplemental type-certificate procedures, and establishes the rights and obligations of the applicants for, and holders of, those certificates.

21.A.112A Eligibility U.K.

Any natural or legal person (‘organisation’) that has demonstrated, or is in the process of demonstrating, its capability under point 21.A.112B shall be eligible as an applicant for a supplemental type-certificate under the conditions laid down in this Subpart.

21.A.112B Demonstration of capability U.K.

(a)Any organisation applying for a supplemental type-certificate shall demonstrate its capability by holding a design organisation approval, issued by the Agency in accordance with Subpart J.U.K.

(b)By way of derogation from point (a), as an alternative procedure to demonstrate its capability, an applicant may seek Agency agreement for the use of procedures setting out the specific design practices, resources and sequence of activities necessary to comply with this Subpart.U.K.

(c)By way of derogation from points (a) and (b), an applicant may choose for demonstration of capability through Agency approval of a certification programme detailing the means for compliance demonstration for an STC on an aircraft, engine and propeller defined in point 21.A.14(c).U.K.

21.A.113 Application for a supplemental type-certificate U.K.

(a)An application for a supplemental type-certificate shall be made in a form and manner established by the Agency.U.K.

(b)An application for a supplemental type-certificate shall include the descriptions and identification required by point 21.A.93. In addition, such an application shall include a justification that the information on which those identifications are based is adequate either from the applicant’s own resources, or through an arrangement with the type-certificate holder.U.K.

21.A.114 Showing of compliance U.K.

Any applicant for a supplemental type-certificate shall comply with point 21.A.97.

21.A.115 Issue of a supplemental type-certificate U.K.

The applicant shall be entitled to have a supplemental type-certificate issued by the Agency after:

submitting the declaration referred to in point 21.A.20(d); and

it is demonstrated that:

the changed product meets the applicable certification specifications and environmental protection requirements, as specified in point 21.A.101;

any airworthiness provisions not complied with are compensated for by factors that provide an equivalent level of safety; and

no feature or characteristic makes the product unsafe for the uses for which certification is requested.

demonstrating its capability in accordance with point 21.A.112B;

where, under point 21.A.113(b), the applicant has entered into an arrangement with the type-certificate holder,

the type-certificate holder has advised that it has no technical objection to the information submitted under point 21.A.93; and

the type-certificate holder has agreed to collaborate with the supplemental type-certificate holder to ensure discharge of all obligations for continued airworthiness of the changed product through compliance with points 21.A.44 and 21.A.118A.

21.A.116 Transferability U.K.

A supplemental type-certificate shall only be transferred to a natural or legal person that is able to undertake the obligations of point 21.A.118A and for this purpose has demonstrated its ability to qualify under the criteria of point 21.A.112B except for ELA1 aircraft for which the natural or legal person has sought the Agency agreement for the use of procedures setting out its activities to undertake these obligations.

21.A.117 Changes to that part of a product covered by a supplemental type-certificate U.K.

(a)Minor changes to that part of a product covered by a supplemental type-certificate shall be classified and approved in accordance with Subpart D.U.K.

(b)Each major change to that part of a product covered by a supplemental type-certificate shall be approved as a separate supplemental type-certificate in accordance with this Subpart.U.K.

(c)By way of derogation from point (b), a major change to that part of a product covered by a supplemental type-certificate submitted by the supplemental type-certificate holder itself may be approved as a change to the existing supplemental type-certificate.U.K.

21.A.118A Obligations and EPA marking U.K.

Each holder of a supplemental type-certificate shall:

undertake the obligations:

laid down in points 21.A.3A, 21.A.3B, 21.A.4, 21.A.105, 21.A.119 and 21.A.120;

implicit in the collaboration with the type-certificate holder under point 21.A.115(c)(2);

and for this purpose continue to meet the criteria of point 21.A.112B;

specify the marking, including EPA letters, in accordance with point 21.A.804(a).

21.A.118B Duration and continued validity U.K.

(a)A supplemental type-certificate shall be issued for an unlimited duration. It shall remain valid subject to:U.K.

the holder remaining in compliance with this Annex I (Part 21); and

the certificate not being surrendered or revoked under the applicable administrative procedures established by the Agency.

(b)Upon surrender or revocation, the supplemental type-certificate shall be returned to the Agency.U.K.

21.A.119 Manuals U.K.

The holder of a supplemental type-certificate shall produce, maintain, and update master copies of variations in the manuals required by the applicable type-certification basis and environmental protection requirements for the product, necessary to cover the changes introduced under the supplemental type-certificate, and furnish copies of these manuals to the Agency on request.

21.A.120 Instructions for continued airworthiness U.K.

(a)The holder of the supplemental type-certificate for an aircraft, engine, or propeller, shall furnish at least one set of the associated variations to the instructions for continued airworthiness, prepared in accordance with the applicable type-certification basis, to each known owner of one or more aircraft, engine, or propeller incorporating the features of the supplemental type-certificate, upon its delivery, or upon issuance of the first certificate of airworthiness for the affected aircraft, whichever occurs later, and thereafter make those variations in instructions available, on request, to any other person required to comply with any of the terms of those instructions. Availability of some manual or portion of the variations to the instructions for continued airworthiness, dealing with overhaul or other forms of heavy maintenance, may be delayed until after the product has entered into service, but shall be available before any of the products reaches the relevant age or flight-hours/cycles.U.K.

(b)In addition, changes to those variations of the instructions for continued airworthiness shall be made available to all known operators of a product incorporating the supplemental type-certificate and shall be made available, on request, to any person required to comply with any of those instructions. A programme showing how changes to the variations to the instructions for continued airworthiness are distributed shall be submitted to the Agency.U.K.

SUBPART F —PRODUCTION WITHOUT PRODUCTION ORGANISATION APPROVALU.K.

21.A.121 Scope U.K.

(a)This Subpart establishes the procedure for demonstrating the conformity with the applicable design data of a product, part and appliance that is intended to be manufactured without a production organisation approval under Subpart G.U.K.

(b)This Subpart establishes the rules governing the obligations of the manufacturer of a product, part, or appliance being manufactured under this Subpart.U.K.

21.A.122 Eligibility U.K.

Any natural or legal person may apply to show conformity of individual products, parts or appliances under this Subpart, if:

it holds or has applied for an approval covering the design of that product, part or appliance; or

it has ensured satisfactory coordination between production and design, through an appropriate arrangement with the applicant for, or holder of, an approval of such a design.

21.A.124 Application U.K.

(a)Each application for an agreement to the showing of conformity of individual products, parts and appliances under this Subpart shall be made in a form and manner established by the competent authority.U.K.

(b)Such application shall contain:U.K.

evidence which demonstrates, where applicable, that:

the issuance of a production organisation approval under Subpart G would be inappropriate; or

the certification or approval of a product, part or appliance under this Subpart is needed pending the issuance of a production organisation approval under Subpart G;

an outline of the information required in point 21.A.125A(b).

21.A.125A Issue of a letter of agreement U.K.

The applicant shall be entitled to have a letter of agreement issued by the competent authority agreeing to the showing of conformity of individual products, parts and appliances under this Subpart, after:

having established a production inspection system that ensures that each product, part or appliance conforms to the applicable design data and is in condition for safe operation;

having provided a manual that contains:

a description of the production inspection system required under point (a);

a description of the means for making the determination of the production inspection system;

a description of the tests required in points 21.A.127 and 21.A.128, and the names of persons authorised for the purpose of point 21.A.130(a);

demonstrating that it is able to provide assistance in accordance with points 21.A.3A and 21.A.129(d).

21.A.125B Findings U.K.

(a)When objective evidence is found showing non-compliance of the holder of a letter of agreement with the applicable requirements of this Annex I (Part 21), the finding shall be classified as follows:U.K.

a level one finding is any non-compliance with this Annex I (Part 21) which could lead to uncontrolled non-compliances with applicable design data and which could affect the safety of the aircraft;

a level two finding is any non-compliance with this Annex I (Part 21) which is not classified as level one.

(b)A level three finding is any item where it has been identified, by objective evidence, to contain potential problems that could lead to a non-compliance under point (a).U.K.

(c)After receipt of notification of findings according to point 21.B.125:U.K.

in case of a level one finding, the holder of the letter of agreement shall demonstrate corrective action to the satisfaction of the competent authority within a period of no more than 21 working days after written confirmation of the finding;

in case of level two findings, the corrective action period granted by the competent authority shall be appropriate to the nature of the finding but in any case initially shall not be more than three months. In certain circumstances and subject to the nature of the finding, the competent authority may extend the three months period subject to the provision of a satisfactory corrective action plan agreed by the competent authority;

a level three finding shall not require immediate action by the holder of the letter of agreement.

(d)In case of level one or level two findings, the letter of agreement may be subject to a partial or full limitation, suspension and revocation under point 21.B.145. The holder of the letter of agreement shall provide confirmation of receipt of the notice of limitation, suspension or revocation of the letter of agreement in a timely manner.U.K.

21.A.125C Duration and continued validity U.K.

(a)The letter of agreement shall be issued for a limited duration not exceeding one year. It shall remain valid unless:U.K.

the holder of the letter of agreement fails to demonstrate compliance with the applicable requirements of this Subpart; or

there is evidence that the manufacturer cannot maintain satisfactory control of the manufacture of products, parts, or appliances under the agreement; or

the manufacturer no longer meets the requirements of point 21.A.122; or

the letter of agreement has been surrendered, revoked under point 21.B.145, or has expired.

(b)Upon surrender, revocation or expiry, the letter of agreement shall be returned to the competent authority.U.K.

21.A.126 Production inspection system U.K.

(a)The production inspection system required under point 21.A.125A(a) shall provide a means for determining that:U.K.

incoming materials, and bought or subcontracted parts, used in the finished product are as specified in the applicable design data;

incoming materials, and bought or subcontracted parts, are properly identified;

processes, manufacturing techniques and methods of assembly affecting the quality and safety of the finished product are accomplished in accordance with specifications accepted by the competent authority;

design changes, including material substitutions, have been approved under Subpart D or E and controlled before being incorporated in the finished product.

(b)The production inspection system required by point 21.A.125A(a), shall also be such as to ensure that:U.K.

parts in process are inspected for conformity with the applicable design data at points in production where accurate determinations can be made;

materials subject to damage and deterioration are suitably stored and adequately protected;

current design drawings are readily available to manufacturing and inspection personnel, and used when necessary;

rejected materials and parts are segregated and identified in a manner that precludes installation in the finished product;

materials and parts that are withheld because of departures from design data or specifications, and that are to be considered for installation in the finished product, are subjected to an approved engineering and manufacturing review procedure. Those materials and parts determined by this procedure to be serviceable shall be properly identified and reinspected if rework or repair is necessary. Materials and parts rejected by this procedure shall be marked and disposed of to ensure that they are not incorporated in the final product;

records produced under the production inspection system are maintained, identified with the completed product or part where practicable, and retained by the manufacturer in order to provide the information necessary to ensure the continued airworthiness of the product.

21.A.127 Tests: aircraft U.K.

(a)Each manufacturer of an aircraft manufactured under this Subpart shall establish an approved production ground and flight test procedure and check-off forms, and in accordance with those forms, test each aircraft produced, as a means of establishing relevant aspects of compliance with point 21.A.125A(a).U.K.

(b)Each production test procedure shall include at least the following:U.K.

a check on handling qualities;

a check on flight performance (using normal aircraft instrumentation);

a check on the proper functioning of all aircraft equipment and systems;

a determination that all instruments are properly marked, and that all placards and required flight manuals are installed after flight test;

a check of the operational characteristics of the aircraft on the ground;

a check on any other items peculiar to the aircraft being tested.

21.A.128 Tests: engines and propellers U.K.

Each manufacturer of engines, or propellers manufactured under this Subpart shall subject each engine, or variable pitch propeller, to an acceptable functional test as specified in the type-certificate holder’s documentation, to determine if it operates properly throughout the range of operation for which it is type-certificated, as a means of establishing relevant aspects of compliance with point 21.A.125A(a).

21.A.129 Obligations of the manufacturer U.K.

Each manufacturer of a product, part or appliance being manufactured under this Subpart shall:

make each product, part or appliance available for inspection by the competent authority;

maintain at the place of manufacture the technical data and drawings necessary to determine whether the product conforms to the applicable design data;

maintain the production inspection system that ensures that each product conforms to the applicable design data and is in condition for safe operation;

provide assistance to the holder of the type-certificate, restricted type-certificate or design approval in dealing with any continuing airworthiness actions that are related to the products, parts or appliances that have been produced;

establish and maintain an internal occurrence reporting system in the interest of safety, to enable the collection and assessment of occurrence reports in order to identify adverse trends or to address deficiencies, and to extract reportable occurrences. This system shall include evaluation of relevant information relating to occurrences and the promulgation of related information;