- Latest available (Revised)

- Point in Time (31/12/2020)

- Original (As adopted by EU)

Commission Delegated Regulation (EU) No 3/2014Show full title

Commission Delegated Regulation (EU) No 3/2014 of 24 October 2013 supplementing Regulation (EU) No 168/2013 of the European Parliament and of the Council with regard to vehicle functional safety requirements for the approval of two- or three-wheel vehicles and quadricycles (Text with EEA relevance)

You are here:

- Show Geographical Extent(e.g. England, Wales, Scotland and Northern Ireland)

- Show Timeline of Changes

More Resources

Revised version PDFs

- Revised 16/10/20166.74 MB

When the UK left the EU, legislation.gov.uk published EU legislation that had been published by the EU up to IP completion day (31 December 2020 11.00 p.m.). On legislation.gov.uk, these items of legislation are kept up-to-date with any amendments made by the UK since then.

This item of legislation originated from the EU

Legislation.gov.uk publishes the UK version. EUR-Lex publishes the EU version. The EU Exit Web Archive holds a snapshot of EUR-Lex’s version from IP completion day (31 December 2020 11.00 p.m.).

Changes over time for:

Status:

Point in time view as at 31/12/2020.

Changes to legislation:

There are currently no known outstanding effects by UK legislation for Commission Delegated Regulation (EU) No 3/2014.![]()

Changes to Legislation

Revised legislation carried on this site may not be fully up to date. At the current time any known changes or effects made by subsequent legislation have been applied to the text of the legislation you are viewing by the editorial team. Please see ‘Frequently Asked Questions’ for details regarding the timescales for which new effects are identified and recorded on this site.

LIST OF ANNEXES

| [F1Annex number | Annex title |

|---|---|

| I | [F1List of UNECE regulations which apply on a compulsory basis] |

| II | Test procedures and performance requirements applying to audible warning devices |

| III | Requirements applying to braking, including anti-lock and combined braking systems |

| IV | Requirements regarding electrical safety |

| V | Requirements applying to manufacturers’ declaration regarding endurance testing of functional safety critical systems, parts and equipment |

| VI | Requirements applying to front and rear protective structures |

| VII | Requirements applying to glazing, windscreen wipers and washers, and defrosting and demisting systems |

| VIII | Requirements applying to driver-operated controls including identification of controls, tell-tales and indicators |

| IX | Requirements applying to installation of lighting and light signalling devices, including automatic switching of lighting |

| X | Requirements regarding rearward visibility |

| XI | Requirements applying to roll-over protective structure (ROPS) |

| XII | Requirements applying to safety belt anchorages and safety belts |

| XIII | Requirements applying to seating positions (saddles and seats) |

| XIV | Requirements regarding steer-ability, cornering properties and turn-ability |

| XV | Requirements regarding the installation of tyres |

| XVI | Requirements applying to the vehicle maximum speed limitation plate and its location on the vehicle |

| XVII | Requirements regarding vehicle occupant protection, including interior fittings and vehicle doors |

| XVIII | Requirements regarding maximum continuous rated or net power and/or maximum vehicle speed limitation by design |

| XIX | Requirements regarding vehicle structure integrity] |

[F1ANNEX I

List of UNECE regulations which apply on a compulsory basis U.K.

| UNECE regulation No | Subject | Series of amendments | OJ reference | Applicability |

|---|---|---|---|---|

| 1 | Headlamps for motor vehicles (R2, HS1) | 02 | OJ L 177, 10.7.2010, p. 1 . | L1e, L2e, L3e, L4e, L5e, L6e and L7e |

| 3 | Retro-reflectors | Supplement 12 to the 02 series of amendments | OJ L 323, 6.12.2011, p. 1 . | L1e, L2e, L3e, L4e, L5e, L6e and L7e |

| 6 | Direction indicators | Supplement 25 to the 01 series of amendments | OJ L 213, 18.7.2014, p. 1 . | L1e, L2e, L3e, L4e, L5e, L6e and L7e |

| 7 | Front and rear position lamps and stop lamps | Supplement 23 to the 02 series of amendments | OJ L 285, 30.9.2014, p. 1 . | L1e, L2e, L3e, L4e, L5e, L6e and L7e |

| 8 | Head lamps for motor vehicles (H1, H2, H3, HB3, HB4, H7, H8, H9, H11, HIR1, HIR2) | 05 | OJ L 177, 10.7.2010, p. 71 . | L1e, L2e, L3e, L4e, L5e, L6e and L7e |

| 16 | Safety belts, restraint systems and child restraint systems | Supplement 5 to the 06 series of amendments | OJ L 304, 20.11.2015, p. 1 . | L2e, L4e, L5e, L6e and L7e |

| 19 | Front fog lamps | Supplement 6 to the 04 series of amendments | OJ L 250, 22.8.2014, p. 1 . | L3e, L4e, L5e and L7e |

| 20 | Headlamps for motor vehicles (H4) | 03 | OJ L 177, 10.7.2010, p. 170 . | L1e, L2e, L3e, L4e, L5e, L6e and L7e |

| 28 | Audible warning devices | Supplement 3 to the 00 series of amendments | OJ L 323, 6.12.2011, p. 33 . | L3e, L4e and L5e |

| 37 | Filament bulbs | Supplement 42 to the 03 series of amendments | OJ L 213, 18.7.2014, p. 36 . | L1e, L2e, L3e, L4e, L5e, L6e and L7e |

| 38 | Rear fog lamps | Supplement 15 to the 00 series of amendments | OJ L 4, 7.1.2012, p. 20 . | L3e, L4e, L5e and L7e |

| 39 | Uniform provisions concerning the approval of vehicles with regard to the speedometer equipment including its installation | Supplement 5 to the original version of the Regulation | OJ L 120, 13.5.2010, p. 40 . | L1e, L2e, L3e, L4e, L5e, L6e and L7e |

| 43 | Safety glazing | Supplement 2 to the 01 series of amendments | OJ L 42, 12.2.2014, p. 1 . | L1e, L2e, L3e, L4e, L5e, L6e and L7e |

| 46 | Devices for indirect vision (rear-view mirrors) | Supplement 1 to the 04 series of amendments | OJ L 237, 8.8.2014, p. 24 . | L2e, L5e, L6e and L7e |

| 50 | Lighting components for vehicles of category L | Supplement 16 to the 00 series of amendments | OJ L 97, 29.3.2014, p. 1 . | L1e, L2e, L3e, L4e, L5e, L6e and L7e |

| 53 | Installation of lighting (motorcycle) | Supplement 14 to the 01 series of amendments | OJ L 166, 18.6.2013, p. 55 . | L3e |

| 56 | Headlamps for mopeds and vehicles treated as such | 01 | OJ L 89, 25.3.2014, p. 1 . | L1e, L2e and L6e |

| 57 | Headlamps for motorcycles and vehicles treated as such | 02 | OJ L 130, 1.5.2014, p. 45 . | L3e, L4e, L5e and L7e |

| 60 | Identification of controls tell-tales and indicators | Supplement 4 to the 00 series of amendments | OJ L 297, 15.10.2014, p. 23 . | L1e and L3e |

| 72 | Headlamps for motorcycles and vehicles treated as such (HS1) | 01 | OJ L 75, 14.3.2014, p. 1 . | L3e, L4e, L5e and L7e |

| 74 | Installation of lighting (moped) | [X1Supplement 7 to the 01 series of amendments] | OJ L 166, 18.6.2013, p. 88 . | L1e |

| 75 | Tyres | Supplement 13 to the 01 series of amendments | OJ L 84, 30.3.2011, p. 46 . | L1e, L2e, L3e, L4e and L5e |

| 78 | Braking, including anti-lock and combined brake systems | Corrigendum 2 to the 03 series of amendments | OJ L 24, 30.1.2015, p. 30 . | L1e, L2e, L3e, L4e and L5e |

| 81 | Rear-view mirrors | Supplement 2 to the 00 series of amendments | OJ L 185, 13.7.2012, p. 1 . | L1e, L2e, L3e, L4e, L5e, L6e and L7e |

| 82 | Headlamps for mopeds and vehicles treated as such (HS2) | 01 | OJ L 89, 25.3.2014, p. 92 . | L1e, L2e and L6e |

| 87 | Daytime running lamps | Supplement 15 to the 00 series of amendments | OJ L 4, 7.1.2012, p. 24 . | L1e, L2e, L3e, L4e, L5e, L6e and L7e |

| 90 | Replacement brake lining assemblies and drum brake linings | 02 | OJ L 185, 13.7.2012, p. 24 . | L1e, L2e, L3e, L4e, L5e, L6e and L7e |

| 98 | Headlamps with gas-discharge light sources | Supplement 4 to the 01 series of amendments | OJ L 176, 14.6.2014, p. 64 . | L3e |

| 99 | Gas-discharge light sources | Supplement 9 to the 00 series of amendments | OJ L 285, 30.9.2014, p. 35 . | L3e |

| 112 | Headlamps with asymmetrical beams | Supplement 4 to the 01 series of amendments | OJ L 250, 22.8.2014, p. 67 . | L1e, L2e, L3e, L4e, L5e, L6e and L7e |

| 113 | Headlamps with symmetrical beams | Supplement 3 to the 01 series of amendments | OJ L 176, 14.6.2014, p. 128 . | L1e, L2e, L3e, L4e, L5e, L6e and L7e |

Explanatory note: The fact that a component is included in this list does not make its installation mandatory. For certain components, however, mandatory installation requirements are laid down in other annexes to this Regulation.] U.K.

Editorial Information

X1 Substituted by Corrigendum to Commission Delegated Regulation (EU) 2016/1824 of 14 July 2016 amending Delegated Regulation (EU) No 3/2014, Delegated Regulation (EU) No 44/2014 and Delegated Regulation (EU) No 134/2014 with regard, respectively, to vehicle functional safety requirements, to vehicle construction and general requirements and to environmental and propulsion unit performance requirements (Official Journal of the European Union L 279 of 15 October 2016).

ANNEX II

Test procedures and performance requirements applying to audible warning devices U.K.

PART 1U.K. Requirements applying to the component type-approval of a type of mechanical or electrical audible warning device intended to be fitted to vehicles of categories L1e, L2e and L6e

1.General requirementsU.K.

1.1.Electrical audible warning devices shall emit a continuous, uniform sound and their sound spectrum shall not vary perceptibly during operation. In the case of warning devices supplied with an alternating current, this requirement applies solely at constant generator speed, that speed lying within the range specified in point 2.3.2.U.K.

1.2.Electrical audible warning devices shall have sound characteristics (spectral distribution of the sound energy, sound pressure level) and mechanical characteristics such that, in the order stated, they pass the tests specified in points 2 to 3.4.U.K.

1.3.Electrical audible warning devices may incorporate a feature enabling the device to operate at a significantly lower sound pressure level volume.U.K.

1.4.Mechanical audible warning devices shall be equipped with a thumb-operated lever, either of the puller bell type geared to rapidly rotate two loosely-slung metal discs inside the bell housing, or of the single stroke bell type.U.K.

2.Sound level measurementsU.K.

2.1.Audible warning devices shall preferably be tested in an anechoic environment. They may alternatively be tested in a semi-anechoic chamber or in a cleared outside space. In this case, precautions shall be taken to avoid reflections off the ground in the measuring area, e.g. by providing a number of absorbent screens. It shall be checked that the spherical distortion is no more than 1 dB(A) within a hemisphere of a radius of at least 5 m up to the maximum frequency to be measured, this mainly being in the direction of measurement and at the height of the device and microphone. The ambient noise shall be at least 10 dB(A) lower than the sound pressure levels to be measured.U.K.

The device submitted for testing and the microphone shall be at the same height, which shall be between 1,15 and 1,25 m. The line of maximum sensitivity of the microphone shall coincide with the direction in which the sound level of the warning device is at its highest level.

The microphone shall be positioned such that its diaphragm is at a distance of 2 ± 0,01 m from the exit plane of the sound emitted by the device. In the case of devices with several exits, this distance shall be determined in relation to the exit plane closest to the microphone.

2.2.The measurements of the sound pressure level shall involve the use of a class-1 precision sound-level meter meeting the requirements of IEC publication No 651, first edition (1979).U.K.

All measurements shall be carried out using the ‘rapid’ time constant. The (A) weighting curve shall be used to measure the overall sound pressure levels.

The Fourier transform of the sound signal shall be used in measuring the emitted-sound spectrum. Alternatively, third-octave filters meeting the requirements set out in IEC publication No 225, first edition (1966), may be used, in which case the sound pressure level within the 2 500 Hz centre-octave frequency band shall be determined by adding the quadratic means of the sound pressures in the third-octave bands of centre frequencies of 2 000, 2 500 and 3 150 Hz.

In all cases, only the Fourier transform method may be regarded as a reference method.

2.3.The electrical audible warning device shall be supplied with one of the following voltages, as appropriate:U.K.

In the case of audible warning devices receiving direct current, a test voltage of 6,5, 13,0 or 26,0 V, measured at the output side of the electricity source and corresponding to a nominal voltage of 6, 12 or 24 V respectively.

Where an audible warning device receives direct current which has to be supplied by an electrical generator of the type normally used with this type of device, the acoustic characteristics of the device shall be recorded at alternator speeds corresponding to 50 %, 75 % and 100 % of the maximum speed stated by the manufacturer of the alternator for continuous operation. The alternator shall be subject to no other electrical load during the test. The endurance test described in points 3 to 3.4 shall be carried out at a speed stated by the manufacturer of the equipment and selected from the range referred to above.

If a rectified current is used for the test on an audible warning device receiving direct current, the unsmoothed component of the voltage at its terminals, measured from peak to peak during operation of the warning device, shall not exceed 0,1 V.

The resistance of the electrical conductor for audible warning devices receiving direct current, including the resistance of the terminals and contacts, shall lie as close as possible to 0,05 Ω for a nominal voltage of 6 V, 0,10 Ω for a nominal voltage of 12 V and 0,20 Ω for a nominal voltage of 24 V.

2.4.The mechanical audible warning device shall be tested as follows:U.K.

The device to be tested shall be operated by a person or other external means, pushing the operating lever as recommended by the manufacturer. The presence of any operator shall have no noticeable influence on the test results. One measurement sequence consists of ten consecutive operations over the operating lever’s full travel within 4 ± 0,5 s. Five sequences shall be carried out, each interrupted by a pause. The complete operation shall be carried out five times.

The A-weighted sound level shall be recorded for each of the 25 measurement sequences, shall be within 2,0 dB(A) and is averaged for the calculation of the final result.

2.5.The audible warning device shall be rigidly mounted, using the part or parts intended for that purpose by its manufacturer, on a support of a mass at least 10 times greater than that of the warning device to be tested and at least 30 kg. The support shall be arranged in such a way that the reflections off its walls and the vibrations have no significant effect on the results of the measurements.U.K.

2.6.Under the conditions set out above, the A-weighted sound level shall not exceed 115 dB(A) in case of electric audible warning devices and 95 dB(A) in case of mechanical audible warning devices.U.K.

2.7.The sound pressure level within the 1 800 to 3 550 Hz frequency band of electric audible warning devices shall be higher than that of any frequency component above 3 550 Hz, and in any case at least 90 dB(A). The sound pressure level of mechanical audible warning devices shall be at least 80 dB(A).U.K.

2.8.The characteristics set out in points 2.6 to 2.7 shall also be displayed by any audible warning device that has been subjected to the endurance test provided for in points 3 to 3.4.U.K.

2.8.1.Any variation in voltage shall be between 115 % and 95 % of the rated value in the case of electrical audible warning devices receiving direct current, or between 50 % and 100 % of the maximum alternator speed stated by the manufacturer of the alternator for continuous operation in the case of electrical audible warning devices receiving alternating current.U.K.

2.9.The time lag between actuation and the moment when the sound reaches the minimum value as required in points 2.6 to 2.7 shall not exceed 0,2 seconds measured at an ambient temperature of 293 ± 5 K (20 ± 5 °C). This requirement applies, in particular, to pneumatic or electro-pneumatic warning devices.U.K.

2.10.Under the power supply conditions laid down by their manufacturers, pneumatic or electro-pneumatic warning devices shall yield the same acoustic performance as those required for normal electric audible warning devices.U.K.

2.11.The minimum value as required in points 2.6 to 2.7 shall be obtained for each component of a multi-tone device which may emit sound independently. The maximum overall sound level shall be achieved with all of the component parts operating at the same time.U.K.

3.Endurance testU.K.

3.1.The ambient temperature shall lie between 288 K and 303 K (15 °C and 30 °C).U.K.

3.2.The electrical audible warning device shall be supplied with the nominal voltage at the conductor resistance specified in points 2.3.1 to 2.3.4, while in compliance with point 2.8.1, and be operated 10 000 times at a rate of one second of being activated followed by four seconds of not being activated. During the test, the audible warning device shall be exposed to a forced wind or draught with a speed of 10 m/s ± 2 m/s.U.K.

3.2.1.If a test is conducted within an insulated chamber, that chamber shall be of sufficient volume to ensure normal dissipation of the heat given off by the warning device during the endurance test.U.K.

3.3.When half of the total number of operations required has been completed, the electrical audible warning device may be reset if the characteristics of the sound level have altered since before the test. When the total number of operations required has been completed, the audible warning device may again be reset and shall subsequently meet the requirements of the tests specified in point 2.8.U.K.

3.4.Four units of a type of mechanical audible warning device shall be subjected to the durability test. Each device shall be in new condition and shall not be lubricated during the test. It shall be activated 30 000 times over the full travel of the operating lever at a rate of 100 ± 5 operations per minute. The four devices shall then be subjected to a salt spray test according to EN ISO 9227:2012. Three out of the four units shall meet the requirements of the tests specified in point 2.8.U.K.

PART 2U.K. Requirements for the approval of a type of vehicle with regard to the audible warning

1.Fitting requirementsU.K.

1.1.Vehicles of categories L1e-B, L2e and L6e shall be fitted with at least one electrical audible warning device which has been component type-approved pursuant to this Regulation or UNECE regulation No 28(1).U.K.

1.2.Vehicles of category L1e-B with a maximum design vehicle speed ≤ 25 km/h and a maximum continuous rated or net power ≤ 500 W may alternatively be fitted with a mechanical audible warning device which has been component type-approved pursuant to this Regulation, in which case the requirements of points 2.1.1 to 2.1.7 are not applicable.U.K.

1.3.Vehicles of categories L3e, L4e and L5e shall meet all the relevant fitting requirements of UNECE regulation No 28.U.K.

1.3.1.In the absence of specific instructions, the term ‘motor cycles’ in that regulation shall be construed as referring to vehicles of categories L3e, L4e and L5e.U.K.

1.4.Vehicles of category L7e shall meet all the relevant fitting requirements of UNECE regulation No 28, as prescribed for vehicle category L5e.U.K.

1.5.In the absence of specific requirements in UNECE regulation No 28 and as provided in point 1.3 of Part 1, audible warning or additional devices installed on vehicles which are propelled by means of one or more electric motors may incorporate a feature enabling the device to be intermittently activated in such a way that it operates at a significantly lower sound pressure level than required for audible warning devices, emitting a continuous, uniform sound with a sound spectrum that does not vary perceptibly during operation, with the aim to for instance alert pedestrians about the vehicle approaching.U.K.

2.Performance requirements of installed electric audible warning devices.U.K.

2.1.For vehicles of categories L1e-B, L2e and L6e:U.K.

The test voltage shall be as laid down in points 2.3 to 2.3.2 in Part 1.

The sound pressure levels shall be measured under the conditions laid down in point 2.2 in Part 1.

The A-weighted sound pressure level emitted by the audible warning device(s) shall be measured at a distance of 7,0 m in front of the vehicle, the latter being placed on an open site, on ground as smooth as practicable and, if fitted with audible warning devices supplied with direct current, with its engine stopped.

The microphone of the measuring instrument shall be placed in the mean longitudinal plane of the vehicle.

The sound pressure level of the background noise and wind noise shall be at least 10 dB(A) below the sound to be measured.

The maximum sound pressure level shall be sought within the range of 0,5 and 1,5 m above the ground.

When measured under the conditions in points 2.1.1 to 2.1.5, the maximum sound level value as determined in point 2.1.6 shall be between 75 dB(A) and 112 dB(A).

2.2.Vehicles of categories L3e, L4e and L5e shall meet all the relevant performance requirements of UNECE regulation No 28.U.K.

2.2.1.In the absence of specific instructions, the term ‘motor cycles’ in that regulation shall be construed as referring to vehicles of categories L3e, L4e and L5e.U.K.

2.3.Vehicles of category L7e shall meet all the relevant performance requirements of UNECE regulation No 28, as prescribed for vehicle category L5e.U.K.

ANNEX III

Requirements applying to braking, including anti-lock and combined braking systems U.K.

1.Requirements for the approval of a type of vehicle with regard to brakingU.K.

1.1.Vehicles of categories L1e, L2e, L3e, L4e and L5e shall meet all the relevant requirements of UNECE regulation No 78.U.K.

1.1.1.Notwithstanding the requirements laid down in point 1.1, the provisions of points 1.1.1.1 to 1.1.1.3 apply for vehicles of category L1e with a mass in running order ≤ 35 kg which are equipped as follows:U.K.

In braking devices where the transmission is hydraulic, receptacles containing the reserve fluid shall be exempted from the requirements regarding ease of fluid-level checking of the UNECE regulation mentioned above.

For rim brakes, for the purposes of the special provisions relating to testing with wet brakes in the UNECE regulation mentioned above, the water shall be directed onto the part of the wheel rim providing the friction, with the nozzles positioned 10 to 30 mm to the rear of the brake blocks.

For vehicles with wheel rims widths of 45 mm or less (code 1.75), as regards braking performance with the front brake only when laden to its technically permissible maximum mass, the stopping distance or corresponding mean fully developed deceleration (MFDD) shall be as prescribed in the UNECE regulation mentioned above. If this requirement cannot be achieved because of limited adhesion between tyre and road surface, the stopping distance S ≤ 0,1 + V2/115 with corresponding mean fully developed deceleration 4,4 m/s2 shall be applied for a test on a vehicle laden to its technically permissible maximum mass using both braking devices simultaneously.

1.1.2.For the approval of a type of vehicle, the provisions set out in Annex VIII to Regulation (EU) No 168/2013 on the mandatory fitting of advanced brake systems shall apply.U.K.

1.2.Vehicles of category L6e shall meet all the relevant requirements of UNECE regulation No 78, as prescribed for vehicle category L2e.U.K.

1.3.Vehicles of category L7e shall meet all the relevant requirements of UNECE regulation No 78, as prescribed for vehicle category L5e.U.K.

ANNEX IV

Requirements regarding electrical safety U.K.

1.Requirements for the approval of a type of vehicle with regard to electrical safetyU.K.

1.1.Vehicles which are propelled by means of one or more electric motors, including pure and hybrid electric vehicles, shall fulfil the requirements of this Annex.U.K.

2.General requirements concerning the protection against electrical shock and electrical safety applying to high voltage buses under conditions where they are not connected to external high voltage power supplies.U.K.

2.1.The protection against direct contact with live parts shall comply with the requirements set out below. The protections provided (e.g. solid insulator, barrier, enclosure) shall not be able of being opened, disassembled or removed without the use of tools.U.K.

The protection against access to live parts shall be tested in accordance with the provisions laid down in Appendix 3 — Protection against direct contacts of parts under voltage.

2.1.1.For protection of live parts inside the enclosed driving and passenger compartment as well as luggage compartment the protection degree IPXXD shall be met.U.K.

2.1.2.For protection of live parts in areas other than the enclosed driving and passenger compartment or luggage compartment, the protection degree IPXXB shall be met.U.K.

2.1.3.For protection of live parts of vehicles where no enclosed driving and passenger compartment is present, the protection degree IPXXD shall be met by the entire vehicle.U.K.

2.1.4.Connectors (including vehicle inlet) are deemed to meet the requirements if:U.K.

they also comply with the protection degree IPXXB when separated without the use of tools;

they are located underneath the vehicle floor and are provided with a locking mechanism (e.g. screw locking, bayonet locking);

they are provided with a locking mechanism and other components shall first be removed with the use of tools in order to separate the connector; or

the voltage of the live parts becomes ≤ DC 60 V or ≤ AC 30 V (rms) within one second after the connector is separated.

2.1.5.In case a service disconnect can be opened, disassembled or removed without the use of tools, the protection degree IPXXB shall be met under all these conditions.U.K.

2.1.6.Specific marking requirementsU.K.

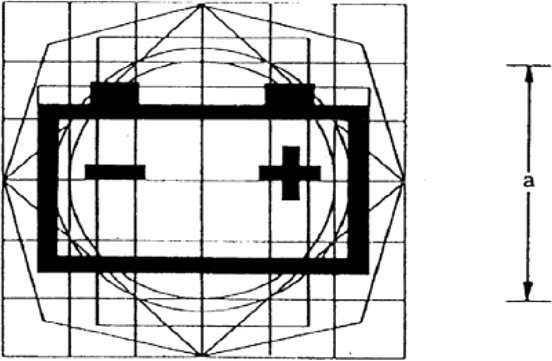

2.1.6.1.In the case of a REESS having high voltage capability, the symbol shown in Figure 4-1 shall be placed on or near the REESS. The symbol background shall be yellow, the bordering and the arrow shall be black.U.K.

2.1.6.2.The symbol shall in addition be placed on all enclosures and barriers, which when removed expose live parts of high voltage circuits. This provision is optional for connectors for high voltage buses and does not apply to any of the following cases:U.K.

Where barriers or enclosures cannot be physically accessed, opened, or removed unless other vehicle components are removed with the use of tools; or

Where barriers or enclosures are located underneath the vehicle floor.

2.1.6.3.Cables for high voltage buses which are not located fully within enclosures shall be identified by having an outer covering with the colour orange.U.K.

2.2.The protection against indirect contact with live parts shall comply with the requirements set out below.U.K.

2.2.1.Concerning protection against electrical shock which could arise from indirect contact, the exposed conductive parts, such as the conductive barrier and enclosure, shall be securely galvanically connected to the electrical chassis for instance by connections with electrical wire, ground cable, welds or by connections using bolts so that no dangerous electric potential can exist.U.K.

2.2.2.The resistance between all exposed conductive parts and the electrical chassis shall be lower than 0,1 Ω when there is current flow of at least 0,2 A. This requirement is deemed as satisfied if the galvanic connection has been established by welding.U.K.

2.2.3.In the case of vehicles intended to be connected to a grounded external electric power supply through a conductive connection, a device enabling the galvanic connection of the electrical chassis to the earth ground shall be provided.U.K.

The device shall enable connection to the earth ground before external voltage is supplied to the vehicle and shall retain this connection until after the exterior voltage is removed from the vehicle.

Compliance with these requirements may be demonstrated by using the connector specified by the vehicle manufacturer or by other analysis.

2.2.3.1.A galvanic connection of the electrical chassis to the earth ground does not need to be provided in the following cases:U.K.

the vehicle can only use a dedicated charger that is protected when any single isolation fault arises;

the vehicle’s whole metallic body is protected when any single isolation fault arises; or

the vehicle cannot be charged without completely removing the traction battery pack from the vehicle.

2.3.Isolation resistance shall comply with the requirements set out below.U.K.

2.3.1.Concerning electric power trains consisting of separate DC or AC-buses:U.K.

If AC buses and DC buses are galvanically isolated from each other, isolation resistance between all high voltage busses and the electrical chassis shall have a minimum value of 100 Ω/V of the working voltage for DC buses, and a minimum value of 500 Ω/V of the working voltage for AC buses.

The measurements shall be conducted in accordance with the provisions laid down in Appendix 1 — Isolation resistance measurement method.

2.3.2.Concerning electric power train consisting of combined DC- and AC-buses:U.K.

If AC high voltage buses and DC high voltage buses are galvanically connected isolation resistance between all high voltage busses and the electrical chassis shall have a minimum value of 500 Ω/V of the working voltage.

However, if all AC high voltage buses are protected by one of the two following measures, isolation resistance between the high voltage bus and the electrical chassis shall have a minimum value of 100 Ω/V of the working voltage:

double or more layers of solid insulators, barriers or enclosures that meet the requirements of points 2.1 to 2.1.6.3 independently, for example wiring harness; or

mechanically robust protections that have sufficient durability over vehicle service life such as motor housings, electronic converter cases or connectors;

The isolation resistance between the high voltage bus and the electrical chassis may be demonstrated by calculation, measurement or a combination of both.

The measurement shall be conducted according to Appendix 1 — Isolation resistance measurement method.

2.3.3.Concerning Fuel cell vehicles:U.K.

If the minimum isolation resistance requirement cannot be maintained over time, then protection shall be achieved by any of the following:

double or more layers of solid insulators, barriers or enclosures that meet the requirements of points 2.1 to 2.1.6.3 independently; or

on-board isolation resistance monitoring system together with a warning to the driver if the isolation resistance drops below the minimum required value. The isolation resistance between the high voltage bus of the coupling system for charging the REESS, which is not energised besides during charging the REESS, and the electrical chassis need not be monitored.

The correct functioning of the on-board isolation resistance monitoring system shall be tested as described in Appendix 2 — Confirmation method for function of on-board isolation resistance monitoring system.

2.3.4.Isolation resistance requirements for the coupling system for charging the REESS.U.K.

The vehicle inlet or the recharge cable when permanently connected to the vehicle, intended to be conductively connected to the grounded external AC power supply and the electrical circuit that is galvanically connected to the vehicle inlet/recharge cable during charging of the REESS, shall have an isolation resistance between the high voltage bus and the electrical chassis of at least 1,0 MΩ when the charger coupler is disconnected. During the measurement, the traction battery may be disconnected.

3.Requirements concerning the REESSU.K.

3.1.Protection in case of excessive current.U.K.

The REESS shall not overheat in case of excessive current or, if the REESS is prone to overheating due to excessive current, it shall be equipped with one or more protective devices such as fuses, circuit breakers and/or main contactors.

When applicable, the vehicle manufacturer shall supply relevant data and analysis proving that overheating from excessive current is prevented without the use of protective devices.

3.2.Prevention of accumulation of gas.U.K.

Places for containing open type traction battery that may produce hydrogen gas shall be provided with a ventilation fan or a ventilation duct or any other suitable means to prevent the accumulation of hydrogen gas. Vehicles with open type framework that do not allow accumulation of hydrogen gas at such places are not required to have a ventilation fan or a ventilation duct.

3.3.Protection against electrolyte spills.U.K.

Electrolyte shall not spill from the vehicle when the vehicle is tilted in any direction, leaned left or right against the ground or even when the REESS is put upside-down.

In case electrolyte is spilled from the REESS or its components due to other reasons, it shall not reach the driver nor any person on or around the vehicle during normal conditions of use, parked condition (i.e. also when the vehicle is parked on a slope) or any other normal functional operation.

3.4.Accidental or unintentional detachment.U.K.

The REESS and its components shall be installed in the vehicle in such a way so as to preclude the possibility of inadvertent or unintentional detachment or ejection of the REESS.

The REESS and its components shall not be ejected when the vehicle is tilted in any direction, leaned left or right against the ground or even when the REESS is put upside-down

4.In-use safety requirementsU.K.

4.1.Propulsion system power-on and power-off procedureU.K.

4.1.1.At the start-up, including system power-on, in order to select the active driving possible mode, at least two deliberate and distinctive actions shall be performed by the driver.U.K.

4.1.2.At least a momentary indication shall be given to the rider when the vehicle is switched in active driving possible mode, however, this provision does not apply under conditions where an internal combustion engine provides directly or indirectly the vehicle’s propulsion power.U.K.

4.1.3.When leaving the vehicle, the rider shall be informed by a signal (e.g. optical or audible signal) if the vehicle is still in the active driving possible mode.U.K.

[F14.1.4. If the on-board REESS can be externally charged by the driver, vehicle movement by its own propulsion system shall be impossible as long as the connector of the external electric power supply is physically connected to the vehicle inlet. For vehicles of category L1e with a mass in running order ≤ 35 kg vehicle movement by its own propulsion system shall be inhibited as long as the connector of the battery charger is physically connected to the external electric power supply. Compliance with this requirement shall be demonstrated by using the connector or battery charger specified by the vehicle manufacturer. In case of permanently connected charge cables, the requirement above is deemed to be met when use of the charge cable obviously prevents the use of the vehicle (e.g. cable is always routed over operator controls, rider's saddle, driver's seat, handle bar or steering wheel, or the seat covering the cable storage space needs to remain in open position).] U.K.

4.1.5.If a vehicle is equipped with a drive direction control unit (i.e. reversing device) the state of this unit shall be identified to the rider.U.K.

4.1.6.It is permitted that only one action is required to deactivate the active driving possible mode or to complete the power-off procedure.U.K.

4.2.Driving with reduced powerU.K.

4.2.1.Indication of reduced powerU.K.

If the electric propulsion system is equipped with a means to automatically reduce the vehicle propulsion power (e.g. powertrain malfunction operating mode), significant reductions shall be indicated to the rider.

4.2.2.Indication of low energy content of REESSU.K.

If the state of charge in the REESS has a significant impact on vehicle driving performance (i.e. acceleration and drivability, to be evaluated by the Technical Service together with the vehicle manufacturer), a low energy content shall be indicated to the rider by an obvious device (e.g. a visual or audible signal). The indication used for point 4.2.1 shall not be used for this purpose.

[F14.3. Driving backwards U.K.

It shall not be possible to activate the vehicle reverse control function in an uncontrolled manner whilst the vehicle is in forward motion, insofar as such activation could cause a sudden and strong deceleration or wheel lock. However, it may be possible for the vehicle reverse control function to be activated in such a way that it may slow down the vehicle gradually.]

4.4.Determination of hydrogen emissionsU.K.

4.4.1.This verification shall be carried out on all vehicle types equipped with open type traction batteries and all requirements shall be met.U.K.

4.4.2.Vehicles shall be equipped with on-board chargers. The tests shall be conducted following the method described in Annex 7 to UNECE regulation No 100(2). The hydrogen sampling and analysis shall be the ones as prescribed, however, other analysis methods may be used provided that it can be demonstrated that these give equivalent results.U.K.

4.4.3.During a normal charge procedure under the conditions given in Annex 7 to UNECE regulation No 100, hydrogen emissions shall be < 125 g measured over 5 hours, or below (25 × t2) (g) during t2 (h).U.K.

4.4.4.During a charge carried out by an on-board charger presenting a failure (conditions given in Annex 7 to UNECE regulation No 100), hydrogen emissions shall be below 42 g. Furthermore the on-board charger shall limit this possible failure to 30 minutes.U.K.

4.4.5.All the operations linked to the REESS charging shall be controlled automatically, included the stop for charging.U.K.

4.4.6.It shall not be possible to manually override the charging phases.U.K.

4.4.7.Normal operations of connection and disconnection to the mains or power cuts shall not affect the control system of the charging phases.U.K.

4.4.8.Charging failures that can lead to a malfunction of the on-board charger during subsequent charging procedures shall be permanently signalled to the driver or clearly indicated to the operator about to commence a charging procedure.U.K.

4.4.9.Detailed instructions concerning the charging procedure and a statement of conformity to the requirements as set out in points 4.4.1 to 4.4.8 shall be included in the vehicle’s instruction manual.U.K.

4.4.10.Test results obtained from other vehicle types common to those within the same family, in accordance with the provisions laid down in Appendix 2 of Annex 7 to regulation No 100, may be applied.U.K.

Appendix 1

Isolation resistance measurement method for vehicle based test U.K.

1.GeneralU.K.

The isolation resistance for each high voltage bus of the vehicle shall be measured or shall be determined by calculation using measurement values from each part or component unit of a high voltage bus (hereinafter referred to as the ‘divided measurement’).

2.Measurement methodU.K.

The isolation resistance measurement shall be conducted by selecting an appropriate measurement method from among those listed in points 2.1 to 2.2, depending on the electrical charge of the live parts or the isolation resistance, etc.

The range of the electrical circuit to be measured shall be clarified in advance, using electrical circuit diagrams, etc.

Moreover, modification necessary for measuring the isolation resistance may be carried out, such as removal of the cover in order to reach the live parts, drawing of measurement lines, change in software, etc.

In cases where the measured values are not stable due to the operation of the on-board isolation resistance monitoring system, etc., necessary modification for conducting the measurement may be carried out, such as stopping of the operation of the device concerned or removing it. Furthermore, when the device is removed, it shall be proven, using drawings, etc., that it will not change the isolation resistance between the live parts and the electrical chassis.

Utmost care shall be exercised as to short circuit, electric shock, etc., for this confirmation might require direct operations of the high-voltage circuit.

2.1.Measurement method using voltage from off-vehicle sourcesU.K.

2.1.1.Measurement instrumentU.K.

An isolation resistance test instrument capable of applying a DC voltage higher than the working voltage of the high voltage bus shall be used.

2.1.2.Measurement methodU.K.

An insulator resistance test instrument shall be connected between the live parts and the electrical chassis. Then, the isolation resistance shall be measured by applying a DC voltage at least half of the working voltage of the high voltage bus.

If the system has several voltage ranges (e.g. because of boost converter) in galvanically connected circuit and some of the components cannot withstand the working voltage of the entire circuit, the isolation resistance between those components and the electrical chassis can be measured separately by applying at least half of their own working voltage with those component disconnected.

2.2.Measurement method using the vehicle’s own REESS as DC voltage sourceU.K.

2.2.1.Test vehicle conditionsU.K.

The high voltage-bus shall be energised by the vehicle’s own REESS and/or energy conversion system and the voltage level of the REESS and/or energy conversion system throughout the test shall be at least the nominal operating voltage as specified by the vehicle manufacturer.

2.2.2.Measurement instrumentU.K.

The voltmeter used in this test shall measure DC values and shall have an internal resistance of at least 10 MΩ.

2.2.3.Measurement methodU.K.

2.2.3.1.First stepU.K.

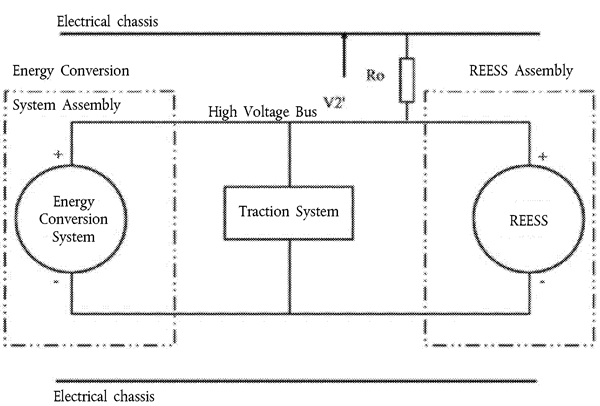

The voltage is measured as shown in Figure 4-Ap1-1 and the high voltage bus voltage (Vb) is recorded. Vb shall be equal to or greater than the nominal operating voltage of the REESS and/or energy conversion system as specified by the vehicle manufacturer.

2.2.3.2.Second stepU.K.

Measure and record the voltage (V1) between the negative side of the high voltage bus and the electrical chassis (see Figure 4-Ap1-1).

2.2.3.3.Third stepU.K.

Measure and record the voltage (V2) between the positive side of the high voltage bus and the electrical chassis (see Figure 4-Ap1-1).

2.2.3.4.Fourth stepU.K.

If V1 is greater than or equal to V2, insert a standard known resistance (Ro) between the negative side of the high voltage bus and the electrical chassis. With Ro installed, measure the voltage (V1’) between the negative side of the high voltage bus and the electrical chassis (see Figure 4-Ap1-2).

Calculate the electrical isolation (Ri) according to the following formula:

If V2 is greater than V1, insert a standard known resistance (Ro) between the positive side of the high voltage bus and the electrical chassis. With Ro installed, measure the voltage (V2’) between the positive side of the high voltage bus and the electrical chassis (see Figure 4-Ap1-3). Calculate the electrical isolation (Ri) according to the formula shown. Divide this electrical isolation value (in Ω) by the nominal operating voltage of the high voltage bus (in V).

Calculate the electrical isolation (Ri) according to the following formula:

2.2.3.5.Fifth stepU.K.

The electrical isolation value Ri (in Ω) divided by the working voltage of the high voltage bus (in volts) results in the isolation resistance (in Ω/V).

Note: The standard known resistance Ro (in Ω) should be the value of the minimum required isolation resistance (in Ω/V) multiplied by the working voltage of the vehicle plus/minus 20 per cent (in V). Ro is not required to be precisely this value since the equations are valid for any Ro; however, a Ro value in this range should provide good resolution for the voltage measurements.U.K.

Appendix 2

Confirmation method for function of on-board isolation resistance monitoring system U.K.

1.The function of the on-board isolation resistance monitoring system shall be confirmed by the following method:U.K.

Insert a resistor that does not cause the isolation resistance between the terminal being monitored and the electrical chassis to drop below the minimum required isolation resistance value. The warning shall be activated.

Appendix 3

Protection against direct contacts of parts under voltage U.K.

1.Access probesU.K.

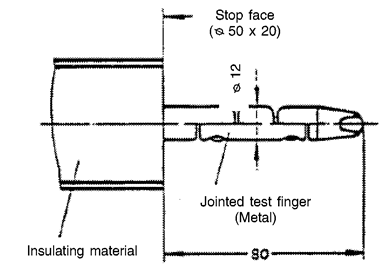

Access probes to verify the protection of persons against access to live parts are given in Table 4-Ap3-1.

2.Test conditionsU.K.

The access probe is pushed against any openings of the enclosure with the force specified in Table 4-Ap3-1. If it partly or fully penetrates, it is placed in every possible position, but in no case shall the stop face fully penetrate through the opening.

Internal barriers are considered part of the enclosure

A low-voltage supply of ≥ 40 V and ≤ 50 V in series with a suitable lamp shall be connected, if necessary, between the probe and live parts inside the barrier or enclosure.

The signal-circuit method shall also be applied to the moving live parts of high voltage equipment.

Internal moving parts may be operated or otherwise repositioned slowly, where this is possible.

3.Acceptance conditionsU.K.

The access probe shall not touch live parts.

If this requirement is verified by a signal circuit between the probe and live parts, the lamp shall not light up.

In the case of the test for IPXXB, the jointed test finger may penetrate to its 80 mm length, but the stop face (diameter 50 mm x 20 mm) shall not pass through the opening. Starting from the straight position, both joints of the test finger shall be successively bent through an angle of up to 90 degree with respect to the axis of the adjoining section of the finger and shall be placed in every possible position.

In case of the tests for IPXXD, the access probe may penetrate to its full length, but the stop face shall not fully penetrate through the opening.

Table 4-Ap3-1

Access probes for the tests for protection of persons against access to hazardous parts

ANNEX V

Requirements applying to manufacturers’ declaration regarding endurance testing of functional safety critical systems, parts and equipment U.K.

1.Requirements for the approval of a type of vehicle with regard to endurance testingU.K.

1.1.For the purpose of the statement in conformity with Article 22(2) of, and Annex VIII to, Regulation (EU) No 168/2013:U.K.

Vehicles and their systems, parts and equipment critical for functional safety shall be capable of withstanding use under normal conditions and when serviced in accordance with the manufacturer’s recommendations, taking into account regular and scheduled maintenance and specific equipment adjustments carried out as per the clear and unambiguous instructions provided by the vehicle manufacturer in the instruction manual provided with the vehicle.

The normal use of a vehicle shall cover five years after first registration and a total distance travelled equal to 1,5 times the distance as specified in Annex VII to Regulation (EU) No 168/2013 in direct relation to the vehicle category in question and the emission stage (i.e. Euro level) according to which the vehicle is to be type-approved, however, the required distance shall not exceed 60 000 km for any vehicle category. Normal use does not include use under harsh conditions (e.g. extreme cold or heat) and road conditions inflicting damage to the vehicle due to its state of repair.

1.2.Type-approved tyres, replaceable light sources of lighting components and other consumable items are excluded from the endurance requirements.U.K.

1.3.The vehicle manufacturer is not obliged to surrender information such as a file containing proprietary information pertaining to company data concerning endurance testing procedures and other related internal practices.U.K.

1.4.The manufacturer’s statement is without prejudice to its warranty obligations towards the owner of the vehicle.U.K.

ANNEX VI

Requirements applying to front and rear protective structures U.K.

1.Requirements for the approval of a type of vehicle with regard to front and rear protective structuresU.K.

1.1.If the requirements of UNECE regulation No 26 as regards the external projections have been applied to the entire vehicle, as provided through the relevant provisions of Annex II(C)(7) to Regulation (EU) 168/2013, the requirements of this Annex are deemed met.U.K.

1.2.If the requirements of UNECE regulation No 26 as regards the external projections have not been applied, or have been applied only partly to the vehicle as permitted through the relevant provisions of Annex II(C)(7) to Regulation (EU) 168/2013, the following requirements shall be met:U.K.

Vehicles of which the relevant front structure has been fully assessed in accordance with UNECE regulation No 26 are deemed to comply with the requirements on front protective structures.

Vehicles with a single front wheel and of which the external projections forward of the front axle have been assessed by means of the testing device in accordance with the relevant provisions of Annex II(C)(7) to Regulation (EU) 168/2013, are deemed to comply with the requirements on front protective structures.

Vehicles with more than one front wheel and of which the relevant front structure has not been fully assessed in accordance with UNECE regulation No 26 shall meet the following requirements:

At least two thirds of the maximum width of the forward section of the vehicle, measured at the location of the front axle or in front of it, shall consist of vehicle structure forward of the transverse line which is halfway between the front axle and the foremost point of the vehicle (i.e. the relevant structure, see Figure 6-1). The location, in terms of height, of this structure is relevant only above the floor line and below 2,0 m.

None of the vehicle structure forward of the line described in point 1.2.3.1 shall have pointed or sharp parts or projections which are directed outwards and which are likely to catch or significantly increase the severity of injuries or chance of lacerations to vulnerable road users in the event of a collision while the vehicle is being driven forward. The structure shall in any case exhibit no edges which can be contacted by a 100 mm sphere and which have a radius of curvature of less than 2,5 mm. Edges may however be blunted where their projection is less than 5,0 mm and there are no specific requirements for edges with a projection of less than 1,5 mm.

Vehicles which are not equipped with a device for reversing are exempted from the requirements on rear protective structures in points 1.2.5 to 1.2.6.2.1.

Vehicles which are equipped with a device for reversing and of which the relevant rear structure has been fully assessed in accordance with UNECE regulation No 26 are deemed to comply with the requirements applying to rear protective structures.

Vehicles which are equipped with a device for reversing and of which the relevant rear vehicle structure has not been fully assessed in accordance with UNECE regulation No 26 shall meet the following requirements:

At least two thirds of the width of the vehicle, as measured at the rear axle, shall consist of vehicle structure (i.e. the relevant structure, see Figure 6-2). The location, in terms of height, of this structure is relevant only above the floor line and below 2,0 m.

None of the structure rearward of the rear axle shall have pointed or sharp parts or projections which are directed outwards and which are likely to catch or significantly increase the severity of injuries or chance of lacerations to vulnerable road users in the event of a collision while the vehicle is being driven rearward. The structure shall in any case exhibit no edges which can be contacted by a 100 mm sphere and which have a radius of curvature of less than 2,5 mm. Edges may however be blunted where their projection is less than 5,0 mm and there are no specific requirements for edges with a projection of less than 1,5 mm.

In case of vehicles of categories L2e-U, L5e-B, L6e-BU and L7e-CU, the edges which can be contacted by a 100 mm sphere shall at least be blunted when their projection is 1,5 mm or more.

1.3.If the material hardness is measured upon request of the technical service, the measurement shall be taken with the material as installed on the vehicle. Where it is impossible to carry out such a measurement correctly, the technical service may accept alternative assessment methods.U.K.

ANNEX VII

Requirements applying to glazing, windscreen wipers and washers, and defrosting and demisting systems U.K.

PART 1U.K. Requirements for the approval of a type of vehicle with regard to glazing

1.Fitting requirements.U.K.

1.1.Vehicles shall be fitted only with safety glazing.U.K.

[F11.1.1. All safety glazing fitted to the vehicle shall be type-approved in accordance with UNECE regulation No 43 (3) .] U.K.

1.1.2.Safety glazing shall be fitted in such a way that, despite the stresses to which the vehicle is subject under normal operating conditions, it remains in position and continues to afford visibility and safety to the occupants or riders of the vehicle.U.K.

1.1.3.Plastic windscreens which are fitted to vehicles without bodywork and which are not supported at the top are not deemed to be safety glazing and are exempted from the requirements laid down in this Annex.U.K.

1.1.3.1.By way of derogation to Article 2(5) and for the purpose of this Annex, a vehicle is deemed to have bodywork if there are structural elements such as A-pillars or a rigid frame around the windscreen, in combination with other possible elements such as side doors, side windows and/or a roof creating an enclosed or partly enclosed compartment and the technical service shall provide clear justification for the judgment criteria in the test report.U.K.

2.Specific provisionsU.K.

2.1.Vehicles of category L shall meet all the relevant requirements set out in Annex 21 to UNECE regulation No 43, as prescribed for vehicle category M1.U.K.

2.1.1.Points 4.2.1.2 and 4.2.2.2 of Annex 21 to UNECE regulation No 43 shall not apply. Instead, flexible-plastic glazing bearing the approval mark ‘IX’ may be fitted as safety glazing other than windscreens.U.K.

2.1.2.Rigid plastic safety glazing, provided that it is type-approved and bears the approval mark ‘VIII /A/L’ or ‘X /A/L’, may be fitted as a windscreen on vehicles of categories L1e, L2e, L3e, L4e and L5e.U.K.

2.1.3.Vehicles of categories L5e-B, L6e-B and L7e-C shall be fitted with a windscreen forming a part of the enclosed driving and passenger compartment.U.K.

PART 2U.K. Requirements for the approval of a type of vehicle with regard to windscreen wipers and washers

1.Fitting requirementsU.K.

1.1.All vehicles fitted with a windscreen made from safety glazing shall be equipped with a windscreen wiper system that can function when the vehicle master control switch has been activated, without any action by the driver other than switching on the operating control for starting and stopping the windscreen wiper system.U.K.

1.1.1.The windscreen wiper system shall consist of one or more wiper arms with wiper blades that are easily replaceable and can be cleaned manually. Wiper arms shall be fitted in such a way that they can be folded away from the windscreen.U.K.

1.1.2.The windscreen wiper field shall cover at least 90 % of vision area A, as determined in accordance with Appendix 1.U.K.

1.1.2.1.The windscreen wiper field shall meet the requirements when the system is operating at a sweep frequency corresponding to point 1.1.3. The windscreen wiper field shall be assessed under the conditions set out in points 2.1.10 to 2.1.10.3.U.K.

1.1.3.The windscreen wiper shall have a sweep frequency of at least 40 cycles per minute, to be attained under the conditions specified in points 2.1.1 to 2.1.6 and 2.1.8.U.K.

1.1.4.The windscreen wiper system shall be capable of operating for two minutes on a dry windscreen without deterioration of performance.U.K.

1.1.4.1.The performance of the windscreen wiper system on a dry windscreen shall be tested under the conditions set out in point 2.1.11.U.K.

1.1.5.The windscreen wiper system shall be capable of withstanding stalling for at least 15 seconds. The use of automatic circuit protection devices is allowed, provided that no action is required for possible resetting other than operation of the windscreen wiper operating control.U.K.

1.1.5.1.The capability of withstanding stalling shall be tested under the conditions set out in point 2.1.7.U.K.

1.2.All vehicles fitted with a windscreen made from safety glazing shall be fitted with a windscreen washer system that can function when the vehicle master control switch has been activated and is capable of withstanding the loads and pressures resulting when the nozzles are plugged and the system is actuated according to the procedure set out in points 2.2.1.1 to 2.2.1.1.2.U.K.

1.2.1.The performance of the windscreen washer system shall not be adversely affected by exposure to the temperature cycles referred to in points 2.2.1 to 2.2.3.1.U.K.

1.2.2.The windscreen washer system shall be capable of spraying fluid onto the target area of the windscreen without any trace of leakage, disconnection of any tubing and malfunctioning of any nozzle, at normal conditions when subjected to ambient temperatures between 255 K and 333 K (– 18 °C and 60 °C). In addition, when the nozzles are blocked, the system shall show no signs of leakage and disconnection of any tubing.U.K.

1.2.3.The windscreen washer system shall be capable of delivering sufficient fluid to clear at least 60 % of vision area A, as determined in accordance with Appendix 1, under the conditions set out in points 2.2.5 to 2.2.5.4.U.K.

1.2.4.The windscreen washer system shall be capable of being activated manually by means of the washer control. In addition, activation and deactivation of the system may be coordinated and combined with any other vehicle system.U.K.

1.2.5.The capacity of the reservoir containing the liquid shall not be less than 1,0 litre.U.K.

1.2.6.A windscreen washer system which has been approved as a separate technical unit in accordance with Commission Regulation (EU) No 1008/2010(4) may be installed, provided that the provisions of point 2.2.6 are complied with.U.K.

2.Test procedureU.K.

2.1.Windscreen wiper system test conditions.U.K.

2.1.1.The tests described below shall be carried out under the conditions stated in points 2.1.2 to 2.1.5 unless specified otherwise.U.K.

2.1.2.The ambient temperature shall be between 278 K and 313 K (5 °C and 40 °C).U.K.

2.1.3The windscreen shall be kept constantly wet.U.K.

2.1.4.Electric windscreen wiper systems shall meet the following additional conditions:U.K.

All batteries shall be fully charged at the start of the test.

The engine, if fitted, shall run at a speed not exceeding 30 % of the speed corresponding to its maximum power output. However, if this is proven not to be practicable due to specific engine control strategies, for instance in the case of electric hybrid vehicles, a realistic scenario shall be determined, taking into account the engine speeds and periodical or complete absence of a running engine during normal driving conditions. If the windscreen wiper system can meet the requirements without a running engine, the engine does not have to run at all.

The passing beam headlamps shall be switched on.

All fitted heating, ventilation, defrosting and demisting systems (regardless of their location in the vehicle) shall be operating at maximum electrical consumption.

2.1.5.Compressed air or vacuum operated windscreen wiper systems shall be capable of functioning continuously at the prescribed sweep frequencies whatever the engine speed and engine load or minimum and maximum battery charge levels specified by the manufacturer for normal operation.U.K.

2.1.6.The sweep frequency of the windscreen wiper system shall comply with the requirements of point 1.1.3 after a preliminary operating time of 20 minutes on a wet windshield.U.K.

2.1.7.The requirements of point 1.1.5 shall be satisfied when the wiper arms are restrained in a position corresponding to half a cycle, for a period of 15 seconds with the windscreen wiper control set at the maximum sweep frequency.U.K.

2.1.8.The outer face of the windscreen shall be thoroughly degreased by means of methylated spirit or an equivalent degreasing agent. After drying, a solution of ammonia of not less than 3 % and not more than 10 % shall be applied. The surface shall be allowed to dry again and then be wiped with a dry cotton cloth.U.K.

2.1.9.A coating of the test mixture, complying with the specifications laid down in Appendix 2, shall be applied uniformly to the outer surface of the windscreen and allowed to dry.U.K.

2.1.9.1.Where the outer face of the windscreen has been prepared in accordance with points 2.1.8 and 2.1.9, the windscreen washer system may be used during the relevant tests.U.K.

2.1.10.The wiper field of the windscreen wiper system, as prescribed in point 1.1.2, shall be determined as follows:U.K.

The outer face of the windscreen shall be treated in accordance with points 2.1.8 and 2.1.9.

In order to verify that the requirements of point 1.1.2 are met, the windscreen wiper system shall be activated, taking into account point 2.1.9.1, and a trace of the wiper field shall be made and compared with a trace of vision area A, as determined in accordance with Appendix 1.

The technical service may agree to an alternative test procedure (e.g. virtual testing) to verify that the requirements of point 1.1.2 are met.

2.1.11.The requirements of point 1.1.4 shall be satisfied under the conditions of point 2.1.2. The vehicle shall be prepared for operation under the conditions set out in points 2.1.4 to 2.1.5. During the test, the wiper system shall operate normally, but at the maximum sweep frequency. The wiper field does not have to be observed.U.K.

2.2.Windscreen washer system test conditions.U.K.

2.2.1.Test No 1: The windscreen washer system shall be filled with water, fully primed and placed in an ambient temperature of 293 ± 2 K (20 ± 2 °C) for a minimum of four hours. The water shall be stabilised at this temperature.U.K.

2.2.1.1.All nozzle outlets shall be plugged and the windscreen washer control shall be actuated six times in one minute, each time for at least three seconds.U.K.

2.2.1.1.1If the windscreen washer system is powered by the muscular energy of the driver, the force applied shall be 11,0 to 13,5 daN if a hand-operated washer pump is used, or 40,0 to 44,5 daN if a foot-operated washer pump is used.U.K.

2.2.1.1.2.Where electric washer pumps are used, the test voltage shall not be less than the rated voltage and not more than the rated voltage plus 2 Volt.U.K.

2.2.1.2.The performance of the windscreen washer system at the end of the test shall be in compliance with point 1.2.2.U.K.

2.2.2.Test No 2. The windscreen washer system shall be filled with water, fully primed, and placed in an ambient temperature of 255 ± 3 K (– 18 ± 3 °C) for a minimum of four hours, ensuring that all the water contained in the device is frozen. The device is then exposed to an ambient temperature of 293 ± 2 K (20 ± 2 °C) until the ice has completely melted.U.K.

2.2.2.1.The performance of the windscreen washer system shall then be verified by actuating the system in accordance with points 2.2.1.1 to 2.2.1.2.U.K.

2.2.3.Test No 3. The windscreen washer system shall be filled with water of a temperature of 333 ± 3 K (60 ± 3 °C).U.K.

2.2.3.1.The performance of the windscreen washer system shall then be verified by actuating the system in accordance with points 2.2.1.1 to 2.2.1.2.U.K.

2.2.4.The windscreen washer system tests set out in points 2.2.1 to 2.2.3.1 shall be carried out in sequence on the same windscreen washer system. The system may be tested either as installed on the vehicle type for which EC type-approval is sought, or separately.U.K.

2.2.5.Test No 4: Windscreen washer system capability testU.K.

2.2.5.1.The windscreen washer system shall be filled with water and fully primed. With the vehicle stationary and no significant wind effect, the nozzle(s) may, if possible, be adjusted so as to point towards the target area on the outer face of the windscreen.U.K.

2.2.5.2.The outer face of the windscreen shall be treated as prescribed in points 2.1.8 and 2.1.9.U.K.

2.2.5.3.The windscreen washer system shall be actuated according to the manufacturer’s instructions, taking into account points 2.2.1.1.1 and 2.2.1.1.2. The total duration of the test shall not exceed 10 complete cycles of automatic operation of the windscreen wiper system operating at the maximum sweep frequency.U.K.

2.2.5.4.In order to verify that the requirements of point 1.2.3 are met, a trace of the relevant cleaned area shall be made and compared with a trace of vision area A, as determined in accordance with Appendix 1. If it is clear to the observer that the requirements are met, the traces do not have to be prepared.U.K.

2.2.6.Where a type-approved separate technical unit is installed on the vehicle, in accordance with point 1.2.6, only the test set out in points 2.2.5 to 2.2.5.4 needs to be carried out on the windscreen washer system.U.K.

Appendix 1 to Part 2U.K. Procedure for determining vision areas on windscreens of vehicles

Vision area A is established in accordance with Annex 18 to UNECE regulation 43.

Appendix 2 to Part 2U.K. Specifications of the mixture for testing the windscreen wiper and washer systems

The test mixture referred to in point 2.1.9 of Part 2 shall comply with Appendix 4 to Annex III to Regulation (EU) No 1008/2010.

Appendix 3 to Part 2U.K. Procedure for verification of the R-point or seating reference point

The R-point or seating reference point is established in accordance with Annex 3 to UNECE regulation No 17.

Appendix 4 to Part 2U.K. Procedure for determining primary reference marks in the three-dimensional reference system

The dimensional relationships between primary reference marks on drawings and their position on the vehicle are established in accordance with Annex 4 to UNECE regulation No 125(5).

PART 3U.K. Requirements for the approval of a type of vehicle with regard to defrosting and demisting systems

1.Fitting requirementsU.K.

1.1.All vehicles fitted with a windscreen made from safety glazing, except vehicles of categories L2e and L6e as well as any vehicles not fitted with side doors capable of covering the door aperture by at least 75 %, either as standard or optional equipment, shall be equipped with a system for removing frost and ice from the exterior glazed surface of the windscreen and removing mist from the interior glazed surface of the windscreen. The windscreen defrosting and demisting system shall be effective enough to ensure adequate visibility through the windscreen in cold weather.U.K.

1.1.1.Vehicles with a maximum power not exceeding 15 kW shall meet all the relevant requirements of UNECE regulation No 122(6), as prescribed for vehicle category M1.U.K.

1.1.2.Vehicles with a maximum power exceeding 15 kW shall meet all the relevant requirements of Commission Regulation (EU) No 672/2010(7), as prescribed for vehicle category M1.U.K.

1.2.However, if the windscreen is fitted in such a way that no vehicle structure attached to the windscreen extends rearwards for more than 100 mm, with any detachable or retractable door or roof installed and in the closed position, the defrosting and demisting system is not required.U.K.

ANNEX VIII

Requirements applying to driver-operated controls including identification of controls, tell-tales and indicators U.K.

1.Requirements for the approval of a type of vehicle with regard to identification of controls, tell-tales and indicatorsU.K.

1.1.Identification of controls, tell-tales and indicatorsU.K.

1.1.1.Vehicles of categories L1e-B and L3e shall meet all the relevant requirements of UNECE regulation No 60 except those in Annex 3 to that regulation. The requirements of points 1.1.1.1 and 1.1.1.2 shall also be taken into account.U.K.

[F11.1.1.1. It shall be ensured that no deviations in the shape and orientation of the provided symbols are permitted, notably that any customised appearance of the provided symbols shall be prohibited. U.K.

1.1.1.2. Small irregularities concerning line thickness, the marking application and other relevant production tolerances shall be accepted, as provided in paragraph 4 of ISO 2575:2010/Amd1:2011 (design principles).] U.K.

1.1.2.Vehicles of category L4e shall meet all the relevant requirements in points 1.1.1 to 1.1.1.2 for vehicle category L3e.U.K.

1.1.3.Vehicles of categories L2e, L5e, L6e and L7e shall meet the requirements of point 2 to 2.2.1.6 or, alternatively, the relevant requirements of UNECE regulation No 121(8), as prescribed for vehicle category M1.U.K.

1.2.Speedometer and odometerU.K.

1.2.1.Vehicles with a maximum design vehicle speed exceeding 25 km/h shall be fitted with a speedometer as well as an odometer.U.K.

1.2.1.1.Vehicles of categories L1e, L2e, L3e, L4e and L5e fitted with a speedometer shall meet all the relevant requirements of UNECE regulation No 39.U.K.

1.2.1.2.Vehicles of category L6e fitted with a speedometer shall, in the absence of specific requirements for vehicles of that category, meet all the relevant requirements of UNECE regulation No 39, as prescribed for vehicle category L2e.U.K.

1.2.1.3.Vehicles of category L7e fitted with a speedometer shall, in the absence of specific requirements for vehicles of that category, meet all the relevant requirements of UNECE regulation No 39, as prescribed for vehicle category L5e.U.K.

1.2.2.Explanatory notes to UNECE regulation No 39U.K.

1.2.2.1.The technical service may accept an increased temperature range of 296 ± 15 K (23 ± 15 °C) instead of the range stated in point 5.2.3 of UNECE regulation No 39 if it can be demonstrated that the speedometer equipment is not sensitive to such temperature variations (e.g. with digital displays).U.K.

2.Specific requirementsU.K.

2.1.Controls, tell-tales and indicators fitted to the vehicle and listed in point 2.1.10 shall comply with the requirements regarding location, identification, colour and illumination. For functions for which no symbol is provided in this Regulation, the manufacturer may use a symbol following the appropriate ISO 6727:2012 or 2575:2010/Amd1:2011 standards. Where no ISO symbol is available, the manufacturer may use a symbol of its own conception. In any case, such symbol shall not cause confusion with any prescribed symbol.U.K.

2.1.1.The symbols shall stand out clearly against the background.U.K.

2.1.1.1.Contrasting colours shall be used to comply with the requirements of point 2.1.1.U.K.

2.1.2.The symbols shall be placed on the control or control tell-tale to be identified, or in immediate proximity thereof. Where this is not possible, the symbol and control or tell-tale shall be joined by a continuous dash that is as short as possible.U.K.

[F12.1.3. It shall be ensured that no deviations in the shape and orientation of the provided symbols are permitted, notably that any customised appearance of the provided symbols shall be prohibited. U.K.

Small irregularities concerning line thickness, the marking application and other relevant production tolerances shall be accepted, as provided in paragraph 4 of ISO 2575:2010/Amd1:2011 (design principles).]

2.1.4.If necessary for clarity, supplementary symbols may be used in conjunction with any symbol as specified, provided that they do not cause confusion with any symbol specified in this Regulation.U.K.

2.1.5.At the manufacturer’s discretion, any control or indicator as well as their identifications may be capable of being illuminated at any time.U.K.

2.1.6.A tell-tale shall not emit light except when identifying the malfunction or vehicle condition it is designed to indicate or during a functional check (e.g. bulb check).U.K.

2.1.7.Means shall be provided to ensure that tell-tales and their identification are visible and recognisable under all driving conditions.U.K.

2.1.7.1.When illuminated, tell-tales and their associated identifying symbols shall be perfectly visible and recognisable under all ambient lighting conditions.U.K.

2.1.8.When used for optical tell-tales, the following colours shall have the meanings indicated:U.K.

red: danger to persons or very serious damage to equipment is immediate or imminent,

yellow: outside normal operating limits, vehicle system malfunction, damage to vehicle likely, or other condition which may produce hazard in the longer term (caution),

green: safety, normal operating condition (except if blue or yellow is required).

The mandatory colours are given in point 2.1.10. It shall be verified that no inappropriate colour is used for tell-tales even if fitted cumulatively (e.g. red for normal cruise control operation or for ‘sport’ mode).

2.1.9.If colour coding is used to identify the limits of the adjustment range of a temperature function (e.g. passenger compartment heating system), the hot limit shall be identified by the colour red and the cold limit by the colour blue. If the status or limit of a function is shown by an indicator separated from and not adjacent to the control for that function, both the control and the indicator shall be independently identified with the appropriate symbol.U.K.

2.1.10.Designation and identification of symbols:U.K.

Figure 8-4

Hazard warning signal (control / tell-tale)

Two possibilities:

Identifying signal (Figure 8-4),

Tell-tale colour: red

or

Simultaneous operation of the separate direction indicator tell-tales (Figure 8-3), provided that these normally operate independently (see Note below Figure 8-3).

Explanatory notes:U.K.

(1)The framed areas may be solid.U.K.

(2)The dark part of this symbol may be replaced by its silhouette.U.K.

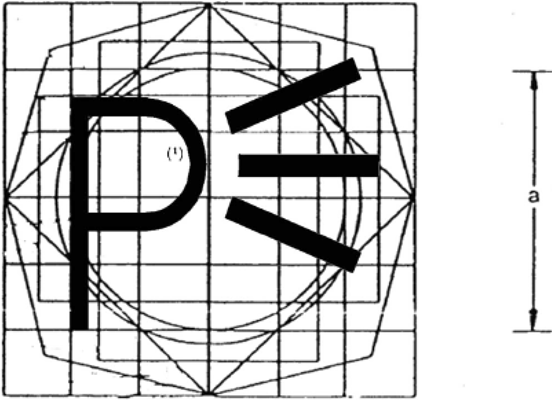

2.1.11.The model base provided in Figure 8-22 shall be used.U.K.

The model base consists of:

a base 50 mm square, this dimension being equal to nominal dimension ‘a’ in the original;

a base circle 56 mm in diameter having approximately the same area as the base square (1);

a second 50 mm-diameter circle is drawn within the base square (1);

a second square the tips of which lie on the base circle (2) and the sides of which are parallel to those of the base square (1);

and (6) two rectangles having the same area as the base square (1), their sides being at right angles to each other and each of them devised so as to divide the opposite sides of the base square into symmetrical points;

a third square the sides of which pass through the points of intersection of the base square (1) and the base circle (2) and are inclined at 45°, thus providing the greatest horizontal and vertical dimensions of the model base;

an irregular octagon formed by lines inclined at 30° to the sides of the square (7).

The base model is laid upon a grid the lower side of which measures 12,5 mm and coincides with the base square (1).

2.2.Common space for displaying multiple information.U.K.

2.2.1.A common space may be used to show information from any source, provided that the following requirements are met:U.K.

2.2.1.1.The tell-tales and indicators displayed in the common space shall meet the requirements of points 2.1 to 2.1.11 and shall light up at the initiation of the condition they are designed to identify.U.K.

2.2.1.2.The tell-tales and indicators listed in point 2.1.10 and shown in the common space shall light up at the initiation of any underlying condition.U.K.

2.2.1.3.Except as provided in points 2.2.1.4 to 2.2.1.6, when the condition exists for actuation of two or more tell-tales, the information shall be either:U.K.

repeated automatically in sequence,

or

indicated by visible means and capable of being selected for viewing by the driver when seated in the driving position.

2.2.1.4.The tell-tales for any braking system malfunction, headlamp driving beam and direction indicator shall not be shown in the same common space.U.K.

2.2.1.5.If any of those tell-tales are displayed in a common space with other tell-tales, their activation shall take precedence over that of anything else in the common space.U.K.

2.2.1.6.It shall not be possible to deactivate the braking system malfunction, headlamp driving beam and direction indicator tell-tales, or any other red tell-tale, when the condition for their activation still exists. It may be possible for other information displayed in a common space to be cancelled automatically or by the driver.U.K.

ANNEX IX

Requirements applying to installation of lighting and light signalling devices, including automatic switching of lighting U.K.

1.Requirements for the approval of a type of vehicle with regard to installation of lightingU.K.