- Latest available (Revised)

- Point in Time (16/06/2014)

- Original (As adopted by EU)

Regulation (EU) No 540/2014 of the European Parliament and of the CouncilShow full title

Regulation (EU) No 540/2014 of the European Parliament and of the Council of 16 April 2014 on the sound level of motor vehicles and of replacement silencing systems, and amending Directive 2007/46/EC and repealing Directive 70/157/EEC (Text with EEA relevance)

You are here:

- Regulations originating from the EU

- 2014 No. 540

- Annexes only

- Show Geographical Extent(e.g. England, Wales, Scotland and Northern Ireland)

- Show Timeline of Changes

More Resources

Revised version PDFs

- Revised 27/05/20191.10 MB

- Revised 22/09/20171.01 MB

- Revised 16/06/20140.84 MB

When the UK left the EU, legislation.gov.uk published EU legislation that had been published by the EU up to IP completion day (31 December 2020 11.00 p.m.). On legislation.gov.uk, these items of legislation are kept up-to-date with any amendments made by the UK since then.

This item of legislation originated from the EU

Legislation.gov.uk publishes the UK version. EUR-Lex publishes the EU version. The EU Exit Web Archive holds a snapshot of EUR-Lex’s version from IP completion day (31 December 2020 11.00 p.m.).

Changes over time for: Regulation (EU) No 540/2014 of the European Parliament and of the Council (Annexes only)

Version Superseded: 22/09/2017

Status:

Point in time view as at 16/06/2014.

Changes to legislation:

Regulation (EU) No 540/2014 of the European Parliament and of the Council is up to date with all changes known to be in force on or before 04 November 2024. There are changes that may be brought into force at a future date. Changes that have been made appear in the content and are referenced with annotations.![]()

Changes to Legislation

Changes and effects yet to be applied by the editorial team are only applicable when viewing the latest version or prospective version of legislation. They are therefore not accessible when viewing legislation as at a specific point in time. To view the ‘Changes to Legislation’ information for this provision return to the latest version view using the options provided in the ‘What Version’ box above.

ANNEX IU.K.EU TYPE-APPROVAL IN RESPECT OF THE SOUND LEVEL OF A VEHICLE TYPE

1.APPLICATION FOR EU TYPE-APPROVAL OF A VEHICLE TYPEU.K.

1.1.The application for EU type-approval pursuant to Article 7(1) and (2) of Directive 2007/46/EC of a vehicle type with regard to its sound level shall be submitted by the vehicle manufacturer.U.K.

1.2.A model for the information document is contained in Appendix 1.U.K.

1.3.A vehicle representative of the type in respect of which type-approval is sought shall be submitted by the vehicle manufacturer to the technical service responsible for the tests. In selecting the vehicle representative of the type, the technical service responsible for the tests shall do so to the satisfaction of the approval authority. Virtual testing methods may be used to aid decision-making during the selection process.U.K.

1.4.At the request of the technical service, a specimen of the silencing system and an engine of at least the same cylinder capacity and rated maximum power as that fitted to the vehicle in respect of which type-approval is sought shall also be submitted.U.K.

2.MARKINGSU.K.

2.1.The exhaust and intake system components, excluding fixing hardware and pipes, shall bear the following markings:U.K.

2.1.1.the trade mark or name of the manufacturer of the systems and their components;U.K.

2.1.2.the manufacturer's trade description.U.K.

2.2.The markings referred to in points 2.1.1 and 2.1.2 shall be clearly legible and indelible, even when the system is fitted to the vehicle.U.K.

3.GRANTING OF EU TYPE-APPROVAL OF A VEHICLE TYPEU.K.

3.1.If the relevant requirements are satisfied, EU type-approval pursuant to Article 9(3) and, if applicable, Article 10(4) of Directive 2007/46/EC shall be granted.U.K.

3.2.A model for the EU type-approval certificate is contained in Appendix 2.U.K.

3.3.An approval number in accordance with Annex VII to Directive 2007/46/EC shall be assigned to each vehicle type approved. The same Member State shall not assign the same number to another vehicle type.U.K.

3.3.1.If the vehicle type complies with the limit values of Phase 1 in Annex III, Section 3 of the type-approval number shall be followed by the character ‘A’. If the vehicle type complies with the limit values of Phase 2 in Annex III, Section 3 of the type-approval number shall be followed by the character ‘B’. If the vehicle type complies with the limit values of Phase 3 in Annex III, Section 3 of the type-approval number shall be followed by the character ‘C’.U.K.

4.AMENDMENTS TO EU TYPE-APPROVALSU.K.

In the case of amendments to the type approved pursuant to this Regulation, Articles 13, 14, 15, 16 and Article 17(4) of Directive 2007/46/EC shall apply.

5.CONFORMITY OF PRODUCTION ARRANGEMENTSU.K.

5.1.Measures to ensure the conformity of production arrangements shall be taken in accordance with the requirements laid down in Article 12 of Directive 2007/46/EC.U.K.

5.2.Special provisions:U.K.

5.2.1.The tests laid down in Annex VI to this Regulation shall correspond to those referred to in point 2.3.5 of Annex X to Directive 2007/46/EC.U.K.

5.2.2.The frequency of inspections referred to in point 3 of Annex X to Directive 2007/46/EC shall normally be once every two years.U.K.

Appendix 1Information document No … pursuant to Annex I of Directive 2007/46/EC relating to EU type-approval of a vehicle with respect to the permissible sound level

The following information, if applicable, shall be supplied in triplicate and include a list of contents. Any drawings shall be supplied in appropriate scale and in sufficient detail on size A4 or on a folder of A4 format. Photographs, if any, shall show sufficient detail.

If the systems, components or separate technical units have electronic controls, information concerning their performance shall be supplied.

0.GENERALU.K.

0.1.Make (trade name of manufacturer):U.K.

0.2.Type:U.K.

0.3.Means of identification of type, if marked on the vehicle (b):U.K.

0.3.1.Location of that marking:U.K.

0.4.Category of vehicle (c):U.K.

0.5.Company name and address of manufacturer:U.K.

0.8.Name(s) and address(es) of assembly plant(s):U.K.

0.9.Name and address of the manufacturer's representative (if any):U.K.

1.GENERAL CONSTRUCTION CHARACTERISTICS OF THE VEHICLEU.K.

1.1.Photographs and/or drawings of a representative vehicle:U.K.

1.3.Number of axles and wheels (4):U.K.

1.3.3.Powered axles (number, position, interconnection):U.K.

1.6.Position and arrangement of the engine:U.K.

2.MASSES AND DIMENSIONS (f) (g) (7) (IN KG AND MM) (REFER TO DRAWING WHERE APPLICABLE)U.K.

2.4.Range of vehicle dimensions (overall):U.K.

2.4.1.For chassis without bodywork:U.K.

2.4.1.1.Length (g5):U.K.

2.4.1.2.Width (g7):U.K.

2.4.2.For chassis with bodywork:U.K.

2.4.2.1.Length (g5):U.K.

2.4.2.2.Width (g7):U.K.

2.6.Mass in running order (h)U.K.

minimum and maximum for each variant:

mass of each version (a matrix shall be provided):

2.8.Technically permissible maximum laden mass stated by the manufacturer (i) (3):U.K.

3.POWER PLANT (q)U.K.

3.1.Manufacturer of the engine:U.K.

3.1.1.Manufacturer's engine code (as marked on the engine, or other means of identification):U.K.

3.2.Internal combustion engineU.K.

3.2.1.1.Working principle: positive ignition/compression ignition, cycle four-stroke/two-stroke/rotary (1)U.K.

3.2.1.2.Number and arrangement of cylinders:U.K.

3.2.1.2.3.Firing order:U.K.

3.2.1.3.Engine capacity (m): … cm3 U.K.

3.2.1.8.Maximum net power (n): … kW at … min–1 (manufacturer's declared value)U.K.

3.2.4.Fuel feedU.K.

3.2.4.2.By fuel injection (compression ignition only): yes/no (1)U.K.

3.2.4.2.2.Working principle: Direct injection/pre-chamber/swirl chamber (1)U.K.

3.2.4.2.4.GovernorU.K.

3.2.4.2.4.1.Type:U.K.

3.2.4.2.4.2.1.Speed at which cut-off starts under load: … min–1 U.K.

3.2.4.3.By fuel injection (positive ignition only): yes/no (1)U.K.

3.2.4.3.1.Working principle: Intake manifold (single-/multi-point (1))/direct injection/other (specify) (1)U.K.

3.2.8.Intake systemU.K.

3.2.8.1.Pressure charger: yes/no (1)U.K.

3.2.8.4.2.Air filter, drawings: orU.K.

3.2.8.4.2.1.Make(s):U.K.

3.2.8.4.2.2.Type(s):U.K.

3.2.8.4.3.Intake silencer, drawings: orU.K.

3.2.8.4.3.1.Make(s):U.K.

3.2.8.4.3.2.Type(s):U.K.

3.2.9.Silencing systemU.K.

3.2.9.2.Description and/or drawing of the silencing system:U.K.

3.2.9.4.Exhaust silencer(s):U.K.

Type, marking of exhaust silencer(s):

Where relevant for exterior noise, reducing measures in the engine compartment and on the engine:

3.2.9.5.Location of the exhaust outlet:U.K.

3.2.9.6.Exhaust silencer containing fibrous materials:U.K.

3.2.12.2.1.Catalytic convertor: yes/no (1)U.K.

3.2.12.2.1.1.Number of catalytic convertors and elements (provide the information below for each separate unit):U.K.

3.2.12.2.6.Particulate trap: yes/no (1)U.K.

3.3.Electric motorU.K.

3.3.1.Type (winding, excitation):U.K.

3.3.1.1.Maximum hourly output: … kWU.K.

3.3.1.2.Operating voltage: … VU.K.

3.4.Engines or motors or combinations thereofU.K.

3.4.1.Hybrid electric vehicle: yes/no (1)U.K.

3.4.2.Category of hybrid electric vehicle: off-vehicle charging/non off-vehicle charging (1)U.K.

3.4.3Operating mode switch: with/without (1)U.K.

3.4.3.1.Selectable modesU.K.

3.4.3.1.1.Pure electric: yes/no (1)U.K.

3.4.3.1.2.Pure fuel consuming: yes/no (1)U.K.

3.4.3.1.3.Hybrid modes: yes/no (1) (if yes, short description):U.K.

3.4.5.Electric motor (describe each type of electric motor separately)U.K.

3.4.5.1.Make:U.K.

3.4.5.2.Type:U.K.

3.4.5.4.Maximum power: … kWU.K.

4.TRANSMISSION (P)U.K.

4.2.Type (mechanical, hydraulic, electric, etc.):U.K.

4.6.Gear ratiosU.K.

4.7.Maximum vehicle design speed (in km/h) (q):U.K.

6.SUSPENSIONU.K.

6.6.Tyres and wheelsU.K.

6.6.1.Tyre/wheel combination(s)U.K.

for tyres indicate size designation, load-capacity index and speed category symbol,

for wheels indicate rim size(s) and off-set(s).

6.6.2.Upper and lower limits of rolling radiiU.K.

6.6.2.1.Axle 1:U.K.

6.6.2.2.Axle 2:U.K.

6.6.2.3.Axle 3:U.K.

6.6.2.4.Axle 4:U.K.

etc.

9.BODYWORKU.K.

9.1.Type of bodywork using the codes defined in Part C of Annex II to Directive 2007/46/EC:U.K.

9.2.Materials used and method of construction:U.K.

12.MISCELLANEOUSU.K.

12.5.Details of any non-engine devices designed to reduce noise (if not covered by other items):U.K.

Date:

Signed:

Position in company:

Appendix 2Model EU type-approval certificate(Maximum Format: A4 (210 × 297 mm))

Stamp of approval authority

Communication concerning the

type-approval(1)

extension of type-approval(1)

refusal of type-approval(1)

withdrawal of type-approval(1)

of a type of a vehicle with regard to the sound level (Regulation (EU) No 540/2014).

Type-approval number:

Reason for extension:

SECTION IU.K.

0.1.Make (trade name of manufacturer):U.K.

0.2.Type:U.K.

0.3.Means of identification of type if marked on the vehicle(2):U.K.

0.3.1.Location of that marking:U.K.

0.4.Category of vehicle(3):U.K.

0.5.Company name and address of manufacturer:U.K.

0.8.Name(s) and address(es) of assembly plant(s):U.K.

0.9.Name and address of the manufacturer's representative (if any):U.K.

SECTION IIU.K.

1.Additional information (where applicable): See AddendumU.K.

2.Technical service responsible for carrying out the tests:U.K.

3.Date of test report:U.K.

4.Number of test report:U.K.

5.Remarks (if any): See AddendumU.K.

6.Place:U.K.

7.Date:U.K.

8.Signature:U.K.

| Attachments: | Information package |

| Test report (for systems)/Test results (for whole vehicles) |

Addendumto EU type-approval certificate No …

1.Additional informationU.K.

1.1.Power plantU.K.

1.1.1.Manufacturer of the engine:U.K.

1.1.2.Manufacturer's engine code:U.K.

1.1.3.Maximum net power (g): … kW at … min -1 or maximum continuous rated power (electric motor) … kW(4) U.K.

1.1.4.Pressure charger(s), make and type:U.K.

1.1.5.Air filter, make and type:U.K.

1.1.6.Intake silencer(s), make and type:U.K.

1.1.7.Exhaust silencer(s), make and type:U.K.

1.1.8.Catalyst(s), make and type:U.K.

1.1.9.Particulate trap(s), make and type:U.K.

1.2.TransmissionU.K.

1.2.1.Type (mechanical, hydraulic, electric, etc.):U.K.

1.3.Non-engine devices designed to reduce noise:U.K.

2.Test resultsU.K.

2.1.Sound level of moving vehicle: … dB(A)U.K.

2.2.Sound level of stationary vehicle: … dB(A) at … min-1 U.K.

2.2.1.Sound level of compressed air, service brake: … dB(A)U.K.

2.2.1.Sound level of compressed air, parking brake: … dB(A)U.K.

2.2.1.Sound level of compressed air, during the pressure regulator actuation: … dB(A)U.K.

2.3.Data to facilitate in-use compliance test of hybrid electric vehicles, where an internal combustion engine cannot operate when the vehicle is stationaryU.K.

2.3.1.Gear (i) or position of the gear selector chosen for the test:U.K.

2.3.2.Position of the operating switch during measurement Lwot,(i) (if switch is fitted)U.K.

2.3.3.Pre-acceleration length lPA … mU.K.

2.3.4.Vehicle speed at the beginning of the acceleration … km/hU.K.

2.3.5.Sound pressure level Lwot,(i) … dB(A)U.K.

3.Remarks:U.K.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ANNEX IIU.K.METHODS AND INSTRUMENTS FOR MEASURING THE NOISE MADE BY MOTOR VEHICLES

1.METHODS OF MEASUREMENTU.K.

1.1.The noise made by the vehicle type submitted for EU type-approval shall be measured by the two methods described in this Annex for the vehicle in motion and for the vehicle when stationary. In the case of a hybrid electric vehicle where an internal combustion engine cannot operate when the vehicle is stationary, the emitted noise shall only be measured in motion.U.K.

Vehicles having a technically permissible maximum laden mass exceeding 2800 kg shall be subjected to an additional measurement of the compressed air noise with the vehicle stationary in accordance with the specifications of Annex V, if the corresponding brake equipment is part of the vehicle.

1.2.The values measured in accordance with the tests set out in point 1.1 of this Annex shall be entered in the test report and on a form conforming to the model contained in Appendix 2 to Annex I.U.K.

2.MEASURING INSTRUMENTSU.K.

2.1.Acoustic measurementsU.K.

The apparatus used for measuring the sound level shall be a precision sound-level meter or equivalent measurement system meeting the requirements of class 1 instruments (inclusive of the recommended windscreen, if used). Those requirements are described in ‘IEC 61672-1:2002: Precision sound level meters’, second edition, of the International Electrotechnical Commission (IEC).

Measurements shall be carried out using the ‘fast’ response of the acoustic measurement instrument and the ‘A’ weighting curve also described in ‘IEC 61672-1:2002’. When using a system that includes a periodic monitoring of the A-weighted sound pressure level, a reading shall be made at a time interval not greater than 30 ms (milliseconds).

The instruments shall be maintained and calibrated in accordance with the instructions of the instrument manufacturer.

2.2.Compliance with requirementsU.K.

Compliance of the acoustic measurement instrumentation shall be verified by the existence of a valid certificate of compliance. A certificate of compliance shall be deemed to be valid if certification of compliance with the standards was conducted within the previous 12-month period for the sound calibration device and within the previous 24-month period for the instrumentation system. All compliance testing shall be conducted by a laboratory, which is authorised to perform calibrations traceable to the appropriate standards.

2.3.Calibration of the entire Acoustic Measurement System for measurement sessionU.K.

At the beginning and at the end of every measurement session, the entire acoustic measurement system shall be checked by means of a sound calibrator that complies with the requirements for sound calibrators of precision class 1 as set out in IEC 60942: 2003. Without any further adjustment the difference between the readings shall be less than or equal to 0,5 dB. If that value is exceeded, the results of the measurements obtained after the previous satisfactory check shall be discarded.

2.4.Instrumentation for speed measurementsU.K.

The engine speed shall be measured with instrumentation having an accuracy of ± 2 % or better at the engine speeds required for the measurements being performed.

The road speed of the vehicle shall be measured with instrumentation having an accuracy of at least ± 0,5 km/h, when using continuous measurement devices.

If testing uses independent measurements of speed, this instrumentation shall meet specification limits of at least ± 0,2 km/h.

2.5.Meteorological instrumentationU.K.

The meteorological instrumentation used to monitor the environmental conditions during the test shall include the following devices, which meet at least the accuracies listed below:

temperature measuring device, ± 1 °C;

wind speed-measuring device, ± 1,0 m/s;

barometric pressure measuring device, ± 5 hPa;

a relative humidity measuring device, ± 5 %.

3.CONDITIONS OF MEASUREMENTU.K.

3.1.Test Site and ambient conditionsU.K.

3.1.1.The surface of the test track and the dimensions of the test site shall be in accordance with ISO 10844:2011. The surface of the site shall be free of powdery snow, tall grass, loose soil or cinders. There shall be no obstacle which could affect the sound field within the vicinity of the microphone and the sound source. The observer carrying out the measurements shall so position himself as not to affect the readings of the measuring instrument.U.K.

3.1.2.Measurements shall not be made under adverse weather conditions. It shall be ensured that the results are not affected by gusts of wind.U.K.

The meteorological instrumentation shall be positioned adjacent to the test area at a height of 1,2 m ± 0,02 m. The measurements shall be made when the ambient air temperature is between + 5 °C and + 40 °C.

The tests shall not be carried out if the wind speed, including gusts, at microphone height exceeds 5 m/s, during the noise measurement interval.

A value representative of temperature, wind speed and direction, relative humidity, and barometric pressure shall be recorded during the noise measurement interval.

Any noise peak which appears to be unrelated to the characteristics of the general sound level of the vehicle shall be ignored in taking the readings.

The background noise shall be measured for a duration of 10 seconds immediately before and after a series of vehicle tests. The measurements shall be made with the same microphones and microphone locations used during the test. The A-weighted maximum noise pressure level shall be reported.

The background noise (including any wind noise) shall be at least 10 dB below the A-weighted noise pressure level produced by the vehicle under test. If the difference between the ambient noise and the measured noise is between 10 and 15 dB(A), the appropriate correction shall be subtracted from the readings on the noise-level meter in order to calculate the test results, as in the following table:

| Difference between ambient noise and noise to be measured dB(A) | 10 | 11 | 12 | 13 | 14 | 15 |

| Correction dB(A) | 0,5 | 0,4 | 0,3 | 0,2 | 0,1 | 0,0 |

3.2.VehicleU.K.

3.2.1.The vehicle tested shall be representative of vehicles to be put on the market and selected by the manufacturer in agreement with the technical service, to comply with the requirements of this Regulation. Measurements shall be made without any trailer, except in the case of non-separable vehicles. At the request of the manufacturer, measurements may be made on vehicles with lift axle(s) in a raised position.U.K.

Measurements shall be made on vehicles at the test mass mt specified in accordance with the following table:

| Vehicle Category | Vehicle test mass (mt) |

|---|---|

| M1 | mt = mro |

| N1 | mt = mro |

| N2, N3 | mt = 50 kg per kW rated engine power Extra loading to reach the test mass of the vehicle shall be placed above the driven rear axle(s). The extra loading is limited to 75 % of the technically permissible maximum laden mass allowed for the rear axle. The test mass shall be achieved with a tolerance of ± 5 %. If the centre of gravity of the extra loading cannot be aligned with the centre of the rear axle, the test mass of the vehicle shall not exceed the sum of the front axle and the rear axle load in unladen condition plus the extra loading. The test mass for vehicles with more than two axles shall be the same as for a two-axle vehicle. |

| M2, M3 | mt = mro — mass of the crew member (if applicable) or, if the tests are carried out on an incomplete vehicle not having bodywork, mt = 50 kg per kW rated engine power respectively in compliance with conditions above (see category N2, N3). |

3.2.2.At the applicant's request, the vehicle of a category M2, M3, N2 or N3 shall be deemed representative of its completed type if the tests are carried out on an incomplete vehicle not having bodywork. In the test of an incomplete vehicle, all relevant soundproofing materials, panels and noise reduction components and systems shall be fitted on the vehicle as designed by the manufacturer except a part of bodywork which is built at a later stage.U.K.

No new test shall be required due to the fitting of a supplement fuel tank or re-location of the original fuel tank on the condition that other parts or structures of the vehicle apparently affecting sound emissions have not been altered.

3.2.3.Tyre rolling sound emissions are laid down in Regulation (EC) No 661/2009. The tyres to be used for the test shall be representative for the vehicle and shall be selected by the vehicle manufacturer and recorded in Addendum to Appendix 2 to Annex I to this Regulation. They shall correspond to one of the tyre sizes designated for the vehicle as original equipment. The tyre is or will be commercially available on the market at the same time as the vehicle(5). The tyres shall be inflated to the pressure recommended by the vehicle manufacturer for the test mass of the vehicle. The tyres shall have at least 1,6 mm tread depth.U.K.

3.2.4.Before the measurements are started, the engine shall be brought to its normal operating conditions.U.K.

3.2.5.If the vehicle is fitted with more than two-wheel drive, it shall be tested in the drive which is intended for normal road use.U.K.

3.2.6.If the vehicle is fitted with one or more fans having an automatic actuating mechanism, this system shall not be interfered with during the measurements.U.K.

3.2.7.If the vehicle is equipped with a silencing system containing fibrous materials, the exhaust system is to be conditioned before the test in accordance with Annex IV.U.K.

4.METHODS OF TESTINGU.K.

4.1.Measurement of noise of vehicles in motionU.K.

4.1.1.General test conditionsU.K.

Two lines, AA' and BB', parallel to line PP' and situated respectively 10 m forward and 10 m rearward of line PP' shall be marked out on the test runway.

At least four measurements shall be made on each side of the vehicle and for each gear. Preliminary measurements may be made for adjustment purposes, but shall be disregarded.

The microphone shall be located at a distance of 7,5 m ± 0,05 m from the reference line CC' of the track and 1,2 m ± 0,02 m above the ground.

The reference axis for free field conditions (see IEC 61672-1:2002) shall be horizontal and directed perpendicularly towards the path of the vehicle line CC'.

4.1.2.Specific test conditions for vehiclesU.K.

4.1.2.1.Vehicles of category M1, M2 ≤ 3 500 kg, N1 U.K.

The path of the centreline of the vehicle shall follow line CC' as closely as possible throughout the entire test, from the approach to line AA' until the rear of the vehicle passes line BB'. If the vehicle is fitted with more than two-wheel drive, it shall be tested in the drive selection which is intended for normal road use.

If the vehicle is fitted with an auxiliary manual transmission or a multi-gear axle, the position used for normal urban driving shall be used. In all cases, the gear ratios for slow movements, parking or braking shall be excluded.

The test mass of the vehicle shall be that set out in the Table in point 3.2.1.

The test speed vtest is 50 km/h ± 1 km/h. The test speed shall be reached when the reference point is at line PP'.

4.1.2.1.1.Power to mass ratio index (PMR)U.K.

PMR is calculated using the following formula:

PMR = (Pn/mt) × 1 000 where Pn is measured in kW and mt is measured in kg in accordance with point 3.2.1 of this Annex.

PMR, with no dimension, is used for the calculation of acceleration.

4.1.2.1.2.Calculation of accelerationU.K.

Acceleration calculations are applicable to M1, N1 and M2 ≤ 3 500 kg categories only.

All accelerations are calculated using different speeds of the vehicle on the test track. The formulae given are used for the calculation of awot i, awot i+1 and awot test. The speed either at AA' or PP' is defined as the vehicle speed when the reference point passes AA' (vAA') or PP' (vPP'). The speed at BB' is defined when the rear of the vehicle passes BB' (vBB'). The method used for calculating the acceleration shall be indicated in the test report.

Due to the definition of the reference point for the vehicle, the length of the vehicle (lveh) is considered differently in the formula below. If the reference point is in the front of the vehicle, then l = lveh, mid: l = 1/2 lveh and rear: l = 0.

4.1.2.1.2.1The calculation procedure for vehicles with manual transmission, automatic transmission, adaptive transmissions and continuous variable transmissions (CVTs) tested with locked gear ratios is as follows:U.K.

awot test = ((vBB'/3,6)2 – (vAA'/3,6)2)/(2*(20+l))

awot test used in the determination of gear selection shall be the average of the four awot test, i during each valid measurement run.

Pre-acceleration may be used. The point of depressing the accelerator before line AA' shall be reported in the test report.

4.1.2.1.2.2.The calculation procedure for vehicles with automatic transmissions, adaptive transmissions and CVTs tested with non-locked gear ratios is as follows:U.K.

awot test used in the determination of gear selection shall be the average of the four awot test, i during each valid measurement run.

Where devices or measures described in point 4.1.2.1.4.2 can be used to control transmission operation for the purpose of achieving test requirements, awot test shall be calculated using the following formula:

awot test = ((vBB'/3,6)2 – (vAA'/3,6)2)/(2*(20+l))

Pre-acceleration may be used:

Where devices or measures described in point 4.1.2.1.4.2 are not used, awot test shall be calculated using the following formula:

awot_testPP-BB = ((vBB'/3,6)2 – (vPP'/3,6)2)/(2*(10+l))

:

acceleration between point PP and BB

Pre-acceleration shall not be used.

The location of depressing the accelerator shall be where the reference point of the vehicle passes line AA'.

4.1.2.1.2.3Target accelerationU.K.

The target acceleration a urban defines the typical acceleration in urban traffic and is derived from statistical investigations. It is a function depending on the PMR of a vehicle.

The target acceleration a urban shall be calculated using the following formula:

a urban = 0,63 * log10 (PMR) – 0,09

4.1.2.1.2.4.Reference accelerationU.K.

The reference acceleration awot ref defines the required acceleration during the acceleration test on the test track. It is a function depending on the PMR of a vehicle. That function is different for specific vehicle categories.

The reference acceleration awot ref shall be calculated using the following formula:

a wot ref = 1,59 * log10 (PMR) –1,41 for PMR ≥ 25

a wot ref = a urban = 0,63 * log10 (PMR) – 0,09 for PMR < 25

4.1.2.1.3.Partial power factor kP U.K.

The partial power factor kP (see point 4.1.3.1) is used for the weighted combination of the test results of the acceleration test and the constant speed test for vehicles of category M1 and N1.

In cases other than a single gear test, a wot ref shall be used instead of a wot test (see point 4.1.3.1).

4.1.2.1.4.Gear ratio selectionU.K.

The selection of gear ratios for the test depends on their specific acceleration potential awot under full throttle condition, in accordance with the reference acceleration awot ref required for the full throttle acceleration test.

Some vehicles may have different software programs or modes for the transmission (e.g. sporty, winter, adaptive). Where the vehicle has different modes leading to valid accelerations, the vehicle manufacturer shall prove to the satisfaction of the technical service, that the vehicle is tested in the mode which achieves an acceleration closest to a wot ref.

4.1.2.1.4.1.Vehicles with manual transmissions, automatic transmissions, adaptive transmissions or CVTs tested with locked gear ratiosU.K.

The following conditions for selection of gear ratios are possible:

if one specific gear ratio gives an acceleration in a tolerance band of ± 5 % of the reference acceleration awot ref, not exceeding 2,0 m/s2, test with that gear ratio.

if none of the gear ratios give the required acceleration, then choose a gear ratio i, with an acceleration higher and a gear ratio i + 1, with an acceleration lower than the reference acceleration. If the acceleration value in gear ratio i does not exceed 2,0 m/s2, use both gear ratios for the test. The weighting ratio in relation to the reference acceleration awot ref is calculated by:

k = (a wot ref – a wot (i+1))/(a wot (i) – a wot (i+1))

if the acceleration value of gear ratio i exceeds 2,0 m/s2, the first gear ratio that gives an acceleration below 2,0 m/s2 shall be used unless gear ratio i + 1 provides an acceleration less than aurban. In this case, two gears, i and i + 1 shall be used, including the gear i with the acceleration exceeding 2,0 m/s2. In other cases, no other gear shall be used. The achieved acceleration awot test during the test shall be used for the calculation of the partial power factor kP instead of awot ref.

if the vehicle has a transmission in which there is only one selection for the gear ratio, the acceleration test shall be carried out in this vehicle gear selection. The achieved acceleration is then used for the calculation of the partial power factor kP instead of awot ref.

if rated engine speed is exceeded in a gear ratio before the vehicle passes BB' the next higher gear shall be used.

4.1.2.1.4.2.Vehicles with automatic transmission, adaptive transmissions and CVTs tested with non-locked gear ratiosU.K.

The gear selector position for full automatic operation shall be used.

The acceleration value awot test shall be calculated as defined in point 4.1.2.1.2.2.

The test may then include a gear change to a lower range and a higher acceleration. A gear change to a higher range and a lower acceleration is not allowed. A gear shifting to a gear ratio which is not used in urban traffic shall be avoided.

Therefore, it shall be permitted to establish and use electronic or mechanical devices, including alternate gear selector positions, to prevent a downshift to a gear ratio which is typically not used at the specified test condition in urban traffic.

The achieved acceleration awot test shall be greater or equal to aurban.

If possible, the manufacturer shall take measures to avoid an acceleration value awot test greater than 2,0 m/s2.

The achieved acceleration a wot test shall then be used for the calculation of the partial power factor kp (see point 4.1.2.1.3) instead awot ref.

4.1.2.1.5.Acceleration testU.K.

The manufacturer shall define the position of the reference point in front of line AA' of fully depressing the accelerator. The accelerator shall be fully depressed (as rapidly as is practicable) when the reference point of the vehicle reaches the defined point. The accelerator shall be kept in this depressed condition until the rear of the vehicle reaches line BB'. The accelerator shall then be released as rapidly as possible. The point of fully depressing the accelerator shall be reported in the test report. The technical service shall have the possibility of pre-testing.

In the case of articulated vehicles consisting of two non-separable units regarded as a single vehicle, the semi-trailer shall be disregarded in determining when line BB' is crossed.

4.1.2.1.6.Constant speed testU.K.

The constant speed test shall be carried out with the same gear(s) specified for the acceleration test and a constant speed of 50 km/h with a tolerance of ± 1 km/h between AA' and BB'. During the constant speed test, the acceleration control shall be positioned to maintain a constant speed between AA' and BB' as specified. If the gear is locked for the acceleration test, the same gear shall be locked for the constant speed test.

The constant speed test is not required for vehicles with a PMR < 25.

4.1.2.2.Vehicles of categories M2 > 3 500 kg, M3, N2, N3 U.K.

The path of the centreline of the vehicle shall follow line CC' as closely as possible throughout the entire test, from the approach to line AA' until the rear of the vehicle passes line BB'. The test shall be conducted without a trailer or semi-trailer. If a trailer is not readily separable from the towing vehicle, the trailer shall not be taken into consideration when assessing the crossing of line BB'. If the vehicle incorporates equipment such as a concrete mixer, a compressor, etc., this equipment shall not be in operation during the test. The test mass of the vehicle shall be set out in the table set out in point 3.2.1.

Target conditions of category M2 > 3 500 kg, N2

When the reference point passes line BB', the engine speed nBB' shall be between 70 % and 74 % of speed S, at which the engine develops its rated maximum power, and the vehicle speed shall be 35 km/h ± 5 km/h. Between line AA' and line BB' a stable acceleration condition shall be ensured.

Target conditions of category M3, N3:

When the reference point passes line BB', the engine speed nBB' shall be between 85 % and 89 % of speed S, at which the engine develops its rated maximum power, and the vehicle speed shall be 35 km/h ± 5 km/h. Between line AA' and line BB' a stable acceleration condition shall be ensured.

4.1.2.2.1.Gear ratio selectionU.K.

4.1.2.2.1.1.Vehicles with manual transmissionsU.K.

Stable acceleration conditions shall be ensured. The gear choice shall be determined by the target conditions. If the difference in speed exceeds the given tolerance, then two gears shall be tested, one above and one below the target speed.

If more than one gear fulfils the target conditions, the gear which is closest to 35 km/h shall be used. If no gear fulfils the target condition for vtest, two gears shall be tested, one above and one below vtest. The target engine speed shall be reached under all conditions.

A stable acceleration condition shall be ensured. If a stable acceleration cannot be ensured in a gear, that gear shall be disregarded.

4.1.2.2.1.2.Vehicles with automatic transmissions, adaptive transmissions and CVTsU.K.

The gear selector position for full automatic operation shall be used. The test may then include a gear change to a lower range and a higher acceleration. A gear change to a higher range and a lower acceleration shall not be permitted. A gear shifting to a gear ratio which is not used in urban traffic, at the specified test condition, shall be avoided. Therefore, it shall be permitted to establish and use electronic or mechanical devices to prevent a downshift to a gear ratio which is typically not used at the specified test condition in urban traffic.

If the vehicle includes a transmission design, which provides only a single gear selection (drive), which limits engine speed during the test, the vehicle shall be tested using only a target vehicle speed. If the vehicle uses an engine and transmission combination that does not comply with the requirements set out in point 4.1.2.2.1.1, the vehicle shall be tested using only the target vehicle speed. The target vehicle speed (vBB') for the test is = 35 km/h ± 5km/h. A gear change to a higher range and a lower acceleration is allowed after the reference point of the vehicle passes line PP'. Two tests shall be performed, one with the end speed of vtest = vBB' + 5 km/h, and one with the end speed of vtest = vBB' – 5 km/h. The reported sound level shall be the result of the test with the highest engine speed obtained during the test from AA' to BB'.

4.1.2.2.2.Acceleration testU.K.

When the reference point of the vehicle reaches the line AA' the accelerator control shall be fully depressed (without operating the automatic downshift to a lower range than normally used in urban driving) and held fully depressed until the rear of the vehicle passes BB', but the reference point shall be at least 5 m behind BB'. The accelerator control shall then be released.

In the case of articulated vehicles consisting of two non-separable units regarded as a single vehicle, the semi-trailer shall be disregarded in determining when line BB' is crossed.

4.1.3.Interpretation of resultsU.K.

The maximum A-weighted sound pressure level indicated during each passage of the vehicle between the two lines AA' and BB' shall be noted. If a noise peak obviously out of character with the general sound pressure level is observed, the measurement shall be discarded. At least four measurements for each test condition shall be made on each side of the vehicle and for each gear ratio. Left and right side may be measured simultaneously or sequentially. The first four valid consecutive measurement results, within 2 dB(A), allowing for the deletion of non valid results (see point 3.1), shall be used for the calculation of the final result for the given side of the vehicle. The results of each side shall be averaged separately. The intermediate result is the higher value of the two averages mathematically rounded to the first decimal place.

The speed measurements at AA', BB', and PP' shall be noted and used in calculations to the first significant digit after the decimal place.

The calculated acceleration awot test shall be noted to the second digit after the decimal place.

4.1.3.1.Vehicles of categories M1, N1 and M2 ≤ 3 500 kgU.K.

The calculated values for the acceleration test and the constant speed test are given by:

Lwot rep = Lwot (i+1) + k * (Lwot(i) – Lwot (i+1))

Lcrs rep = Lcrs(i+1) + k * (Lcrs (i) – Lcrs (i+1))

Where k = (awot ref – awot (i+1))/(awot (i) – awot (i+1))

In the case of a single gear ratio test, the values are the test result of each test.

The final result is calculated by combining Lwot rep and Lcrs rep. The equation is:

Lurban = Lwot rep – kP * (Lwot rep – Lcrs rep)

The weighting factor kP, gives the partial power factor for urban driving. In cases other than a single gear test kP is calculated by:

kP = 1 – (aurban/awot ref)

If only one gear was specified for the test kP is given by:

kP = 1 – (aurban/awot test)

In cases where awot test is less than aurban:

kP = 0

4.1.3.2.Vehicles of categories M2 > 3 500 kg, M3, N2, N3 U.K.

When one gear is tested, the final result shall be equal to the intermediate result. When two gears are tested the arithmetic mean of the intermediate results shall be calculated.

4.2.Measurement of noise emitted by stationary vehiclesU.K.

4.2.1.Sound level in the vicinity of vehiclesU.K.

The measurement results shall be entered into the test report referred to in the Addendum to Appendix 2 to Annex I.

4.2.2.Acoustic measurementsU.K.

A precision sound level meter, or equivalent measuring system, as defined in point 2.1 shall be used for the measurements

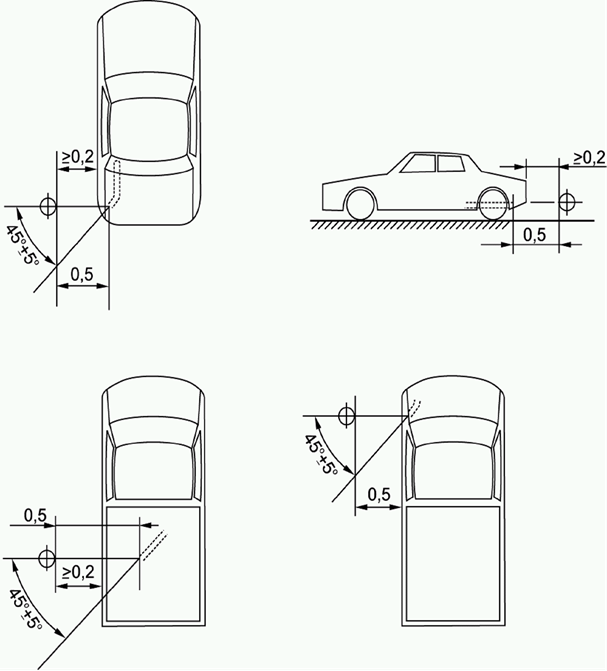

4.2.3.Test site — local conditions as referred to in Figures 2 and 3a to 3d of the Appendix.U.K.

4.2.3.1.In the vicinity of the microphone, there shall be no obstacle that could influence the acoustical field and no person shall remain between the microphone and the noise source. The meter observer shall be positioned so as not to influence the meter reading.U.K.

4.2.4.Disturbance sound and wind interferenceU.K.

Readings on the measuring instruments produced by ambient noise and wind shall be at least 10 dB(A) below the sound level to be measured. A suitable windscreen may be fitted to the microphone provided that account is taken of its effect on the sensitivity of the microphone (see point 2.1).

4.2.5.Measuring methodU.K.

4.2.5.1.Nature and number of measurementsU.K.

The maximum sound level expressed in A-weighted decibels (dB(A)) shall be measured during the operating period referred to in point 4.2.5.3.2.1.

At least three measurements shall be taken at each measuring point.

4.2.5.2.Positioning and preparation of the vehicleU.K.

The vehicle shall be located in the centre part of the test area with the gear selector in the neutral position and the clutch engaged. If the design of the vehicle does not allow this, the vehicle shall be tested in conformity with the manufacturer's prescriptions for stationary engine testing. Before each series of measurements, the engine shall be brought to its normal operating condition, as specified by the manufacturer.

If the vehicle is fitted with a fan or fans having an automatic actuating mechanism, this system shall not be interfered with during the sound level measurements.

The engine hood or compartment cover, if so fitted, shall be closed.

4.2.5.3.Measuring of noise in proximity to the exhaust as referred to in Figure 2 and Figures 3a to 3d of the Appendix.U.K.

4.2.5.3.1.Positions of the microphoneU.K.

4.2.5.3.1.1.The microphone shall be located at a distance of 0,5 m ± 0,01 m from the reference point of the exhaust pipe defined in Figure 2 and Figures 3a to 3d of the Appendix, and at an angle of 45°(± 5°) to the flow axis of the pipe termination. The microphone shall be at the height of the reference point, but not less than 0,2 m from the ground surface. The reference axis of the microphone shall lie in a plane parallel to the ground surface and shall be directed toward the reference point on the exhaust outlet. If two microphone positions are possible, the location farthest laterally from the vehicle longitudinal centreline shall be used. If the flow axis of the exhaust outlet pipe is at 90° to the vehicle longitudinal centreline, the microphone shall be located at the point, which is farthest from the engine.U.K.

4.2.5.3.1.2.For vehicles having an exhaust provided with outlets spaced more than 0,3 m apart, measurements shall be made for each outlet. The highest level shall be recorded.U.K.

4.2.5.3.1.3.In the case of an exhaust provided with two or more outlets spaced less than 0,3 m apart and which are connected to the same silencer, only one measurement shall be made; the microphone position is related to the outlet nearest to one extreme edge of the vehicle or, when such outlet does not exist, to the outlet which is the highest above the ground.U.K.

4.2.5.3.1.4.For vehicles with a vertical exhaust (e.g. commercial vehicles) the microphone shall be placed at the height of the exhaust outlet. Its axis shall be vertical and oriented upwards. It shall be placed at a distance of 0,5 m ± 0,01 m from the exhaust pipe reference point, but never less than 0,2 m from the side of the vehicle nearest to the exhaust.U.K.

4.2.5.3.1.5.For exhaust outlets located under the vehicle body, the microphone shall be located a minimum of 0,2 m from the nearest part of the vehicle, at a point closest to, but never less than 0,5 m from the exhaust pipe reference point, and at a height of 0,2 m above the ground, and not in line with the exhaust flow. If it is not physically possible, the angularity requirement in point 4.2.5.3.1.1 need not be met.U.K.

4.2.5.3.1.6.Examples of the position of the microphone, depending on the location of the exhaust pipe, are given in Figures 3a-3d of the Appendix.U.K.

4.2.5.3.2.Operating conditions of the engineU.K.

4.2.5.3.2.1.Target engine speedU.K.

75 % of the engine speed S for vehicles with a rated engine speed ≤ 5 000 min-1

3 750 min-1 for vehicles with a rated engine speed above 5 000 min-1 and below 7 500 min-1

50 % of the engine speed S for vehicles with a rated engine speed ≥ 7 500 min-1.

If the vehicle cannot reach such engine speed, the target engine speed shall be 5 % below the maximum possible engine speed for that stationary test.

4.2.5.3.2.2.Test procedureU.K.

The engine speed shall be gradually increased from idle to the target engine speed, not exceeding a tolerance band of ± 3 % of the target engine speed, and held constant. Then the throttle control shall be rapidly released and the engine speed shall return to idle. The sound level shall be measured during a period of operation consisting of maintaining constant engine speed of 1 second and throughout the entire deceleration period. The maximum sound level meter reading during this period of operation, mathematically rounded to the first decimal place, shall be taken as the test value.

4.2.5.3.2.3.Test validationU.K.

The measurement shall be regarded as valid if the test engine speed does not deviate from the target engine speed by more than ± 3 % for at least 1 second.

4.2.6.ResultsU.K.

At least three measurements for each test position shall be made. The maximum A-weighted sound pressure level indicated during each of the three measurements shall be recorded. The first three valid consecutive measurement results, within 2 dB(A), allowing for the deletion of non valid results (taking into account the specifications of the test site as referred to in point 3.1), shall be used for the determination of the final result for the given measurement position. The maximum sound level, for all measurement positions, and of the three measurement results, shall constitute the final result.

5.Noise from hybrid electric vehicles of categories M1 in motion, where an internal combustion engine cannot operate when the vehicle is stationary (data reported to facilitate testing of the vehicle in use).U.K.

5.1.In order to facilitate in-use compliance testing of hybrid electric vehicles — where an internal combustion engine cannot operate when the vehicle is stationary — the following information relating to the sound-pressure level measurements carried out in accordance with point 4.1 of Annex II for the motor vehicles in motion is referred to as in-use compliance reference data:U.K.

gear (i) or, for vehicles tested with non-locked gear ratios, the position of the gear selector chosen for the test;

position of the operating switch during measurement of the sound pressure level Lwot,(i) (if switch is fitted).

pre-acceleration length lPA in m;

average vehicle speed in km/h at the beginning of the full throttle acceleration for tests in gear (i); and

sound pressure level Lwot,(i) in dB(A) of the wide-open-throttle tests in gear (i), defined as the maximum of the two values resulting from averaging the individual measurement results at each microphone position separately.

5.2.The in-use compliance reference data shall be entered in the EU type-approval certificate as specified in point 2.3 of the Addendum to Appendix 2 to Annex I.U.K.

AppendixFigures

=

top view

=

side view

=

metered pipe

=

bent down pipe

=

straight pipe

=

vertical pipe

=

reference point

=

road surface

:

Examples of the position of the microphone, depending on the location of the exhaust pipe

ANNEX IIIU.K.LIMIT VALUES

The sound level measured in accordance with the provisions of Annex II, mathematically rounded to the nearest integer value, shall not exceed the following limits:

| a M1 vehicles derived from N1 vehicles: M1 vehicles with an R point > 850 mm from the ground and a total permissible laden mass more than 2 500 kg have to fulfil the limit values of N1 (2 500 kg < mass ≤ 3 500 kg). | ||||

| b + two years for new vehicle type and + one year for new vehicles registration. | ||||

| Limit values shall be increased by 1dB (2 dB(A) for N3 and M3 categories) for vehicles that meet the relevant definition for off-road vehicles set out in point 4 of Part A of Annex II to Directive 2007/46/EC. | ||||

| For M1 vehicles the increased limit values for off-road vehicles are only valid if the technically permissible maximum laden mass > 2 tonnes. | ||||

| Limit values shall be increased by 2 db(A) for wheelchair accessible vehicles and armoured vehicles, as defined in Annex II to Directive 2007/46/EC. | ||||

| Vehicle category | Description of vehicle category | Limit values expressed in dB(A)[decibels (A)] | ||

|---|---|---|---|---|

| Phase 1 applicable for new vehicle types from 1 July 2016 | Phase 2 applicable for new vehicle type from 1 July 2020 and for first registration from 1 July 2022 | Phase 3 applicable for new vehicle type from 1 July 2024 and for first registration from 1 July 2026 | ||

| M | Vehicles used for the carriage of passengers | |||

| M1 | power to mass ratio ≤ 120 kW/1 000 kg | 72a | 70a | 68a |

| M1 | 120 kW/1 000 kg < power to mass ratio ≤ 160 kW/1 000 kg | 73 | 71 | 69 |

| M1 | 160 kW/1 000 kg < power to mass ratio | 75 | 73 | 71 |

| M1 | power to mass ratio > 200 kW/1 000 kg number of seats ≤ 4 R point of driver seat ≤ 450 mm from the ground | 75 | 74 | 72 |

| M2 | mass ≤ 2 500 kg | 72 | 70 | 69 |

| M2 | 2500 kg < mass ≤ 3 500 kg | 74 | 72 | 71 |

| M2 | 3500 kg < mass ≤ 5 000 kg; rated engine power ≤ 135 kW | 75 | 73 | 72 |

| M2 | 3500 kg < mass ≤ 5 000 kg; rated engine power > 135 kW | 75 | 74 | 72 |

| M3 | rated engine power ≤ 150 kW | 76 | 74 | 73b |

| M3 | 150 kW <rated engine power ≤ 250 kW | 78 | 77 | 76b |

| M3 | rated engine power > 250 kW | 80 | 78 | 77b |

| N | Vehicles used for the carriage of goods | |||

| N1 | mass ≤ 2 500 kg | 72 | 71 | 69 |

| N1 | 2 500 kg < mass ≤ 3 500 kg | 74 | 73 | 71 |

| N2 | rated engine power ≤ 135 kW | 77 | 75b | 74b |

| N2 | rated engine power > 135 kW | 78 | 76b | 75b |

| N3 | rated engine power ≤ 150 kW | 79 | 77 | 76b |

| N3 | 150 kW < rated engine power ≤ 250 kW | 81 | 79 | 77b |

| N3 | rated engine power > 250 kW | 82 | 81 | 79b |

ANNEX IVU.K.SILENCING SYSTEMS CONTAINING ACOUSTICALLY ABSORBING FIBROUS MATERIALS

1.GENERALU.K.

Sound absorbing fibrous materials may be used in silencing systems, or components thereof, where either of the following conditions are fulfilled:

the exhaust gas is not in contact with the fibrous materials; or

the silencing system, or components thereof, are of the same design family as systems or components for which it has been proven, in the course of EU type-approval process in accordance with the requirements of this Regulation for another vehicle-type, that they are not subject to deterioration.

Where neither the condition in point (a) nor in point (b) of the first subparagraph is fulfilled, the complete silencing system, or components thereof, shall be submitted to a conventional conditioning using one of three installations and procedures described in points 1.1, 1.2 and 1.3.

For the purposes of point (b) of the first subparagraph, a group of silencing system, or components thereof, shall be considered as being of the same design family when all of the following characteristics are the same:

the presence of net gas flow of the exhaust gases through the absorbing fibrous material when in contact with that material;

the type of the fibres;

where applicable, binder material specifications;

average fibre dimensions;

minimum bulk material packing density in kg/m3;

maximum contact surface between the gas flow and the absorbing material.

1.1.Continuous road operation for 10 000 km.U.K.

1.1.1.50 ± 20 % of this operation shall consist of urban driving and the remaining operation shall be long-distance runs at high speed; continuous road operation may be replaced by a corresponding test-track programme.U.K.

1.1.2.The two speed regimes shall be alternated at least twice.U.K.

1.1.3.The complete test programme shall include a minimum of 10 breaks of at least three hours duration in order to reproduce the effects of cooling and any condensation which may occur.U.K.

1.2.Conditioning on a test benchU.K.

1.2.1.Using standard parts and observing the vehicle manufacturer's instructions, the silencing system, or components thereof, shall be fitted to the vehicle referred to in point 1.3 of Annex I or the engine referred to in point 1.4 of Annex I. In the case of the vehicle referred to in point 1.3 of Annex I, the vehicle shall be mounted on a roller dynamometer. In the case of an engine referred to in point 1.4 of Annex I, the engine shall be coupled to a dynamometer.U.K.

1.2.2.The test shall be conducted in six six-hour periods with a break of at least 12 hours between each period in order to reproduce the effects of cooling and any condensation which may occur.U.K.

1.2.3.During each six-hour period, the engine shall be run, under the following conditions in turn:U.K.

five minutes at idling speed;

one-hour sequence under 1/4 load at 3/4 of rated maximum speed (S);

one-hour sequence under 1/2 load at 3/4 of rated maximum speed (S);

10-minute sequence under full load at 3/4 of rated maximum speed (S);

15-minute sequence under 1/2 load at rated maximum speed (S);

30-minute sequence under 1/4 load at rated maximum speed (S).

Total duration of the six sequences: three hours.

Each period shall comprise two sequenced sets of those conditions in consecutive order from (a) to (f).

1.2.4.During the test, the silencing system, or components thereof, shall not be cooled by a forced draught simulating normal airflow around the vehicle. Nevertheless, at the request of the manufacturer, the silencing system or components thereof may be cooled in order not to exceed the temperature recorded at its inlet when the vehicle is running at maximum speed.U.K.

1.3.Conditioning by pulsationU.K.

1.3.1.The silencing system or components thereof shall be fitted to the vehicle referred to in point 1.3 of Annex I or the engine referred to in point 1.4 of Annex I. In the former case the vehicle shall be mounted on a roller dynamometer.U.K.

In the second case, the engine shall be mounted on a dynamometer. The test apparatus, a detailed diagram of which is shown in Figure 1 of the Appendix to this Annex shall be fitted at the outlet of the silencing system. Any other apparatus providing equivalent results shall be acceptable.

1.3.2.The test apparatus shall be adjusted in such a way that the exhaust-gas flow is alternatively interrupted and re-established by the quick-action valve for 2 500 cycles.U.K.

1.3.3.The valve shall open when the exhaust-gas back pressure, measured at least 100 mm downstream of the intake flange, reaches a value of between 0,35 and 0,40 kPa. It shall close when this pressure does not differ by more than 10 % from its stabilized value with the valve open.U.K.

1.3.4.The time-delay switch shall be set for the duration of gas exhaust resulting from the provisions laid down in point 1.3.3.U.K.

1.3.5Engine speed shall be 75 % of the speed (S) at which the engine develops maximum power.U.K.

1.3.6.The power indicated by the dynamometer shall be 50 % of the full-throttle power measured at 75 % of engine speed (S).U.K.

1.3.7.Any drain holes shall be closed off during the test.U.K.

1.3.8.The entire test shall be completed within 48 hours.U.K.

If necessary, one cooling period shall be observed after each hour.

Appendix

ANNEX VU.K.COMPRESSED AIR NOISE

1.METHOD OF MEASUREMENTU.K.

The measurement is performed at microphone positions 2 and 6 as shown in Figure 1 of the Appendix, with the vehicle stationary. The highest A-weighted sound level shall be registered during venting the pressure regulator and during ventilating after the use of both the service and parking brakes.

The noise during venting the pressure regulator is measured with the engine at idling speed. The ventilating noise is registered while operating the service and parking brakes; before each measurement, the air-compressor unit has to be brought up to the highest permissible operating pressure, and then the engine switched off.

2.EVALUATION OF THE RESULTSU.K.

For all microphone positions two measurements are taken. In order to compensate for inaccuracies of the measuring equipment, the metre reading is reduced by 1 dB(A), and the reduced value is taken as the result of measurement. The results are taken as valid if the difference between the measurements at one microphone position does not exceed 2 dB(A). The highest value measured is taken as the result. If this value exceeds the sound level limit by 1 dB(A), two additional measurements are to be taken at the corresponding microphone position. In this case, three out of the four results of measurement obtained at this position have to comply with the sound level limit.

3.LIMITING VALUEU.K.

The sound level shall not exceed the limit of 72 dB(A).

Appendix

The measurement is performed at the stationary vehicle in accordance with Figure 1, using two microphone positions at a distance of 7 m from the contour of the vehicles and at 1,2 m above ground.

ANNEX VIU.K.CHECKS ON CONFORMITY OF PRODUCTION FOR VEHICLES

1.GENERALU.K.

The requirements of this Annex are consistent with the test to be held to check conformity of production (COP) in accordance with point 5 of Annex I.

2.TESTING PROCEDUREU.K.

The test site and measuring instruments shall be those described in Annex II.

2.1.The vehicle(s) under test shall be subjected to the test for measurement of sound of vehicle in motion set out in point 4.1 of Annex II.U.K.

2.2.Compressed air noiseU.K.

Vehicles having a technically permissible maximum laden mass exceeding 2800 kg and equipped with compressed air systems shall be subjected to the additional test for measurement of the compressed air noise set out in point 1 of Annex V.

2.3.Additional sound emission provisionsU.K.

The vehicle manufacturer shall assess the compliance with ASEP by an appropriate evaluation or may perform the test described in Annex VII.

3.SAMPLING AND EVALUATION OF THE RESULTSU.K.

One vehicle has to be chosen and subjected to the tests set out in point 2 of this Annex. If the sound level of the vehicle tested does not exceed by more than 1 dB(A) the limit value set out in Annex III, and, where appropriate, point 3 of Annex V, the vehicle type shall be considered to conform to the requirements of this Regulation.

If one of the test results does not comply with the COP requirements of Annex X to Directive 2007/46/EC, two more vehicles of the same type shall be tested pursuant to point 2 of this Annex.

If the test results for the second and the third vehicle comply with the COP requirements of Annex X to Directive 2007/46/EC, the vehicle is considered in compliance with the COP.

If one of the test results of the second or third vehicle does not comply with the COP requirements of Annex X to Directive 2007/46/EC, the vehicle type shall be considered not to conform to the requirements of this Regulation and the manufacturer shall take the necessary measures to re-establish the conformity.

ANNEX VIIU.K.MEASURING METHOD TO EVALUATE COMPLIANCE WITH THE ADDITIONAL SOUND EMISSION PROVISIONS

1.GENERALU.K.

This Annex describes a measuring method to evaluate compliance of the vehicle with the additional sound emission provisions (ASEP) set out in Article 7.

It is not mandatory to perform actual tests when applying for EU type-approval. The manufacturer shall sign the declaration of compliance set out in the Appendix. The approval authority may ask for additional information about the declaration of compliance and carry out the tests described below.

The procedure set out in this Annex requires the performance of a test in accordance with Annex II. The test specified in Annex II shall be carried out on the same test track under conditions similar to those required in the tests prescribed in this Annex.

2.MEASURING METHODU.K.

2.1Measuring instruments and condition of measurementsU.K.

Unless otherwise specified, the measuring instruments, the conditions of the measurements and the condition of the vehicle are equivalent to those specified in points 2 and 3 of Annex II.

If the vehicle has different modes that affect sound emission, all modes shall comply with the requirements of this Annex. In the case where the manufacturer has performed tests to prove to the approval authority compliance with those requirements, the modes used during those tests shall be reported in a test report.

2.2.Method of testingU.K.

Unless otherwise specified, the conditions and procedures of points 4.1 to 4.1.2.1.2.2 of Annex II shall be used. For the purpose of this Annex, single test runs shall be measured and evaluated.

2.3.Control rangeU.K.

Operation conditions are as follows:

vAA ≥ 20 km/h

awot ≤ 5,0 m/s2

nBB ≤ 2,0 * PMR–0,222 * s or

nBB ≤ 0,9 * s, whichever is the lowest

Vehicle speed VBB ASEP:

vBB ≤ 70 km/h

vBB ≤ 80 km/h

K ≤ gear ratio i as determined in Annex II

If the vehicle, in the lowest valid gear, does not achieve the maximum engine speed below 70 km/h, the vehicle speed limit is 80 km/h.

2.4.Gear ratiosU.K.

The ASEP requirements apply to every gear ratio K that leads to test results within the control range as defined in point 2.3 of this Annex.

In case of vehicles with automatic transmissions, adaptive transmissions and CVTs tested with non-locked gear ratios, the test may include a gear ratio change to a lower range and a higher acceleration. A gear change to a higher range and a lower acceleration is not allowed. A gear shift which leads to a condition that is not in compliance with the boundary conditions shall be avoided. In such a case, it is permitted to establish and use electronic or mechanical devices, including alternate gear selector positions. In order for the ASEP test to be representative and repeatable (to the approval authority), the vehicles shall be tested using production gearbox calibration.

2.5.Target conditionsU.K.

The sound emission shall be measured in each valid gear ratio at the four test points as specified below.

The first test point P1 is defined by using an entry speed vAA of 20 km/h. If a stable acceleration condition cannot be achieved, the speed shall be increased in steps of 5 km/h until a stable acceleration is reached.

The fourth test point P4 is defined by the maximum vehicle speed at BB' in that gear ratio within the boundary conditions in accordance with point 2.3.

The other two test points are calculated using the following formula:

Test Point Pj: vBB_j = vBB_1 + ((j – 1)/3) * (vBB_4 – vBB_1) for j = 2 and 3

Where:

=

vehicle speed at BB' of test point P1

=

vehicle speed at BB' of test point P4

Tolerance for vBB_j: ±3 km/h

For all test points the boundary conditions as specified in point 2.3 shall be met.

2.6.Test of the vehicleU.K.

The path of the centreline of the vehicle shall follow line CC' as closely as possible throughout the entire test, starting from the approach to line AA' until the rear of the vehicle passes line BB'.

At line AA' the accelerator shall be fully depressed. To achieve a more stable acceleration or to avoid a down shift between line AA' and BB' pre-acceleration before line AA' may be used. The accelerator shall be kept in depressed condition until the rear of the vehicle reaches line BB'.

For every separate test run, the following parameters shall be determined and noted:

The maximum A-weighted sound pressure level of both sides of the vehicle, indicated during each passage of the vehicle between the two lines AA' and BB', shall be mathematically rounded to the first decimal place (Lwot,kj). If a sound peak obviously out of character with the general sound pressure level is observed, the measurement shall be discarded. Left and right side may be measured simultaneously or separately.

The vehicle speed readings at AA' and BB' shall be reported with the first significant digit after the decimal place (vAA,kj; vBB,kj).

If applicable, the engine speed readings at AA' and BB' shall be reported as a full integer value (nAA,kj; nBB,kj).

The calculated acceleration shall be determined in accordance to the formula in point 4.1.2.1.2 of Annex II and reported to the second digit after the decimal place (awot,test,kj).

3.ANALYSIS OF RESULTSU.K.

3.1.Determination of the anchor point for each gear ratioU.K.

For measurements in gear i and lower, the anchor point consists of the maximum sound level Lwoti, the reported engine speed nwoti and vehicle speed vwoti at BB' of gear ratio i of the acceleration test in Annex II.

=

Lwoti,Annex II

=

nBB,woti,Annex II

=

vBB,woti,Annex II

For measurements in gear i+1 the anchor point consists of the maximum sound level Lwoti+1, the reported engine speed nwoti+1 and vehicle speed vwoti+1 at BB' of gear ratio i+1 of the acceleration test in Annex II.

=

Lwoti+1,Annex II

=

nBB,woti+1,Annex II

=

vBB,woti+1,Annex II

3.2.Slope of the regression line for each gearU.K.

The sound measurements shall be evaluated as a function of engine speed in accordance with point 3.2.1.

3.2.1.Calculation of the slope of the regression line for each gearU.K.

The linear regression line is calculated using the anchor point and the four correlated additional measurements.

where nj = engine speed measured at line BB'

3.2.2.Slope of the regression line for each gearU.K.

The Slopek of a particular gear for the further calculation is the derived result of the calculation in point 3.2.1 rounded to the first decimal place, but not higher than 5 dB/1 000 min–1.

3.3.Calculation of the linear sound level increase expected for each measurementU.K.

The sound level LASEP,kj for measurement point j and gear k shall be calculated using the engine speeds measured for each measurement point, using the slope specified in point 3.2 to the specific anchor point for each gear ratio.

For nBB_k,j ≤ nanchor,k:

LASEP_k,j = Lanchor_k + (Slopek – Y) * (nBB_k,j – nanchor,k)/1 000

For nBB_k,j > nanchor,k:

LASEP_k,j = Lanchor_k + (Slopek + Y) * (nBB_k,j – nanchor,k)/1 000

Where Y = 1

3.4.SamplesU.K.

On request of the approval authority two additional runs within the boundary conditions in accordance with point 2.3 shall be carried out.

4.INTERPRETATION OF RESULTSU.K.

Every individual noise measurement shall be evaluated.

The sound level of every specified measurement point shall not exceed the limits given below:

Lkj ≤ LASEP_k.j + x

With:

=

3 dB(A) for vehicle with a non-lockable automatic transmission or non-lockable CVT

=

2 dB(A) + limit value – Lurban of Annex II for all other vehicles

If the measured sound level at a point exceeds the limit, two additional measurements at the same point shall be carried out to verify the measurement uncertainty. The vehicle is still in compliance with ASEP, if the average of the three valid measurements at this specific point fulfils the specification.

5.REFERENCE SOUND ASSESSMENTU.K.

The reference sound is assessed at a single point in one discrete gear, simulating an acceleration condition starting with an entry speed at vaa equal to 50 km/h and assuming an exit speed at vbb equal to 61 km/h. The sound compliance at this point can either be calculated using the results of point 3.2.2 and the specification below or be evaluated by direct measurement using the gear as specified below.

5.1The determination of gear K is as follows:U.K.

=

3 for all manual transmission and for automatic transmission with up to 5 gears;

=

4 for automatic transmission with 6 or more gears

If no discrete gears are available, e.g. for non-lockable automatic transmissions or non-lockable CVTs, the gear ratio for further calculation shall be determined from the acceleration test result in Annex II using the reported engine speed and vehicle speed at line BB'.

5.2.Determination of reference engine speed nref_K U.K.

The reference engine speed, nref_K, shall be calculated using the gear ratio of gear K at the reference speed of vref = 61 km/h.

5.3.Calculation of Lref U.K.

Lref = Lanchor_K + SlopeK * (nref_K – nanchor_K)/1 000

Lref shall be less than or equal to 76 dB(A).

For vehicles fitted with a manual gear box having more than four forward gears and equipped with an engine developing a rated maximum net power greater than 140 kW and having a rated maximum net power/maximum-mass ratio greater than 75 kW/t, Lref shall be less than or equal to 79 dB(A).

For vehicles fitted with an automatic gear box having more than four forward gears and equipped with an engine developing a rated maximum net power greater than 140 kW and having a rated maximum net power/maximum-mass ratio greater than 75 kW/t, Lref shall be less than or equal to 78 dB(A).

6.EVALUATION OF ASEP USING THE PRINCIPLE OF L urban U.K.

6.1GeneralU.K.

This evaluation procedure is an alternative selected by the manufacturer to the procedure described in point 3 of this Annex and is applicable to all vehicle technologies. The manufacturer shall be responsible for determining the correct manner of testing. Unless otherwise specified, all testing and calculation shall be as specified in Annex II.

6.2.Calculation of Lurban ASEP U.K.

From any Lwot ASEP as measured in accordance with this Annex, Lurban ASEP shall be calculated as follows:

calculate awot test ASEP as specified in point 4.1.2.1.2.1 or point 4.1.2.1.2.2 of Annex II, as applicable;

determine the vehicle speed (VBB ASEP) at BB' during the Lwot ASEP test;

calculate kP ASEP as follows:

kP ASEP = 1 – (aurban/awot test ASEP)

Test results where awot test ASEP are less than aurban shall be disregarded.

calculate Lurban measured ASEP as follows:

Lurban measured ASEP =

Lwot ASEP – kP ASEP * (Lwot ASEP – Lcrs)

For further calculation, use the Lurban from Annex II without rounding, including the digit after the decimal (xx.x).

calculate Lurban normalized as follows:

Lurban normalized = Lurban measured ASEP – Lurban

calculate Lurban ASEP as follows:

Lurban ASEP =

Lurban normalized – (0,15 * (VBB ASEP – 50))

compliance with sound level limits:

Lurban ASEP shall be less than or equal to 3,0 dB.

AppendixModel statement of compliance with the Additional Sound Emission Provisions(Maximum format: A4 (210 × 297 mm))

(Name of manufacturer) attests that vehicles of this type (type with regard to its sound emission pursuant to Regulation (EU) No 540/2014) comply with the requirements of Article 7 of Regulation (EU) No 540/2014.

(Name of manufacturer) makes this statement in good faith, after having performed an appropriate evaluation of the sound emission performance of the vehicles.

Date:

Name of authorized representative:

Signature of authorized representative:

ANNEX VIIIU.K.MEASURES CONCERNING THE ACOUSTIC VEHICLE ALERTING SYSTEM (AVAS)

This Annex sets out measures concerning the Acoustic Vehicle Alerting System (AVAS) for hybrid electric and pure electric vehicles.

AVASU.K.

1.System performanceU.K.

If AVAS is installed on a vehicle, it shall comply with the requirements referred to below.

2.Operation conditionsU.K.

(a)Sound generation methodU.K.

The AVAS shall automatically generate a sound in the minimum range of vehicle speed from start up to approximately 20 km/h and during reversing. Where the vehicle is equipped with an internal combustion engine that is in operation within the vehicle speed range defined above, the AVAS shall not generate a sound.

For vehicles having a reversing sound warning device, it is not necessary for the AVAS to generate a sound whilst reversing.

(b)SwitchU.K.

The AVAS shall be fitted with a switch which is easily accessible by the vehicle driver in order to allow engaging and disengaging. Upon restarting the vehicle, AVAS shall default to the switched on position.

(c)AttenuationU.K.

The AVAS sound level may be attenuated during periods of vehicle operation.

3.Sound type and volumeU.K.

(a)The sound to be generated by the AVAS shall be a continuous sound that provides information to the pedestrians and other road users of a vehicle in operation. The sound should be easily indicative of vehicle behaviour and should sound similar to the sound of a vehicle of the same category equipped with an internal combustion engine.U.K.

(b)The sound to be generated by the AVAS shall be easily indicative of vehicle behaviour, for example, through the automatic variation of sound level or characteristics in synchronization with vehicle speed.U.K.

(c)The sound level generated by the AVAS shall not exceed the approximate sound level of a vehicle of the M1 category equipped with an internal combustion engine and operating under the same conditions.U.K.

ANNEX IXU.K.EU TYPE-APPROVAL IN RESPECT OF THE SOUND LEVEL OF SILENCING SYSTEMS AS SEPARATE TECHNICAL UNITS (REPLACEMENT SILENCING SYSTEMS)

1.APPLICATION FOR EU TYPE-APPROVALU.K.

1.1.The application of EU type-approval pursuant to Article 7(1) and (2) of Directive 2007/46/EC in respect of a replacement silencing system, or components thereof, as a separate technical unit intended for vehicles of categories M1 and N1 shall be submitted by the vehicle manufacturer or the manufacturer of the separate technical unit in question.U.K.

1.2.A model for the information document is contained in Appendix 1.U.K.

1.3.At the request of the technical service concerned, the applicant shall submit:U.K.

1.3.1two examples of the system in respect of which application for EU type-approval has been made,U.K.

1.3.2.a silencing system of the type originally fitted to the vehicle when EU type-approval was granted,U.K.

1.3.3.a vehicle representative of the type to which the system is to be fitted, which meets the requirements of point 2.1 of Annex VI,U.K.

1.3.4.a separate engine corresponding to the type of vehicle described.U.K.

2.MARKINGSU.K.

2.4.1.The replacement silencing system, or components thereof, excluding fixing hardware and pipes shall bear:U.K.

2.4.1.1.the trade mark or trade name of the manufacturer of the replacement silencing system and its components,U.K.

2.4.1.2.the manufacturer's trade description.U.K.

2.4.2.These marks shall be clearly legible and indelible, even when the system is fitted to the vehicle.U.K.

3.GRANTING OF EU TYPE-APPROVALU.K.

3.1.If the relevant requirements are satisfied, EU type-approval pursuant to Article 9(3) and, if applicable, Article 10(4) of Directive 2007/46/EC shall be granted.U.K.

3.2.A model for the EU type-approval certificate is contained in Appendix 2.U.K.

3.3.A type-approval number in accordance with Annex VII to Directive 2007/46/EC shall be assigned to each type of replacement silencing system, or components thereof, approved as a separate technical unit; section 3 of the type-approval number shall indicate the number of this Regulation. Furthermore, if the replacement silencing system is intended to be fitted on vehicle types complying with the limit values of Phase 1 in Annex III only, section 3 of the type-approval number shall be followed by the character ‘A’. If the replacement silencing system is intended to be fitted on vehicle types complying with the limit values of Phase 2 in Annex III only, section 3 of the type- approval number shall be followed by the character ‘B’. If the replacement silencing system is intended to be fitted on vehicle types complying with the limit values of Phase 3 in Annex III, section 3 of the type- approval number shall be followed by the character ‘C’. The same Member State shall not assign the same number to another type of replacement silencing system, or components thereof.U.K.

4.EU TYPE-APPROVAL MARKU.K.

4.1.Every replacement silencing system, or components thereof, excluding fixing hardware and pipes, conforming to a type approved under this Regulation shall bear an EU type-approval mark.U.K.

4.2.The EU type-approval mark shall consist of a rectangle surrounding the lower case letter ‘e’ followed by the distinguishing letter(s) or number of the Member State which has granted the approval:U.K.

‘1’ for Germany

‘2’ for France

‘3’ for Italy

‘4’ for the Netherlands