- Latest available (Revised)

- Original (As adopted by EU)

Commission Delegated Regulation (EU) 2015/68Show full title

Commission Delegated Regulation (EU) 2015/68 of 15 October 2014 supplementing Regulation (EU) No 167/2013 of the European Parliament and of the Council with regard to vehicle braking requirements for the approval of agricultural and forestry vehicles (Text with EEA relevance)

You are here:

- Regulations originating from the EU

- 2015 No. 68

- Whole Regulation

- Previous

- Next

More Resources

Revised version PDFs

- Revised 09/06/20182.16 MB

- Revised 14/10/20162.17 MB

When the UK left the EU, legislation.gov.uk published EU legislation that had been published by the EU up to IP completion day (31 December 2020 11.00 p.m.). On legislation.gov.uk, these items of legislation are kept up-to-date with any amendments made by the UK since then.

This item of legislation originated from the EU

Legislation.gov.uk publishes the UK version. EUR-Lex publishes the EU version. The EU Exit Web Archive holds a snapshot of EUR-Lex’s version from IP completion day (31 December 2020 11.00 p.m.).

Status:

This is the original version as it was originally adopted in the EU.

This legislation may since have been updated - see the latest available (revised) version

Commission Delegated Regulation (EU) 2015/68

of 15 October 2014

supplementing Regulation (EU) No 167/2013 of the European Parliament and of the Council with regard to vehicle braking requirements for the approval of agricultural and forestry vehicles

(Text with EEA relevance)

THE EUROPEAN COMMISSION,

Having regard to the Treaty on the Functioning of the European Union,

Having regard to Regulation (EU) No 167/2013 of the European Parliament and of the Council of 5 February 2013 on the approval and market surveillance of agricultural and forestry vehicles(1), and in particular Article 17(5),

Whereas:

(1) The internal market comprises an area without internal frontiers in which the free movement of goods, persons, services and capital is ensured. To that end, a comprehensive EU type-approval system and a strengthened market surveillance system for agricultural and forestry vehicles and their systems, components and separate technical units as defined by Regulation (EU) No 167/2013 apply.

(2) The term ‘agricultural and forestry vehicles’ covers a wide range of different vehicle types with one or more axles and two, four or more wheels or track-laying vehicles, e.g. wheeled tractors, track-laying tractors, trailers and towed equipment, used for a wide variety of agricultural and forestry purposes, including special purpose works.

(3) While the requirements of this Regulation are based on existing legislation last amended in 1997, technical progress requires in particular the adaptation of the test rules in detail, as well as the introduction of specific provisions for energy reservoirs, vehicles with hydrostatic drive, vehicles with inertia braking systems, vehicles with complex electronic control systems, anti-lock braking systems and electronically controlled braking systems.

(4) This Regulation also includes stricter requirements on brake control of towed vehicles and brake coupling between the tractor and towed vehicles than Council Directive 76/432/EEC(2), repealed by Regulation (EU) No 167/2013.

(5) By Council Decision 97/836/EC(3), the Union acceded to United Nations Economic Commission for Europe (UNECE) Regulation No 13. The substantive requirements laid down in Annex 18 to that Regulation on safety aspects of complex electronic vehicle control systems should be taken over into this Regulation, as they reflect the latest state of technology.

(6) While anti-lock braking systems are wide-spread for vehicles with a maximum design speed of above 60 km/h and could thus be considered as appropriate and made compulsory as of its application by this Regulation, such systems are not yet widely available for vehicles with a design speed between 40 km/h and 60 km/h. For those vehicles, the introduction of anti-lock braking systems should thus be confirmed after a final assessment by the Commission of the availability of such systems. To this effect, the Commission should assess, at the latest by 31 December 2016, the availability of anti-lock braking systems for agricultural and forestry vehicles with a maximum design speed between 40 km/h and 60 km/h. Should this assessment not confirm that such technology is available or applicable, the Commission should amend this Regulation in order to provide that these requirements will not become applicable to vehicles with a design speed between 40 km/h and 60 km/h.

(7) Where manufacturers may choose to apply for national type approval in accordance with Article 2 of Regulation (EU) No 167/2013, Member States should, for all subjects covered in this Regulation be free to set requirements for the purposes of national type approval which are different from the requirements of this Regulation. Member States should not, for the purposes of national type-approval, refuse, on ground relating to the functional safety with respect to braking performance, to approve vehicles, systems, components and separate technical units which are compliant with the requirements provided for in this Regulation, with the exception of requirements applying to hydraulic connections of the single-line type. This Regulation should introduce harmonised requirements for hydraulic connections of the single-line type under which such connections could be accepted for the purposes of EU-type approval for a limited period of time. However, as some Member States used to have stricter requirements at national level, Member States should be allowed to refuse granting national type-approvals to vehicle types equipped with hydraulic connections of the single-line type already as from the application date of this Regulation, if they consider this to be in line with their safety requirements at national level.

(8) In order to allow for a harmonised application date of all new type-approval rules, this Regulation should apply from the same date of application as Regulation (EU) No 167/2013,

HAS ADOPTED THIS REGULATION:

CHAPTER I SUBJECT MATTER AND DEFINITIONS

Article 1Subject matter

This Regulation establishes the detailed technical requirements and test procedures regarding functional safety with respect to braking performance for the approval and market surveillance of agricultural and forestry vehicles and systems, components and separate technical units intended for such vehicles in accordance with Regulation (EU) No 167/2013.

Article 2Definitions

The definitions of Regulation (EU) No 167/2013 shall apply. In addition, the following definitions shall apply:

‘braking system’ means the combination of parts whose function is progressively to reduce the speed of a moving vehicle or to bring it to a halt, or to keep it stationary if it has already halted; the system consists of the control device, the transmission and the brake;

‘service braking system’ means the braking system that enables the driver to control the movement of the vehicle and to halt it safely, speedily and effectively, for all the range of speed and load that the vehicle is approved to operate, on any up or down gradient;

‘graduated braking’ means braking which, within the normal range of operation of the equipment, during either the application or the releasing of the brakes, fulfils all the following conditions:

the driver can, at any time, increase or reduce the braking force through action of the control device;

the braking force acts in the same direction as the action on the control device (monotonic function);

it is easily possible to make a sufficiently fine adjustment to the braking force;

‘control device’ means the device actuated directly by the driver to supply to the transmission the energy required for braking or controlling it. This energy may be the muscular energy of the driver, or energy from another source controlled by the driver, or in appropriate cases the kinetic energy of a towed vehicle, or a combination of these various kinds of energy;

‘transmission’ means the combination of components comprised between the control device and the brake, excluding the control lines between tractors and towed vehicles and supply lines between tractors and towed vehicles, and linking them functionally through mechanical, hydraulic, pneumatic or electric means or through the use of a combination of those means; where the braking power is derived from or assisted by a source of energy independent of the driver, the reserve of energy in the system is likewise part of the transmission;

‘control transmission’ means the combination of the components of the transmission which control the operation of the brakes and of the necessary reserve(s) of energy;

‘energy transmission’ means the combination of the components which supply to the brakes the necessary energy for their function;

‘friction brake’ means a brake where forces are generated by the friction between two parts of the vehicle moving relatively to one another;

‘fluid brake’ means a brake where forces are generated by the action of a fluid situated between two parts of the vehicle moving relatively to one another; the fluid is liquid in the case of a ‘hydraulic brake’ and air in the case of a ‘pneumatic brake’;

‘engine brake’ means a brake where forces are derived from a controlled increase in the braking action of the engine transmitted to the wheels;

‘parking braking system’ means a system that enables the vehicle to be held stationary on an up or down gradient even in the absence of the driver;

‘continuous braking’ means the braking of vehicles constituting a combination of vehicles through an installation having all the following characteristics:

a single control device which the driver actuates progressively, by a single movement, from his driving seat;

the energy used for braking the vehicles constituting the combination of vehicles is supplied from the same source;

the braking installation ensures simultaneous or suitably phased braking of each of the constituent vehicles of the combination, whatever their relative positions;

‘semi-continuous braking’ means the braking of vehicles constituting a combination of vehicles through an installation having all the following characteristics:

a single control device which the driver actuates progressively, by a single movement, from his driving seat;

the energy used for braking the vehicles constituting the combination of vehicles is supplied from two different sources;

the braking installation ensures simultaneous or suitably phased braking of each of the constituent vehicles of the combination, wherever their relative positions;

‘automatic braking’ means braking of the towed vehicle or towed vehicles occurring automatically in the event of separation of any of the vehicles constituting the combination of vehicles, including such separation through coupling breakage, without the effectiveness of the remainder of the combination being affected;

‘inertia braking’ means braking by utilising the forces generated by the towed vehicle's moving up on the tractor;

‘non-disengageable transmission’ means the transmission for which either pressure or force or torque are continuously transmitted at any time during travelling of the vehicle in the drive train between the vehicle engine and the wheels and in the braking system between the brake control device and the wheels;

‘laden vehicle’ means a vehicle loaded at its technically permissible maximum laden mass;

‘wheel load’ means the vertical static force of the road surface in the contact area on the wheel;

‘axle load’ means the sum of the vertical static forces of the road surface in the contact area on the wheels of the axle;

‘maximum stationary wheel load’ means the stationary wheel load achieved under the condition of the technically permissible maximum laden mass of the vehicle;

‘maximum stationary axle load’ means the stationary axle load achieved under the condition of the technically permissible maximum laden mass of the vehicle;

‘towed vehicle’ means a trailer as defined in Article 3(9) of Regulation (EU) No 167/2013 or an interchangeable towed equipment as defined in Article 3(10) of that Regulation;

‘drawbar towed vehicle’ means a towed vehicle of category R or S with at least two axles of which at least one is a steered axle, equipped with a towing device which can move vertically in relation to the towed vehicle and which transmits no significant static vertical load to the tractor;

‘centre-axle towed vehicle’ a towed vehicle of category R or S where one or more axles are positioned close to the centre of gravity of the vehicle when uniformly loaded so that only a small static vertical load, not exceeding 10 % of that corresponding to the maximum mass of the towed vehicle or a load of 1 000 daN, whichever is less, is transmitted to the tractor;

‘rigid drawbar towed vehicle’ means a towed vehicle of category R or S with one axle or one group of axles fitted with a drawbar which transmits a significant static load to the tractor due to its construction and which does not meet the definition of a centre-axle towed vehicle; the coupling to be used for a vehicle combination shall not consist of a king pin and a fifth wheel; some slight vertical movement may occur at a rigid drawbar; a hydraulically adjustable articulated drawbar is considered to be a rigid drawbar;

‘endurance braking system’ means an additional braking system having the capability to provide and to maintain a braking effect over a long period of time without a significant reduction in performance, including the control device which may comprise a single device or a combination of several devices each of which may have its own control;

‘electronically controlled braking system’ (EBS) means a braking system where the control is generated and processed as an electrical signal in the control transmission and electrical output signals to devices which generate actuating forces produced from stored or generated energy;

‘automatically commanded braking’ means a function within a complex electronic control system where actuation of the braking system or brakes of certain axles is made for the purpose of generating vehicle retardation with or without a direct action of the driver, resulting from the automatic evaluation of on board initiated information;

‘selective braking’ means a function within a complex electronic control system where actuation of individual brakes is made by automatic means and where vehicle retardation is secondary to vehicle behaviour modification;

‘electric control line’ means the electrical connection between two vehicles which provides the braking control function to a towed vehicle within a combination; it comprises the electrical wiring and connector and includes the parts for data communication and the electrical energy supply for the towed vehicle control transmission;

‘spring compression chamber’ means the chamber where the pressure variation that induces the compression of the spring is actually produced;

‘hydrostatic drive’ means a type of vehicle propulsion which uses a hydrostatic transmission, with open or closed circuit, in which fluid circulates as the energy medium between one or more hydraulic pumps and one or more hydraulic motors;

‘complex electronic vehicle control system’ is an electronic control system which is subject to a hierarchy of control in which a controlled function may be overridden by a higher level electronic control function or by a function performed by higher level electronic control system;

‘anti-lock braking system’ means the part of a service braking system which automatically controls the degree of slip, in the direction of rotation of the wheel, on one or more wheels of the vehicle during braking;

‘directly controlled wheel’ means a wheel whose braking force is modulated according to data provided at least by its own sensor;

‘hydraulic connection of the single line type’ means the connection of the brakes between the tractor and the towed vehicle through a single line of hydraulic fluid.

CHAPTER II REQUIREMENTS APPLYING TO BRAKING DEVICES AND TRAILER BRAKING COUPLINGS

Article 3Fitting and demonstration requirements related to braking performance

1.Manufacturers shall equip agricultural and forestry vehicles with systems, components and separate technical units affecting their braking performance that are designed, constructed and assembled so as to enable the vehicle in normal use and maintained according to the prescriptions of the manufacturer to comply with the detailed technical requirements and testing procedures laid down in Articles 4 to 17.

2.Manufacturers shall demonstrate by means of physical demonstration testing to the approval authority that the agricultural and forestry vehicles made available on the market, registered or entering into service in the Union comply with the detailed technical requirements and test procedures laid down in Articles 4 to 17.

3.Manufacturers shall ensure that spare parts that are made available on the market or are entering into service in the Union comply with the detailed technical requirements and test procedures laid down in this Regulation.

4.Instead of complying with the requirements of this Regulation, the manufacturer may present in the information folder the test report of a component or relevant documentation that proves the compliance of a system or of a vehicle with the requirements of UNECE Regulation No 13, as referenced in Annex X.

5.Instead of complying with the requirements of this Regulation, the manufacturer may present in the information folder relevant documentation that proves the compliance of Anti-lock Braking Systems for towed vehicles, if fitted, with the requirements in Annex 19, paragraph 5 to UNECE Regulation No 13, as referenced in Annex X.

6.The components and systems mentioned in paragraphs 4. and 5. will be referenced in the implementing act adopted in accordance with Article 68 of Regulation (EU) No 167/2013.

Article 4Requirements applying to construction and fitting of braking devices and trailer braking couplings

The test procedures and requirements applying to the construction and fitting of braking devices and trailer braking couplings shall be conducted and verified in accordance with Annex I.

Article 5Requirements applying to testing and performance of braking systems and trailer braking couplings and of vehicles fitted with them

The test procedures and performance requirements applying to braking systems and trailer braking couplings and to vehicles fitted with them shall be conducted and verified in accordance with Annex II.

Article 6Requirements applying to the measurement of the response time

The test procedures and performance requirements applying to the response time of braking devices and trailer braking couplings shall be conducted and verified in accordance with Annex III.

Article 7Requirements applying to energy sources and energy storage devices of braking systems and trailer braking couplings and to vehicles fitted with them

The test procedures and performance requirements applying to energy sources and energy storage devices of braking systems and trailer braking couplings and to vehicles fitted with them shall be conducted and verified in accordance with Annex IV.

Article 8Requirements applying to spring brakes and to vehicles fitted with them

The test procedures and performance requirements applying to spring brakes and to vehicles fitted with them shall be conducted and verified in accordance with Annex V.

Article 9Requirements applying to parking braking systems equipped with a mechanical brake-cylinder locking device

The performance requirements applying to parking braking systems equipped with a mechanical brake-cylinder locking device shall be verified in accordance with Annex VI.

Article 10Alternative test requirements for vehicles for which Type-I, Type-II or Type-III tests are not mandatory

1.The conditions under which test Type I, Type II or Type III are not mandatory for certain types of vehicles are laid down in Annex VII.

2.The test procedures and performance requirements applying to vehicles and their braking devices for which Type-I, Type-II or Type-III tests are not mandatory in accordance with paragraph 1 shall be conducted and verified in accordance with Annex VII.

Article 11Requirements applying to the testing of inertia braking systems, braking devices and trailer braking couplings and of vehicles fitted with them as regards braking

The procedures and requirements applying to the testing of inertia braking systems, braking devices and trailer braking couplings and of vehicles fitted with them as regards braking shall be conducted and verified in accordance with Annex VIII.

Article 12Requirements applying to vehicles with hydrostatic drive and their braking devices and braking systems

The test procedures and performance requirements applying to vehicles with hydrostatic drive and their braking devices and braking systems shall be conducted and verified in accordance with Annex IX.

Article 13Requirements applying to the safety aspects of complex electronic vehicle control systems

The test procedures and performance requirements applying to the safety aspects of complex electronic vehicle control systems shall be conducted and verified in accordance with Annex X.

Article 14Requirements and test procedures applying to anti-lock braking systems and to vehicles fitted with them

The test procedures and requirements applying to anti-lock braking systems and to vehicles fitted with them shall be conducted and verified in accordance with Annex XI.

Article 15Requirements applying to EBS of vehicles with compressed-air braking systems or of vehicles with data communication via pin 6 and 7 of ISO 7638 connector and to vehicles fitted with such EBS

The test procedures and performance requirements applying to EBS of vehicles with compressed-air braking systems or of vehicles with data communication via pin 6 and 7 of ISO 7638 connector and to vehicles fitted with such EBS shall be conducted and verified in accordance with Annex XII.

Article 16Requirements applying to hydraulic connections of the single-line type and to vehicles fitted with them

1.The performance requirements applying to hydraulic connections of the single-line type of braking devices and trailer braking couplings and to vehicles fitted with hydraulic connections of the single-line type are laid down in Annex XIII.

2.Vehicle manufacturers shall not fit hydraulic connections of the single-line type to new types of vehicles of category T and C after 31 December 2019 and to new vehicles of those categories after 31 December 2020.

CHAPTER III OBLIGATIONS OF THE MEMBER STATES

Article 17Type-approval of vehicles, systems, components and separate technical units

Pursuant to Article 6(2) of Regulation (EU) No 167/2013, with effect from 1 January 2016, approval authorities shall not refuse, on grounds relating to functional safety with regard to braking performance, to grant EU type-approval to agricultural and forestry vehicle types which comply with the requirements of this Regulation.

With effect from 1 January 2020 and in accordance with Article 6(2) of Regulation (EU) No 167/2013 and Article 16 of this Regulation, type-approval authorities shall refuse to grant type-approval to vehicle types of categories T and C fitted with hydraulic connections of the single-line type.

With effect from 1 January 2018, national authorities shall, in the case of new vehicles that do not comply with Regulation (EU) No 167/2013 and the provisions of this Regulation on functional safety with regard to braking performance, prohibit the making available on the market, registration, or entry into service of such vehicles.

With effect from 1 January 2021, for new vehicles of categories T and C fitted with hydraulic connections of the single-line type set out in Article 16, national authorities shall prohibit the making available on the market, registration, or entry into service of such vehicles.

Article 18National type-approval of vehicles, systems, components and separate technical units

National authorities shall not refuse to grant national type-approval to a type of vehicle, system, component or separate technical unit on grounds relating to the functional safety with regard to braking performance where the vehicle, system, component or separate technical unit complies with the requirements set out in this Regulation, with the exception of the requirements applying to hydraulic connections of the single-line type.

CHAPTER IV FINAL PROVISION

Article 19Entry into force and application

This Regulation shall enter into force on the twentieth day following that of its publication in the Official Journal of the European Union.

It shall apply as of 1 January 2016.

This Regulation shall be binding in its entirety and directly applicable in all Member States.

Done at Brussels, 15 October 2014.

For the Commission

The President

José Manuel Barroso

LIST OF ANNEXES

| Annex Number | Annex title | Page No. |

|---|---|---|

| I | Requirements applying to construction and fitting of braking devices and trailer braking couplings | 10 |

| II | Requirements applying to testing and performance of braking systems and trailer braking couplings and of vehicles fitted with them | 27 |

| III | Requirements applying to the measurement of the response time | 49 |

| IV | Requirements applying to energy sources and energy storage devices of braking systems and trailer braking couplings and to vehicles fitted with them | 60 |

| V | Requirements applying to spring brakes and to vehicles fitted with them | 67 |

| VI | Requirements applying to parking braking systems equipped with a mechanical brake-cylinder locking device | 70 |

| VII | Alternative test requirements for vehicles for which Type-I, Type-II or Type-III tests are not mandatory | 71 |

| VIII | Requirements applying to the testing of inertia braking systems, braking devices and trailer braking couplings and of vehicles fitted with them as regards braking | 83 |

| IX | Requirements applying to vehicles with hydrostatic drive and their braking devices and braking systems | 98 |

| X | Requirements applying to the safety aspects of complex electronic vehicle control systems | 104 |

| XI | Requirements and test procedures applying to anti-lock braking systems and to vehicles fitted with them | 105 |

| XII | Requirements applying to EBS of vehicles with compressed-air braking systems or of vehicles with data communication via pin 6 and 7 of ISO 7638 connector and to vehicles fitted with such EBS | 121 |

| XIII | Requirements applying to hydraulic connections of the single-line type and to vehicles fitted with them | 136 |

ANNEX I Requirements applying to construction and fitting of braking devices and trailer braking couplings

1. Definitions

For the purposes of this Annex:

‘coupling force control’ means a system or function to balance automatically the braking rate of tractor and towed vehicle;

‘nominal demand value’ means a characteristic of coupling force control that relates the coupling head signal to the braking rate and which can be demonstrated at type-approval, within the limits of the compatibility bands of Appendix 1 of Annex II;

‘track rollers’ means the system that transmits the weight of the vehicle and crawler undercarriage to the ground via the track belt, transmits torque from the vehicle's drive system to the track belt and may produce a change of direction of the moving belt;

‘crawler undercarriage’ means a system comprising at least two track rollers, which are spaced a specified distance apart in one plane (in-line) and a continuous metallic or rubber track belt that runs around them;

‘track belt’ means a continuous flexible belt, which can absorb longitudinal tractive forces.

2. Construction and fitting requirements

2.1.General

The maximum design speed is considered, throughout this Annex, to be in the forward direction of the vehicle travel, unless otherwise explicitly mentioned.

2.1.1.Braking components, separate technical units and parts

2.1.1.1.The braking components, separate technical units and parts shall be so designed, constructed and fitted as to enable the vehicle in normal use, despite the vibration to which it may be subjected, to comply with the under mentioned requirements.

2.1.1.2.In particular, the braking components, separate technical units and parts shall be so designed, constructed and fitted as to be able to resist the corrosion and ageing phenomena to which it is exposed.

2.1.1.3.Brake linings shall not contain asbestos.

2.1.1.4.It is not permitted to fit any components, separate technical units and parts (such as valves) that would allow the performance of the braking system to be changed by the user of the vehicle such that, in service, it falls outside the requirements of this Regulation. A component, separate technical unit and part that can only be operated by the manufacturer through the use of special tool or the provision of a tamper proof seal or both shall be permitted provided that the user of the vehicle is not able to modify this component, separate technical unit and part or that any user modification is readily identifiable by enforcement authorities.

2.1.1.5.A towed vehicle shall be equipped with an automatic load sensing device, with the exception of the following cases:

If a towed vehicle with a maximum design speed not exceeding 30 km/h cannot be equipped for technical reasons with an automatic load sensing device, it may be equipped with a device having at least three discrete settings for the control of the braking forces.

In the special case that a towed vehicle allows by design that only two discrete loading conditions ‘unladen’ and ‘laden’ can be realised then the vehicle may have only two discrete settings for the control of the braking forces.

S-category vehicles the machinery of which does not contain any other load including consumable material.

2.1.2.Functions of the braking system

The braking system shall fulfil the following functions:

2.1.2.1.Service braking system

It shall be possible to graduate the service braking system action. The driver shall be able to achieve this braking action from his driving position without removing his hands from the steering control device.

2.1.2.2.Secondary braking system

The secondary braking system shall make it possible to halt the vehicle within a reasonable distance in the event of the failure of the service braking system. On tractors, it shall be possible to graduate this braking action. The driver shall be able to obtain this braking action from his driving seat while keeping at least one hand on the steering control device. For the purpose of these requirements, it is assumed that not more than one failure of the service braking system can occur at one time.

2.1.2.3.Parking braking system

The parking braking system shall enable the vehicle to be held stationary on an up or down gradient even in the absence of the driver, the working parts of the braking system being then held in the locked position by a purely mechanical device. The driver shall be able to achieve this braking action from his driving seat, subject, in the case of a towed vehicle, to the requirements of point 2.2.2.11.

The towed vehicle service braking system (pneumatic or hydraulic) and the parking braking system of the tractor may be operated simultaneously, provided that the driver is able to check, at any time, that the parking braking system performance of the vehicle combination, obtained by the purely mechanical action of the parking braking system, is sufficient.

2.1.3.The relevant requirements of Appendix 1 of Annex II shall be applied to vehicles and their braking systems.

2.1.4.Connections, for compressed-air braking systems, between tractors and towed vehicles

2.1.4.1.The connections of the compressed-air braking systems between tractors and towed vehicles shall be provided according to the following points 2.1.4.1.1, 2.1.4.1.2 or 2.1.4.1.3.

one pneumatic supply line and one pneumatic control line;

one pneumatic supply line, one pneumatic control line and one electric control line;

one pneumatic supply line and one electric control line. Until uniform technical standards have been agreed, which ensure compatibility and safety, connections between tractors and trailers conforming to the provisions of this point shall not be permitted.

2.1.5.Connections between tractors and towed vehicles with hydraulic braking systems

2.1.5.1.Type of connections

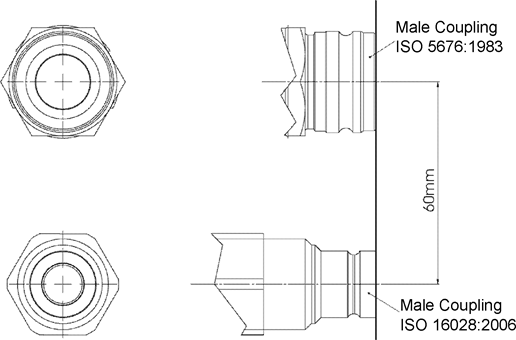

2.1.5.1.1.Hydraulic control line: this is the connecting line with the male connector on the tractor and the female connector on the towed vehicle. The connectors shall comply with ISO 5676:1983.

2.1.5.1.2.Hydraulic supplementary line: this is the connecting line with the male connector on the tractor and the female connector on the towed vehicle. The connectors shall comply with ISO 16028:2006, size 10.

2.1.5.1.3.ISO 7638:2003 connector (optional). The ISO 7638:2003 connector may be used for 5 pin or 7 pin applications, as appropriate.

The positioning of the connectors as specified in points 2.1.5.1.1 and 2.1.5.1.2 shall be arranged on the tractor as illustrated in Figure 1.

2.1.5.2.With the engine running and the parking braking system of the tractor fully applied:

a pressure of 0+100 kPa is present on the supplementary line and/or

a pressure between 11 500 kPa and 15 000 kPa is generated on the control line.

2.1.5.3.With the engine running and the parking braking system of the tractor fully released a pressure between the values provided at point 2.2.1.18.3 shall be present on the supplementary line.

2.1.5.4.With the engine running and no brake control on the tractor applied (driving or stand-by condition), the pressure supplied at the coupling head of the control line shall be the one provided at point 2.2.1.18.2.

2.1.5.5.With the engine running and the service brake control device on the tractor fully actuated a pressure between 11 500 kPa and 15 000 kPa shall be generated in the control line. For pressurising the control line during service brake application the tractor shall be capable to comply with requirement of point 3.6 of Annex III.

2.1.6.The flexible hoses and cables connecting tractors and towed vehicles shall be a part of the towed vehicle.

2.1.7.Shut-off devices which are not automatically actuated shall not be permitted.

2.1.8.Pressure test connections

2.1.8.1.For the purpose of determining the in-use braking forces of each axle of the vehicle, with a compressed-air braking system, air pressure test connections must be provided:

In each independent circuit of the braking system, at the closest readily accessible position to the brake cylinder which is the least favourably placed as far as the response time described in Annex III is concerned.

In a braking system which incorporates a device that modulates the air or hydraulic pressure in the brake transmission as referred to in point 6.2 of Appendix I to Annex II, located in the pressure line upstream and downstream of this device at the closest accessible position. If this device is pneumatically controlled an additional test connection is required to simulate the laden condition. Where no such device is fitted, a single pressure test connection, equivalent to the downstream connector mentioned above, shall be provided. These test connections shall be so located as to be easily accessible from the ground or within the vehicle.

At the closest readily accessible position to the least favourably placed energy storage device within the meaning of point 2.4 of section A of Annex IV.

In each independent circuit of the braking system so it is possible to check the input and output pressure of the complete transmission line.

The pressure test connections shall comply with clause 4 of ISO Standard 3583:1984.

2.2.Requirements of braking systems

2.2.1.Vehicles of categories T and C

2.2.1.1.The set of braking systems with which a vehicle is equipped shall satisfy the requirements laid down for the service, secondary and parking braking systems.

In order to assist the driver in steering (to enable differential braking in the field) the service braking system of the tractor may consist of two independent brake circuits, each connected to one separate right or left brake pedal.

If the differential braking function is activated it shall not be possible to travel at speeds exceeding 40 km/h or at speeds in excess of 40 km/h the differential braking function shall be disabled. These two operations shall be ensured by automatic means.

If the differential mode is activated an actuation of the towed vehicle service braking system is not required up to a speed of 12 km/h.

In tractors where the separate pedals can be connected manually, the driver shall be able to easily verify from his driving place whether these pedals are connected or not.

2.2.1.2.The equipment providing service, secondary and parking braking may have common components, provided that they fulfil the following conditions:

There shall be at least two controls, each corresponding to a different braking system, independent of each other and readily accessible to the driver from his normal driving position. For all categories of vehicles, every brake control device (excluding endurance braking system control device) shall be designed in a way that it returns to the fully-off position when released. This requirement shall not apply to a parking braking system control device (or that part of a combined control device) when it is mechanically locked in an applied position or it is utilised for the secondary braking or in both cases.

The control device of the service braking system shall be independent of the control device of the parking braking system.

Where the service and secondary braking systems have the same control device, the effectiveness of the linkage between that control device and the various components of the transmission systems shall not be liable to deteriorate after a certain period of use.

Where the service and secondary braking systems have the same control device, the parking braking system shall be so designed that it can be actuated when the vehicle is in motion. This requirement shall not apply if the vehicle's service braking system can be actuated, even partially, by means of an auxiliary control.

In the event of a breakage of any component other than the brakes or the components specified in point 2.2.1.2.7, or of any other failure of the service braking system (malfunction, partial or total exhaustion of an energy reserve), the secondary braking system or that part of the service braking system which is not affected by the failure shall be able to bring the vehicle to a halt in the conditions prescribed for secondary braking.

In particular, where the secondary braking system and the service braking system have a common control device and common transmission:

where the service braking system is actuated by the muscular energy of the driver assisted by one or more energy reserves, the secondary braking performance shall, in the event of failure of that assistance, be capable of being ensured by the muscular energy of the driver assisted by the energy reserves, if any, which are unaffected by the failure, the force applied to the control device not exceeding the prescribed maxima.

If the service braking force and transmission depend exclusively on the use, controlled by the driver, of an energy reserve, there shall be at least two completely independent energy reserves, each provided with its own transmission likewise independent; each of them may act on the brakes of only two or more wheels so selected as to be capable of ensuring by themselves the prescribed degree of secondary braking without endangering the stability of the vehicle during braking; in addition, each of the those energy reserves shall be equipped with a warning device. In at least one of the air reservoirs of each service braking circuit a device for draining and exhausting is required in an adequate and easily accessible position.

If the service braking force and transmission depend exclusively on the use of an energy reserve, one energy reserve for the transmission is deemed to be sufficient, provided that the prescribed secondary braking is ensured by the action of the driver's muscular energy acting on the service brake control device and the requirements of point 2.2.1.5 are met.

Certain parts, such as the pedal and its bearing, the master cylinder and its piston(s) (hydraulic systems), the control valve (hydraulic or pneumatic systems), the linkage between the pedal and the master cylinder or the control valve, the brake cylinders and their pistons (hydraulic or pneumatic systems), and the lever-and-cam assemblies of brakes, shall not be regarded as liable to breakage if they are amply dimensioned, are readily accessible for maintenance, and exhibit safety features at least equal to those prescribed for other essential components (such as the steering linkage) of the vehicle. Where the failure of any such part would make it impossible to brake the vehicle with a performance at least equal to that prescribed for the secondary braking system that part shall be made of metal or of a material with equivalent characteristics and shall not be subject to significant distortion in the normal operation of the braking systems.

2.2.1.3.Where there are separate control devices for the service and secondary braking systems simultaneous actuation of control devices shall not render both the service and secondary braking systems inoperative, either when both braking systems are in good working order or when one of them is faulty.

2.2.1.4.Where use is made of energy other than the muscular energy of the driver, there need not be more than one source of such energy (hydraulic pump, air compressor, etc.), but the means by which the device constituting that source is driven shall be as safe as practicable.

2.2.1.4.1.In the event of failure in any part of the transmission of a vehicle's braking system consisting of two service braking circuits fulfilling the requirements of point 2.2.1.25, the supply to the part not affected by the failure shall continue to be ensured where this is required for the purpose of halting the vehicle with the degree of effectiveness prescribed for residual and/or for secondary braking. This condition shall be satisfied by automatic means.

2.2.1.4.2.Furthermore, storage devices located down-circuit of this device are such that in the event of a failure in the energy supply, after four full-stroke actuations of the service braking system control device under the testing conditions prescribed in point 1.2 of section A or in point 1.2 of section B or in point 1.2 of section C of Annex IV, following to the kind of braking system, it is still possible to halt the vehicle at the fifth application with the degree of effectiveness prescribed for secondary braking.

2.2.1.4.3.For hydraulic braking systems with stored energy, requirements of points 2.2.1.4.1 and 2.2.1.4.2 shall be considered to be met, provided that the requirements of point 1.2.2. of Part C of Annex IV to this Regulation, are satisfied.

2.2.1.4.4.In the case of a service braking system consisting of only one service braking circuit it is required that in the event of a failure or non-availability of the energy source it shall be possible halting the vehicle with the service braking system control with the degree of effectiveness prescribed for secondary braking.

2.2.1.5.The requirements of points 2.2.1.2, 2.2.1.4 and 2.2.1.25 shall be satisfied without the use of any automatic device of a kind such that its ineffectiveness might pass unnoticed because the parts which are normally in an ‘at rest’ position are actuated only in the event of failure of the braking system.

2.2.1.6.On vehicles with a maximum design speed not exceeding 30 km/h, the service braking system shall act on all the wheels of at least one axle. In all other cases the service braking system shall act on all the wheels of the vehicle. However, in case of vehicles with one braked axle and an automatic engagement of the drive to all other axles during braking, all wheels are deemed to be braked.

For category C vehicles this condition is considered to be met if all of the track rollers of the vehicle are braked. For category C vehicles with a design speed of less than 30 km/h, this condition is considered to be met if at least one track roller on each side of the vehicle is braked.

For vehicles equipped with a straddle seat and handlebars, the service braking may act either on the front axle or on the rear axle provided that all the performance requirements prescribed in point 2 of Annex II to this Regulation are met.

For articulated tractors of category Ta, if an axle is subject to braking and the differential is mounted between the service brake and the wheels, all wheels of that axle are deemed to be braked when the activation of the service braking system automatically locks the differential on this axle.

2.2.1.6.1.Performance of hydraulic lines and hose assemblies in case of vehicles with one braked axle and an automatic engagement of the drive to all other axles during braking

The hydraulic lines of hydraulic transmission shall be capable of a burst pressure at least four times the maximum normal service pressure (T) specified by the vehicle manufacturer. Hose assemblies shall comply with ISO Standards 1402:1994, 6605:1986 and 7751:1991.

2.2.1.7.If the service braking system acts on all wheels or track rollers of the vehicle, the action shall be appropriately distributed among the axles. Where this is achieved by means of a device which modulates the pressure in the brake transmission, this shall conform to the requirements of point 6 of Appendix 1 to Annex II and point 2.1.8.

2.2.1.7.1.In the case of vehicles with more than two axles, in order to avoid wheel-locking or glazing of the brake linings, the brake force on certain axles may be reduced to zero automatically when carrying a much reduced load, provided that the vehicle meets all the performance requirements prescribed in Annex II.

2.2.1.8.The action of the service braking system shall be distributed between the wheels or track rollers of the same axle symmetrically in relation to the longitudinal median plane of the vehicle.

2.2.1.9.The service, secondary and the parking braking systems shall act on braking surfaces permanently connected to the wheels through components of adequate strength. It shall not be possible to disconnect a braking surface from the wheels; however, such disconnection shall be permitted in the case of the parking braking system, provided that it is controlled exclusively by the driver from his driving seat by a system which cannot be actuated by a leak. When more than one axle is normally subject to braking in the case of vehicles of categories T and C with a maximum design speed not exceeding 60 km/h, one axle may be decoupled provided that activation of the service braking system automatically re-couples this axle and that, in the case of a failure in the energy supply or a failure in the control transmission of the re-coupling control device, then automatic re-coupling shall be ensured.

2.2.1.10.It shall be possible for the wear of the service brakes to be compensated by means of a system of manual adjustment. For vehicles of categories Tb and Cb, the wear of the service brakes shall be compensated by means of a system of automatic adjustment. In addition, the control device and the components of the transmission and of the brakes shall possess a reserve of travel and, if necessary, suitable means of compensation such that, when the brakes become heated or when the brake linings have reached a certain degree of wear, effective braking shall be ensured without immediate adjustment being necessary.

Vehicles of categories Ta, and category Ca, do not need to be fitted with a system where the wear of the brakes are compensated by means of a system of automatic adjustment. However, if vehicles of these categories are equipped with system where the wear of the brakes are compensated by means of a system of automatic adjustment, this system shall comply with the same requirements as those of category Tb and Cb.

2.2.1.10.1.Automatic wear adjustment devices, if fitted, shall, after heating followed by cooling, be capable of free running as laid down in point 2.3.4 of Annex II following the Type-I test also specified in point 1.3 of that Annex.

It shall be possible to easily check this wear on service brake linings from the outside or underside of the vehicle, utilising only the tools or equipment normally supplied with the vehicle; for instance, by the provision of appropriate inspection holes or by some other means. Alternatively, acoustical or optical devices warning the driver at his driving position when lining replacement is necessary are acceptable.

2.2.1.10.2.The requirements of 2.2.1.10 and 2.2.1.10.1 are not applicable to oil immersed brakes which are designed for the whole lifetime of the vehicle without servicing.

2.2.1.11.In hydraulic braking systems:

The filling ports of the fluid reservoirs shall be readily accessible; in addition, the containers of reserve fluid shall be so made that the level of the reserve fluid can be easily checked without the containers having to be opened. Where this last condition is not fulfilled, the red warning signal specified in point 2.2.1.29.1.1 shall draw the driver's attention to any fall in the level of reserve fluid liable to cause a failure of the braking system.

A failure in the hydraulic transmission where the prescribed service braking performance cannot be obtained shall be signalled to the driver by a device comprising a warning signal, as specified in point 2.2.1.29.1.1. Alternatively, the lighting up of this device when the fluid in the reservoir is below a certain level specified by the manufacturer shall be permitted.

The type of fluid to be used in the hydraulic transmission of braking systems shall be identified by the symbol in accordance with Figure 1 or 2 of Standard ISO 9128:2006. The symbol shall be affixed within 100 mm of the filling ports of the fluid reservoirs, in accordance with the requirements laid down on the basis of Article 17(2)(k) and (5) of Regulation (EU) No 167/2013. Additional information may be provided by the manufacturers. This requirement only applies to vehicles having a separate filling port for the fluid of the braking system.

2.2.1.12.Warning device

2.2.1.12.1.Any vehicle fitted with a service braking system actuated by an energy reservoir shall, where the prescribed secondary braking performance cannot be obtained by means of this braking system without the use of stored energy, be provided with a warning device — in addition to a pressure gauge where fitted — giving an optical or acoustic signal when the stored energy in any part of the system falls to a value at which, without recharging of the reservoir and irrespective of the loading conditions of the vehicle, it shall be possible to apply the service braking system control device a fifth time after four full-stroke actuations and obtain the prescribed secondary braking performance (without faults in the service-brake transmission and with the brakes adjusted as closely as possible). The warning device shall be directly and permanently connected to the circuit. When the engine is running under normal operating conditions and there are no faults in the braking system, the warning device shall give no signal except during the time required for charging the energy reservoir(s) after start-up of the engine.

2.2.1.12.1.1.However, in the case of vehicles which are only considered to comply with the requirements of point 2.2.1.4.1 by virtue of meeting the requirements of point 1.2.2 of section C of Annex IV the alarm device shall consist of an acoustic signal in addition to an optical signal. These devices need not operate simultaneously, provided that each of them meets the above requirements and the acoustic signal is not actuated before the optical signal.

2.2.1.12.2.This acoustic device may be rendered inoperative while the parking braking system is applied or, at the choice of the manufacturer, in the case of automatic transmission the selector in the ‘park’ position or in both cases.

2.2.1.13.Without prejudice to the requirements of point 2.1.2.3, where the use of an auxiliary energy source is essential for the operation of a braking system, the energy reserve shall be such as to ensure that, should the engine stop, or in the event of a failure of the means by which the energy source is driven, the braking performance remains sufficient to bring the vehicle to a halt in the prescribed conditions. In addition, if the muscular energy applied by the driver to the parking braking system is reinforced by some aid, the actuation of the parking braking system shall be ensured in the event of failure of that aid, if necessary by using a reserve of energy independent of that normally supplying such aid. This reserve of energy may be that intended for the service braking system.

2.2.1.14.In the case of a tractor to which the coupling of a towed vehicle equipped with a brake controlled by the driver of the tractor is authorised, the service braking system of the tractor shall be fitted with a device so designed that if the towed vehicle braking system should fail, or the supply line (or such other type of connection as may be adopted) between the tractor and towed vehicle should break, it will still be possible to brake the tractor with the performance prescribed for the secondary braking system; it is accordingly prescribed, in particular, that this device be fitted to the tractor service braking system ensuring that the tractor can still be braked by the service braking system with a performance prescribed for the secondary braking system.

2.2.1.15.The pneumatic or hydraulic auxiliary equipment shall be automatically supplied with energy in such a way that during its operation the prescribed performance values can be reached and that even in the event of damage to the source of energy, the operation of the auxiliary equipment cannot cause the reserves of energy feeding the braking systems to fall below the level indicated in point 2.2.1.12.

2.2.1.16.A tractor authorised to tow a category R2, R3, R4 or S2 vehicle shall satisfy the following conditions:

When the service braking system of the tractor is actuated there shall also be a graduated braking action on the towed vehicle, see also point 2.2.1.18.4.

When the tractor's secondary braking system comes into action, there shall also be a braking action in the towed vehicle. In the case of tractors of categories Tb and Cb this braking action shall be graduable.

Should the service braking system of the tractor fail, and if this system is made up of at least two independent sections, the section or sections not affected by this failure shall be able to fully or partially actuate the towed vehicle brakes. This requirement does not apply where the two independent sections consist in one section braking left hand wheels and one section braking right hand wheels, such a design aiming at permitting differential braking for cornering in the fields. Should in the latter case, the service braking system of the tractor fail, then the secondary braking system shall be able to fully or partially actuate the towed vehicle brakes. If this operation is achieved by a valve which is normally at rest, then such a valve may only be incorporated if its correct functioning can easily be checked by the driver, either from within the cab or from outside the vehicle, without the use of tools.

2.2.1.17.Additional requirements in the case of tractors authorised to draw towed vehicles with compressed-air braking systems.

2.2.1.17.1.In the event of a failure (e.g. breakage) in one of the pneumatic connecting lines, interruption or defect in the electric control line, it shall nevertheless be possible for the driver, fully or partially, to actuate the brakes of the towed vehicle by means either of the service braking control device or of the secondary braking control device or of the parking braking control device, unless the failure automatically causes the towed vehicle to be braked with the performance prescribed in point 3.2.3 of Annex II.

2.2.1.17.2.The automatic braking in point 2.2.1.17.1 shall be considered to be met when the following conditions are fulfilled:

When the designated brake control device of the ones mentioned in point 2.2.1.17.1, is fully actuated, the pressure in the supply line shall fall to 150 kPa within the following two seconds; in addition, when the brake control device is released, the supply line shall be re-pressurised.

When the supply line is evacuated at the rate of at least 100 kPa per second the automatic braking of the towed vehicle shall start to operate before the pressure in the supply line falls to 200 kPa.

2.2.1.17.3.In the event of a failure in one of the control lines connecting two vehicles equipped according to point 2.1.4.1.2, the control line not affected by the failure shall automatically ensure the braking performance prescribed for the towed vehicle in point 3.2.3 of Annex II.

2.2.1.17.4.In the case of a pneumatic service braking system comprising two or more independent sections, any leakage between those sections at or downstream of the control device shall be continuously vented to atmosphere.

2.2.1.18.Additional requirements in the case of tractors authorised to draw towed vehicles with hydraulic braking systems.

2.2.1.18.1.The pressure supplied at both coupling heads with the engine not running shall always be 0 kPa.

2.2.1.18.2.The pressure supplied at the coupling head of the control line with the engine running and no braking control force applied shall be 0+200 kPa.

2.2.1.18.3.With the engine running it shall be possible to generate at the coupling head of the supplementary line a pressure of at least 1 500 kPa but not exceeding 3 500 kPa

2.2.1.18.4.As a derogation from the requirement of point 2.2.1.16.1, a graduated braking action on the towed vehicle is only required when the service braking system of the tractor is actuated when the engine is running.

2.2.1.18.5.In the case of a failure (e.g. fracture or leak) in the supplementary line, it shall nevertheless be possible for the driver to fully or partially actuate the towed vehicle brakes, by means either of the service braking system control device or of the parking braking system control device, unless this failure automatically causes the towed vehicle to be braked with the performance prescribed in point 3.2.3 of Annex II.

2.2.1.18.6.In the case of a failure (e.g. fracture or leak) in the control line, the pressure in the supplementary line shall fall to 1 000 kPa within the following two seconds after the service brake control device has been fully actuated; in addition, when the service brake control device is released, the supplementary line shall be re-pressurised (see also point 2.2.2.15.3).

2.2.1.18.7.The pressure in the supplementary line shall fall from its maximum value to 0+300 kPa within the following second after the parking braking system control device has been fully actuated.

In order to check the evacuation time the supplementary line of the towed vehicle simulator according to point 3.6.2.1 of Annex III is connected to the supplementary line of the tractor.

The accumulators of the simulator are then charged to the maximum value generated by the tractor with the engine running and the bleeding device (point 1.1 of Appendix 2 of Annex III) fully closed.

2.2.1.18.8.In order to be able to connect and disconnect the hydraulic connecting lines even when the engine is running and the parking braking system applied, an appropriate device may be fitted on the tractor.

This device shall be so designed and constructed that the pressure in the connecting lines is positively restored to the rest position not later than the control (e.g. push button) of this device is automatically released (e.g. valve returns automatically into the normal operation position).

2.2.1.18.9.Tractors towing a vehicle of category R or S and which can only comply with the braking performance requirements of the service braking system and/or parking braking system and/or automatic braking system with the assistance of energy stored in a hydraulic energy storage device shall be equipped with an ISO 7638:2003 connector in order to be able to indicate the low level of stored energy on the towed vehicle, received by the latter, as laid down in point 2.2.2.15.1.1 by the separate warning signal via pin 5 of the electrical connector conforming to ISO 7638:2003 specified in point 2.2.1.29.2.2 (see also point 2.2.2.15.1). The ISO 7638:2003 connector may be used for 5 pin or 7 pin applications, as appropriate.

2.2.1.19.In the case of a tractor authorised to tow a vehicle of categories R3, R4 or S2, the service braking system of the towed vehicle may only be operated in conjunction with the service, secondary or parking braking system of the tractor. However, automatic application of the towed vehicle brakes alone is permitted where the operation of the towed vehicle brakes is initiated automatically by the tractor for the sole purpose of vehicle stabilisation.

2.2.1.19.1.By way of derogation from point 2.2.1.19, in order to improve the driving behaviour of the vehicle combination by modifying the coupling force between the tractor and towed vehicle, it is permissible that towed vehicle brakes are applied automatically up to a time of 5 s without the operation of the service, secondary or parking braking system of the tractor.

2.2.1.20.If point 3.1.3 of Annex II can only be fulfilled by complying with the conditions specified in point 3.1.3.4.1.1 of Annex II then

in the case of compressed-air braking system, a control line pressure (or the equivalent digital demand) of at least 650 kPa shall be transmitted when a single control device is fully activated which also applies the tractor parking braking system. This shall also be ensured when the ignition/start switch has been switched off and/or the key has been removed;

in the case of hydraulic braking system, when a single control device is fully activated a pressure of 0+100 kPa shall be generated on the supplementary line.

2.2.1.21.Anti-lock braking systems for tractors of category Tb

2.2.1.21.1.Tractors of category Tb with a maximum design speed exceeding 60 km/h shall be equipped with anti-lock braking systems of category 1 in accordance with the requirements of Annex XI.

2.2.1.21.2.Tractors of category Tb with a maximum design speed exceeding 40 km/h and not exceeding 60 km/h shall be equipped with anti-lock braking systems of category 1 in accordance with the requirements of Annex XI

for new vehicle types as from 1 January 2020; and

for new vehicles as from 1 January 2021.

2.2.1.22.Tractors authorised to tow a vehicle equipped with an anti-lock braking system shall also be equipped with a special electrical connector, conforming to ISO 7638:2003, for the electric control transmission. The ISO 7638:2003 connector may be used for 5 pin or 7 pin applications, as appropriate.

2.2.1.23.If tractors not mentioned in points 2.2.1.21.1 and 2.2.1.21.2 are fitted with anti-lock braking systems, they shall comply with the requirements of Annex XI.

2.2.1.24.The requirements of Annex X shall be applied to the safety aspects of all complex electronic vehicle control systems which provide or form part of the control transmission of the braking function included those which utilise the braking system(s) for automatically commanded braking or selective braking.

2.2.1.25.In the case of category Tb tractors with a maximum design speed exceeding 60 km/h, the service braking system shall, whether or not it is combined with the secondary braking system, be such that in the event of failure in a part of its transmission a sufficient number of wheels are still braked by actuation of the service brake control device; these wheels shall be so selected that the residual performance of the service braking system satisfies the requirements laid down in point 3.1.4 of Annex II.

The part or parts not affected by the failure shall be capable of partially or fully actuating the brakes of the towed vehicle.

2.2.1.25.1.The failure of a part of a hydraulic transmission system shall be signalled to the driver by a device comprising a warning signal, as specified in point 2.2.1.29.1.1. Alternatively, the lighting up of this device when the fluid in the reservoir is below a certain level specified by the manufacturer shall be permitted.

2.2.1.26.Special additional requirements for the electric transmission of the parking braking system

2.2.1.26.1.Tractors with a maximum design speed exceeding 60 km/h

2.2.1.26.1.1.In the case of a failure within the electric transmission, any unintended actuation of the parking braking system shall be prevented.

2.2.1.26.1.2.In the case of an electrical failure in the control or a break in the wiring within the electric control transmission external to the electronic control unit(s), excluding the energy supply, it shall remain possible to apply the parking braking system from the driver's seat and thereby be capable of holding the laden vehicle stationary on an 8 % up or down gradient.

2.2.1.26.2.Tractors with a maximum design speed not exceeding 60 km/h

2.2.1.26.2.1.In the case of an electrical failure in the control or a break in the wiring within the electric control transmission external to the control unit(s), excluding the energy supply,

any unintended actuation of the parking braking system at a vehicle speed above 10 km/h shall be prevented;

it shall remain possible to apply the parking braking system from the driver's seat and thereby be capable of holding the laden vehicle stationary on an 8 % up or down gradient.

2.2.1.26.3.Alternatively to the parking brake performance requirements according to points 2.2.1.26.1.2 and 2.2.1.26.2.1 an automatic actuation of the parking braking system is allowed when the vehicle is stationary, provided that the above performance is achieved and, once applied, the parking braking system remains engaged independently of the status of the ignition (start) switch. In this alternative, the parking braking system shall be automatically released as soon as the driver starts to set the vehicle in motion again.

2.2.1.26.4.It shall also be possible to release the parking braking system, if necessary by the use of tools and/or an auxiliary device carried/fitted on the vehicle.

2.2.1.26.5.A break in the wiring within the electric transmission, or an electric failure in the control device of the parking braking system shall be signalled to the driver by the yellow warning signal specified in point 2.2.1.29.1.2. When caused by a break in the wiring within the electric control transmission of the parking braking system, this yellow warning signal shall be signalled as soon as the break occurs or in the case of tractors with a maximum design speed not exceeding 60 km/h not later than on actuation of the relevant braking control. In addition, such an electric failure in the control device or break in the wiring external to the electronic control unit(s) and excluding the energy supply shall be signalled to the driver by flashing the warning signal specified in point 2.2.1.29.1.1 as long as the ignition (start) switch is in the ‘on’ (run) position including a period of not less than 10 seconds thereafter and the control device is in the ‘on’ (activated) position.

However, if the parking braking system detects correct clamping of the parking braking system, the flashing of the warning signal may be suppressed and the non-flashing red signal shall be used to indicate parking braking system applied.

Where actuation of the parking braking system is normally indicated by a separate warning signal, satisfying all the requirements of 2.2.1.29.3 this signal shall be used to satisfy the above requirement for a red signal.

2.2.1.26.6.Auxiliary equipment may be supplied with energy from the electric transmission of the parking braking system provided that the supply of energy is sufficient to allow the actuation of the parking braking system in addition to the vehicle electrical load under non-fault conditions. In addition, where the energy reserve is also used by the service braking system, the requirements of point 4.1.7 of Annex XII shall apply.

2.2.1.26.7.After the ignition/start switch which controls the electrical energy for the braking equipment has been switched off and/or the key removed, it shall remain possible to apply the parking braking system, whereas releasing shall be prevented.

Releasing of the parking braking system is permitted if the control has to be mechanically unlocked in order to be able to release the parking braking system.

2.2.1.27.The requirements of Annex XII shall be applied with regard to EBS vehicles or vehicles with ‘data communication’ via pin 6 and 7 of ISO 7638 connector.

2.2.1.28.Special requirements for coupling force control

2.2.1.28.1.Coupling force control is only permitted in the tractor.

2.2.1.28.2.The action of the coupling force control shall be to reduce the difference between the dynamic braking rates of tractors and towed vehicles. The operation of the coupling force control shall be checked at the time of type-approval. The method by which this check is carried out shall be agreed between the vehicle manufacturer and the technical service with the method of assessment and results being appended to the type-approval report.

2.2.1.28.2.1.The coupling force control may control the braking rate TM/FM (point 2 of Appendix 1 to Annex II) and/or the brake demand value(s) for the towed vehicle. In the case of a tractor equipped with two control lines according to point 2.1.4.1.2 of this Annex, both signals shall be subject to similar control adjustments.

2.2.1.28.2.2.The coupling force control shall not prevent the maximum possible braking pressure(s) from being applied.

2.2.1.28.3.The vehicle shall fulfil the laden compatibility requirements of Appendix 1 to Annex II, but to achieve the objectives of point 2.2.1.28.2 the vehicle may deviate from these requirements when the coupling force control is in operation.

2.2.1.28.4.A coupling force control failure shall be detected and indicated to the driver by a yellow warning signal such as that specified in point 2.2.1.29.1.2. In the event of a failure the relevant requirements of Appendix 1 to Annex II shall be fulfilled.

2.2.1.28.5.Compensation by the coupling force control system shall be indicated by means of the yellow warning signal specified in point 2.2.1.29.1.2 if this compensation exceeds 150 kPa (pneumatic) and 2 600 kPa (hydraulic) respectively away from the nominal demand value up to a limit, in pm, of 650 kPa (or the equivalent digital demand) and 11 500 kPa (hydraulic) respectively. Above the level of 650 kPa and 11 500 kPa (hydraulic) respectively the warning shall be given if the compensation causes the operating point to lie outside the laden compatibility band as specified in Appendix 1 to Annex II, for tractors.

2.2.1.28.6.A coupling force control system shall control only the coupling forces generated by the service braking system of the tractor and the towed vehicle. Coupling forces resulting from the performance of endurance braking systems shall not be compensated by the service braking system of either the tractor or towed vehicle. It is considered that endurance braking systems are not part of the service braking systems.

2.2.1.29.Brake failure and defect warning signal

The requirements for optical warning signals, whose function is to indicate to the driver certain specified failures or defects within the braking equipment of the tractor or of the towed vehicle, are set out in the points 2.2.1.29.1- 2.2.1.29.6.3. The function of these signals shall be exclusively to indicate failures or defects in the braking equipment. However, the optical warning signal described in point 2.2.1.29.6 may in addition be used to indicate failures or defects in the running gear.

2.2.1.29.1.Tractors shall be capable of providing optical brake failure and defect warning signals, as follows:

A red warning signal, in accordance with the requirements laid down on the basis of Article 18(2)(l), (s), (q) and (4) of Regulation (EU) No 167/2013 indicating failures within the vehicle braking equipment, as specified in other points of this Annex and in Annexes V, VII, IX and XIII, which preclude achievement of the prescribed service braking performance or the functioning of at least one of two independent service braking circuits.

Where applicable, a yellow warning signal, in accordance with the requirements laid down on the basis of Article 18(2)(l), (s), (q) and (4) of Regulation (EU) No 167/2013 indicating an electrically detected defect within the vehicle braking equipment, which is not indicated by the warning signal mentioned in point 2.2.1.29.1.1 above.

2.2.1.29.2.Tractors equipped with an electric control line and/or authorised to tow a vehicle equipped with an electric control transmission, shall be capable of providing a separate warning signal, in accordance with the requirements laid down on the basis of Article 18(2)(l), (s), (q) and (4) of Regulation (EU) No 167/2013 to indicate a defect within the electric control transmission of the braking equipment of the towed vehicle. The signal shall be activated from the towed vehicle via pin 5 of the electric connector conforming to ISO 7638:2003 and in all cases the signal transmitted by the towed vehicle shall be displayed without significant delay or modification by the tractor. This warning signal shall not light up when coupled to a towed vehicle without an electric control line and/or electric control transmission or when no towed vehicle is coupled. This function shall be automatic.

2.2.1.29.2.1.In the case of a tractor equipped with an electric control line, when electrically connected to a towed vehicle with an electric control line, the warning signal specified in point 2.2.1.29.1.1 shall also be used to indicate certain specified failures within the braking equipment of the towed vehicle, whenever the towed vehicle provides corresponding failure information via the data communication part of the electric control line. This indication shall be in addition to the warning signal specified in point 2.2.1.29.2. Alternatively, instead of utilising the warning signal specified in point 2.2.1.29.1.1 and the accompanying warning signal above, a separate warning signal, in accordance with the requirements laid down on the basis of Article 18(2)(l), (s), (q) and (4) of Regulation (EU) No 167/2013 may be provided in the tractor to indicate such a failure within the braking equipment of the towed vehicle.

2.2.1.29.2.2.Tractors equipped with an electric connector conforming to ISO 7638:2003 in order to be able to indicate the low level of stored energy on the towed vehicle as required by points 2.2.2.15.1.1 and 2.2.2.15.2 shall display the separate yellow warning signal mentioned in point 2.2.1.29.2 to the driver when the warning signal is transmitted to the tractor by the towed vehicle via pin 5 of the electric connector conforming to ISO 7638:2003.

2.2.1.29.3.Except where stated otherwise:

a specified failure or defect shall be signalled to the driver by the above-mentioned warning signal(s) not later than on actuation of the relevant braking control device;

the warning signal(s) shall remain displayed as long as the failure or defect persists and the ignition (start) switch is in the ‘on’ (run) position;

the warning signal shall be constant (not flashing).

2.2.1.29.4.The warning signals shall be visible, even by daylight; the satisfactory condition of the signals shall be easily verifiable by the driver from the driver's seat; the failure of a component of the warning devices shall not entail any loss of the braking system's performance.

2.2.1.29.5.The warning signal(s) mentioned above shall light up when the electrical equipment of the vehicle (and the braking system) is energised. With the vehicle stationary, the braking system shall verify that none of the specified failures or defects are present before extinguishing the signals. Specified failures or defects which should activate the warning signals mentioned above, but which are not detected under static conditions, shall be stored upon detection and be displayed at start-up and at all times when the ignition (start) switch is in the ‘on’ (run) position, as long as the failure or defect persists.

2.2.1.29.6.Non-specified failures or defects or other information concerning the brakes or running gear of the tractor, may be indicated by the signal specified in point 2.2.1.29.1.2, provided that all the following conditions are fulfilled:

the vehicle is stationary;

after the braking system is first energised and the signal has indicated that, following the procedures detailed in point 2.2.1.29.5, no specified failures (or defects) have been identified; and

non-specified faults or other information shall be indicated only by the flashing of the warning signal. However, the warning signal shall be extinguished by the time when the vehicle first exceeds 10 km/h.

2.2.1.30.Malfunctions of the electric control transmission shall not apply the brakes contrary to the driver's intentions.