- Latest available (Revised)

- Point in Time (31/12/2020)

- Original (As adopted by EU)

Regulation (EU) 2020/740 of the European Parliament and of the CouncilShow full title

Regulation (EU) 2020/740 of the European Parliament and of the Council of 25 May 2020 on the labelling of tyres with respect to fuel efficiency and other parameters, amending Regulation (EU) 2017/1369 and repealing Regulation (EC) No 1222/2009

You are here:

- Show Geographical Extent(e.g. England, Wales, Scotland and Northern Ireland)

- Show Timeline of Changes

More Resources

Revised version PDFs

- Revised 05/06/20200.60 MB

When the UK left the EU, legislation.gov.uk published EU legislation that had been published by the EU up to IP completion day (31 December 2020 11.00 p.m.). On legislation.gov.uk, these items of legislation are kept up-to-date with any amendments made by the UK since then.

This item of legislation originated from the EU

Legislation.gov.uk publishes the UK version. EUR-Lex publishes the EU version. The EU Exit Web Archive holds a snapshot of EUR-Lex’s version from IP completion day (31 December 2020 11.00 p.m.).

Changes over time for: ANNEX V

Alternative versions:

Status:

Point in time view as at 31/12/2020.

Changes to legislation:

There are currently no known outstanding effects for the Regulation (EU) 2020/740 of the European Parliament and of the Council, ANNEX V.![]()

Changes to Legislation

Revised legislation carried on this site may not be fully up to date. At the current time any known changes or effects made by subsequent legislation have been applied to the text of the legislation you are viewing by the editorial team. Please see ‘Frequently Asked Questions’ for details regarding the timescales for which new effects are identified and recorded on this site.

ANNEX VU.K.LABORATORY ALIGNMENT PROCEDURE FOR THE MEASUREMENT OF ROLLING RESISTANCE

1.DefinitionsU.K.

For the purposes of the laboratory alignment procedure for the measurement of rolling resistance, the following definitions apply:

‘reference laboratory’ means a laboratory that is part of the network of laboratories, the names of which have been published in the Official Journal of the European Union for the purpose of the laboratory alignment procedure, and that is able to achieve the accuracy of test results determined in Section 3 with its reference machine;

‘candidate laboratory’ means a laboratory participating in the laboratory alignment procedure that is not a reference laboratory;

‘alignment tyre’ means a tyre that is tested for the purpose of performing the laboratory alignment procedure;

‘alignment tyre set’ means a set of five or more alignment tyres for the alignment of one single machine;

‘assigned value’ means a theoretical value of the rolling resistance coefficient (RRC) of one alignment tyre as measured by a theoretical laboratory which is representative of the network of reference laboratories that is used for the laboratory alignment procedure;

‘machine’ means every tyre testing spindle in one specific measurement method; for example, two spindles acting on the same drum shall not be considered as one machine.

2.General provisionsU.K.

2.1.PrincipleU.K.

The measured (m) rolling resistance coefficient obtained in a reference laboratory (l), (RRCm,l ), shall be aligned to the assigned values of the network of reference laboratories.

The measured (m) rolling resistance coefficient obtained by a machine in a candidate laboratory (c), (RRCm,c ), shall be aligned through one reference laboratory of the network of its choice.

2.2.Tyre selection requirementsU.K.

Alignment tyre sets shall be selected for the laboratory alignment procedure in accordance with the following criteria. One alignment tyre set shall be selected for C1 tyres and C2 tyres together, and one set for C3 tyres:

the alignment tyre set shall be selected so as to cover the range of different RRCs of C1 tyres and C2 tyres together, or of C3 tyres; in any event, the difference between the highest RRCm of the alignment tyre set, and the lowest RRCm of the alignment tyre set shall be, before and after alignment, at least equal to:

3 N/kN for C1 tyres and C2 tyres; and

2 N/kN for C3 tyres;

the RRCm in the candidate or reference laboratories (RRCm,c or RRCm,l ) based on declared RRC values of each alignment tyre of the alignment tyre set shall be distributed evenly;

load index values shall adequately cover the range of the tyres to be tested, ensuring that the rolling resistance values also cover the range of the tyres to be tested.

Each alignment tyre shall be checked prior to use and shall be replaced when:

the alignment tyre shows a condition which makes it unusable for further tests; or

there are deviations of RRCm,c or RRCm,l greater than 1,5 % relative to earlier measurements after correction for any machine drift.

2.3.Measurement methodU.K.

The reference laboratory shall measure each alignment tyre four times and retain the three last results for further analysis, in accordance with paragraph 4 of Annex 6 to UNECE Regulation No 117 and under the conditions set out in paragraph 3 of Annex 6 to UNECE Regulation No 117.

The candidate laboratory shall measure each alignment tyre (n + 1) times, with n being specified in Section 5 of this Annex and retain the n last results for further analysis, in accordance with paragraph 4 of Annex 6 to UNECE Regulation No 117 and applying the conditions set out in paragraph 3 of Annex 6 to UNECE Regulation No 117.

Each time an alignment tyre is measured, the tyre/wheel assembly shall be removed from the machine and the entire test procedure referred to in paragraph 4 of Annex 6 to UNECE Regulation No 117 shall be followed again from the start.

The candidate or reference laboratory shall calculate:

the measured value of each alignment tyre for each measurement as specified in paragraphs 6.2 and 6.3 of Annex 6 to UNECE Regulation No 117 (i.e. corrected for a temperature of 25 °C and a drum diameter of 2 m);

the mean value of the three last measured values of each alignment tyre (in the case of reference laboratories) or the mean value of the n last measured values of each alignment tyre (in the case of candidate laboratories); and

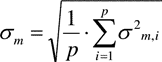

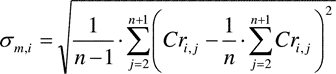

the standard deviation (σm ) as follows:

where:

is the counter from 1 to p for the alignment tyres;

is the counter from 2 to n + 1 for the n last repetitions of each measurement of a given alignment tyre;

is the number of repetitions of tyre measurements (n + 1 = 4 for reference laboratories and n + 1 ≥ 4 for candidate laboratories);

is the number of alignment tyres (p ≥ 5).

2.4.Data formats to be used for the computations and resultsU.K.

The measured RRC values corrected from drum diameter and temperature shall be rounded to two decimal places.

Then the computations shall be made with all digits: there shall be no further rounding except on the final alignment equations.

All standard deviation values shall be displayed to three decimal places.

All RRC values will be displayed to two decimal places.

All alignment coefficients (A1 l , B1 l , A2 c and B2 c ) shall be rounded and displayed to four decimal places.

3.Requirements applicable to the reference laboratories and determination of the assigned valuesU.K.

The assigned values of each alignment tyre shall be determined by a network of reference laboratories. Every second year the network shall assess the stability and validity of the assigned values.

Each reference laboratory participating in the network shall comply with the specifications of Annex 6 to UNECE Regulation No 117 and have a standard deviation (σm ) as follows:

not greater than 0,05 N/kN for C1 tyres and C2 tyres; and

not greater than 0,05 N/kN for C3 tyres.

The alignment tyre sets that have been selected in accordance with Section 2.2 shall be measured in accordance with Section 2.3 by each reference laboratory of the network.

The assigned value of each alignment tyre is the average of the measured values given by the reference laboratories of the network for this alignment tyre.

4.Procedure for the alignment of a reference laboratory to the assigned valuesU.K.

Each reference laboratory (l) shall align itself to each new set of assigned values and always after any significant machine change or any drift in machine control tyre monitoring data.

The alignment shall use a linear regression technique on all individual data. The regression coefficients, A1 l and B1 l , shall be calculated as follows:

RRC = A1 l × RRCm,l + B1 l

where:

l

is the assigned value of the rolling resistance coefficient;

l

is the individual measured value of the rolling resistance coefficient by the reference laboratory ‘l’ (including temperature and drum diameter corrections).

5.Requirements applicable to candidate laboratoriesU.K.

Candidate laboratories shall repeat the alignment procedure at least once every second year for every machine and always after any significant machine change or any drift in machine control tyre monitoring data.

A common set of five different tyres that have been selected in accordance with Section 2.2 shall be measured in accordance with Section 2.3 first by the candidate laboratory and then by one reference laboratory. More than five alignment tyres may be tested at the request of the candidate laboratory.

The candidate laboratory shall provide the alignment tyre set to the selected reference laboratory.

The candidate laboratory (c) shall comply with the specifications of Annex 6 to UNECE Regulation No 117 and preferably have standard deviations (σm ) as follows:

not greater than 0,075 N/kN for C1 tyres and C2 tyres; and

not greater than 0,06 N/kN for C3 tyres.

If the standard deviation (σm ) of the candidate laboratory is higher than those values after four measurements, the last three being used for the computations, then the number n + 1 of measurement repetitions shall be increased as follows for the entire batch:

n + 1 = 1 + (σm /γ)2, rounded up to the nearest higher integer value

where:

γ = 0,043 N/kN for C1 tyres and C2 tyres;

γ = 0,035 N/kN for C3 tyres.

6.Procedure for the alignment of a candidate laboratoryU.K.

One reference laboratory (l) of the network shall calculate the linear regression function on all individual data of the candidate laboratory (c). The regression coefficients, A2 c and B2 c , shall be calculated as follows:

RRCm,l = A2 c × RRCm,c + B2 c

where:

is the individual measured value of the rolling resistance coefficient by the reference laboratory (l) (including temperature and drum diameter corrections);

is the individual measured value of the rolling resistance coefficient by the candidate laboratory (c) (including temperature and drum diameter corrections)

If the coefficient of determination R2 is lower than 0,97, the candidate laboratory shall not be aligned.

The aligned RRC of tyres tested by the candidate laboratory shall be calculated as follows:

RRC = (A1 l × A2 c ) × RRCm,c + (A1 l × B2 c + B1 l )

Options/Help

Print Options

PrintThe Whole Regulation

PrintThis Annex only

Legislation is available in different versions:

Latest Available (revised):The latest available updated version of the legislation incorporating changes made by subsequent legislation and applied by our editorial team. Changes we have not yet applied to the text, can be found in the ‘Changes to Legislation’ area.

Original (As adopted by EU): The original version of the legislation as it stood when it was first adopted in the EU. No changes have been applied to the text.

Point in Time: This becomes available after navigating to view revised legislation as it stood at a certain point in time via Advanced Features > Show Timeline of Changes or via a point in time advanced search.

See additional information alongside the content

Geographical Extent: Indicates the geographical area that this provision applies to. For further information see ‘Frequently Asked Questions’.

Show Timeline of Changes: See how this legislation has or could change over time. Turning this feature on will show extra navigation options to go to these specific points in time. Return to the latest available version by using the controls above in the What Version box.

More Resources

Access essential accompanying documents and information for this legislation item from this tab. Dependent on the legislation item being viewed this may include:

- the original print PDF of the as adopted version that was used for the EU Official Journal

- lists of changes made by and/or affecting this legislation item

- all formats of all associated documents

- correction slips

- links to related legislation and further information resources

Timeline of Changes

This timeline shows the different versions taken from EUR-Lex before exit day and during the implementation period as well as any subsequent versions created after the implementation period as a result of changes made by UK legislation.

The dates for the EU versions are taken from the document dates on EUR-Lex and may not always coincide with when the changes came into force for the document.

For any versions created after the implementation period as a result of changes made by UK legislation the date will coincide with the earliest date on which the change (e.g an insertion, a repeal or a substitution) that was applied came into force. For further information see our guide to revised legislation on Understanding Legislation.

More Resources

Use this menu to access essential accompanying documents and information for this legislation item. Dependent on the legislation item being viewed this may include:

- the original print PDF of the as adopted version that was used for the print copy

- correction slips

Click 'View More' or select 'More Resources' tab for additional information including:

- lists of changes made by and/or affecting this legislation item

- confers power and blanket amendment details

- all formats of all associated documents

- links to related legislation and further information resources