- Latest available (Revised)

- Original (As adopted by EU)

Regulation (EU) 2020/740 of the European Parliament and of the CouncilShow full title

Regulation (EU) 2020/740 of the European Parliament and of the Council of 25 May 2020 on the labelling of tyres with respect to fuel efficiency and other parameters, amending Regulation (EU) 2017/1369 and repealing Regulation (EC) No 1222/2009

You are here:

- Regulations originating from the EU

- 2020 No. 740

- Annexes only

- Show Geographical Extent(e.g. England, Wales, Scotland and Northern Ireland)

- Show Timeline of Changes

More Resources

Revised version PDFs

- Revised 05/06/20200.60 MB

When the UK left the EU, legislation.gov.uk published EU legislation that had been published by the EU up to IP completion day (31 December 2020 11.00 p.m.). On legislation.gov.uk, these items of legislation are kept up-to-date with any amendments made by the UK since then.

This item of legislation originated from the EU

Legislation.gov.uk publishes the UK version. EUR-Lex publishes the EU version. The EU Exit Web Archive holds a snapshot of EUR-Lex’s version from IP completion day (31 December 2020 11.00 p.m.).

Changes over time for: Regulation (EU) 2020/740 of the European Parliament and of the Council (Annexes only)

Changes to legislation:

This version of this Regulation was derived from EUR-Lex on IP completion day (31 December 2020 11:00 p.m.). It has not been amended by the UK since then. Find out more about legislation originating from the EU as published on legislation.gov.uk.![]()

Changes to Legislation

Revised legislation carried on this site may not be fully up to date. At the current time any known changes or effects made by subsequent legislation have been applied to the text of the legislation you are viewing by the editorial team. Please see ‘Frequently Asked Questions’ for details regarding the timescales for which new effects are identified and recorded on this site.

ANNEX IU.K.TESTING, GRADING AND MEASUREMENT OF TYRE PARAMETERS

Part A: Fuel efficiency classes and rolling resistance coefficientU.K.

The fuel efficiency class shall be determined and illustrated on the tyre label on the basis of the rolling resistance coefficient (RRC in N/kN) according to the ‘A’ to ‘E’ scale specified in the table below and measured in accordance with Annex 6 to UNECE Regulation No 117 and aligned in accordance with the laboratory alignment procedure set out in Annex V.

If a tyre type belongs to more than one tyre class (e.g. C1 and C2), the grading scale used to determine the fuel efficiency class of that tyre type shall be that which is applicable to the highest tyre class (e.g. C2, not C1).

| C1 tyres | C2 tyres | C3 tyres | |

|---|---|---|---|

| Fuel efficiency class | RRC in N/kN | RRC in N/kN | RRC in N/kN |

| A | RRC ≤ 6,5 | RRC ≤ 5,5 | RRC ≤ 4,0 |

| B | 6,6 ≤ RRC ≤ 7,7 | 5,6 ≤ RRC ≤ 6,7 | 4,1 ≤ RRC ≤ 5,0 |

| C | 7,8 ≤ RRC ≤ 9,0 | 6,8 ≤ RRC ≤ 8,0 | 5,1 ≤ RRC ≤ 6,0 |

| D | 9,1 ≤ RRC ≤ 10,5 | 8,1 ≤ RRC ≤ 9,0 | 6,1 ≤ RRC ≤ 7,0 |

| E | RRC ≥ 10,6 | RRC ≥ 9,1 | RRC ≥ 7,1 |

Part B: Wet grip classesU.K.

1.The wet grip class shall be determined and illustrated on the tyre label on the basis of the wet grip index (G) according to the ‘A’ to ‘E’ scale specified in the table below, calculated in accordance with point 2 and measured in accordance with Annex 5 to UNECE Regulation No 117.U.K.

2.Calculation of wet grip index (G)U.K.

G = G(T)-0,03

where:

G(T) = wet grip index of the candidate tyre as measured in one test cycle

| C1 tyres | C2 tyres | C3 tyres | |

|---|---|---|---|

| Wet grip class | G | G | G |

| A | 1,55 ≤ G | 1,40 ≤ G | 1,25 ≤ G |

| B | 1,40 ≤ G ≤ 1,54 | 1,25 ≤ G ≤ 1,39 | 1,10 ≤ G ≤ 1,24 |

| C | 1,25 ≤ G ≤ 1,39 | 1,10 ≤ G ≤ 1,24 | 0,95 ≤ G ≤ 1,09 |

| D | 1,10 ≤ G ≤ 1,24 | 0,95 ≤ G ≤ 1,09 | 0,80 ≤ G ≤ 0,94 |

| E | G ≤ 1,09 | G ≤ 0,94 | G ≤ 0,79 |

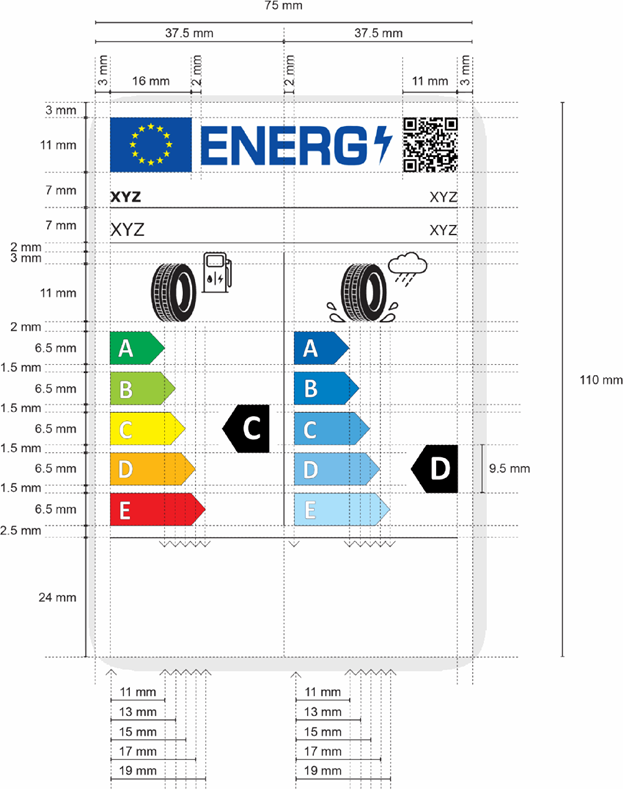

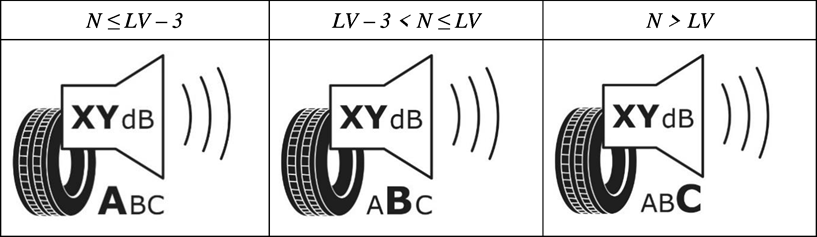

Part C: External rolling noise classes and measured valueU.K.

The external rolling noise measured value (N, in dB(A)) shall be declared in decibels and calculated in accordance with Annex 3 to UNECE Regulation No 117.

The external rolling noise class shall be determined and illustrated on the tyre label on the basis of the limit values (LV) set out in Part C of Annex II to Regulation (EC) No 661/2009 as follows:

[X1

Editorial Information

X1 Substituted by Corrigendum to Regulation (EU) 2020/740 of the European Parliament and of the Council of 25 May 2020 on the labelling of tyres with respect to fuel efficiency and other parameters, amending Regulation (EU) 2017/1369 and repealing Regulation (EC) No 1222/2009 (Official Journal of the European Union L 177 of 5 June 2020).

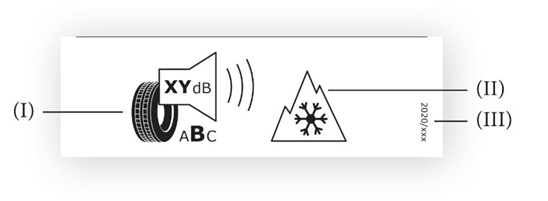

Part D: Snow gripU.K.

The snow grip performance shall be tested in accordance with Annex 7 to UNECE Regulation No 117.

A tyre which satisfies the minimum snow grip index values set out in UNECE Regulation No 117 shall be classified as a tyre for use in severe snow conditions and the following pictogram shall be included on the tyre label.

Part E: Ice gripU.K.

The ice grip performance shall be tested in accordance with reliable, accurate and reproducible methods, including, where appropriate, international standards, which take into account the generally recognised state of the art.

The tyre label of a tyre which satisfies the relevant minimum ice grip index values shall include the following pictogram.

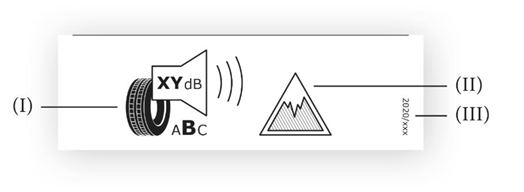

ANNEX IIU.K.CONTENT AND FORMAT OF THE TYRE LABEL

1.Content of the tyre labelU.K.

1.1.Information to be included in the upper part of the tyre label:U.K.

1.2.Information to be included in the bottom part of the tyre label for all tyres other than tyres which satisfy the minimum snow grip index values set out in UNECE Regulation No 117, or the relevant minimum ice grip index values, or both:U.K.

1.3.Information to be included in the bottom part of the tyre label for tyres which satisfy the minimum snow grip index values set out in UNECE Regulation No 117:U.K.

1.4.Information to be included in the bottom part of the tyre label for tyres which satisfy the relevant minimum ice grip index values:U.K.

1.5.Information to be included in the bottom part of the tyre label for tyres which satisfy both the relevant minimum snow grip index values set out in UNECE Regulation No 117 and the minimum ice grip index values:U.K.

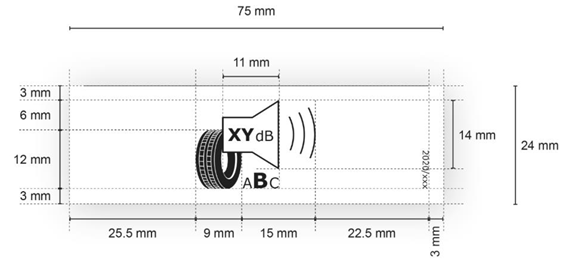

2.Format of the tyre labelU.K.

2.1.Format of the upper part of the tyre label:U.K.

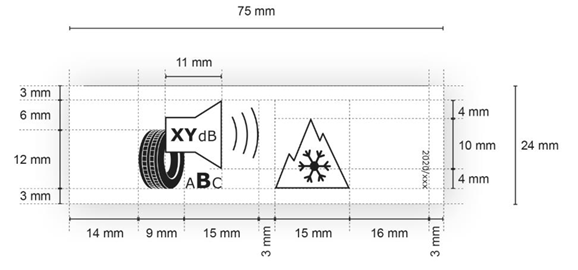

2.1.1.Format of the bottom part of the tyre label for all tyres other than tyres which satisfy the minimum snow grip index values set out in UNECE Regulation No 117, or the relevant minimum ice grip index values, or both:U.K.

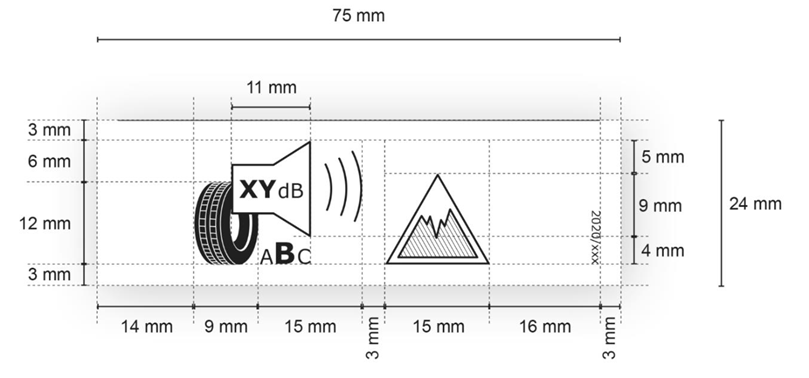

2.1.2.Format of the bottom part of the tyre label for tyres which satisfy the minimum snow grip index values set out in UNECE Regulation No 117:U.K.

2.1.3.Format of the bottom part of the tyre label for tyres which satisfy the minimum ice grip index values:U.K.

2.1.4.Format of the bottom part of the tyre label for tyres which satisfy both the relevant minimum snow grip index values set out in UNECE Regulation No 117 and the minimum ice grip index values:U.K.

2.2.For the purposes of point 2.1:U.K.

Tyre label minimal size: 75 mm wide and 110 mm high. Where the tyre label is printed in a larger format, its content shall nevertheless remain proportionate to the specifications above;

Background of the tyre label: 100 % white;

Typefaces: Verdana and Calibri;

Dimensions and specifications of the elements constituting the tyre label: as specified above;

Colour codes, using CMYK – cyan, magenta, yellow and black, shall fulfil all the following requirements:

colours of the EU logo as follows:

background: 100,80,0,0;

stars: 0,0,100,0;

colour of the energy logo: 100,80,0,0;

QR code: 100 % black;

trade name or trademark of the supplier: 100 % black and in Verdana Bold 7 pt;

tyre type identifier: 100 % black and in Verdana Regular 7 pt;

tyre size designation, load‐capacity index and speed category symbol: 100 % black and in Verdana Regular 10 pt;

tyre class: 100 % black and in Verdana Regular 7 pt, aligned to the right;

letters of the fuel efficiency scale and of the wet grip scale: 100 % white and in Calibri Bold 19 pt; the letters shall be centred on an axis at 4,5 mm from the left side of the arrows;

CMYK colour codes of arrows for the A to E fuel efficiency scale as follows:

A‐class: 100,0,100,0;

B‐class: 45,0,100,0;

C‐class: 0,0,100,0;

D‐class: 0,30,100,0;

E‐class: 0,100,100,0;

CMYK colour codes of arrows for the A to E wet grip scale as follows:

A: 100,60,0,0;

B: 90,40,0,0;

C: 65,20,0,0;

D: 50,10,0,0;

E: 30,0,0,0;

internal dividers: weight of 0,5 pts, colour shall be 100 % black;

letter of the fuel efficiency class: 100 % white and in Calibri Bold 33 pt. Fuel efficiency and wet grip class arrows and the corresponding arrows in the A to E scale shall be positioned in such a way that their tips are aligned. The letter in the fuel efficiency class and in the wet grip class arrow shall be positioned in the centre of the rectangular part of the arrow which shall be 100 % black;

fuel efficiency pictogram: width 16 mm, height 14 mm, weight 1 pts, colour: 100 % black;

wet grip pictogram: width 20 mm, height 14 mm, weight 1 pts, colour: 100 % black;

external rolling noise pictogram: width 24 mm, height 18 mm, weight 1 pts, colour: 100 % black. Number of decibels in the loudspeaker in Verdana Bold 12 pt, the unit ‘dB’ in Regular 9 pt; the range of external rolling noise classes (A to C) centred under the pictogram, with the letter of the applicable external rolling noise class in Verdana Bold 16 pt and the other letters of the external rolling noise classes in Verdana Regular 10 pt;

snow grip pictogram: width 15 mm, height 13 mm, weight 1 pts, colour: 100 % black;

ice grip pictogram: width 15 mm, height 13 mm, weight 1 pts, weight of oblique bars 0,5 pts, colour: 100 % black;

the number of the regulation shall be 100 % black and in Verdana Regular 6 pt.

ANNEX IIIU.K.PRODUCT INFORMATION SHEET

The information in the product information sheet of tyres shall be included in the product brochure or other literature provided with the tyre and shall include the following:

the trade name or trademark of the supplier or of the manufacturer if it is not the same as that of the supplier;

the tyre type identifier;

the tyre size designation, load‐capacity index and speed category symbol, as indicated in UNECE Regulation No 30 or in UNECE Regulation No 54 for C1 tyres, C2 tyres and C3 tyres, as applicable;

the fuel efficiency class of the tyre in accordance with Annex I;

the wet grip class of the tyre in accordance with Annex I;

the external rolling noise class and value in decibels in accordance with Annex I;

an indication of whether the tyre is a tyre for use in severe snow conditions;

an indication of whether the tyre is an ice grip tyre;

the date of start of production of the tyre type (two digits for the week and two digits for the year);

the date of end of production of the tyre type, once known (two digits for the week and two digits for the year).

ANNEX IVU.K.INFORMATION PROVIDED IN TECHNICAL PROMOTIONAL MATERIAL

1.Information on tyres included in technical promotional material shall be provided in the following order:U.K.

the fuel efficiency class (letter ‘A’ to ‘E’);

the wet grip class (letter ‘A’ to ‘E’);

the external rolling noise class and measured value in dB;

an indication of whether the tyre is a tyre for use in severe snow conditions;

an indication of whether the tyre is an ice grip tyre.

2.The information referred to in point 1 shall meet the following requirements:U.K.

it shall be easy to read;

it shall be easy to understand;

if within a tyre family tyre types are classified differently depending on dimension or other characteristics, the range between the lowest performing and highest performing tyre types shall be stated.

3.Suppliers shall also make the following available on their websites:U.K.

a link to the relevant Commission webpage dedicated to this Regulation;

an explanation of the pictograms printed on the tyre label;

a statement highlighting the fact that actual fuel savings and road safety depend heavily on the behaviour of drivers, and in particular on the following:

eco‐driving can significantly reduce fuel consumption;

tyre pressure needs to be regularly checked to optimise fuel efficiency and wet grip;

stopping distances must always be respected.

4.Suppliers and distributors shall also, where relevant, make available on their websites a statement highlighting the fact that ice grip tyres are specifically designed for road surfaces covered with ice and compact snow, and should only be used in very severe climate conditions (e.g. cold temperatures) and that using ice grip tyres in less severe climate conditions (e.g. wet conditions or warmer temperatures) could result in sub‐optimal performance, in particular for wet grip, handling and wear.U.K.

ANNEX VU.K.LABORATORY ALIGNMENT PROCEDURE FOR THE MEASUREMENT OF ROLLING RESISTANCE

1.DefinitionsU.K.

For the purposes of the laboratory alignment procedure for the measurement of rolling resistance, the following definitions apply:

‘reference laboratory’ means a laboratory that is part of the network of laboratories, the names of which have been published in the Official Journal of the European Union for the purpose of the laboratory alignment procedure, and that is able to achieve the accuracy of test results determined in Section 3 with its reference machine;

‘candidate laboratory’ means a laboratory participating in the laboratory alignment procedure that is not a reference laboratory;

‘alignment tyre’ means a tyre that is tested for the purpose of performing the laboratory alignment procedure;

‘alignment tyre set’ means a set of five or more alignment tyres for the alignment of one single machine;

‘assigned value’ means a theoretical value of the rolling resistance coefficient (RRC) of one alignment tyre as measured by a theoretical laboratory which is representative of the network of reference laboratories that is used for the laboratory alignment procedure;

‘machine’ means every tyre testing spindle in one specific measurement method; for example, two spindles acting on the same drum shall not be considered as one machine.

2.General provisionsU.K.

2.1.PrincipleU.K.

The measured (m) rolling resistance coefficient obtained in a reference laboratory (l), (RRCm,l ), shall be aligned to the assigned values of the network of reference laboratories.

The measured (m) rolling resistance coefficient obtained by a machine in a candidate laboratory (c), (RRCm,c ), shall be aligned through one reference laboratory of the network of its choice.

2.2.Tyre selection requirementsU.K.

Alignment tyre sets shall be selected for the laboratory alignment procedure in accordance with the following criteria. One alignment tyre set shall be selected for C1 tyres and C2 tyres together, and one set for C3 tyres:

the alignment tyre set shall be selected so as to cover the range of different RRCs of C1 tyres and C2 tyres together, or of C3 tyres; in any event, the difference between the highest RRCm of the alignment tyre set, and the lowest RRCm of the alignment tyre set shall be, before and after alignment, at least equal to:

3 N/kN for C1 tyres and C2 tyres; and

2 N/kN for C3 tyres;

the RRCm in the candidate or reference laboratories (RRCm,c or RRCm,l ) based on declared RRC values of each alignment tyre of the alignment tyre set shall be distributed evenly;

load index values shall adequately cover the range of the tyres to be tested, ensuring that the rolling resistance values also cover the range of the tyres to be tested.

Each alignment tyre shall be checked prior to use and shall be replaced when:

the alignment tyre shows a condition which makes it unusable for further tests; or

there are deviations of RRCm,c or RRCm,l greater than 1,5 % relative to earlier measurements after correction for any machine drift.

2.3.Measurement methodU.K.

The reference laboratory shall measure each alignment tyre four times and retain the three last results for further analysis, in accordance with paragraph 4 of Annex 6 to UNECE Regulation No 117 and under the conditions set out in paragraph 3 of Annex 6 to UNECE Regulation No 117.

The candidate laboratory shall measure each alignment tyre (n + 1) times, with n being specified in Section 5 of this Annex and retain the n last results for further analysis, in accordance with paragraph 4 of Annex 6 to UNECE Regulation No 117 and applying the conditions set out in paragraph 3 of Annex 6 to UNECE Regulation No 117.

Each time an alignment tyre is measured, the tyre/wheel assembly shall be removed from the machine and the entire test procedure referred to in paragraph 4 of Annex 6 to UNECE Regulation No 117 shall be followed again from the start.

The candidate or reference laboratory shall calculate:

the measured value of each alignment tyre for each measurement as specified in paragraphs 6.2 and 6.3 of Annex 6 to UNECE Regulation No 117 (i.e. corrected for a temperature of 25 °C and a drum diameter of 2 m);

the mean value of the three last measured values of each alignment tyre (in the case of reference laboratories) or the mean value of the n last measured values of each alignment tyre (in the case of candidate laboratories); and

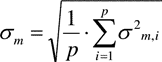

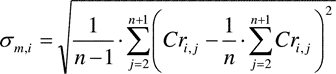

the standard deviation (σm ) as follows:

where:

is the counter from 1 to p for the alignment tyres;

is the counter from 2 to n + 1 for the n last repetitions of each measurement of a given alignment tyre;

is the number of repetitions of tyre measurements (n + 1 = 4 for reference laboratories and n + 1 ≥ 4 for candidate laboratories);

is the number of alignment tyres (p ≥ 5).

2.4.Data formats to be used for the computations and resultsU.K.

The measured RRC values corrected from drum diameter and temperature shall be rounded to two decimal places.

Then the computations shall be made with all digits: there shall be no further rounding except on the final alignment equations.

All standard deviation values shall be displayed to three decimal places.

All RRC values will be displayed to two decimal places.

All alignment coefficients (A1 l , B1 l , A2 c and B2 c ) shall be rounded and displayed to four decimal places.

3.Requirements applicable to the reference laboratories and determination of the assigned valuesU.K.

The assigned values of each alignment tyre shall be determined by a network of reference laboratories. Every second year the network shall assess the stability and validity of the assigned values.

Each reference laboratory participating in the network shall comply with the specifications of Annex 6 to UNECE Regulation No 117 and have a standard deviation (σm ) as follows:

not greater than 0,05 N/kN for C1 tyres and C2 tyres; and

not greater than 0,05 N/kN for C3 tyres.

The alignment tyre sets that have been selected in accordance with Section 2.2 shall be measured in accordance with Section 2.3 by each reference laboratory of the network.

The assigned value of each alignment tyre is the average of the measured values given by the reference laboratories of the network for this alignment tyre.

4.Procedure for the alignment of a reference laboratory to the assigned valuesU.K.

Each reference laboratory (l) shall align itself to each new set of assigned values and always after any significant machine change or any drift in machine control tyre monitoring data.

The alignment shall use a linear regression technique on all individual data. The regression coefficients, A1 l and B1 l , shall be calculated as follows:

RRC = A1 l × RRCm,l + B1 l

where:

l

is the assigned value of the rolling resistance coefficient;

l

is the individual measured value of the rolling resistance coefficient by the reference laboratory ‘l’ (including temperature and drum diameter corrections).

5.Requirements applicable to candidate laboratoriesU.K.

Candidate laboratories shall repeat the alignment procedure at least once every second year for every machine and always after any significant machine change or any drift in machine control tyre monitoring data.

A common set of five different tyres that have been selected in accordance with Section 2.2 shall be measured in accordance with Section 2.3 first by the candidate laboratory and then by one reference laboratory. More than five alignment tyres may be tested at the request of the candidate laboratory.

The candidate laboratory shall provide the alignment tyre set to the selected reference laboratory.

The candidate laboratory (c) shall comply with the specifications of Annex 6 to UNECE Regulation No 117 and preferably have standard deviations (σm ) as follows:

not greater than 0,075 N/kN for C1 tyres and C2 tyres; and

not greater than 0,06 N/kN for C3 tyres.

If the standard deviation (σm ) of the candidate laboratory is higher than those values after four measurements, the last three being used for the computations, then the number n + 1 of measurement repetitions shall be increased as follows for the entire batch:

n + 1 = 1 + (σm /γ)2, rounded up to the nearest higher integer value

where:

γ = 0,043 N/kN for C1 tyres and C2 tyres;

γ = 0,035 N/kN for C3 tyres.

6.Procedure for the alignment of a candidate laboratoryU.K.

One reference laboratory (l) of the network shall calculate the linear regression function on all individual data of the candidate laboratory (c). The regression coefficients, A2 c and B2 c , shall be calculated as follows:

RRCm,l = A2 c × RRCm,c + B2 c

where:

is the individual measured value of the rolling resistance coefficient by the reference laboratory (l) (including temperature and drum diameter corrections);

is the individual measured value of the rolling resistance coefficient by the candidate laboratory (c) (including temperature and drum diameter corrections)

If the coefficient of determination R2 is lower than 0,97, the candidate laboratory shall not be aligned.

The aligned RRC of tyres tested by the candidate laboratory shall be calculated as follows:

RRC = (A1 l × A2 c ) × RRCm,c + (A1 l × B2 c + B1 l )

ANNEX VIU.K.VERIFICATION PROCEDURE

The conformity with this Regulation of the declared fuel efficiency, wet grip and external rolling noise classes, as well as the declared values, and any additional performance information on the tyre label, shall be assessed for each tyre type or each grouping of tyres as determined by the supplier, according to one of the following procedures:

A single tyre or tyre set is tested first. If the measured values meet the declared classes or the declared external rolling noise value within the verification tolerances referred to in the table below, the tyre label shall be considered to comply with this Regulation.

If the measured values do not meet the declared classes or the declared external rolling noise value within the verification tolerances referred to in the table below, three additional tyres or tyre sets are to be tested; the average measurement value stemming from the three additional tyres or tyre sets tested is to be used to verify the declared information, taking into account the verification tolerances referred to in the table below.

Where the classes or values on the tyre label are derived from type‐approval test results obtained in accordance with Regulation (EC) No 661/2009, or UNECE Regulation No 117, Member States may use measurement data obtained from the conformity of production tests on tyres that were carried out under the type‐approval procedure established by Regulation (EU) 2018/858.

Assessments of the measurement data obtained from the conformity of production tests shall take into account the verification tolerances referred to in the table below.

| Measured parameter | Verification tolerances |

|---|---|

| RRC (fuel efficiency) | The aligned measured value shall not be greater than the upper limit (the highest RRC) of the declared class by more than 0,3 N/kN. |

| External rolling noise | The measured value shall not be greater than the declared value of N by more than 1 dB(A). |

| Wet grip | The measured value G(T) shall not be lower than the lower limit (the lowest value of G) of the declared class. |

| Snow grip | The measured value shall not be lower than the minimum snow grip index. |

| Ice grip | The measured value shall not be lower than the minimum ice grip index. |

ANNEX VIIU.K.INFORMATION TO BE ENTERED INTO THE PRODUCT DATABASE BY THE SUPPLIER

1.Information to be entered into the public part of the product database:U.K.

the trade name or trademark, address, contact details and other legal identification of the supplier;

the tyre type identifier;

the tyre label in electronic format;

the class(es) and other parameters of the tyre label; and

the parameters of the product information sheet in electronic format.

2.Information to be entered into the compliance part of the product database:U.K.

the tyre type identifier of all equivalent tyre types that are already placed on the market;

a general description of the tyre type, including its dimensions, load index and speed rating, sufficient for it to be unequivocally and easily identified;

protocols of the testing, grading and measurement of the tyre parameters set out in Annex I;

specific precautions, if any, that shall be taken when the tyre type is assembled, installed, maintained or tested;

the measured technical parameters of the tyre type, where relevant; and

the calculations performed with the measured technical parameters.

ANNEX VIIIU.K.CORRELATION TABLE

| Regulation (EC) No 1222/2009 | This Regulation |

|---|---|

| Article 1(1) | — |

| Article 1(2) | Article 1 |

| Article 2(1) | Article 2(1) |

| Article 2(2) | Article 2(2) |

| Article 3, point (1) | Article 3, point (1) |

| — | Article 3, point (2) |

| Article 3, point (2) | Article 3, point (3) |

| — | Article 3, point (4) |

| — | Article 3, point (5) |

| Article 3, point (3) | Article 3, point (6) |

| Article 3, point (4) | Article 3, point (7) |

| — | Article 3, point (8) |

| Article 3, point (5) | Article 3, point (9) |

| — | Article 3, point (10) |

| — | Article 3, point (11) |

| Article 3, point (6) | Article 3, point (12) |

| Article 3, point (7) | Article 3, point (13) |

| Article 3, point (8) | Article 3, point (14) |

| Article 3, point (9) | Article 3, point (15) |

| Article 3, point (10) | Article 3, point (16) |

| Article 3, point (11) | Article 3, point (17) |

| — | Article 3, point (18) |

| Article 3, point (12) | Article 3, point (19) |

| Article 3, point (13) | Article 3, point (20) |

| — | Article 3, point (21) |

| — | Article 3, point (22) |

| — | Article 3, point (23) |

| — | Article 3, point (24) |

| Article 4 | Article 4 |

| Article 4(1) | Article 4(1) |

| Article 4(1), point (a) | Article 4(1), point (a) |

| Article 4(1), point (b) | Article 4(1), point (b) |

| Article 4(2) | — |

| — | Article 4(2) |

| — | Article 4(3) |

| Article 4(3) | Article 4(4) |

| Article 4(4) | Article 4(5) |

| — | Article 4(6) |

| — | Article 4(7) |

| — | Article 4(8) |

| — | Article 4(9) |

| — | Article 4(10) |

| — | Article 5 |

| Article 5(1) | Article 6(1) |

| Article 5(1), point (a) | Article 6(1), point (a) |

| Article 5(1), point (b) | Article 6(1), point (b) |

| — | Article 6(2) |

| — | Article 6(3) |

| Article 5(2) | Article 6(4) |

| Article 5(3) | — |

| — | Article 6(5) |

| — | Article 6(6) |

| — | Article 6(7) |

| Article 6 | Article 7 |

| — | Article 8 |

| Article 7 | Article 9 |

| Article 8 | Article 10 |

| Article 9(1) | Article 11(1) |

| Article 9(2) | Article 11(1) |

| Article 9(2), 2nd sentence | Article 4(5) |

| Article 10 | Article 11(2) |

| — | Article 11(3) |

| Article 11, point (a) | — |

| Article 11, point (b) | — |

| Article 11, point (c) | Article 13(1), point (b) |

| Article 12 | Article 11(4) |

| — | Article 11(5) |

| — | Article 12 |

| — | Article 13 |

| — | Article 13(1) |

| — | Article 13(2) |

| — | Article 13(3) |

| — | Article 13(4) |

| — | Article 14 |

| Article 13 | — |

| Article 14 | — |

| — | Article 15 |

| Article 15 | — |

| — | Article 16 |

| — | Article 17 |

| Article 16 | Article 18 |

| Annex I | Annex I |

| Annex II | Annex II |

| — | Annex III |

| Annex III | Annex IV |

| Annex IV | Annex VI |

| Annex IVa | Annex V |

| Annex V | — |

| — | Annex VII |

| — | Annex VIII |

Options/Help

Print Options

PrintThe Whole Regulation

PrintThe Annexes only

Legislation is available in different versions:

Latest Available (revised):The latest available updated version of the legislation incorporating changes made by subsequent legislation and applied by our editorial team. Changes we have not yet applied to the text, can be found in the ‘Changes to Legislation’ area.

Original (As adopted by EU): The original version of the legislation as it stood when it was first adopted in the EU. No changes have been applied to the text.

See additional information alongside the content

Geographical Extent: Indicates the geographical area that this provision applies to. For further information see ‘Frequently Asked Questions’.

Show Timeline of Changes: See how this legislation has or could change over time. Turning this feature on will show extra navigation options to go to these specific points in time. Return to the latest available version by using the controls above in the What Version box.

More Resources

Access essential accompanying documents and information for this legislation item from this tab. Dependent on the legislation item being viewed this may include:

- the original print PDF of the as adopted version that was used for the EU Official Journal

- lists of changes made by and/or affecting this legislation item

- all formats of all associated documents

- correction slips

- links to related legislation and further information resources

Timeline of Changes

This timeline shows the different versions taken from EUR-Lex before exit day and during the implementation period as well as any subsequent versions created after the implementation period as a result of changes made by UK legislation.

The dates for the EU versions are taken from the document dates on EUR-Lex and may not always coincide with when the changes came into force for the document.

For any versions created after the implementation period as a result of changes made by UK legislation the date will coincide with the earliest date on which the change (e.g an insertion, a repeal or a substitution) that was applied came into force. For further information see our guide to revised legislation on Understanding Legislation.

More Resources

Use this menu to access essential accompanying documents and information for this legislation item. Dependent on the legislation item being viewed this may include:

- the original print PDF of the as adopted version that was used for the print copy

- correction slips

Click 'View More' or select 'More Resources' tab for additional information including:

- lists of changes made by and/or affecting this legislation item

- confers power and blanket amendment details

- all formats of all associated documents

- links to related legislation and further information resources