- Latest available (Revised)

- Point in Time (04/06/2001)

- Original (As made)

The Noise Emission in the Environment by Equipment for use Outdoors Regulations 2001

You are here:

- UK Statutory Instruments

- 2001 No. 1701

- Schedules only

- Show Geographical Extent(e.g. England, Wales, Scotland and Northern Ireland)

- Show Timeline of Changes

More Resources

Changes over time for: The Noise Emission in the Environment by Equipment for use Outdoors Regulations 2001 (Schedules only)

No versions valid at: 04/06/2001

Alternative versions:

Status:

Point in time view as at 04/06/2001.

Changes to legislation:

There are outstanding changes not yet made by the legislation.gov.uk editorial team to The Noise Emission in the Environment by Equipment for use Outdoors Regulations 2001. Any changes that have already been made by the team appear in the content and are referenced with annotations.![]()

Changes to Legislation

Changes and effects yet to be applied by the editorial team are only applicable when viewing the latest version or prospective version of legislation. They are therefore not accessible when viewing legislation as at a specific point in time. To view the ‘Changes to Legislation’ information for this provision return to the latest version view using the options provided in the ‘What Version’ box above.

Valid from 03/07/2001

Regulation 3

SCHEDULE 1U.K.(Extract from Article 12)

Equipment subject to noise limitsU.K.

builders’ hoists for the transport of goods (combustion-engine driven)

Definition: Annex I, Item 3. Measurement: Annex III, Part B, item 3

compaction machines (only vibrating and non-vibrating rollers, vibratory plates and vibratory rammers)

Definition: Annex I, Item 8. Measurement: Annex III, Part B, item 8

compressors (<350 kW)

Definition: Annex I, Item 9. Measurement: Annex III, Part B, item 9

concrete-breakers and picks, hand-held

Definition: Annex I, Item 10. Measurement: Annex III, Part B, item 10

construction winches (combustion-engine driven)

Definition: Annex I, Item 12. Measurement: Annex III, Part B, item 12

dozers (<500 kW)

Definition: Annex I, Item 16. Measurement : Annex III, Part B, item 16

dumpers (<500 kW)

Definition: Annex I, Item 18. Measurement: Annex III, Part B, item 18

excavators, hydraulic or rope-operated (<500 kW)

Definition: Annex I, Item 20. Measurement: Annex III, Part B, item 20

excavator-loaders (<500 kW)

Definition: Annex I, Item 21. Measurement: Annex III, Part B, item 21

graders (<500 kW)

Definition: Annex I, Item 23. Measurement: Annex III, Part B, item 23

hydraulic power packs

Definition: Annex I, Item 29. Measurement: Annex III, Part B, item 29

landfill compactors, loader-type with bucket (<500 kW)

Definition: Annex I, Item 31. Measurement: Annex III, Part B, item 31

lawnmowers (excluding agricultural and forestry equipment, and multi-purpose devices, the main motorised component of which has an installed power of more than 20 kW)

Definition: Annex I, Item 32. Measurement: Annex III, Part B, item 32

lawn trimmers/lawn edge trimmers

Definition: Annex I, Item 33. Measurement: Annex III, Part B, item 33

lift trucks, combustion-engine driven, counterbalanced (excluding “other counterbalanced lift trucks" as defined in Annex I, Item 36, second indent with a rated capacity of not more than 10 tonnes)

Definition: Annex I, Item 36. Measurement: Annex III, Part B, item 36

loaders (<500 kW)

Definition: Annex I, Item 37. Measurement: Annex III, Part B, item 37

mobile cranes

Definition: Annex I, Item 38. Measurement: Annex III, Part B, item 38

motor hoes (<3 kW)

Definition: Annex I, Item 40. Measurement: Annex III, Part B, item 40

paver-finishers (excluding paver-finishers equipped with a high-compaction screed)

Definition: Annex I, Item 41. Measurement: Annex III, Part B, item 41

power generators (<400 kW)

Definition: Annex I, Item 45. Measurement: Annex III, Part B, item 45

tower cranes

Definition: Annex I, Item 53. Measurement: Annex III, Part B, item 53

welding generators

Definition: Annex I, Item 57. Measurement: Annex III, Part B, item 57

Regulation 3

SCHEDULE 2U.K.(Extract from Article 13)

Equipment subject to noise marking onlyU.K.

aerial access platforms with combustion engine

Definition: Annex I, Item 1. Measurement: Annex III, Part B, item 1

brush cutters

Definition: Annex I, Item 2. Measurement: Annex III, Part B, item 2

builders’ hoists for the transport of goods (with electric motor)

Definition: Annex I, Item 3. Measurement: Annex III, Part B, item 3

building site band saw machines

Definition: Annex I, Item 4. Measurement: Annex III, Part B, item 4

building site circular saw benches

Definition: Annex I, Item 5. Measurement: Annex III, Part B, item 5

chain saws, portable

Definition: Annex I, Item 6. Measurement: Annex III, Part B, item 6

combined high pressure flushers and suction vehicles

Definition: Annex I, Item 7. Measurement: Annex III, Part B, item 7

compaction machines (explosion rammers only)

Definition: Annex I, Item 8. Measurement: Annex III, Part B, item 8

concrete or mortar mixers

Definition: Annex I, Item 11. Measurement: Annex III, Part B, item 11

construction winches (with electric motor)

Definition: Annex I, Item 12. Measurement: Annex III, Part B, item 12

conveying and spraying machines for concrete and mortar

Definition: Annex I, Item 13. Measurement: Annex III, Part B, item 13

conveyor belts

Definition: Annex I, Item 14. Measurement: Annex III, Part B, item 14

cooling equipment on vehicles

Definition: Annex I, Item 15. Measurement: Annex III, Part B, item 15

drill rigs

Definition: Annex I, Item 17. Measurement: Annex III, Part B, item 17

equipment for loading and unloading silos or tanks on trucks

Definition: Annex I, Item 19. Measurement: Annex III, Part B, item 19

glass recycling containers

Definition: Annex I, Item 22. Measurement: Annex III, Part B, item 22

grass trimmers/grass edge trimmers

Definition: Annex I, Item 24. Measurement: Annex III, Part B, item 24

hedge trimmers

Definition: Annex I, Item 25. Measurement: Annex III, Part B, item 25

high pressure flushers

Definition: Annex I, Item 26. Measurement: Annex III, Part B, item 26

high pressure water jet machines

Definition: Annex I, Item 27. Measurement: Annex III, Part B, item 27

hydraulic hammers

Definition: Annex I, Item 28. Measurement: Annex III, Part B, item 28

joint cutters

Definition: Annex I, Item 30. Measurement: Annex III, Part B, item 30

leaf blowers

Definition: Annex I, Item 34. Measurement: Annex III, Part B, item 34

leaf collectors

Definition: Annex I, Item 35. Measurement: Annex III, Part B, item 35

lift trucks, combustion-engine driven, counterbalanced (only “other counterbalanced lift trucks" as defined in Annex I, Item 36, second indent, with a rated capacity of not more than 10 tonnes)

Definition: Annex I, Item 36. Measurement: Annex III, Part B, item 36

mobile waste containers

Definition: Annex I, Item 39. Measurement: Annex III, Part B, item 39

paver-finishers (equipped with a high-compaction screed)

Definition: Annex I, Item 41. Measurement: Annex III, Part B, item 41

piling equipment

Definition: Annex I, Item 42. Measurement: Annex III, Part B, item 42

pipelayers

Definition: Annex I, Item 43. Measurement: Annex III, Part B, item 43

piste caterpillars

Definition: Annex I, Item 44. Measurement: Annex III, Part B, item 44

power generators ( ≥400 kW)

Definition: Annex I, Item 45. Measurement: Annex III, Part B, item 45

power sweepers

Definition: Annex I, Item 46. Measurement: Annex III, Part B, item 46

refuse collection vehicles

Definition: Annex I, Item 47. Measurement: Annex III, Part B, item 47

road milling machines

Definition: Annex I, Item 48. Measurement: Annex III, Part B, item 48

scarifiers

Definition: Annex I, Item 49. Measurement: Annex III, Part B, item 49

shredders/chippers

Definition: Annex I, Item 50. Measurement: Annex III, Part B, item 50

snow-removing machines with rotating tools (self-propelled, excluding attachments)

Definition: Annex I, Item 51. Measurement: Annex III, Part B, item 51

suction vehicles

Definition: Annex I, Item 52. Measurement: Annex III, Part B, item 52

trenchers

Definition: Annex I, Item 54. Measurement: Annex III, Part B, item 54

truck mixers

Definition: Annex I, Item 55. Measurement: Annex III, Part B, item 55

water pump units (not for use under water)

Definition: Annex I, Item 56. Measurement: Annex III, Part B, item 56

Regulation 8

SCHEDULE 3U.K.(Extract from Article 12)

| Type of equipment | Net installed powerP (in kW) Electric powerPel(1) in kW Mass of appliancem in kg Cutting widthL in cm | Permissible sound power level in dB/1 pW | |

|---|---|---|---|

| Stage I as from 3 January 2002 | Stage II as from 3 January 2006 | ||

| Compaction machines (vibrating rollers, vibratory plates, vibratory rammers) | P≤8 8<P≤70 P>70 | 108 109 89 + 11 lgP | 105 106 86 + 11 lgP |

| Tracked dozers, tracked loaders, tracked excavator-loaders | P≤ 55 P> 55 | 106 87 + 11 lgP | 103 84 + 11 lgP |

| Wheeled dozers, wheeled loaders, wheeled excavator-loaders, dumpers, graders, loader-type landfill compactors, combustion-engine driven counter balanced lift trucks, mobile cranes, compaction machines (non-vibrating rollers), paver-finishers, hydraulic power packs | P≤55 P>55 | 104 85 + 11 lgP | 101 82 + 11 lgP |

| Excavators, builders’ hoists for the transport of goods, constrction winches, motor hoes | P≤15 P>15 | 96 83 + 11 lgP | 93 80 + 11 lgP |

| Hand-held concrete-breakers and picks | m≤15 15 <m < 30 m≥ 30 | 107 94 + 11 lgm 96 + 11 lgm | 105 92 + 11 lgm 94 + 11 lgm |

| Tower cranes | 98 + lgP | 96 + lgP | |

| Welding and power generators | P el≤ 2 2 <Pel ≤10 P el > 10 | 97 + lgPel 98 + lgPel 97 + lgPel | 95 + lgPel 96 + lgPel 95 + lgPel |

| Compressors | P≤ 15 P > 15 | 99 97 + 2 lgP | 97 95 + 2 lgP |

| Lawnmowers lawn trimmers/lawn edge trimmers | L≤ 50 50< L≤ 70 70 <L≤ 120 L > 120 | 96 100 100 105 | 94 {s002} 98 98 {s002} 103 {s002} |

{s001}

P el for welding generators: conventional welding current multiplied by the conventional load voltage for the lowest value of the duty factor given by the manufacturer

P el for power generators: prime power according to ISO 8528–1:1993, point 13.3.2

{s002} Indicative figures only. Definitive figures will depend on amendment of the Directive following the report required in Article 20(3). In the absence of any such amendment, the figures for stage I will continue to appy for stage II.

The permissible sound power level shall be rounded to the nearest whole number (less than 0.5 use lower number; greater than or equal to 0.5 use higher number).

Regulation 3

SCHEDULE 4U.K. (ANNEX I to the Directive)

Definitions of EquipmentU.K.

Aerial access platforms with combustion enginesU.K.

1. Equipment consisting of a minimum of a work platform, an extending structure and a chassis. The work platform is a fenced platform or a cage which can be moved under load to the required working position. The extending structure is connected to the chassis and supports the work platform; it allows movement of the work platform to its required position.

Brush cutterU.K.

2. A combustion-engine driven portable hand-held unit fitted with a rotating blade made of metal or plastic intended to cut weeds, brush, small trees and similar vegetation. The cutting device operates in a plane approximately parallel to the ground.

Builders’ hoist for the transport of goodsU.K.

3. A power-operated, temporarily installed builders’ hoist intended for use by persons who are permitted to enter engineering and construction sites, serving:

(i)defined landing levels, having a platform

— designed for the transportation of goods only

— which permits the access of persons during loading and unloading

— which permits the access and travel by authorised persons during erection, dismantling and maintenance

— guided

— travelling vertical or along a path within 15 degrees maximum of the vertical

— supported or sustained by: wire, rope, chain, screwed spindle and nut, rack and pinion, hydraulic jack (direct or indirect), or an expanding linkage mechanism

— where masts may or may not require support from separate structures, or

(ii)either one upper landing or a work area extending to the end of the guide (e.g. a roof), having a load-carrying device:

— designed for the transportation of goods only

— designed that there is no need to step on it for loading or unloading purposes or for maintenance, erection and dismantling

— from which persons are prohibited at any time

— guided

— which is designed to travel at an angle of at least 30 degrees to the vertical but may be used at any angle

— sustained by steel wire rope and a positive drive system

— controlled by constant pressure type controls

— which does not benefit from the use of any counterweight

— having a maximum rated load of 300 kg

— having a maximum speed of 1 m/s

— and where the guides require support from separate structures.

Building site band saw machineU.K.

4. A hand-fed powered machine weighing less than 200 kg fitted with a single circular saw blade in the form of a continuous band mounted on and running between two or more pulleys.

Building site circular saw benchU.K.

5. A hand-fed machine weighing less than 200 kg fitted with a single circular sawblade (other than a scoring saw) with a diameter of 350 mm or more, up to a maximum diameter of 500 mm, which is fixed during the normal cutting operation, and a horizontal table, all or part of which is fixed during operation. The sawblade is mounted on a horizontal non-tilting spindle, the position of which remains stationary during machining. The machine may have any of the following features:

— the facility for the sawblade to be raised and lowered through the table

— machine frame below the table may be open or enclosed

— the saw may be fitted with an additional, manually operated travelling table (not adjacent to the sawblade).

Chain saw, portableU.K.

6. A power-driven tool designed to cut wood with a saw chain and consisting of an integrated compact unit of handles, power source and cutting attachment, designed to be supported with two hands.

Combined high pressure flusher and suction vehicleU.K.

7. A vehicle which may work either as a high pressure flusher or as a suction vehicle. See high pressure flusher and suction vehicle.

Compaction machineU.K.

8. A machine which compacts material, eg rock fills, soil or asphalt surfacing, through a rolling, tamping or vibrating action of the working tool. It may be self-propelled, towed, walk-behind or an attachment to a carrying machine. Compaction machines are subdivided as follows:

— rollers for ride-on operators: self-propelled compaction machines with one or more metallic cylindrical bodies (drums) or rubber tyres; the operator’s station is an integral part of the machine

— walk-behind rollers: self-propelled compaction machines with one or more metallic cylindrical bodies (drums) or rubber tyres in which the operation facilities for travelling, steering, braking and vibrating are disposed in such a way that the machines have to be operated by an attending operator or by remote control

— towed roller: compaction machines with one or more metallic cylindrical bodies (drums) or rubber tyres which do not possess an independent drive system and where the operator’s station is to be found on a tractor unit

— vibratory plates and vibratory rammers: compaction machines with mainly flat base plates which are made to vibrate. They are operated by an attending operator or as an attachment to a carrier machine

— explosion rammers: compaction machines with mainly a flat pad as the compacting tool which is made to move in a predominantly vertical direction by explosion pressure. The machine is operated by an attending operator.

CompressorU.K.

9. Any machine for use with interchangeable equipment which compresses air, gases or vapours to a pressure higher than the inlet pressure. A compressor comprises the bare compressor itself, the prime mover and any component or device supplied, which is necessary for safe operation of the compressor.

Excluded are the following categories of device:

— fans, i.e. devices producing air circulation at a positive pressure of not more than 110,000 pascals

— vacuum pumps, i.e. devices or appliances for extracting air from an enclosed space at a pressure not exceeding atmospheric pressure

— gas turbine engines.

Concrete-breakers and picks, hand heldU.K.

10. Powered (by any method) concrete-breakers and picks used to perform work on civil engineering and building sites.

Concrete or mortar mixerU.K.

11. A machine to prepare concrete or mortar, irrespective of the loading, mixing and emptying process. It may be operated intermittently or constantly. Concrete mixers on trucks are called truck mixers (see definition 55).

Construction winchU.K.

12. A power-operated, temporarily installed lifting appliance which is equipped with means for raising and lowering a suspended load.

Conveying and spraying machine for concrete and mortarU.K.

13. Items of plant pumping and spraying concrete or mortar, with or without agitator, whereby the material to be transported is conveyed to the placing position through pipelines, distribution devices or distribution booms. Conveyance is carried out:

— for concrete mechanically, by piston or rotor pumps

— for mortar mechanically by piston, worm, hose and rotor pumps or pneumatically by compressors with or without air chamber.

These machines may be mounted on trucks, trailers or special vehicles.

Conveyor beltU.K.

14. A temporarily installed machine suitable for transporting material by means of a power-driven belt.

Cooling equipment on vehiclesU.K.

15. A cargo space refrigeration unit on vehicle categories N2, N3, O3 and O4 as defined by Directive 70/156/EEC.

The refrigeration unit may be powered by means of an integral part of the refrigeration unit, a separate part attached to the vehicle body, a driving engine of the vehicle, or by an independent or standby power source.

DozerU.K.

16. A self-propelled wheeled or crawler machine used to exert a push or pull force through mounted equipment.

Drill rigU.K.

17. A machine which is used for drilling holes on construction sites by:

— percussive drilling

— rotary drilling

— rotary percussive drilling.

Drill rigs are stationary during drilling. They may move from one place of work to another, under their own power. Self-propelled drill rigs include those mounted on lorries, wheeled chassis, tractors, crawlers, skid bases (pulled by winch). When drill rigs are mounted on lorries, tractors and trailers, or are wheel-based, transportation may be carried out at higher speeds and on public roads.

DumperU.K.

18. A self-propelled wheeled or crawler machine having an open body, which either transports and dumps or spreads material. Dumpers may be equipped with integral self-loading equipment.

Equipment for loading and unloading of silos or tanks on trucksU.K.

19. Powered devices attached to silo or tanker trucks for loading or unloading of liquids or bulk material by means of pumps or similar equipment.

Excavator, hydraulic or rope-operatedU.K.

20. A self-propelled crawler or wheeled machine having an upper structure capable of a minimum of 360 degrees rotation, which excavates, swings and dumps material by the action of a bucket fitted to the boom and arm or telescopic boom, without moving the chassis or undercarriage during any one cycle of the machine.

Excavator-loaderU.K.

21. A self-propelled wheeled or crawler machine having a main structural support designed to carry both a front-mounted bucket loading mechanism and a rear-mounted backhoe. When used in the backhoe mode, the machine normally digs below ground level with bucket motion towards the machine. The backhoe lifts, swings and discharges material while the machine is stationary. When used in the loader mode, the machine loads or excavates through forward motion of the machine, and lifts, transports and discharges material.

Glass recycling containerU.K.

22. A container, built of whatever material, that is used for the collection of bottles. It is equipped with at least one opening for filling in bottles and another one for emptying the container.

GraderU.K.

23. A self-propelled wheeled machine having an adjustable blade, positioned between front and rear axles, which cuts, moves and spreads material usually to grade requirements.

Grass trimmer/grass edge trimmerU.K.

24. A combustion-engine driven portable hand-held unit fitted with flexible line(s), string(s), or similar non-metallic flexible cutting elements, such as pivoting cutters, intended to cut weeds, grass or similar soft vegetation. The cutting device operates in a plane approximately parallel (grass trimmer) or perpendicular (grass edge trimmer) to the ground.

Hedge trimmerU.K.

25. Hand-held, integrally driven powered equipment which is designed for use by one operator for trimming hedges and bushes utilising one or more linear reciprocating cutter blades.

High pressure flusherU.K.

26. A vehicle equipped with a device to clean sewers or similar installations by means of a high pressure water jet. The device may be either mounted on a proprietary vehicular truck chassis or incorporated into its own chassis embodiment. The equipment may be fixed or demountable as in the case of an exchangeable bodywork system.

High pressure water jet machineU.K.

27. A machine with nozzles or other speed-increasing openings which allow water, also with admixtures, to emerge as a free jet. In general, high pressure jet machines consist of a drive, a pressure generator, hose lines, spraying devices, safety mechanisms, controls and measurement devices. High pressure water jet machines may be mobile or stationary:

— mobile high pressure water jet machines are mobile, readily transportable machines which are designed to be used at various sites, and for this purpose are generally fitted with their own undergear or are vehicle-mounted. All necessary supply lines are flexible and readily disconnectable

— stationary high pressure water jet machines are designed to be used at one site for a length of time but capable of being moved to another site with suitable equipment. Generally skid or frame-mounted with supply line capable of being disconnected.

Hydraulic hammerU.K.

28. Equipment which uses the hydraulic power source of the carrier machine to accelerate a piston (sometimes gas-assisted), which then hits a tool. The stress wave generated by kinetic action flows through the tool into the material, which causes the material to break. Hydraulic hammers need a supply of pressurised oil to function. The complete carrier/hammer unit is controlled by an operator, usually seated in the cabin of the carrier.

Hydraulic power packU.K.

29. Any machine for use with interchangeable equipment which compresses liquids to a pressure higher than the inlet pressure. It means an assembly of a prime mover, pump, with or without reservoir and accessories (e.g. controls, pressure relief valve).

Joint cutterU.K.

30. A mobile machine intended for the production of joints in concrete, asphalt and similar road surfaces. The cutting tool is a rotating high speed disc. The forward motion of the joint cutter can be

— manual

— manual with mechanical assistance

— power-driven

Landfill compactor, loader-type with bucketU.K.

31. A self-propelled wheeled compaction machine having a front-mounted loader linkage with a bucket having steel wheels (drums) primarily designed to compact, move, grade, and load soil, landfill or sanitary (refuse) materials.

LawnmowerU.K.

32. A walk-behind or ride-on grass cutting machine or a machine with grass-cutting attachment(s) where the cutting device operates in a plane approximately parallel to the ground and which uses the ground to determine the height of cut by means of wheels, air cushion or skids, etc., and which utilises an engine or an electric motor for a power source.

The cutting devices are either:

— rigid cutting elements, or

— non-metallic filament line(s) or freely pivoting non-metallic cutter(s) with a kinetic energy of more than 10 J each; the kinetic energy is determined using EN 786:1997, Annex B.

Also a walk-behind or ride-on grass cutting machine or a machine with grass-cutting attachment(s) where the cutting device is rotating about a horizontal axis to provide a shearing action with a stationary cutter bar or knife (cylinder mower).

Lawn trimmer/lawn edge trimmerU.K.

33. An electrically powered walk-behind or hand-held grass cutting machine with cutting element(s) of non-metallic filament line(s) or freely pivoting non-metallic cutters with a kinetic energy of not more than 10 J each, intended to cut grass or similar soft vegetation. The cutting element(s) operate(s) in a plane approximately parallel (lawn trimmer) or perpendicular (lawn edge trimmer) to the ground. The kinetic energy is determined using EN 786:1997, Annex B.

Leaf blowerU.K.

34. A powered machine appropriate to clear lawns, paths, ways, streets, etc. of leaves and other material by means of a high velocity air flow. It may be portable (hand-held) or not portable but mobile.

Leaf collectorU.K.

35. A powered machine suitable for collecting leaves and other debris using a suction device consisting of a power source which produces a vacuum inside the machine and a suction nozzle and a container for the collected material. It may be portable (hand-held) or not portable but mobile.

Lift truck, combustion-engine driven, counterbalancedU.K.

36. A wheeled, internal combustion-engine driven lift truck with counterweight and lifting equipment (mast, telescopic arm or articulated arm). These are:

— rough terrain trucks (wheeled counterbalanced trucks intended primarily for operation on unimproved natural terrain and on disturbed terrain of, e.g., construction sites)

— other counterbalanced lift trucks, excluded are those counterbalanced lift trucks that are specifically constructed for container handling.

LoaderU.K.

37. A self-propelled wheeled or crawler machine having an integral front-mounted bucket-supporting structure and linkage, which loads or excavates through forward motion of the machine, and lifts, transports and discharges material.

Mobile craneU.K.

38. A self-powered jib crane capable of travelling, loaded or unloaded, without the need for fixed runways and relying on gravity for stability. It operates on tyres, crawlers or with other mobile arrangements. In fixed positions it may be supported by outriggers or other accessories increasing its stability. The superstructure of a mobile crane may be of the type of full-circle slewing, of limited slewing or non-slewing. It is normally equipped with one or more hoists and/or hydraulic cylinders for lifting and lowering the jib and the load. Mobile cranes are equipped either with telescopic jibs, with articulated jibs, with lattice jibs or a combination of these, of such a design that may readily be lowered. The loads suspended from the jib may be handled by hook block assemblies or other load-lifting attachments for special services.

Mobile waste containerU.K.

39. An appropriate designed container fitted with wheels intended to store waste temporarily, and which is equipped with a cover.

Motor hoeU.K.

40. A self-propelled machine designed to be pedestrian-controlled

— with or without support wheel(s), in such a way that its working elements act as hoeing tools to ensure propulsion (motor hoe), and

— propelled by one or various wheel(s) directly actuated from the engine and equipped with hoeing tools (motor hoe with drive wheel(s)).

Paver-finisherU.K.

41. A mobile road construction machine used for the purpose of applying layers of construction material, such as bituminous mix, concrete and gravel on surfaces. Paver-finishers may be equipped with a high-compaction screed.

Piling equipmentU.K.

42. Pile installation and extraction equipment, e.g. impact hammers, extractors, vibrators or static pile pushing/pulling devices of an assembly of machines and components used for installation or extraction of piles, which also includes:

— piling rig consisting of carrier machine (crawler, wheel or rail mounted, floating leader attachment, leader or guiding system)

— accessories, e.g. pile caps, helmets, plates, followers, clamping devices, pile handling devices, pile guides, acoustic shrouds and shock/vibration absorbing devices, power packs/generators and personal lifting devices or platforms.

PipelayerU.K.

43. A self-propelled crawler or wheeled machine specifically designed to handle and lay pipes and carry pipeline equipment. The machine, the design of which is based on a tractor, has especially designed components such as undercarriage, main frame, counterweight, boom and load-hoist mechanism, and vertically pivoting side boom.

Piste caterpillarU.K.

44. A self-propelled crawler machine used to exert a push or pull force on snow and ice through mounted equipment.

Power generatorU.K.

45. Any device comprising an internal combustion engine driving a rotary electrical generator producing a continuous supply of electrical power.

Power sweeperU.K.

46. A sweeping collection machine having equipment to sweep debris into the path of a suction inlet that would then pneumatically by way of a high velocity airstream or with a mechanical pick-up system convey the debris to a collection hopper. The sweeping and collecting devices may either be mounted to a proprietary vehicular truck chassis or incorporated into its own chassis embodiment. The equipment can be fixed or demountable as in the case of an exchangeable bodywork system.

Refuse collection vehicleU.K.

47. A vehicle designed for the collection and transportation of domestic and bulky waste based on loading via containers or by hand. The vehicle may be equipped with a compaction mechanism. A refuse collection vehicle comprises a chassis with cab onto which the bodywork is mounted. It may be equipped with a container lifting device.

Road-milling machineU.K.

48. A mobile machine used for removing material from paved surfaces using a power-driven cylindrical body, on which surface the milling tools are fitted; the cutter drums rotate during the cutting operation.

ScarifierU.K.

49. A walk-behind or ride-on powered machine which uses the ground to determine the depth of cut and which is equipped with an assembly appropriate to slit or scratch the surface of the lawn in gardens, parks and other similar areas.

Shredder/chipperU.K.

50. A powered machine designed for use in a stationary position having one or more cutting devices for the purpose of reducing bulk organic materials to smaller pieces. Generally it consists of a feed intake opening through which material (which may be held by an appliance or not) is inserted, a device which cuts up the material by whatever method (cutting, chopping, crushing or other methods) and a discharge chute through which the cut material is discharged. A collecting device may be attached.

Snow-removing machine with rotating toolsU.K.

51. A machine with which snow can be removed from traffic areas by rotating means, accelerated and ejected by blower means.

Suction vehicleU.K.

52. A vehicle equipped with a device to collect water, mud, sludge, refuse or similar material from sewers or similar installations by means of a vacuum. The device may be either mounted on a proprietary vehicular truck chassis or incorporated into its own chassis embodiment. The equipment may be fixed or demountable as in the case of an exchangeable bodywork system.

Tower craneU.K.

53. A slewing jib crane with the jib located at the top of a tower which stays approximately vertical in the working position. This power-driven appliance is equipped with means for raising and lowering suspended loads and for the movement of such loads by changing the load-lifting radius, slewing, travelling of the complete appliance. Certain appliances perform several but not necessarily all of these movements. The appliance can be installed in a fixed position or equipped with means for displacing or climbing.

TrencherU.K.

54. A self-propelled, ride-on or pedestrian-controlled, crawler or wheeled machine, having a front- or rear-mounted excavator linkage and attachment, primarily designed to produce trenches in a continuous operation, through a motion of the machine.

Truck mixerU.K.

55. A vehicle which is equipped with a drum to transport ready-mixed concrete from the concrete mixing plant to the job site; the drum may rotate when the vehicle is driving or stands still. The drum is emptied on the job site by rotating the drum. The drum is driven either by the driving engine of the vehicle or by a supplementary engine.

Water pump unitU.K.

56. A machine consisting of a water pump itself and the driving system. Water pump means a machine for the raising of water from a lower to a higher energy level.

Welding generatorU.K.

57. Any rotary device which produces a welding current.

Regulation 7(2)(d)

SCHEDULE 5U.K. (ANNEX II to the Directive)

EC Declaration of conformityU.K.

The EC declaration of conformity must contain the following particulars:

— Name and address of the manufacturer or his authorised representative established in the Community.

— Name and address of the person who keeps the technical documentation.

— Description of the equipment.

— Conformity assessment procedure followed, and, where appropriate, name and address of the notified body involved.

— Measured sound power level on an equipment representative for this type.

— Guaranteed sound power level for this equipment.

— A reference to this Directive.

— The declaration that the equipment conforms to the requirements of this Directive.

— Where appropriate, the declaration(s) of conformity and references of the other Community Directives applied.

— The place and date of the declaration.

— Particulars of the signatory authorised to sign the legally binding declaration for the manufacturer or his authorised representative established in the Community.

Regulation 8(1)

SCHEDULE 6U.K. (ANNEX III to the Directive)

Method of measurement of airborne noise emitted by equipment for use outdoorsU.K.

ScopeU.K.

This Annex lays down the methods of measurement of airborne noise that shall be used for the determination of the sound power levels of equipment covered by this Directive with a view to the conformity assessment procedures of this Directive.

Part A of this Annex for each type of equipment referred to in Article 2(1) lays down:

— basic noise emission standards

— general supplements to these basic noise emission standards

for measuring the sound pressure level on a measurement surface enveloping the source and for calculating the sound power level produced by the source.

Part B of this Annex for each type of equipment referred to in Article 2(1) lays down:

— a recommended basic noise emission standard including:

— a reference to the basic noise emission standard chosen from Part A

— the test area

— the value of the constant K2A

— the shape of the measurement surface

— the number and position of microphones to be used

— operating conditions including:

— the reference to a standard, if any

— requirements relating to mounting of the equipment

— a method to calculate the resulting sound power levels in the event that several tests with different operating conditions are to be used

— further information.

When testing specific types of equipment, the manufacturer or his authorised representative in the Community may in general choose one of the basic noise emission standards of Part A and apply the operating conditions of Part B for this specific type of equipment. In the event of a dispute, however, the recommended basic noise emission standard laid down in Part B has to be used together with the operating conditions of Part B.

PART A U.K.Basic Noise Emission Standard

For the determination of the sound power level of equipment for use outdoors as defined by Article 2(1) the basic noise emission standards,

EN ISO 3744:1995

EN ISO 3746:1995

may generally be used subject to the following general supplements:

Measurement uncertaintyU.K.

1. Measurement uncertainties are not taken into account in the framework of conformity assessment procedures in the design phase.

Operating of source during testU.K.

2.

Fan speedU.K.

2.1 If the engine of the equipment or its hydraulic system is fitted with (a) fan(s) it (they) must operate during the test. The fan speed is, in accordance with one of the following conditions, stated and set by the manufacturer of the equipment and must appear in the test report, this speed being used in further measurements.

(a)Fan drive directly connected to the engine

If the fan drive is directly connected to the engine and/or hydraulic equipment (e.g. by belt drive) it must operate during the test.

(b)Fan drive with several distinct speeds

If the fan can work at several distinct speeds the test shall be carried out either

— at its maximum working speed, or

—in a first test with the fan set at zero speed and in a second test the fan set at maximum speed. The resulting sound pressure levelLpA shall then be calculated by combining both test results using the following equation:

(c)Fan drive with continuous variable speed

If the fan can work at continuous variable speed, the test shall be carried out either according to 2.1(b) or with the fan speed set by the manufacturer at no less than 70% of the maximum speed.

Test of powered equipment free of loadU.K.

2.2 For these measurements, the engine and hydraulic system of the equipment must be warmed up in accordance with the instructions, and safety requirements must be observed.

The test is carried out with the equipment in a stationary position without operating the working equipment or travelling mechanism. For the purpose of the test, the engine will idle at no less than the rated speed corresponding to the net power F1.

Textual Amendments

F1Net power means the power in “EC kW" obtained on the test bench at the end of the crankshaft, or its equivalent, measured in accordance with the EC method of measuring the power of internal combustion engines for road vehicles, except that the power of the engine cooling fan is excluded.

If the machine is powered by a generator or from the mains, the frequency of the supply current, specified for the motor by the manufacturer, shall be stable at±1 Hz if the machine is equipped with an induction motor, and the supply voltage at ±1% of the rated voltage if the machine is equipped with a commutator motor. The supply voltage is measured at the plug of a non-detachable cable or cord, or at the inlet of the machine if a detachable cable is provided. The waveform of the current supplied from the generator shall be similar to that obtained from the mains.

If the machine is powered by battery, the battery shall be fully charged.

The speed used and the corresponding net power are stated by the manufacturer of the equipment and must appear in the test report.

If the equipment is fitted with several engines, they must work simultaneously during the tests. If this is not possible, each possible combination of engine(s) is to be tested.

Test of powered equipment under loadU.K.

2.3 For these measurements, the engine (driving device) and hydraulic system of the equipment must be warmed up in accordance with the instructions, and safety requirements must be observed. No signalling device such as a warning horn or reversing alarm is to be operated during the test.

The speed or velocity of the equipment during the test must be recorded and appear in the test report.

If the equipment is fitted with several engines and/or aggregates they must work simultaneously during the tests. If this is not possible, each possible combination of engine(s) and/or aggregates is to be tested.

For each type of equipment that is to be tested under load, specific operating conditions must be laid down which shall, in principle, produce effects and stresses similar to those encountered under actual working conditions.

Test of hand-operated equipmentU.K.

2.4 Conventional operating conditions for each type of hand-operated equipment shall be laid down that produce effects and stresses similar to those undergone under actual working conditions.

Calculation of surface sound pressure levelU.K.

3. The surface sound pressure level shall be determined at least three times. If at least two of the determined values do not differ by more than 1 dB, further measurements will not be necessary; otherwise the measurement shall be continued until two values differing by no more than 1 dB are obtained. The A-weighted surface sound pressure level to be used for calculating the sound power level is the arithmetic mean of the two highest values that do not differ by more than 1 dB.

Information to be reportedU.K.

4. The A-weighted sound power level of the source under test shall be reported to the nearest whole number (less than 0.5 use the lower number; greater than or equal to 0.5 use the higher number).

The report shall contain the technical data necessary to identify the source under test as well as the noise test code and the acoustical data.

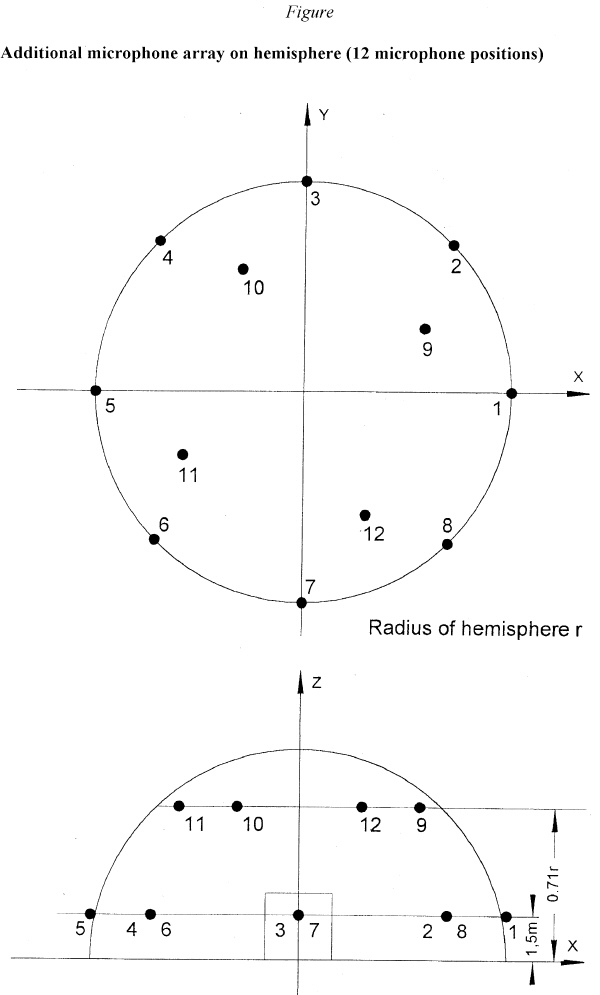

Additional microphone positions on the hemispherical measurement surface (EN ISO 3744:1995)U.K.

5. In addition to clauses 7.2.1 and 7.2.2 of EN ISO 3744:1995 a set of 12 microphones on the hemispherical measurement surface may be used. The location of 12 microphone positions distributed on the surface of a hemisphere of radiusr are listed in the form of Cartesian co-ordinates in the following table. The radiusr of the hemisphere shall be equal to or greater than twice the largest dimension of the reference parallelepiped. The reference parallelepiped is defined as the smallest possible rectangular parallelepiped just enclosing the equipment (without attachments) and terminating on the reflecting plane. The radius of the hemisphere shall be rounded to the nearest higher of the following values: 4, 10, 16m.

The number (12) of microphones may be reduced to six, but the microphone positions 2, 4, 6, 8, 10 and 12 following the requirements of clause 7.4.2 of EN ISO 3744:1995 have to be used in any case.

Generally the arrangement with six microphone positions on a hemispherical measurement surface has to be used. If there are other specifications laid down in a noise test code in this Directive for a specific equipment, these specifications shall be used.

TABLE

Coordinates of the 12 microphone positions

| Number of microphone | x/r | y/r | z |

|---|---|---|---|

| 1 | 1 | 0 | 1.5m |

| 2 | 0.7 | 0.7 | 1.5m |

| 3 | 0 | 1 | 1.5m |

| 4 | -0.7 | 0.7 | 1.5m |

| 5 | -1 | 0 | 1.5m |

| 6 | -0.7 | -0.7 | 1.5m |

| 7 | 0 | -1 | 1.5m |

| 8 | 0.7 | -0.7 | 1.5m |

| 9 | 0.65 | 0.27 | 0.71r |

| 10 | -0.27 | 0.65 | 0.71r |

| 11 | -0.65 | -0.27 | 0.71r |

| 12 | 0.27 | -0.65 | 0.71r |

Environmental correction K2AU.K.

6. Equipment shall be measured on a reflecting surface of concrete or non-porous asphalt, then the environmental correction K2A is set to K2A = 0. If there are other specifications laid down in a noise test code of this Directive for a specific equipment, these specifications shall be used.

PART B U.K.Noise Test Codes for Specific Equipment

Equipment that is tested free of loadU.K.

0.

Basic noise emission standardU.K.

EN ISO 3744:1995

Test area

Reflecting surface of concrete or non-porous asphalt

Environmental correction K2A

K2A = 0

Measurement surface/number of microphone positions/measuring distance

(i)If the largest dimension of the reference parallelepiped does not exceed 8m: hemisphere/six microphone positions according to Part A item 5/according to Part A item 5.

(ii)If the largest dimension of the reference parallelepiped exceeds 8m: parallelepiped according to ISO 3744:1995 with measurement distanced = 1m.

Operating conditions during testU.K.

Test free of load:

The noise tests shall be carried out according to Part A item 2.2.

Period(s) of observation/determination of resulting sound power level if more than one operating condition is used

The period of observation shall at least be 15 seconds.

Aerial access platforms with combustion engineU.K.

1. See No. 0

Brush CuttersU.K.

2.

Basic noise emission standardU.K.

EN ISO 3744:1995

Test area

ISO 10884:1995

Measurement surface/number of microphone positions/measuring distance

ISO 10884:1995

Operating conditions during testU.K.

Test under load

ISO 10884:1995, point 5.3

Period(s) of observation

ISO 10884:1995

Builders’ hoists for the transport of goodsU.K.

3. See No. 0

The geometrical centre of the engine shall be positioned above the centre of the hemisphere; the lift shall move without load and leave the hemisphere—if necessary—in direction of point 1.

Building site band saw machinesU.K.

4.

Basic noise emission standardU.K.

EN ISO 3744:1995

Measurement surface/number of microphone positions/measuring distance

ISO 7960:1995, Annex J withd = 1m

Operating conditions during testU.K.

Test under load

Corresponding to ISO 7960:1995, Annex J (point J2(b) only)

Period of observation

Corresponding to ISO 7960:1995, Annex J

Building site circular saw benchesU.K.

5.

Basic noise emission standardU.K.

EN ISO 3744:1995

Measurement surface/number of microphone positions/measuring distance

ISO 7960:1995, Annex A, measurement distanced = 1m

Operating conditions during testU.K.

Test under load

ISO 7960:1995, Annex A (point A2(b) only)

Period of observation

ISO 7960:1995 Annex A

Chain saws, portableU.K.

6.

Basic noise emission standardU.K.

EN ISO 3744:1995

Test area

ISO 9207:1995

Measurement surface/number of microphone positions/measuring distance

ISO 9207:1995

Operating conditions during testU.K.

Test under load/Test free of load

Full load sawing wood/engine at maximum revolution without load

(a)combustion-engine driven: ISO 9207:1995 points 6.3 and 6.4

(b)electric-motor operated: a test corresponding to ISO 9207:1995 point 6.3 and a test with the motor at maximum revolution without load

Period(s) of observation/determination of resulting sound power level if more than one operating condition is used

ISO 9207:1995 points 6.3 and 6.4

The resulting sound power level Lwa is calculated by:

WhereLw1 and Lw2 are the average sound power levels of the two different modes of operation defined above

Combined High Pressure Flushers and Suction VehiclesU.K.

7. If it is possible to operate both items of equipment simultaneously, this shall be done according to numbers 26 and 52. If not, they shall be measured separately and the higher values are to be stated.

Compaction MachinesU.K.

8.

(i)Non-vibrating rollers

See No. 0

(ii)Vibrating rollers for ride-on operators

Basic noise emission standardU.K.

EN ISO 3744:1995

Operating conditions during testU.K.

Mounting of equipment

The vibrating roller shall be installed on one or more appropriate elastic material(s) such as air-cushion(s). These air-cushions shall be made of a supple material (elastomer or similar) and shall be inflated to a pressure ensuring that the machine is elevated by at least 5 cm; resonance effects shall be avoided. The dimension of the cushion(s) shall be such that the stability of the machine under test is ensured.

Test under load

The machine shall be tested in a stationary position with the engine at rated speed (stated by the manufacturer) and the moving mechanism(s) disconnected. The compacting mechanism shall be operated using the maximum compaction power corresponding to the combination of the highest frequency and the highest possible amplitude for that frequency as declared by the manufacturer.

Period of observation

The period of observation shall be at least 15 seconds.

(iii)Vibratory plates, vibratory rammers, explosive rammers and walk-behind vibrating rollers

Basic noise emission standardU.K.

EN ISO 3744:1995

Test area

EN 500-4 rev. 1:1998, Annex C

Operating conditions during testU.K.

Test under load

EN 500-4 rev. 1:1998, Annex C

Period of observation

EN 500-4 rev. 1:1998, Annex C

CompressorsU.K.

9.

Basic noise emission standardU.K.

EN ISO 3744:1995

Measurement surface/number of microphone positions/measuring distance

hemisphere/six microphone positions according to Part A item 5/according to Part A item 5

or

parallelepiped according to ISO 3744:1995 with measurement distanced = 1m

Operating conditions during testU.K.

Mounting of equipment

The compressors shall be installed on the reflecting plane; skid-mounted compressors shall be placed on a support 0.40 m high, unless otherwise required by the manufacturer’s conditions of installation.

Test under load

The compressor under test shall have been warmed up and be operating in stable conditions as for continuous operation. It shall be properly serviced and lubricated as specified by the manufacturer.

The determination of the sound power level shall be made at full-load or in an operating condition that is reproducible and is representative of the noisiest operation of typical usage of the machine under test, whichever is the noisiest.

Should the layout of the complete plant be such that certain components, e.g. inter-coolers are mounted away from the compressor, endeavours shall be made to separate the noise generated from such parts when performing the noise test. Separation of the various noise sources may require special equipment for the attenuation of the noise from these sources during the measurement. The noise characteristics and description of the operating conditions of such parts shall be given separately in the test report.

During test the gas exhausted from the compressor shall be piped clear of the test area. Care shall be taken to ensure the noise generated by the gas being exhausted is at least 10 dB lower than the noise to be measured at all measurement locations (e.g. by the fitting of a silencer).

Care shall be taken that air discharge does not introduce any extra noise due to turbulence at the compressor discharge valve.

Period of observation

The period of observation shall be at least 15 seconds.

Concrete-breakers and picks, hand-heldU.K.

10.

Basic noise emission standardU.K.

EN ISO 3744:1995

Measurement surface/number of microphone positions/measuring distance

Hemisphere/six microphone positions according to Part A item 5 and the following table/according to mass of equipment as given in the following table:

| Mass of equipmentm in kg | Radius of hemisphere | z for microphone positions 2, 4, 6 and 8 |

|---|---|---|

| m < 10 | 2m | 0.75m |

| m≥ 10 | 4m | 1.50m |

Operating conditions during testU.K.

Mounting of equipment

All appliances shall be tested in the vertical position.

If the test appliance has got an air exhaust, its axis shall be equidistant from two microphone positions. The noise of the power supply shall not influence the measurement of the noise emission from the tested appliance.

Support of the appliance

The appliance shall be coupled during the test run to a tool embedded in a cube-shaped concrete block placed in a concrete pit, sunk into the ground. An intermediate steel piece may be inserted during tests between the appliance and the support tool. This intermediate piece shall form a stable structure between the appliance and the support tool. Figure 10.1 incorporates these requirements.

Block characteristics

The block shall be in the shape of a cube 0.60 m±2 mm long at the edge and as regular as possible; it shall be made of reinforced concrete and thoroughly vibrated in layers of up to 0.20 m to avoid excessive sedimentation.

Quality of the concrete

The quality of the concrete shall correspond to C 50/60 of ENV 206.

The cube shall be reinforced by 8 mm-diameter steel rods without ties, each rod being independent of the other; the design concept is illustrated in figure 10.2.

Supporting tool

The tool shall be sealed into the block and shall consist of a rammer of no less than 178 mm or no more than 220 mm diameter and a tool chuck component identical to that normally used with the appliance being tested and complying with ISO 1180:1983, but sufficiently long to enable the practical test to be carried out.

Suitable treatment shall be carried out to integrate the two components. The tool shall be fixed in the block so that the bottom of the rammer is 0.30 m from the upper face of the block (see Figure 10.2).

The block shall remain mechanically sound, particularly at the point where the supporting tool and the concrete meet. Before and after each test, it shall be established that the tool sealed in the concrete block is integrated with it.

Positioning of the cube

The cube shall be set in a pit cemented throughout, covered by a screening slab of at least 100 kg/m2, as indicated in Figure 10.3, so that the upper surface of the screening slab is flush with the ground. To avoid any parasitic noise, the block shall be insulated against the bottom and sides of the pit by elastic blocks, the cut-off frequency of which shall not be more than half the striking rate of the appliance tested, expressed as strokes per second.

The opening in the screening slab through which the tool chuck component passes shall be as small as possible and sealed by a flexible sound-proof joint.

Test under load

The appliance tested shall be connected to the supporting tool.

The test appliance shall be operated in stable conditions having the same acoustical stability as in normal service.

The test appliance shall be operated at the maximum power specified in the instructions supplied to the purchaser.

Period of observation

The period of observation shall at least be 15 seconds.

Figure 10.1 Schematic diagram of intermediate piece

The value of A should be such that the screening slab resting on the elastic joint J is flush with the ground.

Concrete or mortar mixersU.K.

11.

Basic noise emission standardU.K.

EN ISO 3744:1995

Operating conditions during testU.K.

Test under load

The mixing device (drum) shall be filled to its rated capacity with sand of granulation 0 to 3 mm, the humidity shall be 4–10%.

The mixing device shall be operated at least at the rated speed.

Period of observation

The period of observation shall be at least 15 seconds.

Construction winchesU.K.

12. See No. 0

The geometrical centre of the engine shall be positioned above the centre of the hemisphere; the winch shall be connected but no load shall be applied.

Conveying and spraying machines for concrete and mortarU.K.

13.

Basic noise emission standardU.K.

EN ISO 3744:1995

Operating conditions during testU.K.

If the machine is equipped with a boom, this is set upright and the pipe shall be led back to the filler funnel. If this is not the case the machine shall be equipped with a horizontal pipe of at least 30 m leading back to the filler funnel.

Test under load

(i)For machines conveying and spraying concrete:

The conveying system and the pipe shall be filled with a medium similar to concrete, the cement being replaced by an admixture e.g. finest ash. The machine shall operate at its maximum output, the period of one working cycle being not more than five seconds (if this period is exceeded, water shall be added to the “concrete" in order to reach this value).

(ii)For machines conveying and spraying mortar:

The conveying system and the pipe shall be filled with a medium similar to finishing mortar, the cement being replaced by an admixture, e.g. methyl cellulose. The machine shall operate at its maximum output, the period of one working cycle being not more than five seconds (if this period is exceeded, water shall be added to the “mortar" in order to reach this value).

Period of observation

The period of observation shall at least be 15 seconds.

Conveyor BeltsU.K.

14. See No. 0

The geometrical centre of the engine shall be positioned above the centre of the hemisphere; the belt shall move without load and leave the hemisphere, if necessary, in the direction of point 1.

Cooling equipment on vehiclesU.K.

15.

Basic noise emission standardU.K.

EN ISO 3744:1995

Operating conditions during testU.K.

Test under load

The cooling equipment shall be installed in a real or simulated cargo space and be tested in a stationary position where the height of the cooling equipment shall be representative of the intended installation requirements according to the instructions supplied to the purchaser. The power source of the cooling equipment shall operate at the rate that causes the maximum speed of the cooling compressor and the fan specified in the instructions. If the cooling equipment is intended to be powered by the driving engine of the vehicle the engine shall not be used during the test and the cooling equipment shall be connected to a suitable electrical power source. Removable tractor units shall be removed during the test.

Cooling equipment installed in cargo-space refrigeration units which have a choice of different power sources shall be tested separately for each power source. The test result reported shall as a minimum reflect the mode of operation which leads to the maximum noise output.

Period of observation

The period of observation shall be at least 15 seconds.

DozersU.K.

16.

Basic noise emission standardU.K.

EN ISO 3744:1995

Test area

ISO 6395:1988

Measurement surface/number of microphone positions/measuring distance

ISO 6395:1988

Operating conditions during testU.K.

Mounting of equipment

Crawler dozers shall be tested on the test site corresponding to point 6.3.3 of ISO 6395:1988

Test under load

ISO 6395:1988, Annex B

Period(s) of observation and consideration of different operating conditions, if any

ISO 6395:1988, Annex B

Drill rigsU.K.

17.

Basic noise emission standardU.K.

EN ISO 3744:1995

Operating conditions during testU.K.

Test under load

EN 791:1995, Annex A

Period of observation

The period of observation shall at least be 15 seconds.

DumpersU.K.

18.

Basic noise emission standardU.K.

EN ISO 3744:1995

Test area

ISO 6395:1988

Measurement surface/number of microphone positions/measuring distance

ISO 6395:1988

Operating conditions during testU.K.

Test under load

Equivalent ISO 6395:1988, Annex C, with the following amendment:

C4.3, second paragraph is replaced by:

“The engine shall be operated at its maximum governed speed (high idle). The transmission control shall be set to neutral. Bring the bucket to the tipped position (emptying) up to about 75% of its maximum movement and return it to its travelling position three times. This sequence of events is considered to be a single cycle for the stationary hydraulic mode.

If no engine power is used to tip the bucket, the engine shall be operated at idling speed with the transmission in neutral. The measurement shall be performed without tipping the bucket, the period of observation shall be 15 seconds.”

Period(s) of observation/determination of resulting sound power level if more than one operating condition is used

ISO 6395:1988, Annex C

Equipment for loading and unloading tanks or silos on trucksU.K.

19.

Basic noise emission standardU.K.

EN ISO 3744:1995

Operating conditions during testU.K.

Test under load

The equipment shall be tested with the truck in a stationary position. The engine driving the equipment shall operate at the speed that causes the maximum output of the equipment specified in the instructions supplied to the purchaser.

Period of observation

The period of observation shall at least be 15 seconds.

ExcavatorsU.K.

20.

Basic noise emission standardU.K.

EN ISO 3744:1995

Test area

ISO 6395:1988

Measurement surface/number of microphone positions/measuring distance

ISO 6395:1988

Operating conditions during testU.K.

Test under load

ISO 6395:1988, Annex A

Period(s) of observation/determination of resulting sound power level if more than one operating condition is used

ISO 6395:1988, Annex A

Excavator-loadersU.K.

21.

Basic noise emission standardU.K.

EN ISO 3744:1995

Test area

ISO 6395:1988

Measurement surface/number of microphone positions/measuring distance

ISO 6395:1988

Operating conditions during testU.K.

Test under load

ISO 6395:1988, Annex D

Period(s) of observation/determination of resulting sound power level if more than one operating condition is used

ISO 6395:1988, Annex D

Glass recycling containersU.K.

22.

Basic noise emission standardU.K.

EN ISO 3744:1995

For the purpose of this noise test code the single-event sound pressure level Lpls as defined in EN ISO 3744:1995 point 3.2.2 is used in measuring the sound pressure level at the microphone positions.

Environmental correction K2A

Measurement in the open air

K2A = 0

Measurements indoors

The value of the constant K2A, determined in accordance with Annex A of EN ISO 3744:1995, shall be ≤2.0 dB in which case K2A shall be disregarded.

Operating conditions during testU.K.

The noise measurement shall be carried out during a complete cycle beginning with the empty container and completed when 120 bottles have been thrown into the container.

The glass bottles are defined as follows:

— capacity: 75cl

— mass: 370±30 g.

The testing operator holds each bottle by its neck and with its bottom towards the filling aperture and then he pushes it gently inside through the filling aperture in the direction of the centre of the container, avoiding if possible the bottle hitting against the walls. Only one filling aperture is used for throwing the bottles and it is the one nearest to microphone position 12.

Period(s) of observation/determination of resulting sound power if more than one operating condition is used

The A-weighted single-event sound pressure level is preferably simultaneously measured at the six microphone positions for each bottle thrown into the container.

The A-weighted single-event sound power level averaged over the measurement surface is calculated according to EN ISO 3744:1995, point 8.1.

The A-weighted single-event sound pressure level averaged over all 120 throwings of bottles is calculated as the logarithmic mean of the A-weighted single-event sound pressure levels averaged over the measurement surface.

GradersU.K.

23.

Basic noise emission standardU.K.

EN ISO 3744:1995

Test area

ISO 6395:1988

Measurement surface/number of microphone positions/measuring distance

ISO 6395:1988

Operating conditions during testU.K.

Test under load

Corresponding to ISO 6395:1988, Annex B

Period(s) of observation/determination of resulting sound power level if more than one operating condition is used

ISO 6395:1988, Annex B

Grass trimmers/grass edge trimmersU.K.

24. See No. 2

The trimmer shall be positioned by a suitable device in such a way that its cutting device is above the centre of the hemisphere. For grass trimmers, the centre of the cutting device shall be held at a distance of about 50 mm above the surface. In order to accommodate the cutting blades, grass edge trimmers should be positioned as close as possible to the test surface.

Hedge trimmersU.K.

25.

Basic noise emission standardU.K.

EN ISO 3744:1995

Test area

ISO 11094:1991

in case of dispute, measurements shall be carried out in the open air on the artificial surface (point 4.1.2 to ISO 11094:1991)

Environmental correction K2A

Measurement in the open air

K2A = 0

Measurements indoors

The value of the constant K2A, determined without the artificial surface and in accordance with Annex A of EN ISO 3744:1995, shall be ≤ 2.0 dB, in which case K2A shall be disregarded.

Measurement surface/number of microphone positions/measuring distance

ISO 11094:1991

Operating conditions during testU.K.

Mounting of equipment

The hedge trimmer shall be held in the natural manner for normal use either by a person or by a suitable device in such a way that its cutting device is above the centre of the hemisphere.

Test under load

The hedge clipper shall be operated at its nominal speed with the cutting device working.

Period of observation

The period of observation shall at least be 15 seconds.

High pressure flushersU.K.

26.

Basic noise emission standardU.K.

EN ISO 3744:1995

Operating conditions during testU.K.

Test under load

The high pressure flusher shall be tested in a stationary position. The engine and auxiliary units operate at the speed provided by the manufacturer for the operation of the working equipment; the high pressure pump(s) is (are) operating at its (their) maximum speed and operating pressure provided by the manufacturer. Using an adapted nozzle the pressure reduction valve shall be just on the point of reacting. The flow noise of the nozzle shall not have any influence on the results of the measurements.

Period of observation

The period of observation shall at least be 30 seconds.

High pressure water jet machinesU.K.

27.

Basic noise emission standardU.K.

EN ISO 3744:1995

Measurement surface/number of microphone positions/measuring distance

Parallelepiped/according to EN ISO 3744:1995 with measurement distanced = 1m

Operating conditions during testU.K.

Mounting of equipment

The high pressure water jet machine shall be installed on the reflecting plane; skid-mounted machines shall be placed on a support 0.40m high, unless otherwise required by the manufacturer’s conditions of installation.

Test under load

The high-pressure cleaning machine shall be brought to its steady-state within the range specified by the manufacturer. During testing the nozzle shall be coupled to the high-pressure cleaning machine that causes the highest pressure if used according to the manufacturer’s instructions.

Period of observation

The period of observation shall at least be 15 seconds.

Hydraulic hammersU.K.

28.

Basic noise emission standardU.K.

EN ISO 3744:1995

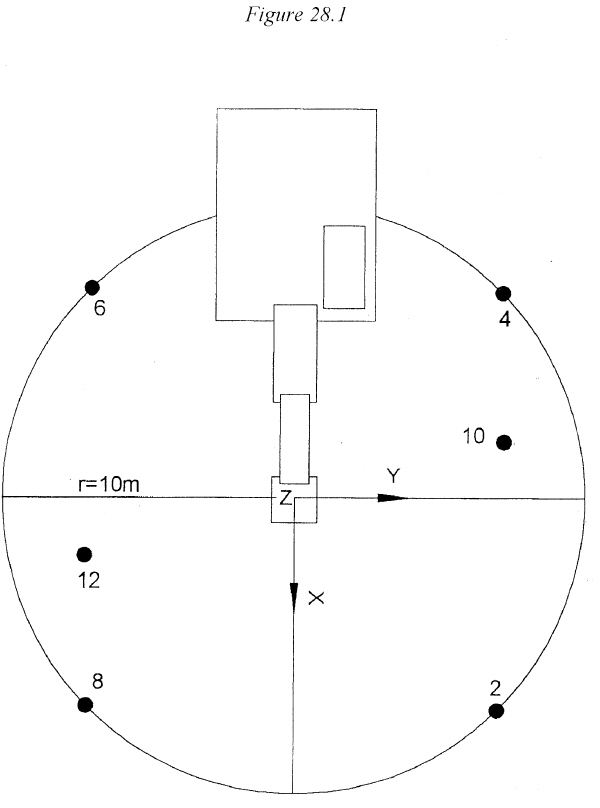

Measurement surface/number of microphone positions/measuring distance

Hemisphere/six microphone positions according to Part A, item 5/r=10 m

Operating conditions during testsU.K.

Mounting of the equipment

For the test the hammer is attached to a carrier and a special test block structure shall be used. Figure 28.1 gives the characteristics of this structure and Figure 28.2 shows the position of the carrier.

Carrier

The carrier for the test hammer shall meet the requirements of the test hammer’s technical specifications especially in weight range, hydraulic output power, supply oil flow and return line back pressure.

Mounting

Mechanical mounting as well as connections (hoses, pipes ...) must correspond to specifications given in the hammer’s technical data. All significant noise caused by pipes and various mechanical components needed for installation, ought to be eliminated. All component connections have to be well tightened.

Hammer stability and static hold force

The hammer shall be firmly held down by the carrier in order to give the same stability as that existing under normal operating conditions. The hammer must be operated in an upright position.

Tool

A blunt tool shall be used in the measurements. The length of the tool must meet the requirements given in Figure 28.1 (test block).

Test under load

Hydraulic input and power and oil flow

Operating conditions of the hydraulic hammer shall be appropriately adjusted, measured and reported along with the corresponding technical specification value. The hammer under test must be used in such a way that 90% or more of the maximum hydraulic input power and oil flow of the hammer can be reached.

Care shall be taken that the total uncertainty of the measurement chains ofps andQ is kept within+5%. This assures the hydraulic input power determination within+10% accuracy. Assuming linear correlation between hydraulic input power and emitted sound power this would mean variation of less than+0.4 dB in the determination of the sound power level.

Adjustable components having effect on the hammer power

Pre-settings of all accumulators, pressure central valves and other possible adjustable components must meet the values given in technical data. If more than one fixed impact rate is optional, measurements have to be made using all settings. Minimum and maximum values are presented.

Quantities to be measured

p s The mean value of the hydraulic supply fine pressure during the hammer’s operation including at least 10 blows.

Q The mean value of the breaker inlet oil flow measured simultaneously withps.

T The oil temperature must lie between + 40/+ 60° C during measurements. The temperature of the hydraulic breaker body must have been stabilised to normal operating temperature before starting the measurements.

Pa The prefill gas pressure of all accumulators must be measured in static situation (breaker not operating) at stable ambient temperature of + 15/+ 25° C. The measured ambient temperature shall be recorded with the measured accumulator prefill gas pressure.

Parameters to be evaluated from the measured operating parameters:

P IN Hydraulic input power of the breaker P IN =ps.Q

Hydraulic supply line pressure measurement, ps

—ps must be measured as close to the breaker IN-port as possible.

—ps shall be measured with a pressure gauge (minimum diameter: 100 mm; accuracy class±1.0% FSO).

Breaker inlet oil flow, Q

—Q must be measured from the supply pressure line as close to the breaker IN-port as possible.

—Q must be measured with an electric flowmeter (accuracy class±2.5% of the flow reading).

Measuring point of the oil temperature, T

—T must be measured from the oil tank of the carrier or from the hydraulic line connected to the hammer. Measuring point shall be specified in the report.

— accuracy of the temperature reading must lie within±2° C of the actual value.

Period of observation/determination of resulting sound power level

The period of observation shall be at least 15 seconds.

The measurements are repeated three times, or more if necessary. The final result is calculated as the arithmetic mean of the two highest values that do not differ by more than 1 dB.

Definitions

d Tool diameter (mm)

d 1 Anvil diameter, 1200±100 mm

d 2 Inner diameter of the anvil support structure, ≤ 1800 mm

d 3 Diameter of the test block deck, ≤ 2200 mm

d 4 Diameter of the tool opening in the deck, ≤350 mm

d 5 Diameter of the tool seal, ≤1000 mm

h¹ Visible tool length between the lowest part of the housing and tool seal upper surface, (mm)h1 =d±d/2

h 2 Tool seal thickness above the deck, ≤20 mm (if the tool seal is located below the deck, its thickness is not limited; it may be made of foam rubber)

h 3 Distance between deck upper surface and anvil upper surface, 250±50 mm

h 4 Isolating foam rubber deck seal thickness, ≤30 mm

h 5 Anvil thickness, 350 ±50 mm

h 6 Tool penetration, ≤50 mm

If the quadratic shape of the test block structure is used, the maximum length dimension equals 0.89× corresponding diameter.

The empty space between the deck and the anvil can be filled with elastic foam rubber or other absorption material, density <220 kg/m3.

Hydraulic power packsU.K.

29.

Basic noise emission standardU.K.

EN ISO 3744:1995

Operating conditions during testU.K.

Mounting of equipment

The hydraulic power pack shall be installed on the reflecting plane; skid-mounted hydraulic power packs shall be placed on a support 0.40 m high, unless otherwise required by the manufacturer’s conditions of installation.

Test under load

During testing, no tools shall be coupled to the hydraulic power pack.

The hydraulic power pack shall be brought to its steady-state within the range specified by the manufacturer. It shall operate at its nominal speed and its nominal pressure. The nominal speed and pressure are those appearing in the instructions supplied to the purchaser.

Period of observation

The period of observation shall at least be 15 seconds.

Joint cuttersU.K.

30.

Basic noise emission standardU.K.

EN ISO 3744:1995

Operating conditions during testU.K.

Test under load

The joint cutter shall be equipped with the largest possible blade foreseen by the manufacturer in the instructions supplied to the purchaser. The engine shall operate at its maximum speed with the blade idling.

Period of observation

The period of observation shall be at least 15 seconds.

Landfill compactorsU.K.

31. See No. 37

LawnmowersU.K.

32.

Basic noise emission standardU.K.

EN ISO 3744:1995

Test area

ISO 11094:1991

In case of dispute, measurements shall be carried out in the open air on the artificial surface (point 4.1.2 of ISO 11094:1991).

Environmental correction K2A

Measurement in the open air

K2A = 0

Measurements indoors

The value of the constant K2A, determined without the artificial surface and in accordance with Annex A to EN ISO 3744:1995 shall be≤ 2.0 dB, in which case K2A shall be disregarded.

Measurement surface/number of microphone positions/measuring distance

ISO 11094:1991

Operating conditions during testU.K.

Mounting of equipment

If the wheels of the lawnmower could cause a compression of the artificial surface of more than 1 cm, the wheels shall be placed on supports so that they are level with the artificial surface before compression. If the cutting device cannot be separated from the driving wheels of the lawnmower, the mower shall be tested on supports with the cutting device operating at its maximum speed laid down by the manufacturer. The supports shall be made in such a way that they do not influence the measurement results.

Test free of load

ISO 11094:1991

Period of observation

ISO 11094:1991

Lawn trimmers/lawn edge trimmersU.K.

33. See No. 32

The trimmer shall be positioned by a suitable device in such a way that its cutting device is above the centre of the hemisphere. For lawn trimmers, the centre of the cutting device shall be held at a distance of about 50 mm above the surface. In order to accommodate the cutting blades, lawn edge trimmers should be positioned as close as possible to the test surface.

Leaf blowersU.K.

34.

Basic noise emission standardU.K.

EN ISO 3744:1995

Test area

ISO 11094:1991

In case of dispute, measurements shall be carried out in the open air on the artificial surface (point 4.1.2 of ISO 11094:1991).

Environmental correction K2A

Measurement in the open air

K2A = 0

Measurements indoors

The value of the constant K2A, determined without artificial surface and in accordance with Annex A to EN ISO 3744:1995, shall be≤ 2.0 dB in which case K2A shall be disregarded.

Measurement surface/number of microphone positions/measuring distance

ISO 11094:1991

Operating conditions during testU.K.

Mounting of equipment

The leaf blower shall be positioned in the natural manner for normal use in such a way that the outlet of its blowing device is situated (50±25) mm above the centre of the hemisphere; if the leaf blower is hand-held it shall be held either by a person or by a suitable device.

Test under load

The leaf blower shall be operated at its nominal speed and the nominal air flow stated by the manufacturer.

Period of observation

The period of observation shall at least be 15 seconds.