- Y Diweddaraf sydd Ar Gael (Diwygiedig)

- Gwreiddiol (Fel y’i mabwysiadwyd gan yr UE)

Commission Regulation (EEC) No 2568/91Dangos y teitl llawn

Commission Regulation (EEC) No 2568/91 of 11 July 1991 on the characteristics of olive oil and olive-residue oil and on the relevant methods of analysis

You are here:

- Rheoliadau yn deillio o’r UE

- 1991 No. 2568

- Annexes only

- Dangos Graddfa Ddaearyddol(e.e. Lloegr, Cymru, Yr Alban aca Gogledd Iwerddon)

- Dangos Llinell Amser Newidiadau

Rhagor o Adnoddau

PDF o Fersiynau Diwygiedig

- ddiwygiedig 20/10/20193.52 MB

- ddiwygiedig 04/12/20163.60 MB

- ddiwygiedig 11/10/20163.55 MB

- ddiwygiedig 04/08/20163.60 MB

- ddiwygiedig 16/10/20153.42 MB

- ddiwygiedig 01/01/20153.68 MB

- ddiwygiedig 01/03/20143.69 MB

- ddiwygiedig 01/01/20142.84 MB

- ddiwygiedig 09/08/20122.49 MB

- ddiwygiedig 01/04/20112.46 MB

- ddiwygiedig 01/10/20081.42 MB

- ddiwygiedig 01/01/20081.42 MB

- ddiwygiedig 01/11/20035.95 MB

- ddiwygiedig 22/05/20020.48 MB

- ddiwygiedig 01/11/20010.66 MB

- ddiwygiedig 01/07/20010.66 MB

- ddiwygiedig 01/06/19990.65 MB

- ddiwygiedig 01/11/19980.65 MB

- ddiwygiedig 10/02/19980.65 MB

- ddiwygiedig 31/10/19950.59 MB

- ddiwygiedig 28/05/19950.59 MB

- ddiwygiedig 01/11/19940.55 MB

- ddiwygiedig 19/02/19940.55 MB

- ddiwygiedig 05/02/19940.55 MB

- ddiwygiedig 01/05/19930.55 MB

- ddiwygiedig 21/03/19930.56 MB

- ddiwygiedig 20/02/19930.56 MB

- ddiwygiedig 01/11/19920.55 MB

- ddiwygiedig 21/07/19920.55 MB

- ddiwygiedig 03/07/19920.54 MB

- ddiwygiedig 05/06/19920.54 MB

- ddiwygiedig 21/12/19910.52 MB

- ddiwygiedig 06/09/19910.52 MB

Pan adawodd y DU yr UE, cyhoeddodd legislation.gov.uk ddeddfwriaeth yr UE a gyhoeddwyd gan yr UE hyd at ddiwrnod cwblhau’r cyfnod gweithredu (31 Rhagfyr 2020 11.00 p.m.). Ar legislation.gov.uk, mae'r eitemau hyn o ddeddfwriaeth yn cael eu diweddaru'n gyson ag unrhyw ddiwygiadau a wnaed gan y DU ers hynny.

Mae'r eitem hon o ddeddfwriaeth yn tarddu o'r UE

Mae legislation.gov.uk yn cyhoeddi fersiwn y DU. Mae EUR-Lex yn cyhoeddi fersiwn yr UE. Mae Archif Gwe Ymadael â’r UE yn rhoi cipolwg ar fersiwn EUR-Lex o ddiwrnod cwblhau’r cyfnod gweithredu (31 Rhagfyr 2020 11.00 p.m.).

Changes over time for: Commission Regulation (EEC) No 2568/91 (Annexes only)

Alternative versions:

- 01/01/2008- Amendment

- 01/10/2008- Amendment

- 01/04/2011- Amendment

- 01/01/2014- Amendment

- 01/03/2014- Amendment

- 16/10/2015- Amendment

- 04/08/2016- Amendment

- 11/10/2016- Amendment

- 04/12/2016- Amendment

- 20/10/2019- Amendment

- Exit day: start of implementation period31/01/2020 11pm- Amendment

- End of implementation period31/12/2020- Amendment

Changes to legislation:

There are outstanding changes by UK legislation not yet made to Commission Regulation (EEC) No 2568/91. Any changes that have already been made to the legislation appear in the content and are referenced with annotations.![]()

Changes to Legislation

Revised legislation carried on this site may not be fully up to date. Changes and effects are recorded by our editorial team in lists which can be found in the ‘Changes to Legislation’ area. Where those effects have yet to be applied to the text of the legislation by the editorial team they are also listed alongside the legislation in the affected provisions. Use the ‘more’ link to open the changes and effects relevant to the provision you are viewing.

Changes and effects yet to be applied to :

- Signature words omitted by S.I. 2019/1422 reg. 6(10)

- Art. 1(1)-(7) words substituted by S.I. 2019/1422 reg. 6(2)(a)

- Art. 1(8) inserted by S.I. 2019/1422 reg. 6(2)(b)

- Art. 1(8)(a)(ii)(bb) omitted in earlier amending provision S.I. 2019/1422, reg. 6(2)(b) by S.I. 2020/1453 reg. 14(16)(a)(i)

- Art. 1(8)(b) words substituted in earlier amending provision S.I. 2019/1422, reg. 6(2)(b) by S.I. 2020/1453 reg. 14(16)(a)(ii)

- Art. 1(8)(c)(ii) omitted in earlier amending provision S.I. 2019/1422, reg. 6(2)(b) by S.I. 2020/1453 reg. 14(16)(a)(iii)

- Annex 1a para. 1.1 words substituted by S.I. 2019/1422 reg. 6(11)(a)

- Annex 1a para. 1.2 words substituted by S.I. 2019/1422 reg. 6(11)(b)

- Art. 2(2) words omitted by S.I. 2019/1422 reg. 6(3)(a)(i)(aa)

- Art. 2(2) words substituted by S.I. 2019/1422 reg. 6(3)(a)(i)(bb)

- Art. 2(2) words substituted by S.I. 2019/1422 reg. 6(3)(a)(ii)

- Art. 2(2) words substituted by S.I. 2019/1422 reg. 6(3)(a)(iii)

- Art. 2(2) words substituted in earlier amending provision S.I. 2019/1422, reg. 6(3)(a)(i)(bb) by S.I. 2020/1453 reg. 14(16)(b)

- Art. 2(3) words substituted by S.I. 2019/1422 reg. 6(3)(b)(i)

- Art. 2(3) words substituted by S.I. 2019/1422 reg. 6(3)(b)(ii)

- Art. 2a(1) words substituted by S.I. 2019/1422, reg. 6(4)(a) (as substituted) by S.I. 2020/1453 reg. 14(16)(c)(i)

- Art. 2a(2) words substituted by S.I. 2019/1422 reg. 6(4)(b)

- Art. 2a(3)(e) words substituted by S.I. 2019/1422, reg. 6(4)(c) (as substituted) by S.I. 2020/1453 reg. 14(16)(c)(ii)

- Art. 2a(4) words substituted by S.I. 2019/1422 reg. 6(4)(d)(i)

- Art. 2a(4) words substituted by S.I. 2019/1422 reg. 6(4)(d)(ii)

- Art. 2a(4) words substituted in earlier amending provision S.I. 2019/1422, reg. 6(4)(d)(ii) by S.I. 2020/1453 reg. 14(16)(c)(iii)

- Art. 2a(5) words substituted by S.I. 2019/1422 reg. 6(4)(e)

- Art. 3 words substituted by S.I. 2019/1422 reg. 6(5)(a)

- Art. 3 words substituted by S.I. 2019/1422 reg. 6(5)(b)

- Art. 4 substituted by S.I. 2019/1422 reg. 6(6)

- Art. 4 words substituted in earlier amending provision S.I. 2019/1422, reg. 6(6) by S.I. 2020/1453 reg. 14(16)(d)(i)

- Art. 4 words substituted in earlier amending provision S.I. 2019/1422, reg. 6(6) by S.I. 2020/1453 reg. 14(16)(d)(ii)

- Art. 7 words substituted by S.I. 2019/1422 reg. 6(7)

- Art. 7a words omitted by S.I. 2019/1422 reg. 6(8)

- Art. 8 omitted by S.I. 2019/1422 reg. 6(9)

- Art. 10 omitted by S.I. 2019/1422 reg. 6(9)

Newidiadau ac effeithiau heb eu gweithredu eto ar yr eitem ddeddfwriaeth gyfan a’r darpariaethau cysylltiedig.

- Signature words omitted by S.I. 2019/1422 reg. 6(10)

- Art. 1(8) inserted by S.I. 2019/1422 reg. 6(2)(b)

- Art. 1(8)(a)(ii)(bb) omitted in earlier amending provision S.I. 2019/1422, reg. 6(2)(b) by S.I. 2020/1453 reg. 14(16)(a)(i)

- Art. 1(8)(b) words substituted in earlier amending provision S.I. 2019/1422, reg. 6(2)(b) by S.I. 2020/1453 reg. 14(16)(a)(ii)

- Art. 1(8)(c)(ii) omitted in earlier amending provision S.I. 2019/1422, reg. 6(2)(b) by S.I. 2020/1453 reg. 14(16)(a)(iii)

- Annex 1a para. 1.1 words substituted by S.I. 2019/1422 reg. 6(11)(a)

- Annex 1a para. 1.2 words substituted by S.I. 2019/1422 reg. 6(11)(b)

- Art. 2a(3)(e) words substituted by S.I. 2019/1422, reg. 6(4)(c) (as substituted) by S.I. 2020/1453 reg. 14(16)(c)(ii)

- Art. 3 words substituted by S.I. 2019/1422 reg. 6(5)(a)

- Art. 3 words substituted by S.I. 2019/1422 reg. 6(5)(b)

[F1ANNEXES U.K. SUMMARY]

Textual Amendments

[F1ANNEX I U.K. OLIVE OIL CHARACTERISTICS

Quality characteristics U.K.

| a The median of defect may be less than or equal to 3,5 when the fruity median is equal to 0,0. | ||||||||

| Category | Acidity (%) (*) | Peroxide value (mEq O 2 /kg) | K 232 | K 268 or K 270 | Delta-K | Organoleptic evaluation | Fatty acid ethyl esters (mg/kg) | |

|---|---|---|---|---|---|---|---|---|

| Median of defect (Md) (*) | Fruity median (Mf) | |||||||

1. Extra virgin olive oil | ≤ 0,80 | ≤ 20,0 | ≤ 2,50 | ≤ 0,22 | ≤ 0,01 | Md = 0,0 | Mf > 0,0 | ≤ 35 |

2. Virgin olive oil | ≤ 2,0 | ≤ 20,0 | ≤ 2,60 | ≤ 0,25 | ≤ 0,01 | Md ≤ 3,5 | Mf > 0,0 | — |

3. Lampante olive oil | > 2,0 | — | — | — | — | Md > 3,5 a | — | — |

4. Refined olive oil | ≤ 0,30 | ≤ 5,0 | — | ≤ 1,25 | ≤ 0,16 | — | — | |

5. Olive oil composed of refined olive oil and virgin olive oils | ≤ 1,00 | ≤ 15,0 | — | ≤ 1,15 | ≤ 0,15 | — | — | |

6. Crude olive-pomace oil | — | — | — | — | — | — | — | |

7. Refined olive-pomace oil | ≤ 0,30 | ≤ 5,0 | — | ≤ 2,00 | ≤ 0,20 | — | — | |

8. Olive-pomace oil | ≤ 1,00 | ≤ 15,0 | — | ≤ 1,70 | ≤ 0,18 | — | — | |

Purity characteristics U.K.

| a Other fatty acids content (%): palmitic: 7,50-20,00; palmitoleic: 0,30-3,50; heptadecanoic: ≤ 0,40; heptadecenoic ≤ 0,60; stearic: 0,50-5,00; oleic: 55,00- 83,00; linoleic: 2,50-21,00. | |||||||||||

| b Total isomers which could (or could not) be separated by capillary column. | |||||||||||

| Category | Fatty acid composition a | Total transoleic isomers (%) | Total trans- linoleic + translinolenic isomers (%) | Stigmasta- dienes (mg/kg) b | Difference: ECN42 (HPLC) and ECN42 (theoretical calculation) | 2-glyceryl monopalmitate (%) | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Myristic (%) | Linolenic (%) | Arachidic (%) | Eicosenoic (%) | Behenic (%) | Lignoceric (%) | ||||||

1. Extra virgin olive oil | ≤ 0,03 | ≤ 1,00 | ≤ 0,60 | ≤ 0,50 | ≤ 0,20 | ≤ 0,20 | ≤ 0,05 | ≤ 0,05 | ≤ 0,05 | ≤ |0,20| | ≤ 0,9 if total palmitic acid % ≤ 14,00 % |

| ≤ 1,0 if total palmitic acid % > 14,00 % | |||||||||||

2. Virgin olive oil | ≤ 0,03 | ≤ 1,00 | ≤ 0,60 | ≤ 0,50 | ≤ 0,20 | ≤ 0,20 | ≤ 0,05 | ≤ 0,05 | ≤ 0,05 | ≤ |0,20| | ≤ 0,9 if total palmitic acid % ≤ 14,00 % |

| ≤ 1,0 if total palmitic acid % > 14,00 % | |||||||||||

3. Lampante olive oil | ≤ 0,03 | ≤ 1,00 | ≤ 0,60 | ≤ 0,50 | ≤ 0,20 | ≤ 0,20 | ≤ 0,10 | ≤ 0,10 | ≤ 0,50 | ≤ |0,30| | ≤ 0,9 if total palmitic acid % ≤ 14,00 % |

| ≤ 1,1 if total palmitic acid % > 14,00 % | |||||||||||

4. Refined olive oil | ≤ 0,03 | ≤ 1,00 | ≤ 0,60 | ≤ 0,50 | ≤ 0,20 | ≤ 0,20 | ≤ 0,20 | ≤ 0,30 | — | ≤|0,30| | ≤ 0,9 if total palmitic acid % ≤ 14,00 % |

| ≤ 1,1 if total palmitic acid % > 14,00 % | |||||||||||

5. Olive oil composed of refined olive oil and virgin olive oils | ≤ 0,03 | ≤ 1,00 | ≤ 0,60 | ≤ 0,50 | ≤ 0,20 | ≤ 0,20 | ≤ 0,20 | ≤ 0,30 | — | ≤ |0,30| | ≤ 0,9 if total palmitic acid % ≤ 14,00 % |

| ≤ 1,0 if total palmitic acid % > 14,00 % | |||||||||||

6. Crude olive-pomace oil | ≤ 0,03 | ≤ 1,00 | ≤ 0,60 | ≤ 0,50 | ≤ 0,30 | ≤ 0,20 | ≤ 0,20 | ≤ 0,10 | — | ≤ |0,60| | ≤ 1,4 |

7. Refined olive-pomace oil | ≤ 0,03 | ≤ 1,00 | ≤ 0,60 | ≤ 0,50 | ≤ 0,30 | ≤ 0,20 | ≤ 0,40 | ≤ 0,35 | — | ≤ |0,50| | ≤ 1,4 |

8. Olive-pomace oil | ≤ 0,03 | ≤ 1,00 | ≤ 0,60 | ≤ 0,50 | ≤ 0,30 | ≤ 0,20 | ≤ 0,40 | ≤ 0,35 | — | ≤ |0,50| | ≤ 1,2 |

| a See the Appendix to this Annex. | |||||||||

| b App β-sitosterol: Delta-5,23-stigmastadienol+clerosterol+beta-sitosterol+sitostanol+delta-5-avenasterol+delta-5,24-stigmastadienol. | |||||||||

| c Oils with a wax content of between 300 mg/kg and 350 mg/kg are considered to be lampante olive oil if the total aliphatic alcohol content is less than or equal to 350 mg/kg or if the erythrodiol and uvaol content is less than or equal to 3,5 %. | |||||||||

| d Oils with a wax content of between 300 mg/kg and 350 mg/kg are considered to be crude olive-pomace oil if the total aliphatic alcohol content is above 350 mg/kg and if the erythrodiol and uvaol content is greater than 3,5 %. | |||||||||

| Category | Sterols composition | Total sterols (mg/kg) | Erythrodiol and uvaol (%) (**) | Waxes (mg/kg) (**) | |||||

|---|---|---|---|---|---|---|---|---|---|

| Cholesterol (%) | Brassicasterol (%) | Campesterol a (%) | Stigmasterol (%) | App β–sitosterol b (%) | Delta-7-stigmastenol a (%) | ||||

1. Extra virgin olive oil | ≤ 0,5 | ≤ 0,1 | ≤ 4,0 | < Camp. | ≥ 93,0 | ≤ 0,5 | ≥ 1 000 | ≤ 4,5 | C 42 + C 44 + C 46 ≤ 150 |

2. Virgin olive oil | ≤ 0,5 | ≤ 0,1 | ≤ 4,0 | < Camp. | ≥ 93,0 | ≤ 0,5 | ≥ 1 000 | ≤ 4,5 | C 42 + C 44 + C 46 ≤ 150 |

3. Lampante olive oil | ≤ 0,5 | ≤ 0,1 | ≤ 4,0 | — | ≥ 93,0 | ≤ 0,5 | ≥ 1 000 | ≤ 4,5 c | C 40 + C 42 + C 44 + C 46 ≤ 300 c |

4. Refined olive oil | ≤ 0,5 | ≤ 0,1 | ≤ 4,0 | < Camp. | ≥ 93,0 | ≤ 0,5 | ≥ 1 000 | ≤ 4,5 | C 40 + C 42 + C 44 + C 46 ≤ 350 |

5. Olive oil composed of refined olive oil and virgin olive oils | ≤ 0,5 | ≤ 0,1 | ≤ 4,0 | < Camp. | ≥ 93,0 | ≤ 0,5 | ≥ 1 000 | ≤ 4,5 | C 40 + C 42 + C 44 + C 46 ≤ 350 |

6. Crude olive-pomace oil | ≤ 0,5 | ≤ 0,2 | ≤ 4,0 | — | ≥ 93,0 | ≤ 0,5 | ≥ 2 500 | > 4,5 d | C 40 + C 42 + C 44 + C 46 > 350 d |

7. Refined olive-pomace oil | ≤ 0,5 | ≤ 0,2 | ≤ 4,0 | < Camp. | ≥ 93,0 | ≤ 0,5 | ≥ 1 800 | > 4,5 | C 40 + C 42 + C 44 + C 46 > 350 |

8. Olive-pomace oil | ≤ 0,5 | ≤ 0,2 | ≤ 4,0 | < Camp. | ≥ 93,0 | ≤ 0,5 | ≥ 1 600 | > 4,5 | C 40 + C 42 + C 44 + C 46 > 350 |

Notes: U.K.

(a) The results of the analyses must be expressed to the same number of decimal places as used for each characteristic. The last digit must be increased by one unit if the following digit is greater than 4. U.K.

(b) If just a single characteristic does not match the values stated, the category of an oil can be changed or the oil is declared non-compliant for the purposes of this Regulation. U.K.

(c) For lampante olive oil, both quality characteristics marked with an asterisk (*) may differ simultaneously from the limits established for that category. U.K.

(d) If a characteristic is marked with two asterisks (**), this means that for crude olive-pomace oil, it is possible for both the relevant limits to be different from the stated values at the same time. For olive-pomace oil and refined olive-pomace oil one of the relevant limits may be different from the stated values. U.K.

Appendix

Decision trees U.K.

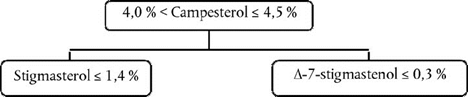

Campesterol decision tree for virgin and extra virgin olive oils:

The other parameters shall comply with the limits fixed in this Regulation.

Delta-7-stigmastenol decision tree for:

The other parameters shall comply with the limits fixed in this Regulation.

The other parameters shall comply with the limits fixed in this Regulation.]

[F2ANNEX Ia U.K. SAMPLING OF OLIVE OIL OR OLIVE-POMACE OIL DELIVERED IN IMMEDIATE PACKAGING

Textual Amendments

This method of sampling is applied to batches of olive oil or olive-pomace oil put up in immediate packaging. Different sampling methods apply, depending on whether the immediate packaging exceeds 5 litres or not.

‘Batch’ shall mean a set of sales units which are produced, manufactured and packed in circumstances such that the oil contained in each sales unit is considered to be homogenous in terms of all analytical characteristics. The individuation of a batch must be done in accordance with Directive 2011/91/EU of the European Parliament and of the Council (1) .

‘ Increment ’ shall mean the quantity of oil contained in an immediate package and taken from a random point of the batch.

1. CONTENT OF PRIMARY SAMPLE U.K.

1.1. Immediate packaging not exceeding 5 litres U.K.

‘ Primary Sample ’ for immediate packaging not exceeding 5 litres shall mean the number of increments taken from a batch and in agreement with Table 1.

Table 1

Primary sample minimum size must comprise the following

The number of packs referred to in Table 1, which shall constitute a primary sample, can be increased by each Member State, according to their own needs (for example organoleptic assessment by a different laboratory from that which performed the chemical analyses, counter-analysis, etc.).

1.2. Immediate packaging exceeding 5 litres U.K.

‘ Primary Sample ’ for immediate packaging exceeding 5 litres shall mean a representative part of the total increments, obtained by a process of reduction and in agreement with Table 2. The primary sample must be composed of various examples.

‘ Example ’ of a primary sample shall mean each of the packages making up the primary sample.

Table 2

Minimum number of increments to be selected

| Number of packages in the lot | Minimum number of increments to be selected |

|---|---|

| Up to 10 | 1 |

| From … 11 to 150 | 2 |

| From … 151 to 500 | 3 |

| From … 501 to 1 500 | 4 |

| From … 1 501 to 2 500 | 5 |

| > 2 500 per 1 000 packages | 1 extra increment |

In order to reduce the volume of the sampling immediate packs, the content of the sampling increments is homogenised for the preparation of the primary sample. The portions of the different increments are poured into a common container for homogenisation by stirring, so that it will be best protected from air.

The content of the primary sample must be poured into a series of packages of the minimum capacity of 1,0 liter, each one of which constitutes an example of the primary sample.

The number of primary samples can be increased by each Member State, according to their own necessity (for example organoleptic assessment by a different laboratory from the one that performed the chemical analyses, counter-analysis, etc).

Each package must be filled in a way to minimise the air layer on top and then suitably closed and sealed to ensure the product is tamper-proof.

These examples must be labeled to ensure correct identification.

2. ANALYSES AND RESULTS U.K.

[F12.1. Each primary sample must be subdivided into laboratory samples, in accordance with point 2.5 of standard EN ISO 5555, and analysed according to the order shown in the flowchart set out in Annex Ib or in any other random order.] U.K.

2.2. Where all the results of the analyses comply with the characteristics of the category of oil declared, the whole batch is to be declared to comply. U.K.

If a single result of the analyses does not comply with the characteristics of the category of oil declared, the whole batch is to be declared non compliant.

3. VERIFICATION OF THE CATEGORY OF BATCH U.K.

3.1. In order to verify the batch category, the competent authority may increase the number of primary samples taken at different points of the batch according to the following table: U.K.

| Table 3 | |

| Number of primary samples determined by the size of batch | |

| Size of batch (litres) | Number of primary samples |

|---|---|

| Less than 7 500 | 2 |

| From 7 500 to less than 25 000 | 3 |

| From 25 000 to less than 75 000 | 4 |

| From 75 000 to less than 125 000 | 5 |

| Equal to and more than 125 000 | 6 + 1 each 50 000 litres more |

Each increment constituting a primary sample must be taken from a continuous place in the batch; it is necessary to take note of the location of each primary sample and to identify it unambiguously.

The formation of each primary sample must be carried out according to the procedures referred to in points 1.1 and 1.2.

Each primary sample is then subjected to the analyses referred to in Article 2(1).

3.2. When one of the results of the analyses referred to in Article 2(1) of at least one primary sample does not comply with the characteristics of the declared category of oil, the whole sampling batch shall be declared non compliant.] U.K.

[F1ANNEX Ib U.K. FLOW-CHART FOR VERIFYING WHETHER AN OLIVE OIL SAMPLE IS CONSISTENT WITH THE CATEGORY DECLARED

General table U.K.

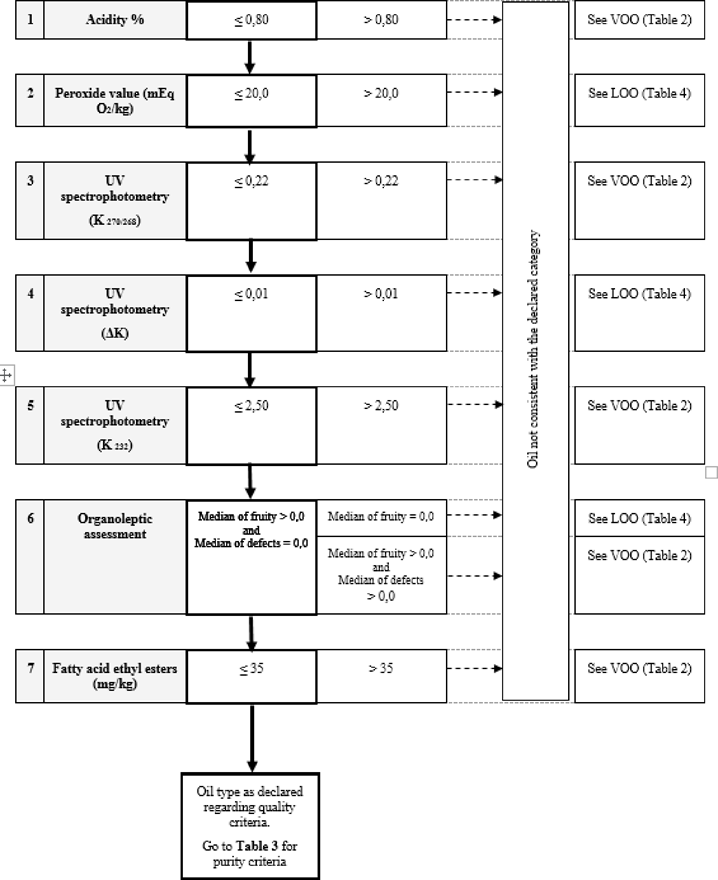

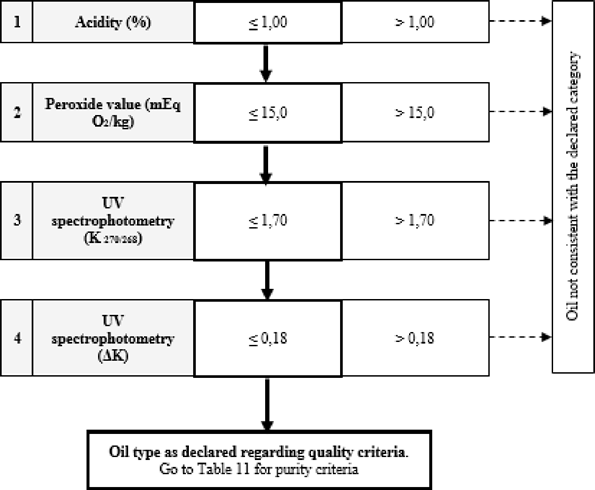

Table 1 — Extra Virgin Olive Oil — Quality criteria U.K.

Table 2 — Virgin Olive Oil — Quality criteria U.K.

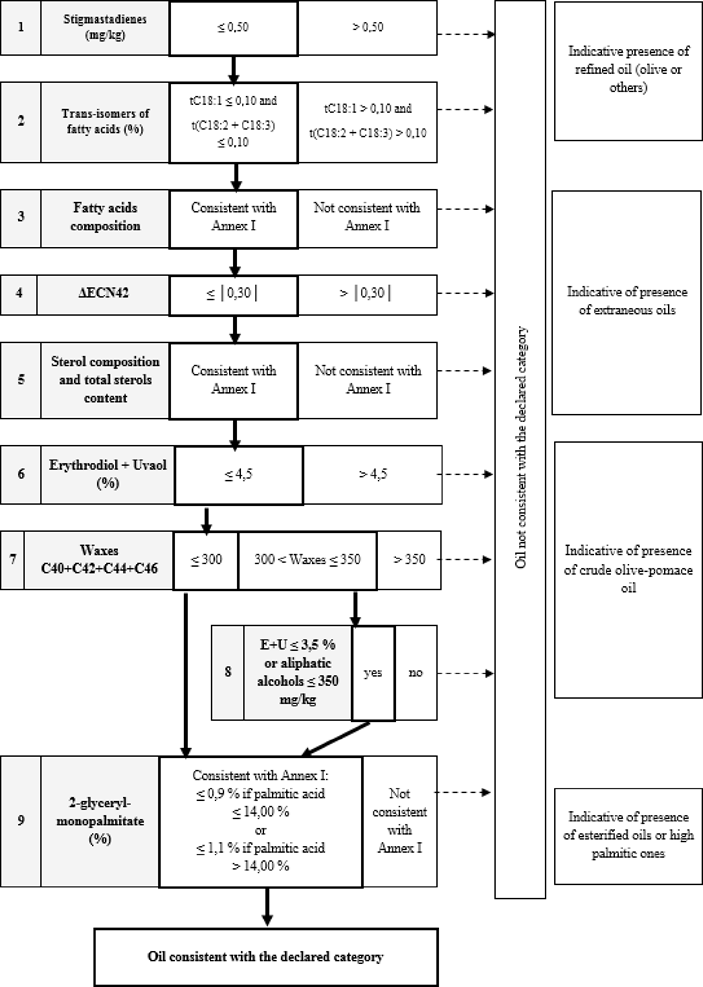

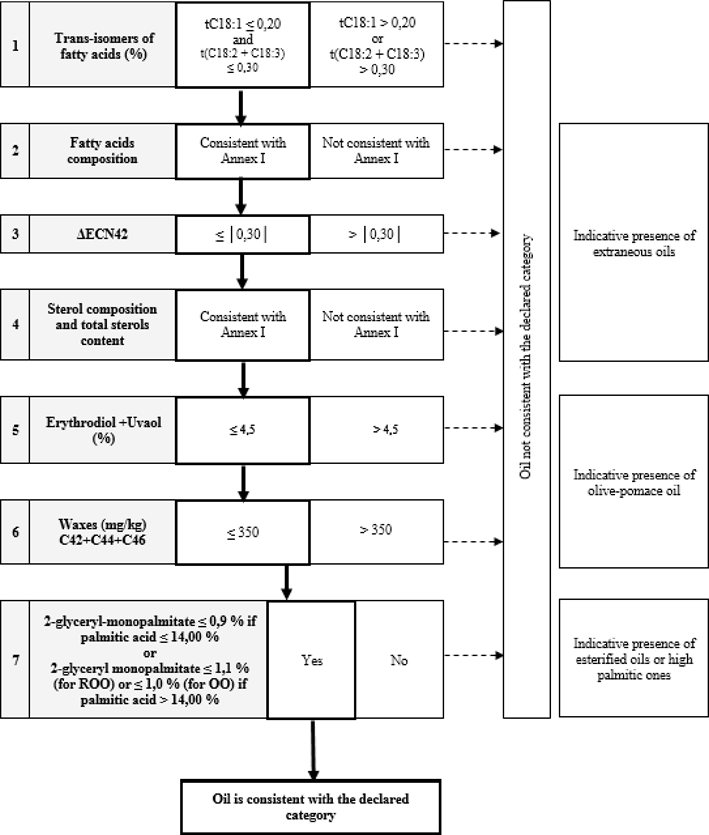

Table 3 — Extra Virgin Olive Oil and Virgin Olive Oil — Purity criteria U.K.

Table 4 — Lampante Olive Oil — Purity criteria U.K.

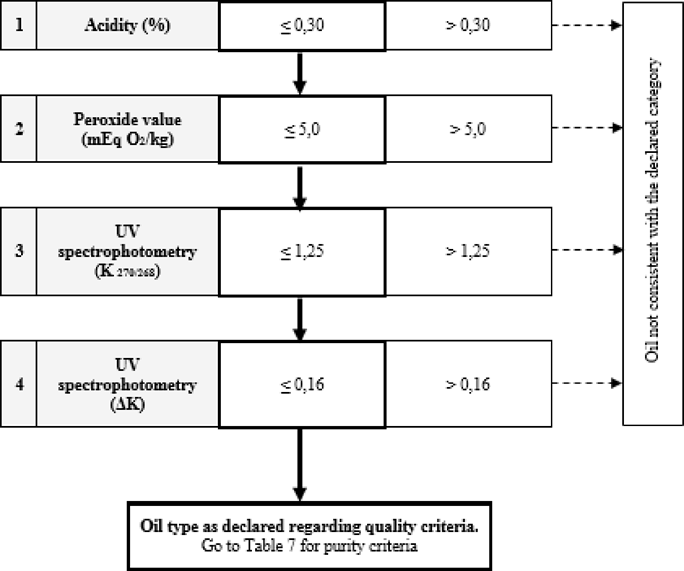

Table 5 — Refined Olive Oil — Quality criteria U.K.

Table 6 — Olive Oil (composed of refined olive oil and virgin olive oils) — Quality criteria U.K.

Table 7 — Refined Olive Oil and olive oil composed of refined olive oil and Virgin Olive Oils — Purity criteria U.K.

Table 8 — Crude Olive-Pomace Oil — Purity criteria U.K.

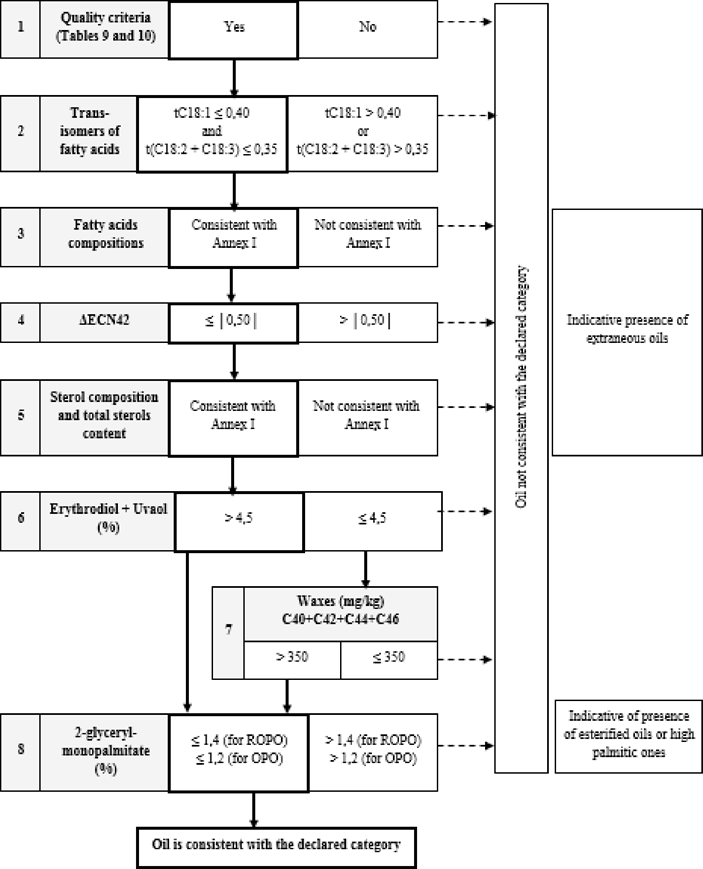

Table 9 — Refined Olive-Pomace Oil — Quality criteria U.K.

Table 10 — Olive Pomace Oil — Quality criteria U.K.

Table 11 — Refined Olive-Pomace Oil and Olive-Pomace Oil — Purity criteria U.K.

[F3ANNEX II U.K. DETERMINATION OF FREE FATTY ACIDS, COLD METHOD

Textual Amendments

1. SCOPE AND FIELD OF APPLICATION U.K.

This method describes the determination of free fatty acids in olive oils and olive pomace oils. The content of free fatty acids is expressed as acidity calculated as the percentage of oleic acid.

2. PRINCIPLE U.K.

A sample is dissolved in a mixture of solvents and the free fatty acids present titrated using a potassium hydroxide or sodium hydroxide solution.

3. REAGENTS U.K.

All the reagents should be of recognized analytical quality and the water used either distilled or of equivalent purity.

3.1 Diethyl ether; 95 % ethanol (v/v), mixture of equal parts by volume. U.K.

Neutralize precisely at the moment of use with the potassium hydroxide solution (3.2), with the addition of 0,3 ml of the phenolphthalein solution (3.3) per 100 ml of mixture.

Note 1: Diethyl ether is highly inflammable and may form explosive peroxides. Special care should be taken in its use. U.K.

Note 2: If it is not possible to use diethyl ether, a mixture of solvents containing ethanol and toluene may be used. If necessary, ethanol may be replaced by propanol-2. U.K.

3.2 Potassium hydroxide or sodium hydroxide, titrated ethanolic or aqueous solution, c(KOH) [or c(NaOH)] about 0,1 mol/l or, if necessary, c(KOH) [or c(NaOH)] about 0,5 mol/l. Commercial solutions are available. U.K.

The exact concentration of potassium hydroxide solution (or sodium hydroxide solution) must be known and checked prior to use. Use a solution prepared at least five days before use and decanted into a brown glass bottle with a rubber stopper. The solution should be colourless or straw coloured.

If phase separation is observed when using aqueous solution of potassium hydroxide (or sodium hydroxide), replace the aqueous solution by an ethanolic solution.

Note 3: A stable colourless solution of potassium hydroxide (or sodium hydroxide) may be prepared as follows. Bring to the boil 1 000 ml of ethanol or water with 8 g of potassium hydroxide (or sodium hydroxide) and 0,5 g of aluminium shavings and continue boiling under reflux for one hour. Distil immediately. Dissolve in the distillate the required quantity of potassium hydroxide (or sodium hydroxide). Leave for several days and decant the clear supernatant liquid from the precipitate of potassium carbonate (or sodium carbonate). U.K.

The solution may also be prepared without distillation as follows: to 1 000 ml of ethanol (or water) add 4 ml of aluminium butylate and leave the mixture for several days. Decant the supernatant liquid and dissolve the required quantity of potassium hydroxide (or sodium hydroxide). The solution is ready for use.

3.3 Phenolphthalein, 10 g/l solution in 95 to 96 % ethanol (v/v) or alkali blue 6B or thymolphthalein, 20 g/l solution in 95 to 96 % ethanol (v/v). In the case of strongly coloured oils, alkali blue or thymolphthalein shall be used. U.K.

4. APPARATUS U.K.

Usual laboratory equipment including:

Analytical balance;

250 ml conical flask;

10 ml burette class A, graduated in 0,05 ml, or equivalent automatic burette.

5. PROCEDURE U.K.

5.1 Preparation of the test sample U.K.

When the sample is cloudy, it should be filtered.

5.2 Test portion U.K.

Take a sample depending on the presumed acidity in accordance with the following table:

| Expected acidity (oleic acidity g/100 g) | Mass of sample (g) | Weighing accuracy (g) |

|---|---|---|

| 0 to 2 | 10 | 0,02 |

| > 2 to 7,5 | 2,5 | 0,01 |

| > 7,5 | 0,5 | 0,001 |

Weigh the sample in the conical flask (4.2).

5.3 Determination U.K.

Dissolve the sample (5.2) in 50 to 100 ml of the previously neutralized mixture of diethyl ether and ethanol (3.1).

Titrate while stirring with the 0,1 mol/l solution of potassium hydroxide (or sodium hydroxide) (3.2) (see Note 4) until the indicator changes (the colour of the coloured indicator persists for at least 10 seconds).

Note 4: If the quantity of 0,1 mol/l potassium hydroxide (or sodium hydroxide) solution required exceeds 10 ml, use the 0,5 mol/l solution or change the sample mass according to the expected free acidity and the proposed table. U.K.

Note 5: If the solution becomes cloudy during titration, add enough of the solvents (3.1) to give a clear solution. U.K.

Carry out a second determination only if the first result is higher than the specified limit for the category of the oil.

6. EXPRESSION OF RESULTS U.K.

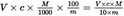

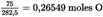

Acidity as a percentage of oleic acid by weight is equal to:

where:

=

the volume of titrated potassium hydroxide solution (or sodium hydroxide) used, in millilitres;

=

the exact concentration in moles per litre of the titrated solution of potassium hydroxide (or sodium hydroxide) used;

=

282 g/mol, the molar mass in grams per mole of oleic acid;

=

the mass of the sample, in grams.

Oleic acidity is reported as follows:

to two decimal places for values from 0 up to and including 1;

to one decimal place for values from 1 up to and including 100.]

[F4ANNEX III U.K. DETERMINATION OF PEROXIDE VALUE

Textual Amendments

1. Scope U.K.

This Annex describes a method for the determination of the peroxide value of animal and vegetable oils and fats.

2. Definition U.K.

The peroxide value is the quantity of those substances in the sample, expressed in terms of milliequivalents of active oxygen per kilogram, which oxidise potassium iodide under the operating conditions described.

3. Principle U.K.

Treatment of the test portion, in solution in acetic acid and chloroform, by a solution of potassium iodide. Titration of the liberated iodine with standardised sodium thiosulphate solution.

4. Apparatus U.K.

All the equipment used must be free from reducing or oxidising substances.

Note 1: Do not grease ground surfaces. U.K.

4.1. 3 ml glass scoop. U.K.

4.2. Flasks, with ground necks and stoppers, of about 250 ml capacity, dried beforehand and filled with a pure, dry inert gas (nitrogen or, preferably, carbon dioxide). U.K.

4.3. Burette of 5-ml, 10-ml or 25-ml capacity, graduated in at least 0,05 ml, preferably with automatic zero adjustment, or equivalent automatic burette. U.K.

4.4. Analytical balance. U.K.

5. Reagents U.K.

5.1. Chloroform, analytical reagent quality, freed from oxygen by bubbling a current of pure, dry inert gas through it. U.K.

5.2. Glacial acetic acid, analytical reagent quality, freed from oxygen by bubbling a current of pure, dry inert gas through it. U.K.

5.3. Potassium iodide, saturated aqueous solution, recently prepared, free from iodine and iodates. Dissolve approximately 14 g of potassium iodide in approximately 10 ml of water at room temperature. U.K.

5.4. Sodium thiosulphate, 0,01 mol/l (equivalent to 0,01 N) accurately standardised aqueous solution, standardised just before use. U.K.

Prepare daily the 0,01 mol/l sodium thiosulfate solution freshly from a 0,1 mol/l sodium thiosulfate standard solution before use, or determine the exact molarity. As experience shows, the stability is limited and depends upon the pH value and the content of free carbon dioxide. Use only freshly boiled water for the dilution, possibly purged with nitrogen.

The following procedure is recommended to determine the exact molarity of the sodium thiosulfate solution:

Weigh, to the nearest 0,001 g, 0,27 g to 0,33 g of potassium iodate (m KIO3 ) into a volumetric flask (250 ml or 500 ml) and dilute to the mark with freshly boiled water (V 2 ), cooled down to room temperature. By means of a pipette, transfer 5 ml or 10 ml of this potassium iodate solution (V 1 ) into a 250 ml Erlenmeyer flask. Add 60 ml of freshly boiled water, 5 ml of 4 mol/l hydrochloric acid, and 25 mg to 50 mg of potassium iodide or 0,5 ml of the saturated potassium iodide solution. Titrate this solution with the sodium thiosulfate solution (V 3 ) to determine the exact molarity of the sodium thiosulfate solution.

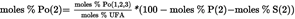

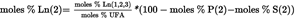

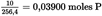

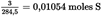

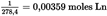

Where

m KIO3 is the mass of potassium iodate, in grams

V 1 is the volume of the potassium iodate solution, in millilitres (5 ml or 10 ml)

V 2 is the total volume of potassium iodate solution, in millilitres (250 ml or 500 ml)

V 3 is the volume of the sodium thiosulfate solution, in millilitres

w KIO3 is the purity of potassium iodate in g/100 g

M KIO3 is the molecular mass of potassium iodate (214 g/mol)

T is the exact molarity of the sodium thiosulphate solution (mol/l).

5.5. Starch solution, 10 g/l aqueous dispersion, recently prepared from natural soluble starch. Equivalent reagents may also be used. U.K.

6. Sample U.K.

Take care that the sample is taken and stored away from the light, kept cold and contained in completely filled glass containers, hermetically sealed with ground-glass or cork stoppers.

7. Procedure U.K.

The test must be carried out in diffuse daylight or in artificial light. Weigh in a glass scoop (4.1) or, failing this, in a flask (4.2), to the nearest 0,001 g, a mass of the sample in accordance with the following table, according to the expected peroxide value:

| Expected peroxide value (meq) | Weight of test portion (g) |

|---|---|

| 0 to 12 | 5,0 to 2,0 |

| 12 to 20 | 2,0 to 1,2 |

| 20 to 30 | 1,2 to 0,8 |

| 30 to 50 | 0,8 to 0,5 |

| 50 to 90 | 0,5 to 0,3 |

Unstopper a flask (4.2) and introduce the glass scoop containing the test portion. Add 10 ml of chloroform (5.1). Dissolve the test portion rapidly by stirring. Add 15 ml of acetic acid (5.2), then 1 ml of potassium iodide solution (5.3). Insert the stopper quickly, shake for one minute, and leave for exactly five minutes away from the light at a temperature from 15 to 25 °C.

Add about 75 ml of distilled water. Titrate the liberated iodine with the sodium thiosulphate solution (5.4) shaking vigorously, using starch solution (5.5) as indicator.

Carry out two determinations on the same test sample.

Carry out simultaneously a blank test. If the result of the blank exceeds 0,05 ml of the 0,01 N sodium thiosulfate solution (5.4), replace the impure reagents.

8. Expression of results U.K.

The peroxide value (PV), expressed in milliequivalents of active oxygen per kilogram, is given by the formula:

where:

=

the number of ml of the standardised sodium thiosulphate solution (5.4) used for the test, corrected to take into account the blank test.

=

the exact molarity of the sodium thiosulphate solution (5.4) used, in mol/l.

=

the weight in g, of the test portion.

Take as the result the arithmetic mean of the two determinations carried out.

Report the result of the determination to one decimal place.]

[F5ANNEX IV U.K. DETERMINATION OF WAX CONTENT BY CAPILLARY COLUMN GAS CHROMATOGRAPHY

Textual Amendments

1. SUBJECT U.K.

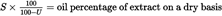

This method describes a process for determining the wax content of olive oils. Waxes are separated according to the number of their carbon atoms. The method may be used in particular to distinguish between olive oil obtained by pressing and that obtained by extraction (olive-residue oil).

2. PRINCIPLE U.K.

Addition of a suitable internal standard to the fat or oil, then fractionation by chromatography on a hydrated silica gel column. Recovery under the test conditions of the fraction eluted first (the polarity of which is less than that of the triglycerides), then direct analysis by capillary column gas chromatography.

3. EQUIPMENT U.K.

3.1. 25 ml Erlenmeyer flask. U.K.

3.2. Glass column for gas chromatography, internal diameter 15,0 mm, length 30 to 40 cm, fitted with a stopcock. U.K.

3.3. Suitable gas chromatograph with a capillary column, equipped with a system for direct introduction into the column comprising the following: U.K.

3.3.1. Thermostatic chamber for the columns, equipped with a temperature programmer. U.K.

3.3.2. Cold injector for direct introduction into the column. U.K.

3.3.3. Flame ionisation detector and converter-amplifier. U.K.

3.3.4. Recorder-integrator capable of working with the converter-amplifier (3.3.3), rate of response no slower than 1 second, with variable paper speed. (It is also possible to use computerised systems that allow the acquisition of gas chromatography data via a PC.) U.K.

3.3.5. Glass or fused silica capillary column 8 to 12 m long and with an internal diameter of 0,25 to 0,32 mm, with liquid phase, with a uniform film thickness between 0,10 and 0,30 μm. (There are liquid phases suitable for the purpose of type SE-52 or SE-54 available on the market.) U.K.

3.4. 10 μl microsyringe for on-column injection, equipped with a hardened needle. U.K.

3.5. Electrovibrator. U.K.

3.6. Rotary evaporator. U.K.

3.7. Muffle furnace. U.K.

3.8. Analytical balance with guaranteed precision of ± 0,1 mg. U.K.

3.9. Normal laboratory glassware. U.K.

4. REAGENTS U.K.

4.1. Silica gel with a granule size of between 60 and 200 μm. U.K.

Place the gel in the furnace at 500 °C for at least four hours. After cooling, add 2 % water in relation to the quantity of sampled silica gel. Shake well to homogenise the slurry. Keep in darkness for at least 12 hours prior to use.

4.2. n-hexane, for chromatography. U.K.

4.3. Ethyl ether, for chromatography. U.K.

4.4. n-heptane, for chromatography. U.K.

4.5. Standard solution of lauryl arachidate, at 0,1 % (m/v) in hexane (internal standard). (It is also possible to use palmityl palmitate or myristyl stearate.) U.K.

4.5.1. Sudan 1 (1-phenyl-azo-2-naphthol). U.K.

4.6. Carrier gas: hydrogen or helium, gas-chromatographic purity. U.K.

4.7. Auxiliary gases: U.K.

pure hydrogen for gas chromatography,

pure air for gas chromatography.

5. PROCEDURE U.K.

5.1. Preparation of the chromatographic column. U.K.

Suspend 15 g of silica gel (4.1) in the n-hexane (4.2) and introduce it into the column (3.2). Allow to settle spontaneously. Complete settling with the aid of an electrovibrator (3.5) to make the chromatographic layer more homogeneous. Percolate 30 ml of n-hexane to remove any impurities. Using the balance (3.8) weigh exactly 500 mg of the sample into the 25 ml Erlenmeyer flask (3.1), add the appropriate quantity of the internal standard (4.5) according to the presumed wax content. For example, add 0,1 mg of lauryl arachidate for olive oil, and 0,25 to 0,5 mg for olive-residue oil. Transfer the prepared sample to the chromotography column using two 2 ml portions of n-hexane (4.2).

Allow the solvent to flow away until it reaches 1 mm above the upper level of the absorbant then percolate a further 70 ml of n-hexane in order to eliminate the n-alkanes naturally present. Then start the chromatographic elution by collecting 180 ml of the mixture of n-hexane/ethyl ether (ratio 99:1), keeping a rate of flow of approximately 15 drops every 10 seconds. Elution of the sample must be carried out at a room temperature of 22 ± 4 °C.

NB: U.K.

The n-hexane/ethyl ether mixture (99:1) must be prepared every day.

For a visual check on the correct elution of the waxes 100 μl of 1 % Sudan in the elution mixture can be added to the sample in solution. Since the colourant has an intermediate retention, between waxes and triglycerides, when the coloration has reached the bottom of the column the elution should be suspended because all the waxes will have been eluted.

Dry the fraction thus obtained in a rotary evaporator (3.6.) until virtually all the solvent has been eliminated. Eliminate the final 2 ml of solvent with the aid of a weak current of nitrogen; then add 2-4 ml n-heptane.

5.2. Analysis by gas chromatography U.K.

5.2.1. Preparatory work U.K.

Fit the column to the gas chromatograph (3.3) by connecting the inlet port to the on-column system and the outlet port to the detector. Perform a general check on the GC apparatus (operation of gas circuits, detector and recorder efficiency, etc.).

If the column is being used for the first time it should be conditioned first. Pass a little gas through the column, then turn on the GC apparatus. Heat gradually until 350 °C is reached after about four hours. Maintain that temperature for at least two hours then regulate the apparatus to operating conditions (set gas flow, light flame, connect to the electronic recorder (3.3.4), set temperature of column chamber, detector, etc.) and record the signal at a sensitivity at least twice as high as that required for the analysis. The baseline must be linear, with no peaks of any kind, and must not show any deviation.

A negative straight-line drift indicates that the column connections are not tight; a positive drift that the column has not been sufficiently conditioned.

5.2.2. Choice of operating conditions U.K.

The operating conditions are generally as follows:

column temperature:

20 °C/minute 5 °C/minute 20 °C/minute Initially 80 °C

(1′)

→ 240 °C → 325 °C

(6′)

→ 340 °C

(10′)

detector temperature: 350 °C;

quantity of substance injected: 1 μl of the n-heptane solution (2-4 ml);

carrier gas: helium or hydrogen at the correct linear velocity for the gas selected (see Appendix);

instrument sensitivity: suitable for the following conditions:

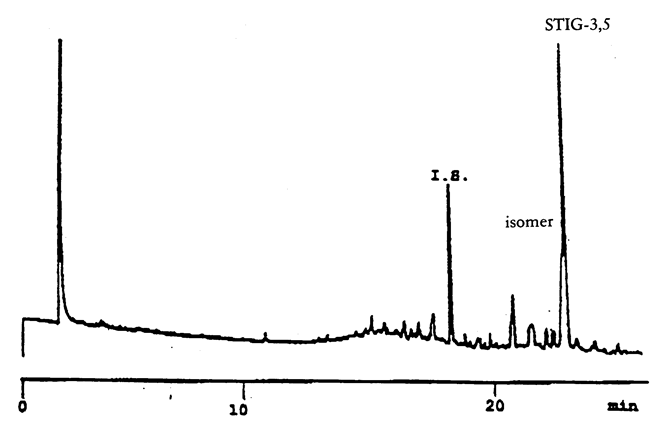

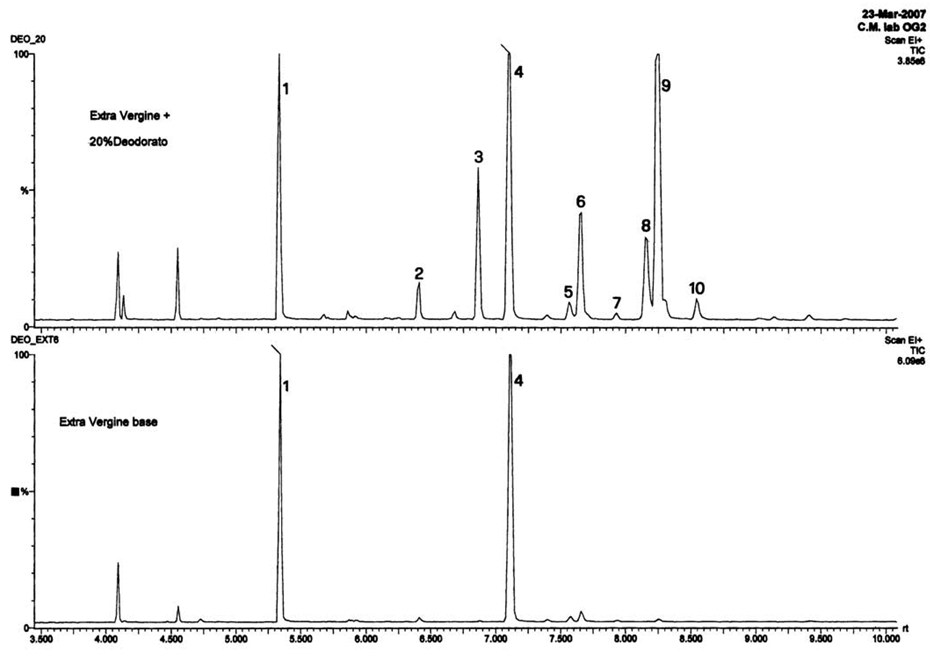

The conditions may be modified according to the characteristics of the column and the GC apparatus to obtain separation of all the waxes and a satisfactory peak resolution (see figure); the internal standard C 32 retention time must be 18 ± 3 minutes. The most representative wax peak must be at least 60 % of the full scale.

The peak integration parameters must be established so as to obtain a correct evaluation of the areas of the peaks in question.

NB : Given the high final temperature, a positive drift of no more than 10 % of the full scale is permitted. U.K.

5.3. Performance of the analysis U.K.

Sample 1 μl of the solution using the 10 μl microsyringe; withdraw the syringe plunger so that the needle is empty. Place the needle in the injector and after 1-2 seconds inject quickly; remove the needle slowly after about five seconds.

Record until the waxes are completely eluted.

The base line must always satisfy the required conditions.

5.4. Identification of peaks U.K.

Identification of the different peaks should be based on retention time by comparison with wax mixtures of known retention times analysed under the same conditions.

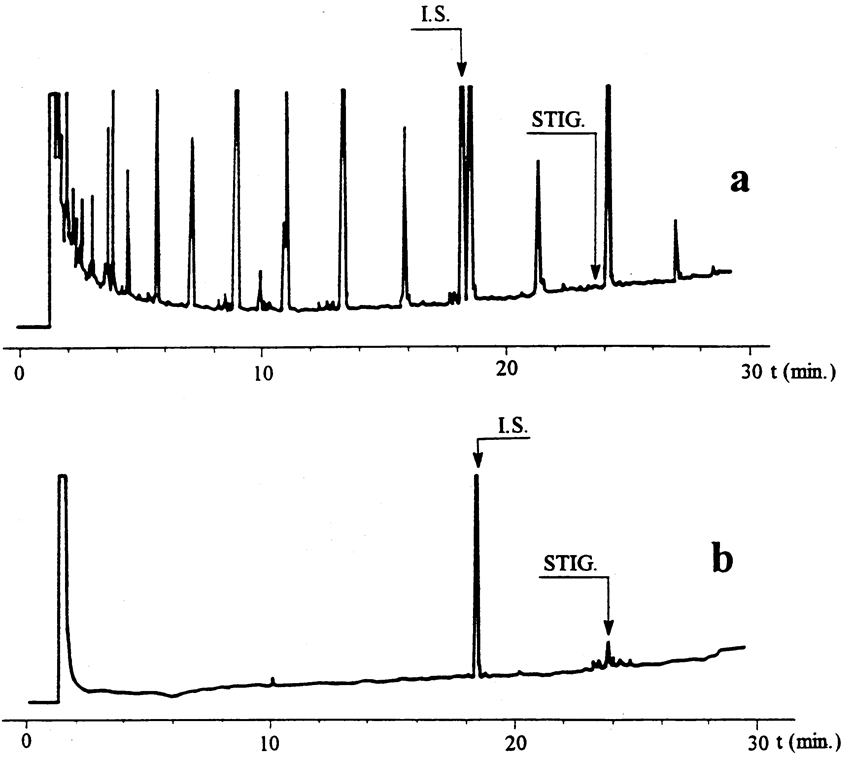

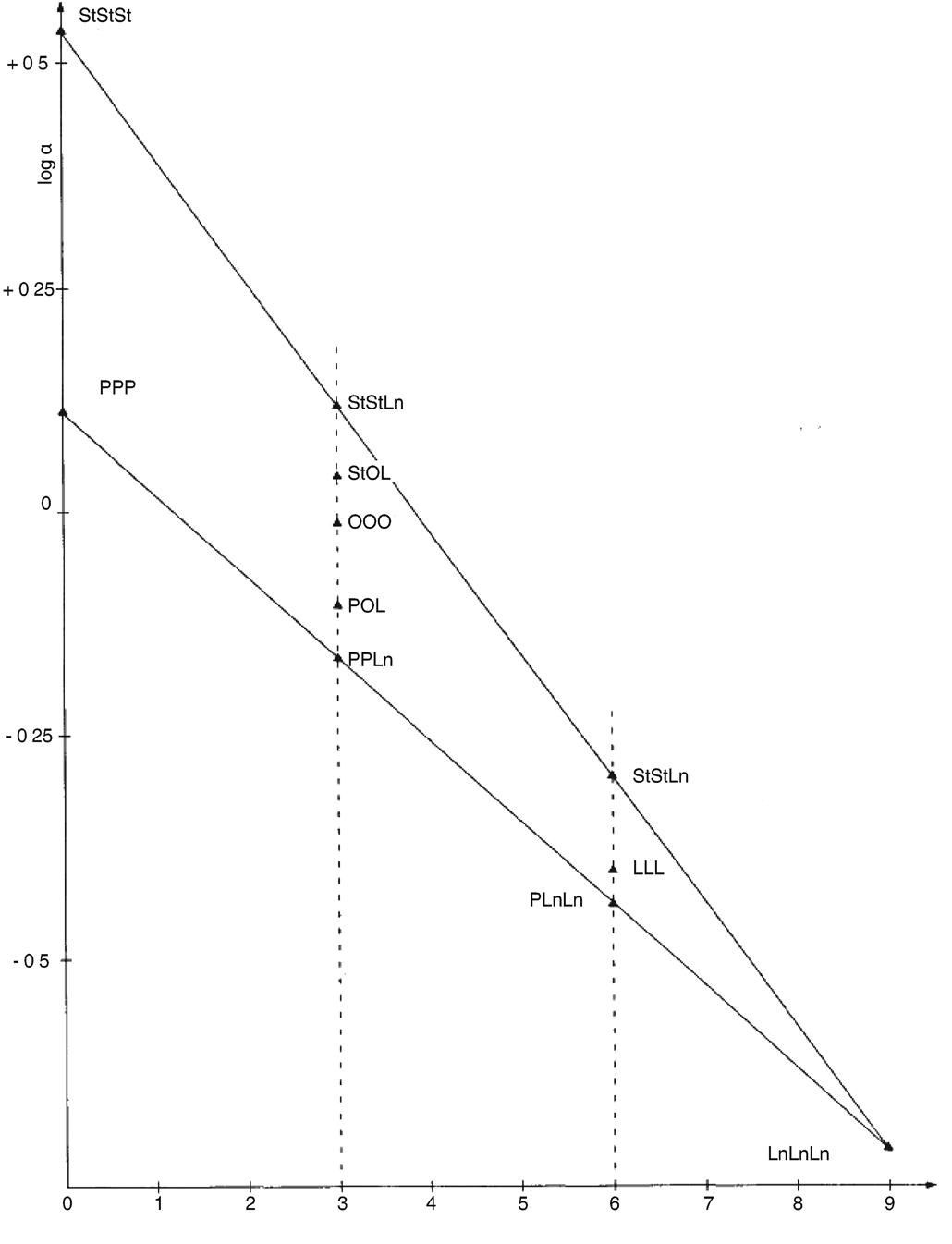

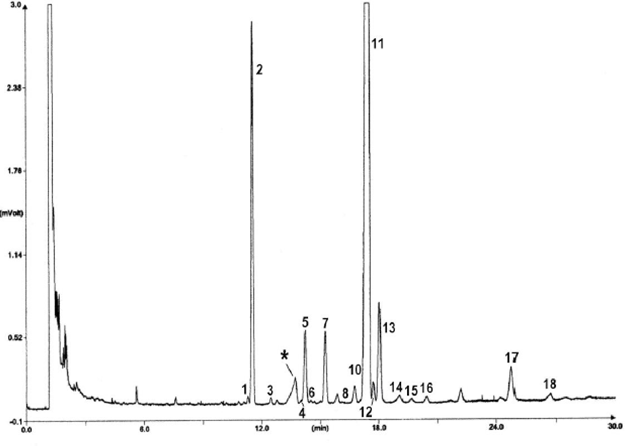

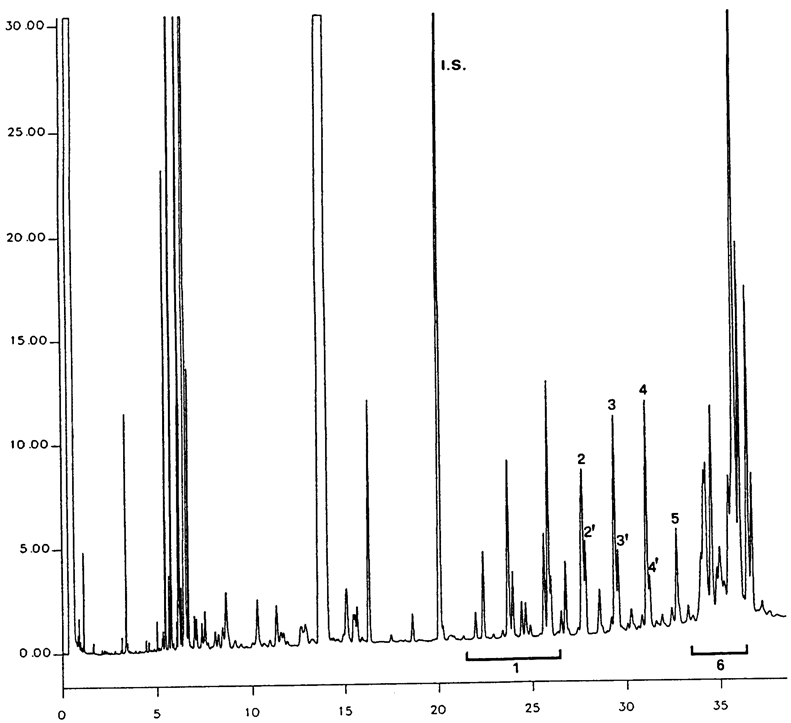

The figure is a chromatogram of the waxes of a virgin olive oil.

5.5. Evaluation of quantity U.K.

Calculate the areas of the peaks of the internal standard and the aliphatic esters of C 40 to C 46 using the integrator.

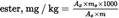

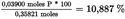

Calculate the wax content of each of the esters in mg/kg fat using the formula:

where:

=

area of each ester’s peak, in square millimetres;

=

area of the internal standard’s peak, in square millimetres;

=

mass of added internal standard, in milligrams;

=

mass of sample for analysis, in grams.

6. EXPRESSION OF RESULTS U.K.

Indicate the total of the contents of the various C 40 to C 46 waxes in mg/kg fat (ppm).

NB : The components to be quantified refer to the peaks with carbon pair numbers between esters C 40 and C 46 , using the example of the olive oil wax chromatogram shown in the figure below. If ester C 46 appears twice, it is recommended that to identify it the fraction of the waxes of an olive-residue oil should be analysed where the C 46 peak is easy to identify because it is in the clear majority. U.K.

The results should be expressed to one decimal place.

Figure Chromatogram of the waxes of an olive oil (2) U.K.

Appendix

Determination of the linear velocity of the gas U.K.

Inject 1-3 μl methane (or propane) into the GC apparatus after it has been regulated to normal operating conditions. Measure the time it takes for the gas to flow through the column from the time it is injected to the time the peak appears (t M ).

The linear velocity in cm/s is given by the formula L/t M , where L is the length of the column in cm and t M the time measured in seconds.]

F6ANNEX VU.K. [F6 [F2DETERMINATION OF THE COMPOSITION AND CONTENT OF STEROLS AND TRITERPENES DIALCOHOLS BY CAPILLARY-COLUMN GAS CHROMATOGRAPHY] ]

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Textual Amendments

F7ANNEX VIU.K. [F7DETERMINATION OF ERYTHRODIOL AND UVAOL]

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Textual Amendments

[F5ANNEX VII U.K. DETERMINATION OF THE PERCENTAGE OF 2-GLYCERYL MONOPALMITATE

1. PURPOSE AND SCOPE U.K.

This method describes the analysis procedure for determining the percentage of palmitic acid in position 2 of the triglycerides by evaluating 2-glyceryl monopalmitate.

This method can be applied to liquid vegetable oils at ambient temperature (20 °C).

2. PRINCIPLE U.K.

After preparation the oil sample is subjected to the action of pancreatic lipase: partial and specific hydrolysis in positions 1 and 3 of the triglyceride molecule causes monoglycerides to appear in position 2. The percentage of 2-glyceryl monopalmitate in the monoglyceride fraction is determined after silylation by capillary-column gas chromatography.

3. APPARATUS AND MATERIALS U.K.

3.1. 25 ml Erlenmeyer flask U.K.

3.2. 100, 250 and 300 ml beakers U.K.

3.3. Glass chromatograph column, internal diameter 21-23 mm, length 400 mm, fitted with a sintered glass disc and a stopcock U.K.

3.4. 10, 50, 100 and 200 ml measuring cylinders U.K.

3.5. 100 and 250 ml flasks U.K.

3.6. Rotary evaporator U.K.

3.7. 10 ml conical-bottomed centrifuge tubes with groundglass stopper U.K.

3.8. Centrifuge for 10 and 100 ml tubes U.K.

3.9. Thermostat permitting a stable temperature of 40 ± 0,5 °C U.K.

3.10. 1 and 2 ml graduated pipettes U.K.

3.11. 1 ml hypodermic syringe U.K.

3.12. 100 μl microsyringe U.K.

3.13. 1 000 ml funnel U.K.

3.14. Capillary gas chromatograph with an on-column cold injector for direct injection of the sample into the column and a furnace able to maintain the selected temperature to approximately 1 °C U.K.

3.15. On-column cold injector for direct injection of the sample into the column U.K.

3.16. Flame ionisation detector and electrometer U.K.

3.17. Recorder-integrator adapted to the electrometer with a response rate no greater than 1 sec and a variable paper roll rate U.K.

3.18. Capillary column made of glass or fused silica 8-12 metres long, 0,25-0,32 mm internal diameter, covered with methylpolysiloxane or phenyl methylpolysiloxane 5 %, 0,10-0,30 μm thick, useable at 370 °C U.K.

3.19. 10 μl microsyringe fitted with a hardened needle, at least 7,5 cm long for direct on-column injection. U.K.

4. REAGENTS U.K.

4.1. Silica gel with a grain size of between 0,063 and 0,200 mm (70/280 mesh) prepared as follows: Place the silica gel in a porcelain capsule, dry in an incubator at 160 °C for four hours, then leave to cool at room temperature in a desiccator. Add water equivalent to 5 % of the mass of the silica gel as follows: Weigh 152 g silica gel into an Erlenmeyer flask then add 8 g of distilled water, stopper and shake gently to distribute the water evenly. Leave to stand for at least 12 hours before use. U.K.

[F14.2. n-hexane (chromatography grade). Hexane may be replaced by iso-octane (2,2,4- trimethylpentane in chromatography grade), provided that comparable precision values are achieved.] U.K.

4.3. Isopropanol U.K.

4.4. Isopropanol, 1/1 (v/v) aqueous solution U.K.

4.5. Pancreatic lipase. It must have an activity of between 2,0 and 10 lipase units per mg. (Pancreatic lipases with an activity of between 2 and 10 units per mg enzyme are commercially available.) U.K.

4.6. Buffer solution of trishydroxymethylaminomethane: 1 M aqueous solution adjusted to pH 8 (potentiometric control) by conc. HCl (1/1 v/v) U.K.

4.7. Enzyme-quality sodium cholate, 0,1 % aqueous solution (this solution must be used within two weeks of its preparation) U.K.

4.8. Calcium chloride, 22 % aqueous solution U.K.

4.9. Diethyl ether for chromatography U.K.

4.10. Developer solvent: mixture of n-hexane/diethyl ether (87:13 v:v) U.K.

4.11. Sodium hydroxide, 12 % by weight solution U.K.

4.12. Phenolphthalein, 1 % solution in ethanol U.K.

4.13. Carrier gas: hydrogen or helium, for gas chromatography U.K.

4.14. Auxiliary gases: hydrogen, 99 % minimum purity, free from moisture and organic substances, and air, for gas chromatography, of the same purity U.K.

4.15. Silanisation reagent: mixture of pyridine/hexamethyldisilazane, trimethylchlorosilane 9/3/1 (v/v/v). (Ready-to-use solutions are commercially available. Other silylation reagents may be used, particularly bis-trimethylsilyl trifluoracetamide + 1 % trimethylchlorosilane, diluted with an identical volume of anhydrous pyridine.) U.K.

4.16. Reference samples: pure monoglycerides or monoglyceride mixtures with a known percentage composition similar to that of the sample. U.K.

5. METHOD U.K.

5.1. Sample preparation U.K.

5.1.1. Oils with a free acidity of less than 3 % do not need to be neutralised before chromatography on a silica gel column. Oils with a free acidity of more than 3 % must be neutralised as per point 5.1.1.1. U.K.

5.1.1.1. Pour 50 g of oil and 200 ml n-hexane into the 1 000 ml funnel (3.13). Add 100 ml of isopropanol and a quantity of 12 % sodium hydroxide solution (4.11) equivalent to the free acidity of the oil plus 5 %. Shake vigorously for one minute. Add 100 ml of distilled water, shake again and leave to stand. U.K.

After decanting, remove the lower layer containing the soaps. Remove any intermediate layers (mucilage and insoluble substances). Wash the hexane solution of the neutralised oil with successive portions of 50-60 ml of the 1/1 (v/v) isopropanol/water solution (4.4) until the pink colouration of the phenolphthalein disappears.

Remove most of the hexane by vacuum distillation (use a rotary evaporator, for example) and transfer the oil into a 100 ml flask (3.5). Dry the oil in vacuum until the solvent is completely removed.

After that procedure is completed, the acidity of the oil should be less than 0,5 %.

5.1.2. Put 1,0 g of the oil prepared as above into a 25 ml Erlenmeyer flask (3.1) and dissolve in 10 ml of developer mixture (4.10). Leave the solution to stand for at least 15 minutes before silica gel column chromatography. U.K.

If the solution is cloudy centrifuge it to ensure optimum conditions for chromatography. (Ready-to-use 500 mg silica gel SPE cartridges can be used).

5.1.3. Preparation of the chromatography column U.K.

Pour about 30 ml of the developer solvent (4.10) into the column (3.3), insert a piece of cotton into the bottom part of the column using a glass rod; press to eliminate the air.

In a beaker prepare a suspension of 25 g of silica gel (4.1) in about 80 ml of developer solvent and pour it into the column using a funnel.

Check that all the silica gel is in the column; wash with developer solvent (4.10), open the stopcock and allow the liquid to reach a level about 2 mm above the level of the silica gel.

5.1.4. Column chromatography U.K.

Weigh accurately 1,0 g of sample prepared as in point 5.1 into a 25 ml Erlenmeyer flask (3.1).

Dissolve the sample in 10 ml of developer solvent (4.10). Pour the solution into the chromatography column prepared as in point 5.1.3. Avoid disturbing the surface of the column.

Open the stopcock and pour the sample solution until it reaches the level of the silica gel. Develop with 150 ml of the developer solvent. Adjust the flow rate to 2 ml/min (so that 150 ml enters the column in about 60-70 minutes).

Recover the eluate in a previously weighed 250 ml flask. Evaporate the solvent under vacuum and remove the final traces of the solvent under a nitrogen current.

Weigh the flask and calculate the recovered extract.

(If ready-to-use silica gel SPE cartridges are used use the following method: Put 1 ml of solution (5.1.2) into the prepared cartridges with 3 ml of n-hexane.

After percolating the solution develop with 4 ml of n-hexane/diethyl ether 9/1 (v/v).

Recover the eluate in a 10 ml tube and evaporate to dry in a nitrogen current.

Expose the dry residue to pancreatic lipase (5.2). (It is essential to check the fatty acid composition before and after crossing the SPE cartridge.)

5.2. Hydrolysis by pancreatic lipase U.K.

5.2.1. Weigh into the centrifuge tube 0.1 g of the oil prepared as in point 5.1. Add 2 ml of buffer solution (4.6), 0,5 ml of the sodium cholate solution (4.7) and 0,2 ml of the calcium chloride solution, stirring well after each addition. Close the tube with the groundglass stopper and place in the thermostat at 40 + 0,5 °C. U.K.

5.2.2. Add 20 mg of lipase, shake carefully (avoid wetting the stopper) and place the tube in the thermostat for exactly two minutes. Then remove it, shake vigorously for exactly 1 minute and leave to cool. U.K.

5.2.3. Add 1 ml of diethyl ether, stopper and shake vigorously, then centrifuge and transfer the ether solution into a clean, dry tube using a microsyringe. U.K.

5.3. Preparation of the silanised derivatives and gas chromatography U.K.

5.3.1. With a microsyringe insert 100 μl of solution (5.2.3) into a 10 ml conical-bottomed tube. U.K.

5.3.2. Remove the solvent under a slight nitrogen current, add 200 μl of silanisation reagent (4.15), stopper the tube and leave to stand for 20 minutes. U.K.

5.3.3. After 20 minutes, add 1 to 5 ml of n-hexane (depending on the chromatography conditions): the resulting solution is ready for gas chromatography. U.K.

5.4. Gas chromatography U.K.

Operating conditions:

Injector temperature (on-column injector) lower than solvent boiling point (68 °C);

Detector temperature: 350 °C;

Column temperature: programming of furnace temperature: 60 °C for 1 minute, increasing by 15 °C per minute up to 180 °C, then by 5 °C per minute up to 340 °C, then 340 °C for 13 minutes;

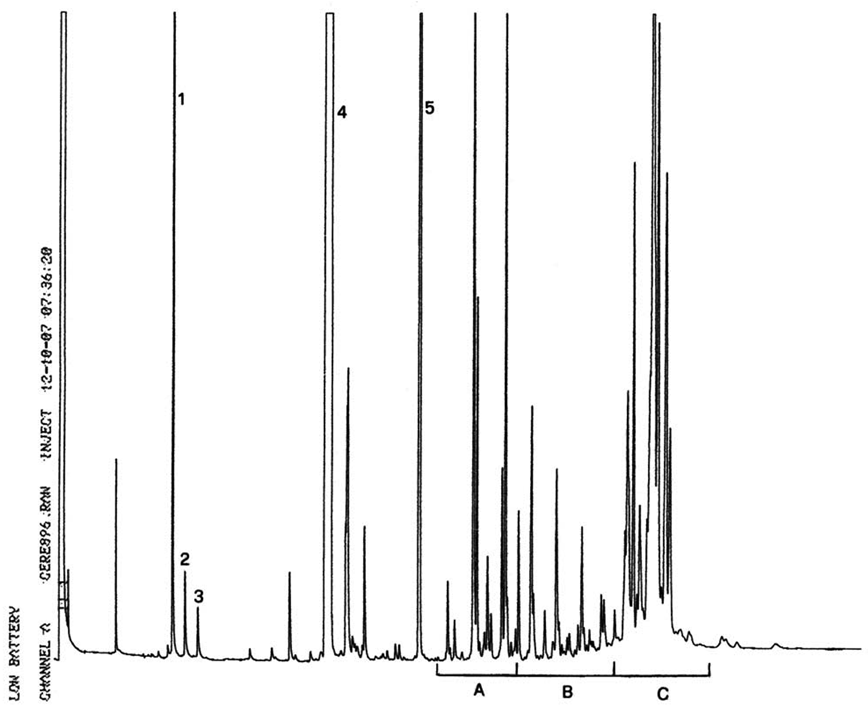

Carrier gas: hydrogen or helium, set at a linear velocity sufficient to obtain the resolution reflected in Figure 1. The retention time of the C 54 triglyceride must be 40 ± 5 minutes (see Figure 2). (The operating conditions indicated above are indicative. Operators will have to optimise them to obtain the desired resolution. The peak corresponding to 2-glyceryl monopalmitate must have a minimum height equal to 10 % of the recorder scale.)

Quantity of substance injected: 0,5-1 μl of the n-hexane solution (5 ml) (5.3.3).

5.4.1. Identification of the peaks U.K.

The individual monoglycerides are identified from their retention times and by comparison with those obtained for standard monoglyceride mixtures under the same conditions.

5.4.2. Quantitative evaluation U.K.

The area of each peak is calculated using an electronic integrator.

6. EXPRESSION OF RESULTS U.K.

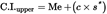

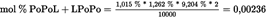

The percentage of glyceryl monopalmitate is calculated from the ratio between the area of the corresponding peak and the areas of the peaks of all the monoglycerides (see Figure 2) using the formula:

where:

=

area of the peak corresponding to glyceryl monopalmitate

=

sum of the areas of all the monoglyceride peaks

The result must be to one decimal place.

7. ANALYSIS REPORT U.K.

The analysis report must specify:

reference to this method,

all the information needed for a full identification of the sample,

the analysis result,

any deviation from the method, whether as the result of a decision by the parties concerned or for another reason,

details to identify the laboratory, the date of the analysis and the signatures of those responsible for the analysis.

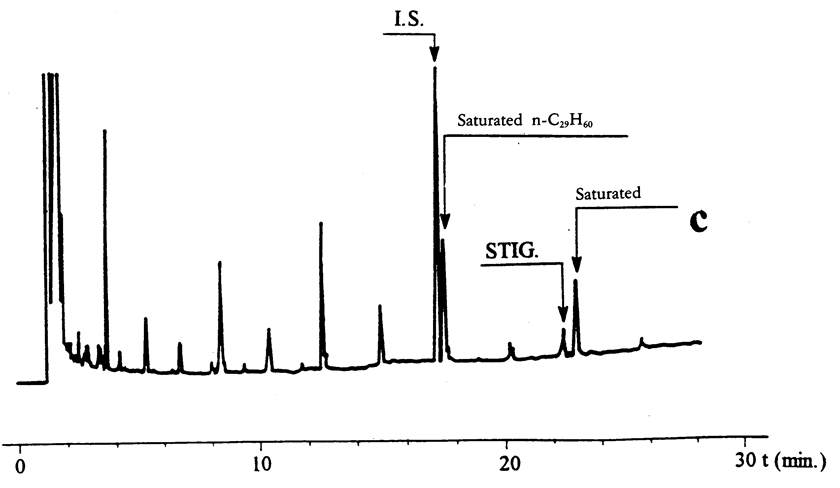

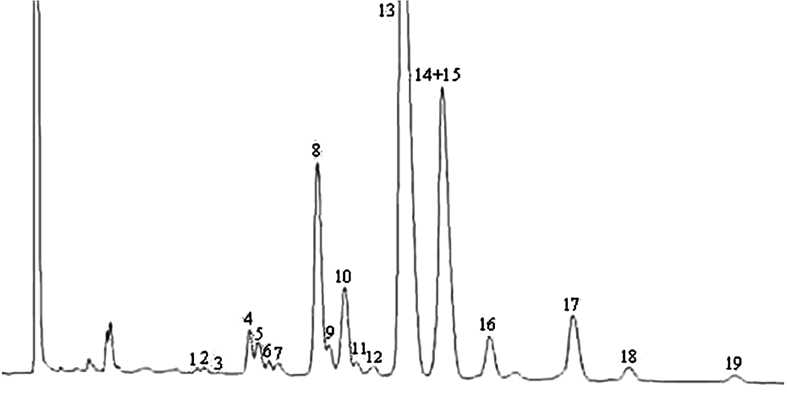

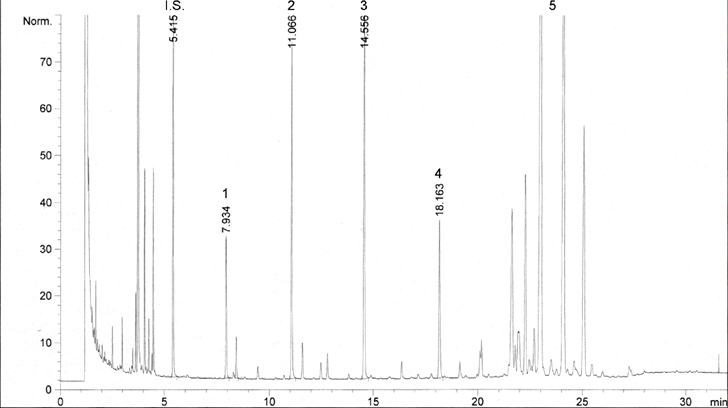

Figure 1

Chromatogram of the products of the silanisation reaction obtained by the action of lipase on a refined olive oil with 20 % esterified oil added (100 %)

Figure 2 U.K.

Chromatogram of :

( A ) unesterified olive oil, after lipase; after silanisation; under these conditions (8-12 m capillary column) the wax fraction is eluted at the same time as the diglyceride fraction or slightly afterwards . U.K.

After lipase, the triglyceride content should not exceed 15 %

Chromatogram of :

( B ) unesterified oil after lipase; after silanisation; under these conditions (8-12 m capillary column) the wax fraction is eluted at the same time as the diglyceride fraction or slightly afterwards . U.K.

After lipase, the triglyceride content should not exceed 15 % .

8. NOTES U.K.

Note 1. PREPARATION OF THE LIPASE U.K.

Lipases with satisfactory activity are commercially available. They can also be prepared in the laboratory in the following manner:

Cool to 0 °C 5 kg of fresh pig’s pancreas. Remove the surrounding solid fat and the connective tissue and grind to a liquid paste in a blender. Stir the paste with 2,5 litres of anhydrous acetone for 4-6 hours, then centrifuge. Extract the residue three more times with the same volume of anhydrous acetone, then twice with an acetone/diethyl ether mixture (1/1 v/v) and twice with diethyl ether.

Vacuum-dry the residue for 48 hours to obtain a stable powder which can be stored for a long time in a refrigerator away from moisture.

Note 2. MONITORING LIPASE ACTIVITY U.K.

Prepare an olive oil emulsion as follows:

In a mixer stir for 10 minutes a mixture of 165 ml of a 100 g/l gum arabic solution, 15 g of crushed ice and 20 ml of a previously neutralised olive oil.

Pour 10 ml of the emulsion into a 50 ml beaker, then 0,3 ml of a 0,2 g/ml sodium cholate solution and then 20 ml of distilled water.

Put the beaker in a thermostat set at 37 °C; introduce the electrodes of the pH meter and the screw agitator.

Using a burette, add a 0,1 N sodium hydroxide solution drop by drop until a pH of 8,3 is obtained.

Add an aliquot of the lipase powder suspension in water (0,1 g/ml of lipase). As soon as the pH meter reads 8,3, start the chronometer and add the sodium hydroxide solution drop by drop at a rate which maintains the pH at 8,3. Note every minute the volume of solution consumed.

Record the data on an x/y graph with the time on the x-axis and millilitres of 0,1 N alkaline solution consumed to keep a constant pH on the y-axis. A linear graph should be obtained.

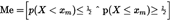

Lipase activity, expressed in lipase units per mg, is given by the following formula:

where:

is activity in lipase units/mg

is the number of millilitres of 0,1 N sodium hydroxide solution per minute (calculated on the basis of the graph)

is the titre of the sodium hydroxide solution

is the mass in mg of the test lipase.

A lipase unit is defined as the quantity of enzyme which releases 10 micro-equivalents of acid per minute.]

F8ANNEX VIIIU.K. [F8DETERMINATION OF TRILINOLEIN CONTENT]

Textual Amendments

1.SCOPEU.K.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.FIELD OF APPLICATIONU.K.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.PRINCIPLEU.K.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.APPARATUSU.K.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.REAGENTSU.K.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.PREPARATION OF SAMPLESU.K.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.PROCEDUREU.K.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.CALCULATION AND EXPRESSION OF RESULTSU.K.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . .U.K.

F8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .]

. . . . .U.K.

[F9ANNEX IX U.K. SPECTROPHOTOMETRIC INVESTIGATION IN THE ULTRAVIOLET

Textual Amendments

FOREWORD U.K.

Spectrophotometric examination in the ultraviolet can provide information on the quality of a fat, its state of preservation and changes brought about by technological processes. The absorption at the wavelengths specified in the method is due to the presence of conjugated diene and triene systems resulting from oxidation processes and/or refining practices. These absorptions are expressed as specific extinctions

1. SCOPE U.K.

This Annex describes the procedure for performing a spectrophotometric examination of olive oil in the ultraviolet region.

2. PRINCIPLE OF THE METHOD U.K.

A sample is dissolved in the required solvent and the absorbance of the solution is measured at the specified wavelengths with reference to pure solvent.

The specific extinctions at 232 nm and 268 nm in iso-octane or 232 nm and 270 nm in cyclohexane are calculated for a concentration of 1 % w/v in a 10 mm cell.

3. EQUIPMENT U.K.

3.1. A spectrophotometer suitable for measurements at ultraviolet wavelengths (220 nm to 360 nm), with the capability of reading individual nanometric units. A regular check is recommended for the accuracy and reproducibility of the absorbance and wavelength scales as well as for stray light. U.K.

3.1.1. Wavelength scale: This may be checked using a reference material consisting of an optical glass filter containing holmium oxide or a holmium oxide solution (sealed or not) that has distinct absorption bands. The reference materials are designed for the verification and calibration of the wavelength scales of visible and ultraviolet spectrophotometers having nominal spectral bandwidths of 5 nm or less. The measurements are carried out against an air blank over the wavelength range of 640 to 240 nm, according to the instructions enclosed with the reference materials. A baseline correction is performed with an empty beam path at every slit width alteration. The wavelengths of the standard are listed in the certificate of the reference material. U.K.

3.1.2. Absorbance scale: This may be checked using commercially available sealed reference materials consisting of acidic potassium dichromate solutions, in certain concentrations and certified values of absorbance at its λmax (of 4 solutions of potassium dichromate in perchloric acid sealed in four UV quartz cells to measure the linearity and photometric accuracy reference in the UV). The potassium dichromate solutions are measured against a blank of the acid used, after baseline correction, according to the instructions enclosed with the reference material. The absorbance values are listed in the certificate of the reference material. U.K.

Another possibility in order to check the response of the photocell and the photomultiplier is to proceed as follows: weigh 0,2000 g of pure potassium chromate for spectrophotometry and dissolve in 0,05 N potassium hydroxide solution in a 1 000 ml graduated flask and make up to the mark. Take precisely 25 ml of the solution obtained, transfer to a 500 ml graduated flask and dilute up to the mark using the same potassium hydroxide solution.

Measure the extinction of the solution so obtained at 275 nm, using the potassium hydroxide solution as a reference. The extinction measured using a 1 cm cuvette should be 0,200 ± 0,005.

3.2. Rectangular quartz cuvettes, with covers, suitable for measurements at the ultraviolet wavelengths (220 to 360 nm) having an optical path-length of 10 mm. When filled with water or other suitable solvent the cuvettes should not show differences between them of more than 0,01 extinction units. U.K.

3.3. One- mark volumetric flasks, capacity 25 ml, class A. U.K.

3.4. Analytical balance, capable of being read to the nearest 0,0001 g U.K.

4. REAGENTS U.K.

During the analysis, unless otherwise stated, use only reagents of recognised analytical grade and distilled or demineralised water or water of equivalent purity.

Solvent: Iso-octane (2,2,4 trimethylpentane) for the measurements at 232 nm and 268 nm and cyclohexane for the measurements at 232 nm and 270 nm, having an absorbance less than 0,12 at 232 nm and less than 0,05 at 270 nm against distilled water, measured in a 10 mm cell.

5. PROCEDURE U.K.

5.1. The sample must be perfectly homogeneous and without suspended impurities. If not, it must be filtered through paper at a temperature of approximately 30 °C. U.K.

5.2. Weigh accurately approximately 0,25 g (to the nearest 1 mg) of the sample so prepared into a 25 ml graduated flask, make up to the mark with the specified solvent and homogenise. The resulting solution must be perfectly clear. If opalescence or turbidity is present, filter quickly through paper. U.K.

NOTE: Generally, a mass of 0,25 to 0,30 g is sufficient for absorbance measurements of virgin and extra virgin olive oils at 268 nm and 270 nm. For measurements at 232 nm, 0,05 g of sample are usually required, so two distinct solutions are usually prepared. For absorbance measurements of olive pomace oils, refined olive oils and adulterated olive oils, a smaller portion of sample, e.g. 0,1 g is usually needed due to their higher absorbance. U.K.

5.3. If necessary, correct the baseline (220-290 nm) with solvent in both quartz cells (sample and reference), then fill the sample quartz cell with the test solution and measure the extinctions at 232, 268 or 270 nm against the solvent used as a reference. U.K.

The extinction values recorded must lie within the range 0,1 to 0,8 or within the range of linearity of the spectrophotometer which should be verified. If not, the measurements must be repeated using more concentrated or more dilute solutions as appropriate.

5.4. After measuring the absorbance at 268 or 270 nm, measure the absorbance at λmax, λmax + 4 and λmax – 4. These absorbance values are used to determine the variation in the specific extinction (ΔΚ). U.K.

NOTE: λmax is considered to be 268 nm for isooctane used as solvent and 270 nm for cyclohexane. U.K.

6. EXPRESSION OF THE RESULTS U.K.

6.1. Record the specific extinctions (extinction coefficients) at the various wavelengths calculated as follows: U.K.

where:

=

specific extinction at wavelength λ;

=

extinction measured at wavelength λ;

=

concentration of the solution in g/100 ml;

=

path length of the quartz cell in cm;

expressed to two decimal places.

6.2. Variation of the specific extinction (ΔΚ) U.K.

The variation of the absolute value of the extinction (ΔΚ) is given by:

where Km is the specific extinction at the wavelength for maximum absorption at 270 nm and 268 nm depending on the solvent used.

The results should be expressed to two decimal places.]

[F9ANNEX X U.K. DETERMINATION OF FATTY ACID METHYL ESTERS BY GAS CHROMATOGRAPHY

1. SCOPE U.K.

This Annex gives guidance on the gas chromatographic determination of free and bound fatty acids in vegetable fats and oils following their conversion into fatty acid methyl esters (FAME).

The bound fatty acids of the triacylglycerols (TAGs) and, depending on the esterification method, the free fatty acids (FFA), are converted into fatty acid methyl esters (FAME), which are determined by capillary gas chromatography.

The method described in this Annex allows the determination of FAME from C 12 to C 24 , including saturated, cis- and transmonounsaturated and cis- and trans-polyunsaturated fatty acid methyl esters.

2. PRINCIPLE U.K.

Gas chromatography (GC) is used for the quantitative analysis of FAME. The FAME are prepared according to Part A. They are then injected into and vaporised within the injector. The separation of FAME is performed on analytical columns of specific polarity and length. A Flame Ionisation Detector (FID) is used for the detection of the FAME. The conditions of analysis are given in Part B.

Hydrogen or helium may be used as the carrier gas (mobile phase) in the gas chromatography of FAME with FID. Hydrogen speeds up separation and gives sharper peaks. The stationary phase is a microscopic layer of a thin liquid film on an inert solid surface made of fused silica.

As they pass through the capillary column the volatilised compounds being analysed interact with the stationary phase coating the inner surface of the column. Due to this different interaction of different compounds, they elute at a different time, which is called the retention time of the compound for a given set of analysis parameters. The comparison of the retention times is used for the identification of the different compounds.

PART A U.K. PREPARATION OF THE FATTY ACID METHYL ESTERS FROM OLIVE OIL AND OLIVE-POMACE OIL

1. SCOPE U.K.

This part specifies the preparation of the methyl esters of fatty acids. It includes methods for preparing fatty acid methyl esters from olive and olive-pomace oils.

2. FIELD OF APPLICATION U.K.

The preparation of the fatty acid methyl esters from olive oils and olive-pomace oils are performed by transesterification with methanolic solution of potassium hydroxide at room temperature. The necessity of purification of the sample prior to the trans-esterification depends on the sample's free fatty acids content and the analytical parameter to be determined, it can be chosen according to the following table:

| Category of oil | Method |

|---|---|

| Virgin olive oil with acidity ≤ 2,0 % | 1. Fatty acids 2. trans -Fatty acids 3. ΔECN42 (after purification with silica-gel SPE) |

| Refined olive oil | |

| Olive oil composed of refined olive oil and virgin olive oils | |

| Refined olive pomace oil | |

| Olive pomace oil | |

| Virgin olive oil with acidity > 2,0 % Crude olive pomace oil | 1. Fatty acids (after purification with silica-gel SPE) 2. trans -Fatty acids (after purification with silica-gel SPE) 3. ΔECN42 (after purification with silica-gel SPE) |

3. METHODOLOGY U.K.

3.1. Trans-esterification with methanolic solution of potassium hydroxide at room temperature U.K.

3.1.1. Principle U.K.

Methyl esters are formed by trans-esterification with methanolic potassium hydroxide as an intermediate stage before saponification takes place.

3.1.2. Reagents U.K.

3.1.2.1. Methanol containing not more than 0,5 % (m/m) water. U.K.

3.1.2.2. Hexane, chromatographic quality. U.K.

3.1.2.3. Heptane, chromatographic quality. U.K.

3.1.2.4. Diethyl ether, stabilised for analysis. U.K.

3.1.2.5. Acetone, chromatographic quality. U.K.

3.1.2.6. Elution solvent for purifying the oil by column/SPE chromatography, mixture hexane/diethyl ether 87/13 (v/v). U.K.

3.1.2.7. Potassium hydroxide, approximately 2M methanolic solution: dissolve 11,2 g of potassium hydroxide in 100 ml of methanol. U.K.

3.1.2.8. Silica gel cartridges, 1 g (6 ml), for solid phase extraction. U.K.

3.1.3. Apparatus U.K.

3.1.3.1. Screw-top test tubes (5 ml volume) with cap fitted with a PTFE joint. U.K.

3.1.3.2. Graduated or automatic pipettes, 2 ml and 0,2 ml. U.K.

3.1.4. Purification of oil samples U.K.

When necessary, the samples will be purified by passing the oil through a silica gel solid-phase extraction cartridge. A silica gel cartridge (3.1.2.8) is placed in a vacuum elution apparatus and washed with 6 ml of hexane (3.1.2.2); washing is performed without vacuum. Then a solution of the oil (0,12 g approximately) in 0,5 ml of hexane (3.1.2.2) is loaded onto the column. The solution is pulled down and then eluted with 10 ml of hexane/diethyl ether (87:13 v/v) (3.1.2.6). The combined eluates are homogenised and divided in two similar volumes. An aliquot is evaporated to dryness in a rotary evaporator under reduced pressure at room temperature. The residue is dissolved in 1 ml of heptane and the solution is ready for fatty acid analysis by GC. The second aliquot is evaporated and the residue is dissolved in 1 ml of acetone for triglyceride analysis by HPLC, if necessary.

3.1.5. Procedure U.K.

In a 5 ml screw-top test tube (3.1.3.1) weigh approximately 0,1 g of the oil sample. Add 2 ml of heptane (3.1.2.2), and shake. Add 0,2 ml of the methanolic potassium hydroxide solution (3.1.2.7), put on the cap fitted with a PTFE joint, tighten the cap, and shake vigorously for 30 seconds. Leave to stratify until the upper solution becomes clear. Decant the upper layer containing the methyl esters. The heptane solution is ready for injection into the gas chromatograph. It is advisable to keep the solution in the refrigerator until gas chromatographic analysis. Storage of the solution for more than 12 hours is not recommended.

PART B U.K. ANALYSIS OF FATTY ACID METHYL ESTERS BY GAS CHROMATOGRAPHY

1. SCOPE U.K.

This part gives general guidance for the application of capillary column gas chromatography to determine the qualitative and quantitative composition of a mixture of fatty acid methyl esters obtained in accordance with the method specified in Part A.

The part is not applicable to polymerised fatty acids.

2. REAGENTS U.K.

2.1. Carrier gas U.K.

Inert gas (helium or hydrogen), thoroughly dried and with an oxygen content of less than 10 mg/kg.

Note 1: Hydrogen can double the speed of analysis but is hazardous. Safety devices are available. U.K.

2.2. Auxiliary gases U.K.

2.2.1. Hydrogen (purity ≥ 99,9 %), free from organic impurities. U.K.

2.2.2. Air or oxygen, free from organic impurities. U.K.

2.2.3. Nitrogen (purity > 99 %). U.K.

2.3. Reference standard U.K.

Mixture of methyl esters of pure fatty acids, or the methyl esters of a fat of known composition, preferably similar to that of the fatty matter to be analysed. Cis and trans isomers of octadecenoic, octadecadienoic and octadecatrienoic methyl esters are useful for the identification of trans isomers of unsaturated acids.

Care should be taken to prevent the oxidation of polyunsaturated fatty acids.

3. APPARATUS U.K.

The instructions given are for the usual equipment used for gas chromatography, employing capillary columns and a flame-ionisation detector.

3.1. Gas chromatograph U.K.

The gas chromatograph shall comprise the following elements.

3.1.1. Injection system U.K.

Use an injection system with capillary columns, in which case the injection system should be specially designed for use with such columns. It may be of the split type or the splitless on-column injector type.

3.1.2. Oven U.K.

The oven shall be capable of heating the capillary column to a temperature of at least 260 °C and of maintaining the desired temperature to within 0,1 °C. The last requirement is particularly important when a fused silica tube is used.

The use of temperature-programmed heating is recommended in all cases, and in particular for fatty acids with less than 16 carbon atoms.

3.1.3. Capillary column U.K.

3.1.3.1. Tube, made of a material inert to the substances to be analysed (usually glass or fused silica). The internal diameter shall be between 0,20 to 0,32 mm. The internal surface shall undergo an appropriate treatment (e.g. surface preparation, inactivation) before receiving the stationary phase coating. A length of 60 m is sufficient for fatty acid and cis and trans isomers of fatty acids. U.K.

3.1.3.2. Stationary phase, polar polysiloxane (cyanopropylsilicone) bonded (cross-linked) columns are suitable. U.K.

Note 2: There is a risk that polar polysiloxanes may give rise to difficulties in the identification and separation of linolenic acid and C 20 acids. U.K.

The coatings shall be thin, i.e. 0,1 to 0,2 μm.

3.1.3.3. Assembly and conditioning of the column U.K.

Observe the normal precautions for assembling capillary columns, i.e. arrangement of the column in the oven (support), choice and assembly of joints (leak tightness), positioning of the ends of the column in the injector and the detector (reduction of dead-spaces). Place the column under a flow of carrier gas (e.g. 0,3 bar (30 kPa) for a column of length 25 m and internal diameter 0,3 mm).

Condition the column by temperature programming of the oven at 3 °C/min from ambient temperature to a temperature 10 °C below the decomposition limit of the stationary phase. Maintain the oven at this temperature for one hour until stabilisation of the baseline. Return it to 180 °C to work under isothermal conditions.

Note 3: Suitably pre-conditioned columns are available commercially. U.K.

3.1.4. Flame ionisation detector and converter-amplifier U.K.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2. Syringe U.K.

The syringe shall have a maximum capacity of 10 μl, graduated in 0,1 μl divisions.

3.3. Data acquisition system U.K.

Data acquisition system connected online with the detectors and employed with a software program suitable for peak integration and normalisation.

4. PROCEDURE U.K.

The operations described in 4.1 to 4.3 are for the use of a flame-ionisation detector.

4.1. Test conditions U.K.

4.1.1. Selection of optimum operating conditions for capillary columns U.K.

Owing to the efficiency and permeability of capillary columns, the separation of the constituents and the duration of the analysis are largely dependent on the flow-rate of the carrier gas in the column. It will therefore be necessary to optimise the operating conditions by adjusting this parameter (or simply column head loss) depending on whether the aim is to improve separation or speed up analysis.

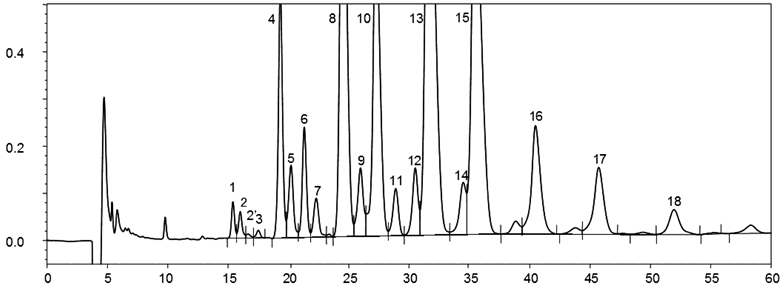

The following conditions have proved to be suitable for the separation of FAMEs (C 4 to C 26 ). Examples of chromatograms are shown in Appendix B:

| Injector temperature: | 250 °C |

| Detector temperature: | 250 °C |

| Oven temperature: | 165 °C (8 min) to 210 °C at 2 °C/min |

| Carrier gas hydrogen: | column head pressure, 179 kPa |

| Total flow: | 154,0 ml/min; |

| Split ratio: | 1:100 |

| Injection volume: | 1 μl |

4.1.2. Determination of the resolution (see Appendix A) U.K.

Calculate the resolution, R, of two neighbouring peaks I and II, using the formula:

R = 2 × (( d dr(II) – d r(I) )/(ω (I) + ω (II) )) or R = 2 × (( t r(II) – t r(I) )/(ω (I) + ω (II) )) (USP) (United States Pharmacopeia),

or

R = 1,18 × (( t r(II) – t r(I) )/(ω 0,5(I) + ω 0,5(II) )) (EP, BP, JP, DAB), (JP (Japanese Pharmacopeia), EP (Pharmacopée Européenne), BP (British Pharmacopeia))

where:

d r(I) is the retention distance of peak I;

d r(II) is the retention distance of peak II;

t r(I) is the retention time of peak I;

t r(II) is the retention time of peak II;

ω (I) is the width of the base of peak I;

ω (II) is the width of the base of peak II;

ω 0,5 is the peak width of the specified compound, at mid-height of the peak;

If ω (I) ≈ ω (II) , calculate R using the following formulas:

R = ( d r(II) – d r(I) )/ω = ( d r(II) – d r(I) )/4σ

where:

σ is the standard deviation (see Appendix A, Figure 1).

If the distance dr between the two peaks d r(II) - d r(I) is equal to 4σ, the resolution factor R = 1.

If two peaks are not separated completely, the tangents to the inflection points of the two peaks intersect at point C. In order to completely separate the two peaks, the distance between the two peaks must be equal to:

d r(II) - d r(I) = 6 σ from where R = 1,5 (see Appendix A, Figure 3).

5. EXPRESSION OF RESULTS U.K.

5.1. Qualitative analysis U.K.

Identify the methyl ester peaks of the sample from the chromatogram in Appendix B, figure 1, if necessary by interpolation, or by comparison with those of the methyl esters reference mixtures (as indicated at point 2.3).

5.2. Quantitative analysis U.K.

5.2.1. Determination of the composition U.K.

Calculate the mass fraction w i of the individual fatty acid methyl esters, expressed as a percentage by mass of methyl esters, as follows:

5.2.2. Method of calculation U.K.

5.2.2.1. General case U.K.

Calculate the content of a given component i, expressed as a percentage by mass of methyl esters, by determining the percentage represented by the area of the corresponding peak relative to the sum of the areas of all the peaks, using the following formula:

w i = (A i /ΣA) × 100

where:

A i is the area under the peak of the individual fatty acid methyl ester i ;

ΣA is the sum of the areas under all the peaks of all the individual fatty acid methyl esters.

The results are expressed to two decimal places.

Note 4: For fats and oils, the mass fraction of the fatty acid methyl esters is equal to the mass fraction of the triacylglycerols in grams per 100 g. For cases in which this assumption is not allowed, see 5.2.2.2. U.K.

5.2.2.2. Use of correction factors U.K.

In certain cases, for example in the presence of fatty acids with less than eight carbon atoms or of acids with secondary groups, the areas shall be corrected with specific correction factors (Fci). These factors shall be determined for each single instrument. For this purpose suitable reference materials with certified fatty acid composition in the corresponding range shall be used.

Note 5: These correction factors are not identical to the theoretical FID correction factors, which are given in Appendix A, as they also include the performance of the injection system etc. However, in the case of bigger differences, the whole system should be checked for performance. U.K.

For this reference mixture, the mass percentage of the FAME i is given by the formula:

w i = (m i /Σ m) × 100

where

m i is the mass of the FAME i in the reference mixture;

Σm is the total of the masses of the various components as FAMEs of the reference mixture.

From the chromatogram of the reference mixture, calculate the percentage by area for the FAME i as follows: