- Latest available (Revised)

- Point in Time (17/05/2005)

- Original (As adopted by EU)

Directive 97/24/EC of the European Parliament and of the Council (repealed)Show full title

Directive 97/24/EC of the European Parliament and of the Council of 17 June 1997 on certain components and characteristics of two or three-wheel motor vehicles (repealed)

You are here:

- Directives originating from the EU

- 1997 No. 24

- Whole Directive

- Previous

- Next

- Show Geographical Extent(e.g. England, Wales, Scotland and Northern Ireland)

- Show Timeline of Changes

More Resources

Revised version PDFs

- Revised 01/01/20160.44 MB

- Revised 11/12/20137.75 MB

- Revised 07/09/20096.33 MB

- Revised 28/11/20063.25 MB

- Revised 08/09/20063.29 MB

- Revised 28/03/20065.31 MB

- Revised 17/05/20054.11 MB

- Revised 10/09/20034.13 MB

- Revised 20/09/20024.04 MB

- Revised 18/08/19974.02 MB

When the UK left the EU, legislation.gov.uk published EU legislation that had been published by the EU up to IP completion day (31 December 2020 11.00 p.m.). On legislation.gov.uk, these items of legislation are kept up-to-date with any amendments made by the UK since then.

This item of legislation originated from the EU

Legislation.gov.uk publishes the UK version. EUR-Lex publishes the EU version. The EU Exit Web Archive holds a snapshot of EUR-Lex’s version from IP completion day (31 December 2020 11.00 p.m.).

Changes over time for: Directive 97/24/EC of the European Parliament and of the Council (repealed)

Version Superseded: 28/03/2006

Alternative versions:

Status:

EU Directives are published on this site to aid cross referencing from UK legislation. Since IP completion day (31 December 2020 11.00 p.m.) no amendments have been applied to this version.

Directive 97/24/EC of the European Parliament and of the Council

of 17 June 1997

on certain components and characteristics of two or three-wheel motor vehicles (repealed)

THE EUROPEAN PARLIAMENT AND THE COUNCIL OF THE EUROPEAN UNION,

Having regard to the Treaty establishing the European Community, and in particular Article 100a thereof,

Having regard to the proposal from the Commission(1),

Having regard to the opinion of the Economic and Social Committee(2),

Acting in accordance with the procedure laid down in Article 189b of the Treaty(3) in the light of the joint text approved by the Conciliation Committee on 4 February 1997,

(1) Whereas it is necessary to adopt measures that are intended to ensure the operation of the internal market;

(2) Whereas, in each Member State, two or three-wheel motor vehicles must, in respect of the components and characteristics covered by this Directive, satisfy certain mandatory technical requirements which differ from one Member State to another; whereas, owing to those differences, such requirements constitute barriers to trade within the Community; whereas those barriers to the operation of the internal market may be removed if the same requirements are adopted by all of the Member States in place of their national regulations;

(3) Whereas the drawing-up of harmonized requirements concerning those components and characteristics of two and three-wheel motor vehicles is necessary in order to enable the type-approval and component type-approval procedures covered by Council Directive 92/61/EEC of 30 June 1992 relating to the type-approval of two or three-wheel vehicles(4) to be implemented in respect of each type of the aforesaid vehicles;

(4) Whereas, in order to facilitate access to markets in third countries, it appears necessary to establish equivalence between the requirements of Chapters 1 (tyres), 2 (lighting and light-signalling devices), 4 (rear-view mirrors) and 11 (safety belts) of the Annex to this Directive and those of United Nations ECE Regulations Nos 30, 54, 64 and 75 in respect of tyres, 3, 19, 20, 37, 38, 50, 56, 57, 72 and 82 in respect of lighting and light-signalling devices, 81 in respect of rear-view mirrors and 16 in respect of safety belts;

(5) Whereas, with regard to the aspects concerning the protection of the environment, namely atmospheric and noise pollution, it is necessary to pursue the aim of constantly improving the environment; whereas, for this purpose, limit values for pollutants and sound level must be laid down for the fastest possible application; whereas subsequent reductions in the limit values and changes in the testing procedure may be decided upon only on the basis of studies and research to be undertaken or pursued into the available or conceivable technological potential and into an analysis of their cost/benefit ratios in order to permit production, on an industrial scale, of vehicles which are able to meet these more stringent limits; whereas the decision on that subsequent reduction must be taken by the European Parliament and the Council at least three years before these limit values enter into force in order to enable the industry to take the necessary measures whereby their products may, by the intended date, comply with the new Community provisions; whereas the Decision of the European Parliament and of the Council will be based on proposals to be submitted by the Commission in due course;

(6) Whereas, pursuant to the provisions of Directive 92/61/EEC, the components and characteristics covered by this Directive may not be placed on the market and sold in the Member States unless they comply with the provisions of this Directive; whereas the Member States must take all the necessary measures to ensure fulfilment of the obligations resulting from this Directive.

(7) Whereas Member States should be enabled, by granting tax incentives, to promote the marketing of vehicles which, in advance, meet the requirements adopted at Community level concerning measures to counter pollutant and noise emissions;

(8) Whereas the methods of measuring the immunity of vehicles and separate technical units to electromagnetic radiation in order to check compliance with the provisions concerning electromagnetic compatibility (Chapter 8) require complex and costly installations; whereas, in order to enable Member States to provide such installations, provision should be made for deferring application of these measuring methods by three years from the entry into force of this Directive;

(9) Whereas, given the scale and impact of the action proposed in the sector in question, the Community measures which are the subject of this Directive are necessary, or even indispensable, to attain the objectives set, namely Community vehicle type approval; whereas these objectives cannot be adequately achieved by the Member States individually;

(10) Whereas technical progress requires rapid adaptation of the technical requirements set out in the Annex to this Directive; whereas, with the exception of the limit values for pollutants and sound level, this task should be assigned to the Commission in order to simplify and speed up the procedure; whereas, in all cases where the European Parliament and the Council confer upon the Commission authority to implement rules laid down in the two or three-wheel motor vehicle sector, it is appropriate to provide for a procedure for prior consultation between the Commission and Member States within a committee;

(11) Whereas safety or environmental requirements call for restrictions on tampering with certain types of two or three-wheel vehicle; whereas, if they are not to prove an obstacle to owner servicing and maintenance, such restrictions must be strictly limited to tampering which significantly modifies the vehicle's performance and pollutant and noise emissions;

(12) Whereas, a long as vehicles conform to the requirements of this Directive, no Member State may refuse registration or use of them; whereas the object of the requirements of this Directive should not be to oblige those Member States which do not allow two or three-wheel motor vehicles in their territory to tow a trailer to amend their rules,

HAVE ADOPTED THIS DIRECTIVE:

Article 1U.K.

This Directive and its Annex shall apply to:

tyres,

lighting and light-signalling devices,

external projections,

rear-view mirrors,

measures to counter air pollution,

fuel tanks,

measures to counter tampering,

electromagnetic compatibility,

permissible sound level and exhaust systems,

coupling devices and attachments,

safety belt anchorages and safety belts,

glazing, windscreen wipers and washers and de-icing and demisting devices,

for all types of vehicles as defined in Article 1 of Directive 92/61/EEC.

Article 2U.K.

Within three years following the date referred to in the third subparagraph of Article 8 (1), the Commission shall carry out a detailed study to ascertain whether the anti-tampering measures for vehicles, particularly those in categories A and B referred to in Chapter 7 of the Annex to this Directive, can be considered appropriate, inadequate or too extreme in light of the intended aims. In the basis of the conclusions of the study, the Commission will, if necessary, propose new legislative measures.

Article 3U.K.

1.The procedures governing the granting of component type-approval in respect of tyres, lighting and light-signalling devices, rear-view mirrors, fuel tanks, exhaust systems, safety belts and glazing for a type of two or three-wheel motor vehicle and the component type approval of a type of tyre, lighting and light-signalling device, rear-view mirror, fuel tank, exhaust system, safety belt and glazing, in the form of components, and the conditions applying to the free movement of such vehicles and for the free placing on the market of components shall be those set out in Chapters II and III respectively of Directive 92/61/EEC.

2.The procedure governing the granting of component type-approval in respect of external projections, measures to counter air pollution, measures to counter tampering, electromagnetic compatibility, permissible sound level, coupling devices for trailers and sidecar attachments, safety belt anchorages, windscreen wipers and washers and de-icing and demisting devices for a type of two or three-wheel motor vehicle, and the conditions applying to the free movement of such vehicles, shall be those set out in Chapters II and III respectively of Directive 92/61/EEC.

Article 4U.K.

1.In accordance with the provisions of Article 11 of Directive 92/61/EEC, the equivalence shall be recognized of the requirements of Chapters 1 (tyres), 2 (lighting and light-signalling devices), 4 (rear-view mirrors) and 11 (safety belts) of the Annex to this Directive and those of United Nations ECE Regulations Nos 30(5), 54(6), 64(7) and 75(8) in respect of tyres, 3(9), 19(10), 20(11), 37(12), 38(13), 50(14), 56(15), 57(16), 72(17) and 82(18) in respect of lighting and light-signalling devices, 81(19) in respect of rear-view mirrors, and 16(20) in respect of safety belts, in the version in force on the date on which this Directive is adopted.

For the purposes of applying the equivalence provided for in the first subparagraph, the installation requirements in Chapters 1 and 11 shall also apply to devices approved in accordance with the corresponding United ECE Regulations.

2.The Member States' authorities granting component type approval shall accept component type approvals issued in accordance with the requirements of the Regulations referred to in paragraph 1, and component type-approval marks, instead of the corresponding component type approvals and component type-approval marks issued in accordance with the requirements of this Directive.

Article 5U.K.

1.Within 24 months from the date of adoption of this Directive, the Commission shall submit to the European Parliament and to the Council a proposal prepared on the basis of research and an assessment of the costs and benefits deriving from the application of tightened-up limit values and laying down a subsequent stage during which measures will be adopted aimed at further tightening of the limit values for pollutants and the sound level of the vehicles concerned, as laid down respectively in Chapter 5, Annex II, Tables I and II and Chapter 9, Annex I. In its proposal, the Commission shall take into account and assess the cost-effectiveness of the various measures for reducing pollutant and noise emissions and shall present proportionate and reasonable measuring having regard to the intended aims.

2.The Decision of the European Parliament and of the Council, adopted on the basis of the Commission proposal referred to in paragraph 1, which shall be adopted by 1 January 2001, shall take account of the need to incorporate factors other than simply limit values which have been tightened up. The costs and benefits deriving from the implementation of the measures provided for in the said Decision shall be researched and assessed, jointly with interested parties such as industry, users and groups representing consumers or the public and these shall be proportionate and reasonable in the light of the intended aims.

Article 6U.K.

1.Member States may make provision for tax incentives only for motor vehicles conforming to the air-pollution and noise-pollution measures laid down in Chapter 5, Annex I, section 2.2.1.1.3 and Annex II, Tables I and II and Chapter 9, Annex I respectively of this Directive.

2.The incentives referred to in paragraph 1 must be in line with the provisions of the Treaty and meet the following conditions:

they shall be valid for all new vehicles placed on the market of a Member State which, in advance, comply with the requirements of this Directive referred to in paragraph 1,

they shall cease upon the mandatory implementation of the measures referred to in paragraph 1,

they shall, for each type of motor vehicle, involve lower amounts than the extra cost of the technical solutions applied and of their incorporation into the motor vehicle to enable the values laid down to be met.

3.The Commission shall be informed in good time of any intentions to introduce or alter any of the tax incentives referred to in paragraph 1, so that it can submit its comments.

Article 7U.K.

The changes needed:

to take into account any amendments to the United Nations ECE Regulations referred to in Article 4,

to adapt the Annex to technical progress — apart from the limit values for air and noise pollution set out in Chapter 5, Annex I, section 2.2.1.1.3, and Annex II, Tables I and II, and in Chapter 9, Annex I respectively,

shall be adopted in accordance with the procedure laid down in Article 13 of Council Directive 70/156/EEC of 6 February 1970 on the approximation of the laws of the Member States relating to the type-approval of motor vehicles and their trailers(21).

Article 8U.K.

1.Member States shall bring into force the laws, regulations and administrative provisions necessary to comply with this Directive before 18 December 1998. They shall forthwith inform the Commission thereof.

From the date referred to in the first subparagraph, Member States may no longer prohibit the first entry into service of vehicles complying with the provisions of this Directive or of certain of its chapters.

They shall apply these provisions from 17 June 1999.

However, the implementation of certain provisions in Chapters 5, 8 and 9 shall be deferred as specified in the said chapters.

2.When Member States adopt the measures referred to in paragraph 1, they shall contain a reference to this Directive or shall be accompanied by such reference on the occasion of their official publication. The methods of making such reference shall be laid down by Member States.

Article 9U.K.

1.Council Directive 80/780(EEC of 22 July 1980 on the approximation of the laws of the Member States relating to rear-view mirrors for two-wheeled motor vehicles with or without a side-car and to their fitting on such vehicles(22) shall be repealed when this Directive becomes applicable.

2.However, components for which approvals as laid down in Annex I to the Directive referred to in paragraph 1 have been granted may continue to be used.

3.Council Directive 78/1015/EEC of 23 November 1978 on the approximation of the laws of the Member States on the permissible sound level and exhaust system of motorcycles(23) shall be repealed on the date referred to the first subparagraph of Article 8.

4.Until the date referred to in the first subparagraph of Article 8 (1), approvals as referred to in Directive 78/1015/EEC may be granted for type approvals of vehicles referred to in Directive 92/61/EEC. The limit values laid down for noise levels in Annex I, [X1section 2.1.1] of Directive 78/1015/EEC shall apply.

Article 15 (4) (c) of Directive 92/61/EEC shall therefore apply when such vehicles are first put into service.

5.On the entry into force of this Directive, the provisions of Council Directive 89/336/EEC of 3 May 1989 on the approximation of the laws of the Member States relating to electromagnetic compatibility(24) shall cease to apply to vehicles covered by this Directive.

Editorial Information

Article 10U.K.

This Directive shall enter into force on the day of its publication in the Official Journal of the European Communities.

Article 11U.K.

This Directive is addressed to the Member States.

CHAPTER 1

TYRES FOR TWO OR THREE-WHEEL MOTOR VEHICLES AND THEIR FITTING

[X1LIST OF ANNEXES

| ANNEX I | Administrative provisons for the component type approval of tyres … |

| Appendix 1 | Information document for a type of tyre intended for two or three-wheel motor vehicles … |

| Appendix 2 | Certificate of component type approval for a type of tyre intended for two or three-wheel motor vehicles … |

| ANNEX II | Definitions, markings and requirements … |

| Appendix 1 | Explanatory diagram … |

| Appendix 2 | Arrangement of tyre markings … |

| Appendix 3 | List of load capacity indices and corresponding permissible maximum mass … |

| Appendix 4 | Marking and dimensions for certain types of tyre … |

| Appendix 5 | Method of measuring tyre dimensions … |

| Appendix 6 | Procedure for testing the load/speed performance … |

| Appendix 7 | Variation of load capacity as a function of speed … |

| Appendix 8 | Method for determining the dynamic growth of tyres … |

| ANNEX III | Requirements for vehicles with regard to the fitting of their tyres … |

| Appendix 1 | Information document in respect of the fitting of tyres to a type of two or three-wheel motor vehicle … |

| Appendix 2 | Certificate of vehicle type approval in respect of the fitting of tyres to a type of two or three-wheel motor vehicle …] |

ANNEX I

ADMINISTRATIVE PROVISIONS FOR THE COMPONENT TYPE APPROVAL OF A TYPE OF TYRE

1.APPLICATION FOR COMPONENT TYPE APPROVALU.K.

1.1.The application for the component type approval of a type of tyre must give precise details of the type of tyre to which the component type approval mark is to be affixed.U.K.

1.2.For each type of tyre that application must also give precise details on:U.K.

1.2.1.the tyre size designation as defined in Annex II, item 1.16,U.K.

1.2.2.the make or trade name,U.K.

1.2.3.category of use: normal, special, snow or moped,U.K.

1.2.4.tyre structure (diagonal or bias ply, bias belted, radial),U.K.

1.2.5.speed category symbol,U.K.

1.2.6.load capacity index,U.K.

1.2.7.whether the tyre is intended for use with or without an inner tube,U.K.

1.2.8.whether the tyre is ‘normal’ or ‘reinforced’,U.K.

1.2.9.the ply-rating number for motor cycle derivatives,U.K.

1.2.10.the outer dimensions: the overall tyre width and overall diameter,U.K.

1.2.11.the rims to which the tyre may be fitted,U.K.

1.2.12.the measuring rim and the test rim,U.K.

1.2.13.the test pressure and the pressure for measurement,U.K.

1.2.14.the coefficient x referred to in Annex II, item 1.19,U.K.

1.2.15.For tyres indentified by means of letter code ‘V’ within the size designation and suitable for speeds over 240 km/h or for tyres indentified by means of letter code ‘Z’ within the size designation and suitable for speeds over 270 km/h, the maximum speed permitted by the tyre manufacturer and the load carrying capacity allowed for that maximum speed. The maximum permitted speed and the relevant load carrying capacity shall be indicated in the type approval certificate (Appendix 2 of this Annex).U.K.

1.3.The application for component type approval shall also be accompanied by sketches or photographs in triplicate which identify the tread pattern and the envelope of the inflated tyre mounted on the measuring rim showing the relevant dimensions (see sections 3.1.1 and 3.1.2 of Annex II) of the tyre type submitted for approval. It shall also be accompanied by the test report issued by an approved test laboratory or by two samples of the tyre type at the discretion of the competent authority.U.K.

1.4.The tyre manufacturer may request that the EC component type approval be extended also to other types of modified tyres.U.K.

1.5.This Directive does not apply to new tyres designed only for ‘off-road’ use and marked ‘NHS’ (not for highway service) or for competitions.U.K.

2.MARKINGSU.K.

The samples of a type of tyre submitted for component type approval shall bear, in a clearly legible and indelible manner, the applicant's make or trade name and shall include sufficient space for the component type approval mark.

3.COMPONENT TYPE APPROVAL MARKU.K.

All tyres conforming to a type that has been component type-approved in compliance with this Directive shall bear the component type-approval mark described in Annex 5 to Directive 92/61/EEC of 30 June 1992 on the type approval of two or three-wheel motor vehicles.

The ‘a’ value defining the dimensions of the rectangle and the digits and letters making up the mark shall not be less than 2 mm.

4.MODIFICATION OF A TYRE TYPEU.K.

4.1.A modification of the tread pattern of a tyre does not require the repetition of tests prescribed in Annex II.U.K.

ANNEX II

DEFINITIONS, MARKINGS, AND REQUIREMENTS

1.DEFINITIONSU.K.

For the purposes of this chapter:

1.1.‘type of tyre’ means tyres which basically do not differ from one another in respect of:U.K.

1.1.1.the make or trade name,U.K.

1.1.2.the tyre size designation,U.K.

1.1.3.the category of use (normal: for tyres intended for normal road use; special: for special-purpose tyres such as those used for on-road and off-road purposes; snow or mopeds),U.K.

1.1.4.structure (diagonal or bias ply (cross-ply), bias-belted, radial),U.K.

1.1.5.speed category symbol,U.K.

1.1.6.load capacity index,U.K.

1.1.7.the cross section profile dimension when fitted to a specified rim;U.K.

1.2.‘tyre structure’ means the technical characteristics of a tyre carcass. A distinction is drawn, in particular, between the following tyre configurations:U.K.

1.2.1.‘diagonal or bias ply (cross-ply)’ means a tyre structure the ply cords of which extend to the beads and are laid in such a way as to form alternating angles which are perceptibly less than 90o to the tread centre line,U.K.

1.2.2.‘bias belted’ means a tyre structure of the ‘cross-ply’ type in which the carcass is restrained by a belt consisting of two or more layers of basically inextensible cord materials forming alternating angles close to those of the carcass,U.K.

1.2.3.‘radial’ means a tyre structure the ply cords of which extend to the beads and are laid substantially at 90o to the tread centre line, while the carcass is stabilized by a basically inextensible circumferential belt,U.K.

1.2.4.‘reinforced’ means a tyre structure in which the carcass is more resistant than that of a corresponding standard tyre;U.K.

1.3.‘bead’ means the part of the tyre the shape and structure of which enables it to fit the rim and hold the tyre on that rim(25);U.K.

1.4.‘cords’ means the strands forming the fabric of the plies in the pneumatic tyre(25);U.K.

1.5.‘ply’ means A layer of rubber coated parallel cords(25);U.K.

1.6.‘carcass’ means the part of the tyre other than the tread and the sidewalls which, when inflated, bears the load(25);U.K.

1.7.‘tread’ means that part of the tyre which comes into contact with the ground(25);U.K.

1.8.‘sidewall’ means that part of a tyre lying between the tread and the part intended to be covered by the wheel rim(25);U.K.

1.9.‘tread groove’ means the space between two adjacent ribs or blocks in the tread pattern(25);U.K.

1.10.‘main grooves’ means the wide grooves located in the central zone of the tread;U.K.

1.11.‘section width (S)’ means the linear distance between the outer edges of the sidewalls of an inflated tyre excluding the protrusions due to markings, embellishments or protective bands or ribs(25);U.K.

1.12.‘overall width’ means the linear distance between the outer edges of the sidewalls of an inflated tyre, including markings, embellishments and protective bands or ribs(25); the overall width of tyres the tread width of which is greater than the section width is the width of the tread;U.K.

1.13.‘section height (H)’ means the distance equalling half the difference beween the outer diameter of the tyre and the nominal rim diameter(26);U.K.

1.14.‘nominal aspect ratio (Ra)’ means one hundred times the number obtained by dividing the nominal section height by the nominal section width (S1) both being expressed in the same unit of measurement;U.K.

1.15.‘outer diameter (D)’ means the overall diameter of an inflated new tyre(26);U.K.

1.16.‘tyre size designation’ means the description containing the following:U.K.

1.16.1.the nominal section width (S1) (expressed in mm, except for certain types of tyre for which the tyre size designation is set out in the first Column of the tables in Appendix 4 to this Annex),U.K.

1.16.2.the nominal aspect ratio (Ra), except for certain types of tyre for which the tyre size designation is given in the first column of the tables in Appendix 4 to this Annex,U.K.

1.16.3.a conventional number (d) denoting the nominal rim diameter and corresponding to that diameter expressed either in the form of a code (a figure of less than 100) or in millimetres (a figure of more than 100).U.K.

1.16.3.1.the values in millimetres of symbol (d) expressed in code form are as follows:U.K.

| ‘d’ code expressed by one or two figures symbolizing the nominal diameter of the rim | Equivalence in mm |

|---|---|

| 4 | 102 |

| 5 | 127 |

| 6 | 152 |

| 7 | 178 |

| 8 | 203 |

| 9 | 229 |

| 10 | 254 |

| 11 | 279 |

| 12 | 305 |

| 13 | 330 |

| 14 | 356 |

| 15 | 381 |

| 16 | 406 |

| 17 | 432 |

| 18 | 457 |

| 19 | 483 |

| 20 | 508 |

| 21 | 533 |

| 22 | 559 |

| 23 | 584 |

1.17.‘nominal rim diameter (d)’ means the diameter of the rim on which a tyre is designed to be mounted(27);U.K.

1.18.‘rim’ means the support for either a tyre and inner tube or a tubeless tyre on which the beads of the tyre are seated(27);U.K.

1.19.‘theoretical rim’ means an imaginary rim the width of which would be X times the nominal section width of a tyre. The X value must be specified by the tyre manufacturer;U.K.

1.20.‘measuring rim’ means the rim on which a tyre must be fitted for dimensional measurement purposes;U.K.

1.21.‘test rim’ means the rim to which a tyre must be fitted for testing;U.K.

1.22.‘chunking’ means the breaking away of pieces of rubber from the tyre tread;U.K.

1.23.‘cord separation’ means parting of the cords from their coating rubber;U.K.

1.24.‘ply separation’ means the parting of adjacent plies;U.K.

1.25.‘tread separation’ means the pulling away of the tread from the carcassU.K.

1.26.‘load-capacity index’ means a figure associated with the maximum permissible load which a tyre can carry at the speed corresponding to its speed symbol according to the operating conditions specified by the manufacturer. Appendix 3 to Annex II certains a list of indices and the corresponding loads;U.K.

1.27.‘table of load variations as a function of speed’ means the table in Appendix 7 to Annex II stating, by reference to indices of load capacity and of capacity at nominal speed, load variations of a tyre used at speeds other than those corresponding to that indicated by the nominal speed category;U.K.

1.28.‘speed category’ meansU.K.

1.28.1.the speed, expressed by the speed category symbol as shown in 1.28.2,U.K.

1.28.2.speed categories are those set out in the following table:U.K.

| Speed category symbol | Relevant speed(km/h) |

|---|---|

| B | 50 |

| F | 80 |

| G | 90 |

| J | 100 |

| K | 110 |

| L | 120 |

| M | 130 |

| N | 140 |

| P | 150 |

| Q | 160 |

| R | 170 |

| S | 180 |

| T | 190 |

| U | 200 |

| H | 210 |

| V | 240 |

| W | 270 |

1.28.3.Tyres suitable for maximum speeds in excess of 240 km/h are indentified by the letter ‘V’ or ‘Z’ placed within the tyre size designation in front of the indications of tyre structure.U.K.

1.29.‘snow tyre’ means a tyre pattern and structure of which are designed primarily to ensure better behaviour than that of normal tyres in mud and fresh snow or slush. The tread pattern of snow tyres generally consists of grooves and/or blocks which are more widely spaced than those of a normal tyre;U.K.

1.30.‘MST’ (multiservice tyre) means a multi-use tyre, or in other words a tyre suitable for both on-road and off-road use;U.K.

1.31.‘maximum load rating’ means the maximum mass which a tyre is rated to carry:U.K.

1.31.1.For speed lower or equal to 130 km/h the maximum load rating must not exceed the percentage of the value associated with the relevant load capacity index of the tyre as indicated in the table ‘Load capacity variation with speed’ (see section 1.27) with reference to the speed category symbol of the tyre and the speed capability of the vehicle to which the tyre is fitted.U.K.

1.31.2.For speed above 130 km/h but not exceeding 210 km/h the maximum load rating must not exceed the value of the mass associated with the load capacity index of the tyre.U.K.

1.31.3.In the case of tyres designed for a speed exceeding 210 km/h but not exceeding 270 km/h, the maximum load rating shall not exceed the percentage of the mass associated with the load capacity index for the tyre set out in the table below with reference to the speed category symbol of the tyre and the maximum design speed of the vehicle to which the tyre is to be fitted.U.K.

| a For intermediate speeds linear interpolation of maximum load rating is allowed. | ||

| b Applicable only to tyres indentified by means of letter code ‘V’ within the size designation and up to the maximum speed specified by the tyre manufacturer. (See Item 1.2.15 of Annex I). | ||

| c Applicable also to tyres identified by means of letter code ‘Z’ within the size designation. | ||

| Maximum speed(km/h)a | Maximum Load Rating(%) | |

|---|---|---|

| Speed Category V Symbol | Speed Category System Wc | |

| 210 | 100 | 100 |

| 220 | 95 | 100 |

| 230 | 90 | 100 |

| 240 | 85 | 100 |

| 250 | (80)b | 95 |

| 260 | (75)b | 85 |

| 270 | (70)b | 75 |

1.31.4.For speeds in excess of 270 km/h the load rating must not exceed the mass specified by the tyre manufacturer with reference to the speed capability of the tyre.U.K.

For intermediate speeds between 270 km/h and the maximum speed permitted by the tyre manufacturer a linear interpolation of the load rating applies.

1.32.‘moped tyre’ means a tyre designed to be fitted on mopeds;U.K.

1.33.‘motor cycle tyre’ means a tyre designed primarily to be fitted on motor cyclesU.K.

1.34.‘rolling circumference (Cr)’ means the theoretical distance covered by the centre (axis) of the wheel of a vehicle in motion during one complete revolution of the tyre and obtained from the following formula:U.K.

Cr = f × D, where:

D is the outer diameter of the tyre in accordance with the tyre size designation set out in item 3.1.2 in this Annex

=

3,02 for tyres the rim diameter code for which is greater than, or equal to, 13

3,03 for radial-ply tyres the rim diameter code for which is not more than 12

2,99 for diagonal or bias-ply (cross-ply) tyres or bias-belted tyres the rim diameter code for which is not more than 12.

2.MARKINGSU.K.

2.1.On at least one of their sidewalls, tyres shall bear the following markings:U.K.

2.1.1.the make or trade name;U.K.

2.1.2.the tyre size designation as defined in item 1.16;U.K.

2.1.3.the indication of the tyre structure as follows:U.K.

2.1.3.1.in the case of diagonal or bias ply (cross-ply) tyres, no marking or the letter ‘D’ preceding the rim diameter code;U.K.

2.1.3.2.in the case of bias-belted tyres, the letter ‘B’ preceding the rim-diameter code and, optionally, the words ‘BIAS-BELTED’;U.K.

2.1.3.3.in the case of radial-ply tyres, the letter ‘R’ preceding the rim-diameter code and, optionally, the word ‘RADIAL’;U.K.

2.1.4.the speed category of the tyre, expressed by the symbol referred to in item 1.28.2;U.K.

2.1.5.the load capacity index as defined in 1.26;U.K.

2.1.6.the word ‘TUBELESS’ where the tyre is intended for use without an inner tube;U.K.

2.1.7.the symbol ‘REINFORCED’ or ‘REINF’ in the case of a reinforced tyre;U.K.

2.1.8.the date of manufacture comprising three digits, the first two giving the week and the third the year. This information need be shown on only one sidewall;U.K.

2.1.9.the symbol ‘M + S’ or ‘M.S’ or ‘M & S’ in the case of a snow tyre;U.K.

2.1.10.the symbol ‘MST’ in the case of multiservice tyres;U.K.

2.1.11.the term ‘MOPED’, ‘CICLOMOTORE’ or ‘CYCLOMOTEUR’ where a tyre is designed for mopeds;U.K.

2.1.12.Tyres suitable for speeds above 240 km/h must be marked with the appropriate letter code ‘V’ or ‘Z’, as applicable (see section 1.31.3) within the tyre size designation and in front of the indication of the structure (see section 2.1.3).U.K.

2.1.13.Tyres suitable for speeds above 240 km/h (or 270 km/h respectively) must bear, within parentheses, the marking of the load capacity index (see Item 2.1.5) applicable at a speed of 210 km/h (or 240 km/h respectively) and a reference speed category symbol (see Item 2.1.4) as follows:U.K.

‘V’ in case of tyres identified with the letter code ‘V’ within the size designation.

‘W’ in case of tyres identified with the letter code ‘Z’ within the size designation.

2.2.Appendix 2 provides an example of layout for the tyre markings.U.K.

2.3.The markings referred to in 2.1 and the component type approval mark prescribed in Section 3 of Annex I shall be moulded into or onto the tyres. They shall be clearly legible.U.K.

3.REQUIREMENTS RELATING TO TYRESU.K.

3.1.Tyre dimensionsU.K.

3.1.1.Section widthU.K.

3.1.1.1.the section width is calculated via the following formula:U.K.

S = S1 + K (A − A1),

where:

=

section width expressed in mm measured on measuring rim

=

nominal section width (in mm) as set out on the tyre sidewall in the tyre size designation

=

width expressed in mm of the measuring rim stated by the manufacturer in the technical description

=

theoretical rim width expressed in mm

The value S1 multiplied by the X factor quoted by the tyre manufacturer is used for A1 and the value 0,4 is used for K.

3.1.1.2.However, where the tyre size designation appears in the first column of the tables in Appendix 4 to Annex II, the section width (S1) and the theoretical rim width (A1) shall be those entered opposite the tyre size designation in those tables.U.K.

3.1.2.Tyre outer diameterU.K.

3.1.2.1.The outer diameter of a tyre is that obtained from the following formula:U.K.

D = d + 2H,

where:

=

the outer diameter expressed in mm

=

the nominal rim diameter expressed in mm

=

the nominal tyre height

H = S1 × 0,01 Ra, where:

=

the nominal section width

=

the nominal aspect ratio

as set out in the description on the tyre sidewall as required by Item 2.1.3.

3.1.2.2.However, the outer diameter of types of tyres for which the tyre size designation is entered in the first column of the tables in Appendix 4 to this Annex shall be that set out in the said tables opposite the tyre description.U.K.

3.1.3.Tyre measuring method;U.K.

The tyre dimensions shall be measured as specified in Appendix 5 to this Annex.

3.1.4.Specifications concerning tyre section width;U.K.

3.1.4.1.The overall width of a tyre may be less than the section width S as determined in accordance with Item 3.1.1.U.K.

3.1.4.2.It may exceed that value up to the value set out in Appendix 4 to this Annex or, in the case of tyre size designations not set out in the said Appendix 4, by the following percentages:U.K.

3.1.4.2.1.for a moped tyre, for a normal-purpose on-road and for a snow tyre for motor cycle:U.K.

+ 10 % in the case of a rim diameter code 13 and larger

+ 8 % for a rim diameter code of not more than 12;

3.1.4.2.2.for a multiservice tyre suitable for restricted on-road use and marked with MST + 25 %.U.K.

3.1.5.Specifications concerning the tyre's outer diameter;U.K.

3.1.5.1.The tyre's outer diameter must not exceed the minimum and maximum diameter values specified in Appendix 4 to this Annex.U.K.

3.1.5.2.The outer tyre diameter when the tyre size designation is not set out in Appendix 4 to this Annex shall not exceed the minimum and maximum diameter values obtained by applying the following formulas:U.K.

Dmin = d + (2H × a)

Dmax = d + (2H × b),

where:

H and d are as defined in Item 3.1.2.1 and a and b are as defined in Items 3.1.5.2.1 and 3.1.5.2.2 respectively:

3.1.5.2.1.for a moped tyre, for normal on-road tyre and for snow tyresU.K.

| a | |

|---|---|

| rim diameter 13 and larger | 0,97 |

| rim diameter not more than 12 | 0,93 |

| for a multiservice tyre | 1,0 |

3.1.5.2.2.for a moped tyre and for a normal-purpose on-road tyre for a motocycleU.K.

| b | |

|---|---|

| rim diameter 13 and larger | 1,07 |

| rim diameter not mor than 12 | 1,1 |

| for snow and multiservice tyres | 1,12 |

3.2.Load/speed perfomance testU.K.

3.2.1.The load/speed performance test shall be carried out on a tyre in accordance with the method set out in Appendix 6 to Annex IIU.K.

3.2.1.1.Where application is made for tyres indentified by means of letter code ‘V’ within the size designation and suitable for speeds over 240 km/h or for tyres identified by means of letter code ‘Z’ within the size designation and suitable for speeds over 270 km/h (see Item 1.2.15 in Annex I), the above Load/Speed Test is carried out on one tyre at the load and speed conditions marked within parenteses on the tyre (see Item 2.1.13). Another load/speed test must be carried out on a second tyre of the same type at the load and speed conditions, if any, specified as maximum by the tyre manufacturer.U.K.

3.2.2.After successfully undergoing the load/speed test a tyre shall not exhibit any tread ply or cord separation or any chunking or cord breakage.U.K.

3.2.3.The outer diameter of the tyre measured at least six hours after the load/speed performance test shall not differ from the outer diameter measured before the test by more than ± 3,5 %.U.K.

3.2.4.The tyre overall width measured at the end of the load/speed performance test shall not exceed the value set out in Item 3.1.4.2.U.K.

3.3.Dynamic growth of tyresU.K.

The tyres referred to in Item 1.1 in Appendix 8 to Annex II which have passed the load/speed performance test required in Item 3.2.1 shall undergo a dynamic growth test, to be carried out in accordance with the practical method set out in the said Appendix.

3.4.Where a tyre manufacturer produces a range of tyres, it is not necessary to carry out load/speed performance tests and dynamic growth tests on each type of tyre in the range. The option of choosing the least favourable case is left to the discretion of the authorities responsible for component type approval.U.K.

3.5.A modification of the tread pattern of a tyre is deemed not to necessitate repetition of the test specified in sections 3.2 and 3.3 of this Annex.U.K.

3.6.Extensions of approval for tyres suitable for speeds over 240 km/h for tyres identified by means of letter code ‘V’ within the size designation (or 270 km/h for tyres identified by means of letter code ‘Z’ within the size designation), with a view to certification for different maximum speeds and/or loads, are permitted, provided that a new test report relating to the new maximum speed and load rating is supplied by the technical service responsible for carrying out tests. Such new load/speed capabilities must be specified in Appendix 2 of Annex I.U.K.

Appendix 2

Arrangement of tyre markings

Example of the markings which must appear on type approved types of tyresU.K.

| b | 100/80 B 18 | 53 S | TUBELESS M + S | 013 |

These markings define a tyre:

having a nominal section width of 100,

having a nominal aspect ratio of 80,

being of bias-belted structure (B),

having a rim diameter of 457 mm, the code for which is 18,

having a load capacity of 206 kg, corresponding to load index 53 (see list in appendix 3),

classified in the speed category S (maximum speed 180 km/h),

which may be fitted without an inner tube (tubeless),

being of the snow type (M + S),

manufactured during week 1 (01) of the year 1993 (3).

The position and order of the markings constituting the tyre designation shall be as follows:

the tyre size designation including the nominal section width, the nominal aspect ratio, the symbol of the structure, where appropriate, and the nominal rim diameter shall be combined as shown in the above example i.e. 100/80 B 18;

the load capacity index and the speed category symbol shall be placed near the tyre size designation. They may either precede or follow this or be located above or below it;

the descriptions ‘TUBELESS’ and ‘REINFORCED’ or ‘REINF’ and ‘M + S’ or ‘M.S.’ or ‘M & S’ and ‘MST’ and/or ‘MOPED’, ‘CICLOMOTORE’ or ‘CYCLOMOTEUR’ may be further away from the dimensional description;

In the case of tyres suitable for speeds above 240 km/h, the letter codes ‘V’ or ‘Z’, as applicable, must be marked in front of the structure marking (e.g. 140/60ZR18). The reference load capacity index and speed category symbol must be marked within parentheses as applicable (see Item 2.1.13 of Annex II).

Appendix 3

List of load-capacity indices and corresponding permissible maximum mass

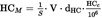

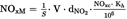

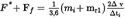

=

load capacity index

=

corresponding maximum mass (kg)

| A | B |

|---|---|

| 0 | 45 |

| 1 | 46,2 |

| 2 | 47,5 |

| 3 | 48,7 |

| 4 | 50 |

| 5 | 51,5 |

| 6 | 53 |

| 7 | 54,5 |

| 8 | 56 |

| 9 | 58 |

| 10 | 60 |

| 11 | 61,5 |

| 12 | 63 |

| 13 | 65 |

| 14 | 67 |

| 15 | 69 |

| 16 | 71 |

| 17 | 73 |

| 18 | 75 |

| 19 | 77,5 |

| 20 | 80 |

| 21 | 82,5 |

| 22 | 85 |

| 23 | 87,5 |

| 24 | 90 |

| 25 | 92,5 |

| 26 | 95 |

| 27 | 97,5 |

| 28 | 100 |

| 29 | 103 |

| 30 | 106 |

| 31 | 109 |

| 32 | 112 |

| 33 | 115 |

| 34 | 118 |

| 35 | 121 |

| 36 | 125 |

| 37 | 128 |

| 38 | 132 |

| 39 | 136 |

| 40 | 140 |

| 41 | 145 |

| 42 | 150 |

| 43 | 155 |

| 44 | 160 |

| 45 | 165 |

| 46 | 170 |

| 47 | 175 |

| 48 | 180 |

| 49 | 185 |

| 50 | 190 |

| 51 | 195 |

| 52 | 200 |

| 53 | 206 |

| 54 | 212 |

| 55 | 218 |

| 56 | 224 |

| 57 | 230 |

| 58 | 236 |

| 59 | 243 |

| 60 | 250 |

| 61 | 257 |

| 62 | 265 |

| 63 | 272 |

| 64 | 280 |

| 65 | 290 |

| 66 | 300 |

| 67 | 307 |

| 68 | 315 |

| 69 | 325 |

| 70 | 335 |

| 71 | 345 |

| 72 | 355 |

| 73 | 365 |

| 74 | 375 |

| 75 | 387 |

| 76 | 400 |

| 77 | 412 |

| 78 | 425 |

| 79 | 437 |

| 80 | 450 |

| 81 | 462 |

| 82 | 475 |

| 83 | 487 |

| 84 | 500 |

| 85 | 515 |

| 86 | 530 |

| 87 | 545 |

| 88 | 560 |

| 89 | 580 |

| 90 | 600 |

| 91 | 615 |

| 92 | 630 |

| 93 | 650 |

| 94 | 670 |

| 95 | 690 |

| 96 | 710 |

| 97 | 730 |

| 98 | 750 |

| 99 | 775 |

| 100 | 800 |

| 101 | 825 |

| 102 | 850 |

| 103 | 875 |

| 104 | 900 |

| 105 | 925 |

| 106 | 950 |

| 107 | 975 |

| 108 | 1 000 |

| 109 | 1 030 |

| 110 | 1 060 |

| 111 | 1 090 |

| 112 | 1 120 |

| 113 | 1 150 |

| 114 | 1 180 |

| 115 | 1 215 |

| 116 | 1 250 |

| 117 | 1 285 |

| 118 | 1 320 |

| 119 | 1 360 |

| 120 | 1 400 |

Appendix 4

Marking and dimensions of certain types of tyre

TABLE 1 A

Moped tyres

Descriptions and rim diameter up to code 12

| Tyre size designation | Width of theoretical RIM (code)(A1) | Overall diameter (mm) | Nominal(S1)(mm)section width | Maximum overall width(mm) | ||

|---|---|---|---|---|---|---|

| Dmin | D | Dmax | ||||

| 2 —12 | 1.35 | 413 | 417 | 426 | 55 | 59 |

| 2¼—12 | 1.50 | 425 | 431 | 441 | 62 | 67 |

| 2½— 8 | 1.75 | 339 | 345 | 356 | 70 | 76 |

| 2½— 9 | 1.75 | 365 | 371 | 382 | 70 | 76 |

| 2¾— 9 | 1.75 | 375 | 381 | 393 | 73 | 79 |

| 3 —10 | 2.10 | 412 | 418 | 431 | 84 | 91 |

| 3 —12 | 2.10 | 463 | 469 | 482 | 84 | 91 |

TABLE 1 B

Motor cycle tyres

Descriptions and rim diameter up to code 12

| Tyre size designation | Width of theoretical RIM (code)(A1) | Overall diameter (mm) | Nominal(S1)(mm)section width | Maximum overall width(mm) | ||

|---|---|---|---|---|---|---|

| Dmin | D | Dmax | ||||

| 2.50— 8 | 1.50 | 328 | 338 | 352 | 65 | 70 |

| 2.50— 9 | 354 | 364 | 378 | |||

| 2.50—10 | 379 | 389 | 403 | |||

| 2.50—12 | 430 | 440 | 451 | |||

| 2.75— 8 | 1.75 | 338 | 348 | 363 | 71 | 77 |

| 2.75— 9 | 364 | 374 | 383 | |||

| 2.75—10 | 389 | 399 | 408 | |||

| 2.75—12 | 440 | 450 | 462 | |||

| 3.00— 4 | 2.10 | 241 | 251 | 264 | 80 | 86 |

| 3.00— 5 | 266 | 276 | 291 | |||

| 3.00— 6 | 291 | 301 | 314 | |||

| 3.00— 7 | 317 | 327 | 342 | |||

| 3.00— 8 | 352 | 362 | 378 | |||

| 3.00— 9 | 378 | 388 | 401 | |||

| 3.00—10 | 403 | 413 | 422 | |||

| 3.00—12 | 454 | 464 | 473 | |||

| 3.25— 8 | 2.50 | 362 | 372 | 386 | 88 | 95 |

| 3.25— 9 | 388 | 398 | 412 | |||

| 3.25—10 | 414 | 424 | 441 | |||

| 3.25—12 | 465 | 475 | 492 | |||

| 3.50— 4 | 2.50 | 264 | 274 | 291 | 92 | 99 |

| 3.50— 5 | 289 | 299 | 316 | |||

| 3.50— 6 | 314 | 324 | 341 | |||

| 3.50— 7 | 340 | 350 | 367 | |||

| 3.50— 8 | 376 | 386 | 397 | |||

| 3.50— 9 | 402 | 412 | 430 | |||

| 3.50—10 | 427 | 437 | 448 | |||

| 3.50—12 | 478 | 488 | 506 | |||

| 4.00— 5 | 2.50 | 314 | 326 | 346 | 105 | 113 |

| 4.00— 6 | 339 | 351 | 368 | |||

| 4.00— 7 | 365 | 377 | 394 | |||

| 4.00— 8 | 401 | 415 | 427 | |||

| 4.00—10 | 452 | 466 | 478 | |||

| 4.00—12 | 505 | 517 | 538 | |||

| 4.50— 6 | 3.00 | 364 | 376 | 398 | 120 | 130 |

| 4.50— 7 | 390 | 402 | 424 | |||

| 4.50— 8 | 430 | 442 | 464 | |||

| 4.50— 9 | 456 | 468 | 490 | |||

| 4.50—10 | 481 | 493 | 515 | |||

| 4.50—12 | 532 | 544 | 568 | |||

| 5.00— 8 | 3.50 | 453 | 465 | 481 | 134 | 145 |

| 5.00—10 | 504 | 516 | 532 | |||

| 5.00—12 | 555 | 567 | 583 | |||

| 6.00— 6 | 4.00 | 424 | 436 | 464 | 154 | 166 |

| 6.00— 7 | 450 | 462 | 490 | |||

| 6.00— 8 | 494 | 506 | 534 | |||

| 6.00— 9 | 520 | 532 | 562 | |||

TABLE 2

Motor cycle and moped tyres

Normal profile

| a Tyres for normal use. | ||||||||

| b Multiservice and snow tyres. | ||||||||

| Tyre size designation | Width of theoretical RIM (code)(A1) | Overall diameter (mm) | Nominal(S1)(mm)section width | Maximum overall width (mm) | ||||

|---|---|---|---|---|---|---|---|---|

| Dmin | D | Dmax a | Dmax b | a | b | |||

| 1¾—19 | 1.20 | 582 | 589 | 597 | 605 | 50 | 54 | 58 |

| 2 —14 | 1.35 | 461 | 468 | 477 | 484 | 55 | 58 | 63 |

| 2 —15 | 486 | 493 | 501 | 509 | ||||

| 2 —16 | 511 | 518 | 526 | 534 | ||||

| 2 —17 | 537 | 544 | 552 | 560 | ||||

| 2 —18 | 562 | 569 | 577 | 585 | ||||

| 2 —19 | 588 | 595 | 603 | 611 | ||||

| 2 —20 | 613 | 620 | 628 | 636 | ||||

| 2 —21 | 638 | 645 | 653 | 661 | ||||

| 2 —22 | 663 | 670 | 680 | 686 | ||||

| 2¼—14 | 1.50 | 474 | 482 | 492 | 500 | 62 | 66 | 71 |

| 2¼—15 | 499 | 507 | 517 | 525 | ||||

| 2¼—16 | 524 | 532 | 540 | 550 | ||||

| 2¼—17 | 550 | 558 | 566 | 576 | ||||

| 2¼—18 | 575 | 583 | 591 | 601 | ||||

| 2¼—19 | 601 | 609 | 617 | 627 | ||||

| 2¼—20 | 626 | 634 | 642 | 652 | ||||

| 2¼—21 | 651 | 659 | 667 | 677 | ||||

| 2¼—22 | 677 | 685 | 695 | 703 | ||||

| 2½—14 | 1.60 | 489 | 498 | 508 | 520 | 68 | 72 | 78 |

| 2½—15 | 514 | 523 | 533 | 545 | ||||

| 2½—16 | 539 | 548 | 558 | 570 | ||||

| 2½—17 | 565 | 574 | 584 | 596 | ||||

| 2½—18 | 590 | 599 | 609 | 621 | ||||

| 2½—19 | 616 | 625 | 635 | 647 | ||||

| 2½—20 | 641 | 650 | 660 | 672 | ||||

| 2½—21 | 666 | 675 | 685 | 697 | ||||

| 2½—22 | 692 | 701 | 711 | 723 | ||||

| 2¾—14 | 1.85 | 499 | 508 | 518 | 530 | 75 | 80 | 86 |

| 2¾—15 | 524 | 533 | 545 | 555 | ||||

| 2¾—16 | 549 | 558 | 568 | 580 | ||||

| 2¾—17 | 575 | 584 | 594 | 606 | ||||

| 2¾—18 | 600 | 609 | 621 | 631 | ||||

| 2¾—19 | 626 | 635 | 645 | 657 | ||||

| 2¾—20 | 651 | 660 | 670 | 682 | ||||

| 2¾—21 | 676 | 685 | 695 | 707 | ||||

| 2¾—22 | 702 | 711 | 721 | 733 | ||||

| 3 —16 | 1.85 | 560 | 570 | 582 | 594 | 81 | 86 | 93 |

| 3 —17 | 586 | 596 | 608 | 620 | ||||

| 3 —18 | 611 | 621 | 633 | 645 | ||||

| 3 —19 | 637 | 647 | 659 | 671 | ||||

| 3¼—16 | 2.15 | 575 | 586 | 598 | 614 | 89 | 94 | 102 |

| 3¼—17 | 601 | 612 | 624 | 640 | ||||

| 3¼—18 | 626 | 637 | 651 | 665 | ||||

| 3¼—19 | 652 | 663 | 675 | 691 | ||||

TABLE 3

Motor cycle tyres

Normal profile

| a Tyres for normal on-road use | |||||||||

| b Special-purpose and snow tyres | |||||||||

| c Tyres for normal on-road use up to and including speed rating P | |||||||||

| d Tyres for normal on-road use beyond speed rating P and snow tyres | |||||||||

| e Special-purpose tyres | |||||||||

| Tyre size designation | Width of theoretical RIM (code)(A1) | Overall diameter (mm) | Nominal (S1)(mm)section width | Maximum overall width (mm) | |||||

|---|---|---|---|---|---|---|---|---|---|

| Dmin | D | Dmax a | Dmax b | c | d | e | |||

| 2.00—14 | 1.20 | 460 | 466 | 478 | 52 | 57 | 60 | 65 | |

| 2.00—15 | 485 | 491 | 503 | ||||||

| 2.00—16 | 510 | 516 | 528 | ||||||

| 2.00—17 | 536 | 542 | 554 | ||||||

| 2.00—18 | 561 | 567 | 579 | ||||||

| 2.00—19 | 587 | 593 | 605 | ||||||

| 2.25—14 | 1.60 | 474 | 480 | 492 | 496 | 61 | 67 | 70 | 75 |

| 2.25—15 | 499 | 505 | 517 | 521 | |||||

| 2.25—16 | 524 | 530 | 542 | 546 | |||||

| 2.25—17 | 550 | 556 | 568 | 572 | |||||

| 2.25—18 | 575 | 581 | 593 | 597 | |||||

| 2.25—19 | 601 | 607 | 619 | 623 | |||||

| 2.50—14 | 1.60 | 486 | 492 | 506 | 508 | 65 | 72 | 75 | 79 |

| 2.50—15 | 511 | 517 | 531 | 533 | |||||

| 2.50—16 | 536 | 542 | 556 | 558 | |||||

| 2.50—17 | 562 | 568 | 582 | 584 | |||||

| 2.50—18 | 587 | 593 | 607 | 609 | |||||

| 2.50—19 | 613 | 619 | 633 | 635 | |||||

| 2.50—21 | 663 | 669 | 683 | 685 | |||||

| 2.75—14 | 1.85 | 505 | 512 | 524 | 530 | 75 | 83 | 86 | 91 |

| 2.75—15 | 530 | 537 | 549 | 555 | |||||

| 2.75—16 | 555 | 562 | 574 | 580 | |||||

| 2.75—17 | 581 | 588 | 600 | 606 | |||||

| 2.75—18 | 606 | 613 | 625 | 631 | |||||

| 2.75—19 | 632 | 639 | 651 | 657 | |||||

| 2.75—21 | 682 | 689 | 701 | 707 | |||||

| 3.00—14 | 1.85 | 519 | 526 | 540 | 546 | 80 | 88 | 92 | 97 |

| 3.00—15 | 546 | 551 | 565 | 571 | |||||

| 3.00—16 | 569 | 576 | 590 | 596 | |||||

| 3.00—17 | 595 | 602 | 616 | 622 | |||||

| 3.00—18 | 618 | 627 | 641 | 647 | |||||

| 3.00—19 | 644 | 653 | 667 | 673 | |||||

| 3.00—21 | 694 | 703 | 717 | 723 | |||||

| 3.00—23 | 747 | 754 | 768 | 774 | |||||

| 3.25—14 | 2.15 | 531 | 538 | 552 | 560 | 89 | 98 | 102 | 108 |

| 3.25—15 | 556 | 563 | 577 | 585 | |||||

| 3.25—16 | 581 | 588 | 602 | 610 | |||||

| 3.25—17 | 607 | 614 | 628 | 636 | |||||

| 3.25—18 | 630 | 639 | 653 | 661 | |||||

| 3.25—19 | 656 | 665 | 679 | 687 | |||||

| 3.25—21 | 708 | 715 | 729 | 737 | |||||

| 3.50—14 | 2.15 | 539 | 548 | 564 | 572 | 93 | 102 | 107 | 113 |

| 3.50—15 | 564 | 573 | 589 | 597 | |||||

| 3.50—16 | 591 | 598 | 614 | 622 | |||||

| 3.50—17 | 617 | 624 | 640 | 648 | |||||

| 3.50—18 | 640 | 649 | 665 | 673 | |||||

| 3.50—19 | 666 | 675 | 691 | 699 | |||||

| 3.50—21 | 716 | 725 | 741 | 749 | |||||

| 3.75—16 | 2.15 | 601 | 610 | 626 | 634 | 99 | 109 | 114 | 121 |

| 3.75—17 | 627 | 636 | 652 | 660 | |||||

| 3.75—18 | 652 | 661 | 677 | 685 | |||||

| 3.75—19 | 678 | 687 | 703 | 711 | |||||

| 4.00—16 | 2.50 | 611 | 620 | 638 | 646 | 108 | 119 | 124 | 130 |

| 4.00—17 | 637 | 646 | 664 | 672 | |||||

| 4.00—18 | 662 | 671 | 689 | 697 | |||||

| 4.00—19 | 688 | 697 | 715 | 723 | |||||

| 4.25—16 | 2.50 | 623 | 632 | 650 | 660 | 112 | 123 | 129 | 137 |

| 4.25—17 | 649 | 658 | 676 | 686 | |||||

| 4.25—18 | 674 | 683 | 701 | 711 | |||||

| 4.25—19 | 700 | 709 | 727 | 737 | |||||

| 4.50—16 | 2.75 | 631 | 640 | 658 | 665 | 123 | 135 | 141 | 142 |

| 4.50—17 | 657 | 666 | 684 | 694 | |||||

| 4.50—18 | 684 | 691 | 709 | 719 | |||||

| 4.50—19 | 707 | 717 | 734 | 745 | |||||

| 5.00—16 | 3.00 | 657 | 666 | 686 | 698 | 129 | 142 | 148 | 157 |

| 5.00—17 | 683 | 692 | 710 | 724 | |||||

| 5.00—18 | 708 | 717 | 735 | 749 | |||||

| 5.00—19 | 734 | 743 | 761 | 775 | |||||

TABLE 4

Motor cycle tyres

Low profile

| a Tyres for normal on-road use | |||||||||

| b Special-purpose and snow tyres | |||||||||

| c Tyres for normal on-road use up to and including speed rating P | |||||||||

| d Tyres for normal on-road use beyond speed rating P and snow tyres | |||||||||

| e Special-purpose tyres | |||||||||

| Tyre size designation | Width of theoretical rim(code)(A1) | Overall diameter (mm) | Nominal(S1)(mm) section width | Maximum overall width (mm) | |||||

|---|---|---|---|---|---|---|---|---|---|

| Dmin | D | Dmax a | Dmax b | c | d | e | |||

| 3.60—18 | 2.15 | 605 | 615 | 628 | 633 | 93 | 102 | 108 | 113 |

| 3.60—19 | 631 | 641 | 653 | 658 | |||||

| 4.10—18 | 2.50 | 629 | 641 | 654 | 663 | 108 | 119 | 124 | 130 |

| 4.10—19 | 655 | 667 | 679 | 688 | |||||

| 5.10—16 | 3.00 | 615 | 625 | 643 | 651 | 129 | 142 | 150 | 157 |

| 5.10—17 | 641 | 651 | 670 | 677 | |||||

| 5.10—18 | 666 | 676 | 694 | 702 | |||||

| 4.25/85—18 | 2.50 | 649 | 659 | 673 | 683 | 112 | 123 | 129 | 137 |

| 4.60—16 | 2.75 | 594 | 604 | 619 | 628 | 117 | 129 | 136 | 142 |

| 4.60—17 | 619 | 630 | 642 | 654 | |||||

| 4.60—18 | 644 | 654 | 670 | 678 | |||||

TABLE 5

Tyres for motorcycle derivatives

| Tyre size designation | Width of theoretical rim(code)(A1) | Overall diameter (mm) | Nominal (S1)(mm) section width | Maximum overall width (mm) | ||

|---|---|---|---|---|---|---|

| Dmin | D | Dmax | ||||

| 3.00— 8C | 2.10 | 359 | 369 | 379 | 80 | 86 |

| 3.00—10C | 410 | 420 | 430 | |||

| 3.00—12C | 459 | 471 | 479 | |||

| 3.50— 8C | 2.50 | 376 | 386 | 401 | 92 | 99 |

| 3.50—10C | 427 | 437 | 452 | |||

| 3.50—12C | 478 | 488 | 513 | |||

| 4.00— 8C | 3.00 | 405 | 415 | 427 | 108 | 117 |

| 4.00—10C | 456 | 466 | 478 | |||

| 4.00—12C | 507 | 517 | 529 | |||

| 4.50— 8C | 3.50 | 429 | 439 | 453 | 125 | 135 |

| 4.50—10C | 480 | 490 | 504 | |||

| 4.50—12C | 531 | 541 | 555 | |||

| 5.00— 8C | 3.50 | 455 | 465 | 481 | 134 | 145 |

| 5.00—10C | 506 | 516 | 532 | |||

| 5.00—12C | 555 | 567 | 581 | |||

TABLE 6

Low-pressure motor cycle tyres

| Tyre size designation | Width of theoretical rim(code)(A1) | Overall diameter (mm) | Nominal (S1)(mm) section width | Maximum overall width (mm) | ||

|---|---|---|---|---|---|---|

| Dmin | D | Dmax | ||||

| 5.4— 6 | 4.00 | 373 | 379 | 395 | 135 | 146 |

| 5.4—10 | 474 | 481 | 497 | |||

| 5.4—12 | 525 | 532 | 547 | |||

| 5.4—14 | 576 | 582 | 598 | |||

| 5.4—16 | 626 | 633 | 649 | |||

| 6.7—10 | 5.00 | 532 | 541 | 561 | 170 | 184 |

| 6.7—12 | 583 | 592 | 612 | |||

| 6.7—14 | 633 | 642 | 662 | |||

TABLE 7

Motor cycle tyres

Descriptions and dimensions of American tyres

| Tyre size designation | Width of theoretical rim(code)(A1) | Overall diameter (mm) | Nominal (S1)(mm) section width | Maximum overall width (mm) | ||

|---|---|---|---|---|---|---|

| Dmin | D | Dmax | ||||

| MH90—21 | 1.85 | 682 | 686 | 700 | 80 | 89 |

| MJ90 —18 | 2.15 | 620 | 625 | 640 | 89 | 99 |

| MJ90 —19 | 2.15 | 645 | 650 | 665 | ||

| ML90 —18 | 2.15 | 629 | 634 | 650 | 93 | 103 |

| ML90 —19 | 2.15 | 654 | 659 | 675 | ||

| MM90—19 | 2.15 | 663 | 669 | 685 | 95 | 106 |

| MN90—18 | 2.15 | 656 | 662 | 681 | 104 | 116 |

| MP90 —18 | 2.15 | 667 | 673 | 692 | 108 | 120 |

| MR90 —18 | 2.15 | 680 | 687 | 708 | 114 | 127 |

| MS90 —17 | 2.50 | 660 | 667 | 688 | 121 | 134 |

| MT90 —16 | 3.00 | 642 | 650 | 672 | 130 | 144 |

| MT90 —17 | 3.00 | 668 | 675 | 697 | ||

| MU90 —15M/C | 3.50 | 634 | 642 | 665 | 142 | 158 |

| MU90 —16 | 3.50 | 659 | 667 | 690 | ||

| MV90 —15M/C | 3.50 | 643 | 651 | 675 | 150 | 172 |

| MP85 —18 | 2.15 | 654 | 660 | 679 | 108 | 120 |

| MR85 —16 | 2.15 | 617 | 623 | 643 | 114 | 127 |

| MS85 —18 | 2.50 | 675 | 682 | 702 | 121 | 134 |

| MT85 —18 | 3.00 | 681 | 688 | 709 | 130 | 144 |

| MV85 —15M/C | 3.50 | 627 | 635 | 658 | 150 | 172 |

Appendix 5

Method of measuring tyre dimensions

1.The tyre is fitted to the measuring rim and inflated to the pressure(28) specified by its manufacturer.U.K.

2.The tyre mounted on its rim is left at ambient laboratory temperature for at least 24 hours.U.K.

3.The pressure is reset at the value specified in Item 1.U.K.

4.The overall width is measured by means of a calliper gauge at six equally spaced points, account being taken of the thickness of the ribs or bands.U.K.

The highest measurement thus obtained shall be retained as the overall width.

5.The outer diameter is determined as follows: the maximum circumference is measured and the figure thus obtained is divided by π (3,1416).U.K.

Appendix 6

Procedure for testing load/speed performance

1.TYRE PREPARATIONU.K.

1.1.A new tyre shall be fitted to the test rim identified by the manufacturer.U.K.

1.2.It shall be inflated to the appropriate pressure as set out in the following table:U.K.

| a For speeds above 240 km/h the test pressure is 3,20 bar (320 kPa). | ||||

| TEST INFLATION PRESSURE | ||||

|---|---|---|---|---|

| Tyre version | Speed category | Pressure | ||

| bar | kPa | |||

| MOPEDS | ||||

| standard | B | 2,25 | 225 | |

| reinforced | B | 3,0 | 300 | |

| MOTORCYCLES standard | F, G, J, K | 2,5 | 250 | |

| L, M, N, P | 2,5 | 250 | ||

| Q, R, S | 3,0 | 300 | ||

| T, U, H, Va | 3,5 | 350 | ||

| reinforced | F, G, J, K, L, M, N, P | 3,3 | 330 | |

| Q, R, S, T, U, H | 3,9 | 390 | ||

| MOTORCYCLE DERIVATIVES | 4PR | F, G, J, K, L, M | 3,7 | 370 |

| 6PR | 4,5 | 450 | ||

| 8PR | 5,2 | 520 | ||

Other types of tyre shall be inflated to the pressure quoted by their manufacturer.

1.3.The tyre manufacturer may request, giving reasons, the use of an inflation pressure differing from those listed in section 1.2. In such a case the tyre is inflated to that pressure (see item 1.12.13 in Annex I).U.K.

1.4.The wheel/tyre combination shall be stored at the temperature of the test chamber for at least three hours.U.K.

1.5.The tyre pressure shall be brought to that specified in Items 1.2 or 1.3.U.K.

2.TEST SEQUENCEU.K.

2.1.The tyre/wheel combination shall be fitted to a test spindle and pressed against the outer surface of a smooth flywheel having a diameter of 1,7 m ± 1 % or 2,0 m ± 1 %.U.K.

2.2.A load which is equal to 65 % of the following shall be applied to the test spindle:U.K.

2.2.1.The load rating corresponding to the load capacity index for tyres bearing speed symbols up to and including ‘H’,U.K.

2.2.2.The load rating associated with a maximum speed of 240 km/h for tyres bearing speed symbol ‘V’ (see paragraph 1.31.3 in this Annex),U.K.

2.2.3.The loading rating associated with a maximum speed of 270 km/h for tyres with speed symbol ‘W’ (see paragraph 1.31.3 of this Annex),U.K.

2.2.4.The load rating associated with the maximum speed specified by the tyre manufacturer for tyres suitable for speeds above 240 km/h (or 270 km/h as applicable) (see paragraph 3.2.1.1),U.K.

2.2.5.In the case of moped tyres (speed category symbol B), the test load shall be 65 % on a test drum which is 1,7 m in diameter and 67 % on a test drum which is 2,0 m in diameter.U.K.

2.3.Throughout the test the tyre pressure shall not be reset and the test load shall be held constant.U.K.

2.4.During the test the temperature in the test room shall be kept at between 20 and 30 oC or at a higher temperature if so accepted by the manufacturer.U.K.

2.5.The test shall proceed uninterrupted, in accordance with the following criteria:U.K.

2.5.1.time for transition from speed 0 to initial test speed: 20 minutes,U.K.

2.5.2.Initial test speed: equal to the maximum speed intended for the type of tyre, reduced by 30 km/h if the test is carried out on a 2 m-diameter drum or by 40 km/h if the test is carried out on a 1,7 m-diameter drum,U.K.

2.5.2.1.The maximum speed to be considered for the second test in the case of tyres suitable for speeds above 240 km/h for tyres identified by means of letter code ‘V’ within the size designation (or 270 km/h for tyres identified by means of letter code ‘Z’ within the size designation) is the maximum speed specified by the tyre manufacturer (see 1.2.15 of Annex I).U.K.

2.5.3.successive speed increments: 10 km/h,U.K.

2.5.4.duration of test at each speed-range: 10 minutes,U.K.

2.5.5.total duration of test: one hour,U.K.

2.5.6.maximum test speed: maximum speed intended for the type of tyre if the test is carried out on a 2 m-diameter drum and maximum speed intended for the type of tyre reduced by 10 km/h if the test is carried out on a 1,7 m-diameter drum,U.K.

2.5.7.In the case of moped tyres (speed-category symbol B), the test speed shall be 50 km/h, the time taken to accelerate from 0 to 50 km/h being 10 minutes, a steady state speed then being held for 30 minutes and the total duration of the test being 40 minutes.U.K.

2.6.However, if a second test is performed to assess the top performances of tyres suitable for speeds above 240 km/h, the procedure shall be as follows:U.K.

2.6.1.Twenty minutes to build up from zero to the initial test speed,U.K.

2.6.2.Twenty minutes at the initial test speed,U.K.

2.6.3.Ten minutes to build up to the maximum test speed,U.K.

2.6.4.Five minutes at the maximum test speed.U.K.

3.EQUIVALENT TEST METHODSU.K.

If a test method other than that described in Item 2 is used, its equivalence shall be demonstrated.

Appendix 7

Variation of load capacity as a function of speed

| Speed(km/h) | Variation in load carrying capacity (%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Moped | rim diameter code ≤ 12 | rim diameter code ≥ 13 | ||||||||

| speed symbol | speed symbol | |||||||||

| B | J | K | L | J | K | L | M | N | P and above | |

| 30 | + 30 | + 30 | + 30 | + 30 | + 30 | + 30 | + 30 | + 30 | + 30 | + 30 |

| 50 | 0 | + 30 | + 30 | + 30 | + 30 | + 30 | + 30 | + 30 | + 30 | + 30 |

| 60 | + 23 | + 23 | + 23 | + 23 | + 23 | + 23 | + 23 | + 23 | + 23 | |

| 70 | + 16 | + 16 | + 16 | + 16 | + 16 | + 16 | + 16 | + 16 | + 16 | |

| 80 | + 10 | + 10 | + 10 | + 10 | + 10 | + 10 | + 10 | + 10 | + 14 | |

| 90 | + 5 | + 5 | + 7,5 | + 5 | + 5 | + 7,5 | + 7,5 | + 7,5 | + 12 | |

| 100 | 0 | 0 | + 5 | 0 | 0 | + 5 | + 5 | + 5 | + 10 | |

| 110 | − 7 | 0 | + 2,5 | 0 | + 2,5 | + 2,5 | + 2,5 | + 8 | ||

| 120 | − 15 | − 6 | 0 | 0 | 0 | 0 | + 6 | |||

| 130 | − 25 | − 12 | − 5 | 0 | 0 | + 4 | ||||

| 140 | 0 | 0 | ||||||||

Appendix 8

Method for determining the dynamic growth of tyres

1.SCOPE AND EXTENTU.K.

1.1.This test method shall apply to motorcycle tyres of the types referred to in Item 3.4.1 of this Appendix.U.K.

1.2.It is intended to determine the maximum growth of the tyre which is due to the effect of the centrifugal force at the maximum permissible speed.U.K.

2.DESCRIPTION OF TEST PROCEDUREU.K.

2.1.The test axle and the rim shall be checked in order to ensure that radial eccentricity is less than ± 0,5 mm and that lateral displacement is less than ± 0,5 mm when measured at the outer periphery of the bead seat of the wheel.U.K.

2.2.Contour-outline deviceU.K.

Any device (projection grid camera, spotlights and others) enabling the outer contour of the cross section of the tyre to be outlined distinctly or to establish an enveloping curve, at right angles to the equator of the tyre at the point of maximum tread deformation.

This device shall reduce any deformation to a minimum and ensure a constant (known) ratio (K) between the contour plotted and the acutual diemensions of the tyre.

This device will enable the tyre contour to be determined in relation to the wheel axis.

3.EXECUTION OF TESTU.K.

3.1.During the test the temperature in the test room shall be held between 20 oC and 30 oC or at a higher temperature if so accepted by the tyre manufacturer.U.K.

3.2.The tyres to be tested must have undergone the load/speed performance test in accordance with Appendix 6 without any faults having emerged.U.K.

3.3.The tyre to be tested shall be fitted to a wheel the rim of which conforms to the applicable standard.U.K.

3.4.The tyre inflation pressure (test inflation pressure) shall be adjusted to the values indicated in Item 3.4.1.U.K.

3.4.1.Diagonal or bias ply (cross-ply) and bias-belted tyres.U.K.

| Speed category symbol | Tyre version | Test inflation pressure | |

|---|---|---|---|

| bar | kPa | ||

| P/Q/R/S | standard | 2,5 | 250 |

| T and above | standard | 2,9 | 290 |

3.5.The wheel/tyre combination shall be stored at the temperature of the test room for at least three hours.U.K.

3.6.Following that period of storage the inflation pressure shall be corrected to the value laid down in Item 3.4.1.U.K.

3.7.The wheel/tyre combination shall be mounted on the test axle and checked to ensure that it turns freely. The tyre may be rotated by a motor acting on the test axle or else via pressure against a test drum.U.K.

3.8.The entire assembly shall be accelerated without interruption in order to achieve, within five minutes, the maximum speed capability of the tyre.U.K.

3.9.The contour-outline device shall be installed, care being taken to ensure that it is at right angles to the (direction of) rotation of the tread of the tyre being tested.U.K.

3.10.A check shall be made that the peripheral speed of the tread surface is equal to the maximum speed capability of the tyre ± 2 %. The equipment shall be kept at a constant speed for five minutes at least and then the cross section of the tyre shall be traced in the area of maximum deformation or a check should be made that the tyre does not exceed the enveloping curve.U.K.

4.ASSESSMENT OF RESULTSU.K.

4.1.The envelope of the tyre/wheel assembly shall be as in the example below.U.K.

With reference to items 3.1.4 and 3.1.5 in this Annex, the limit values for the envelope outline are laid down as follows:

| Tyre speed category | dynH (mm) | |

|---|---|---|

| Category of use: Normal | Category of use: Snow and special | |

| P/Q/R/S | H × 1,1 | H × 1,15 |

| T/U/H | H × 1,13 | H × 1,18 |

| Over 210 km/h | H × 1,16 | — |

4.1.1.The main dimensions of the enveloping curve must be adjusted, if applicable, taking into account the constant ratio K (see paragraph 2.2 above).U.K.

4.2.The tyre contour deformation at maximum speed shall not go beyond the envelope outline when related to the tyre axes.U.K.

4.3.No other test is carried out on the tyre.U.K.

5.EQUIVALENT TEST METHODSU.K.

If a method other than that described in item 2 is used its equivalence shall be demonstrated.

ANNEX III

REQUIREMENTS FOR VEHICLES WITH REGARD TO THE FITTING OF THEIR TYRES

1.GENERALU.K.

1.1.Subject to the provisions of section 2, every tyre fitted to a vehicle, including any spare, shall be type-approved in accordance with the provisions of this Directive.U.K.

1.2.Tyre FitmentU.K.

1.2.1.All tyres fitted to a vehicle shall be identical as regards the aspects covered by Annex II, item 1.1.5,U.K.

1.2.2.All tyres fitted to a given axle shall be of the same type (see Annex II, item 1.1),U.K.

1.2.3.The manufacturer of the vehicle shall indicate the designations of tyres in accordance with the requirements of this Chapter. This or these tyre(s) made by the tyre manufacturer to the tolerances laid down in Annex II, items 3.1.4, 3.1.5 and 3.3 shall move freely in their intended position. The space in which the wheel revolves must be such as to allow unrestricted movement when the maximum permissible size of tyres is used within the suspension, steering and wheel guard constraints provided by the vehicle manufacturer,U.K.

1.3.Load capacityU.K.

1.3.1.The maximum load rating, as defined in item 1.31 of Annex II and account being taken of the requirements set out in Appendix 7 to Annex II, of every tyre with which the vehicle is fitted shall be at least equal to the following:U.K.

the maximum permissible axle mass where the axle is equipped with one tyre only;

half of the maximum permissible axle mass where the axle is equipped with two tyres in single formation;

0,54 times the maximum permissible axle mass where the axle is equipped with two tyres in dual (twin) formation;

0,27 times the maximum permissible axle mass where the axle is equipped with two sets of tyres in dual (twin) formation,

with reference to the maximum permissible axle mass declared by the vehicle manufacturer.

1.4.Speed capabilityU.K.

1.4.1.Every tyre with which a vehicle is normally fitted must have a speed category symbol (see Annex II section 1.28) compatible with the maximum design speed of the vehicle (as declared by the vehicle manufacturer including the tolerance permitted for series production conformity checks) or the applicable load/speed combination (see Annex II section 1.27),U.K.

1.4.2.The above specification does not apply: in the case of vehicles normally equipped with ordinary tyres and occasionally supplied with snow tyres or multiservice tyres.U.K.

However, in this case the speed category symbol of the snow tyres or multiservice tyres must correspond to a speed either greater than the maximum design speed of the vehicle (as declared by the vehicle manufacturer) or of not less than 130 km/h (or both).

If, nevertheless, the maximum design speed of the vehicles (as declared by the vehicle manufacturer) is greater than the speed corresponding to the speed category symbol of the snow tyres or multiservice tyre, a maximum speed warning label specifying the maximum speed capability of the snow tyres must be displayed inside the vehicle in a prominent position readily visible to the driver.

2.SPECIAL CASESU.K.

2.1.Tyres which have been component type approved according to Directive 92/23/EEC may also be fitted to motorcycles with side-car, three-wheel mopeds, tricycles and quadricycles.U.K.

2.2.Motorcycle tyres may also be fitted to mopeds.U.K.

2.3.In the case of a vehicle which is fitted with tyres which are not motorcycle tyres, passenger car tyres or commercial vehicle tyres, due to special conditions of use (e.g. agricultural tyres, industrial truck tyres, all terrain vehicle tyres), the requirements of Annex II do not apply, provided that the approval authority is satisfied that the tyres fitted are suitable for the operating conditions of the vehicle.U.K.

2.4.Tyres fitted to low performance mopeds as defined in the note set out in Annex I to Directive 92/61/EEC on the type approval of two or three-wheel motor vehicles may be of a different type from those covered by the requirements of this Chapter, owing to special conditions of use, provided that the authority responsible for vehicle type approval receives an assurance that the tyres fitted are appropriate to the conditions of use of the vehicle.U.K.

CHAPTER 2

LIGHTING AND LIGHT-SIGNALLING DEVICES OF TWO OR THREE-WHEEL MOTOR VEHICLES

[X1LIST OF ANNEXES

| ANNEX I | General requirements applying to the component type-approval of a type of lighting and light-signalling device for two or three-wheel motor vehicles … |

| Appendix 1 | Colours of light emitted — Trichromatic coordinates … |

| Appendix 2 | Examples of arrangements of approval marks … |

| ANNEX II | Requirements concerning the component type-approval of front position (side) lamps, rear lamps, stop lamps, direction indicator lamps, rear registration-plate illuminating device, front fog lamps, rear fog lamps, reversing lamps and retro-reflectors fitted to two or three-wheel motor vehicles … |

| Appendix 1 | Minimum horizontal (H) and vertical (V) angles of spatial light distribution … |

| Appendix 2 | Photometric measurements … |

| Appendix 3 | Photometric measurements of the rear registration-plate illuminating device … |

| Appendix 4 | Information document … |

| Appendix 5 | Component type-approval certificate … |

| ANNEX III | Requirements relating to the component type-approval of devices (headlamps) using incandescent or halogen filament lamps emitting a passing and/or driving beam fitted to two or three-wheel motor vehicles … |

| ANNEX III-A | Headlamps for mopeds … |

| Appendix 1 | Photometric tests on headlamps equipped with category S 3 and S 4 lamps … |

| Appendix 2 | Photometric tests on headlamps equipped with category HS 2 halogen lamps … |

| Appendix 3 | Information document in respect of a type of headlamp intended for mopeds … |

| Appendix 4 | Component type-approval certificate in respect of a type of headlamp intended for mopeds … |

| ANNEX III-B | Headlamps for motorcycles and tricycles emitting a symmetrical passing beam and a driving beam by means of filament lamps … |

| Appendix 1 | Photometric tests … |

| Appendix 2 | Test on the stability of the photometric behaviour of headlamps in operation … |

| Appendix 3 | Requirements for lamps incorporating lenses of plastic material and testing of lens or material samples and of complete lamps … |

| Appendix 4 | Information document in respect of a type of headlamp fitted with filament lamps, emitting a symmetrical passing beam and a driving beam and intended to be fitted to motorcycles and tricycles … |

| Appendix 5 | Component type-approval certificate in respect of a type of headlamp fitted with filament lamps, emitting a symmetrical passing beam and a driving beam and intended for motorcycles and tricycles … |

| ANNEX III-C | Headlamps for motorcycles and tricycles emitting an asymmetrical passing beam and a driving beam and fitted with halogen filament lamps (HS 1 lamps) or filament lamps of category R 2 … |

| Appendix 1 | Measuring screen … |

| Appendix 2 | Test on the stability of the photometric performance of headlamps in operation |

| Appendix 3 | Requirements for lamps incorporating lenses of plastic material and testing of lens or material samples and of complete lamps … |

| Appendix 4 | Information document in respect of a type of headlamp fitted with halogen filament lamps (HS 1 lamps) or filament lamps of category R 2 , emitting an asymmetrical passing beam and a driving beam and intended to be fitted to motorcycles and tricycles … |

| Appendix 5 | Component type-approval certificate in respect of a type of headlamp fitted with halogen filament lamps, (HS 1 lamps) or filament lamps of category R 2 , emitting an asymmetrical passing beam and a driving beam and intended to be fitted to motorcycles and tricycles … |

| ANNEX III-D | Headlamps for motorcycles and tricycles emitting an asymmetrical passing beam and a driving beam and fitted with halogen filament lamps other than HS 1 lamps … |

| Appendix 1 | Measuring screen … |